10/07/2019

Blog

How to avoid peak currents when charging your traction batteries

Particularly in shift operation, it is often the case that all forklift trucks within a fleet call at their charging stations at the same time. This leads to increased energy consumption – especially at the start of the charging process – which can result in expensive peak currents. Should this occur on a regular basis, consumption will exceed the annual quota agreed with the energy supplier. This can result in supplementary payments and additional provision costs. Many companies respond by disconnecting production machines or even entire warehouses and production areas from the grid and shutting them down when peak currents occur. Disruptions to the company's entire operations can thus be traced to the simultaneous peak current consumption of the battery charging systems.

Thanks to their ‘delayed charging start’ and ‘calendar function’ features, Fronius battery charging systems can optimise the charging start of the forklift truck fleet. Users can set the charging start time to their preference, allowing individual charging processes – and thus the energy consumption – to be spread out over time so that peak currents do not occur. Using the battery charging systems’ calendar function, users can also specify when they prefer charging to start or finish – regardless of when the battery is connected. Operators of large forklift truck fleets are thus able to start the charging process in individual departments or charging stations at different times and thus extend the maximum available time. By avoiding the simultaneous peak current consumption of the battery charging systems in this way, energy costs are drastically reduced.

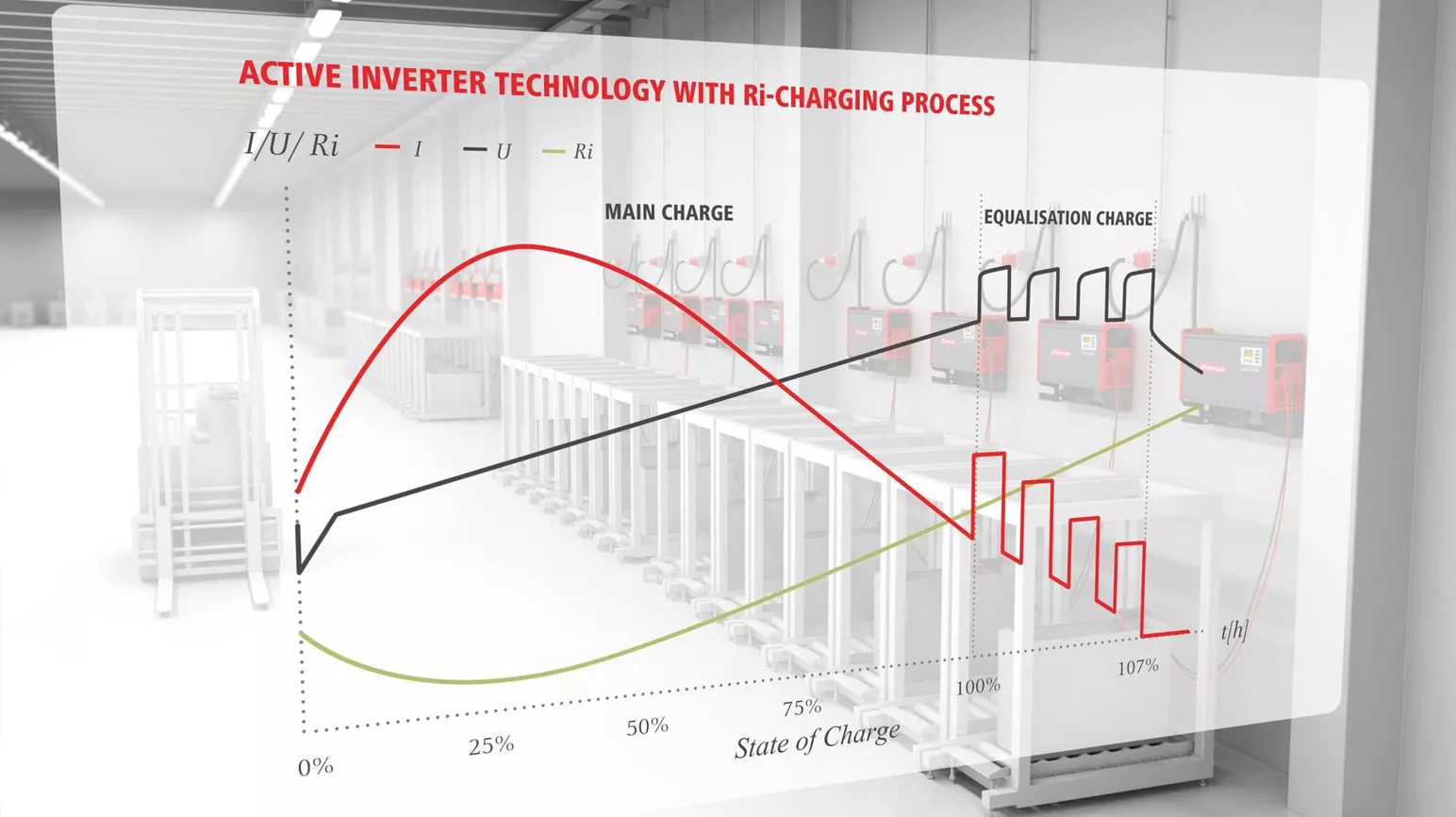

The innovative Ri charging process also helps achieve significant reductions in the energy required at the start of charging compared to other high frequency or 50-Hz devices: the current consumption of the battery is low to start with due to the high effective inner resistance. This also reduces ongoing operating costs.