Spotlight on

Fronius Welding Automation

Perfect symbiosis of welding technology and kinematics

Welding engineers all over the world associate the name Fronius with innovative welding technology. Above all, we are known for providing high-performance, high-tech welding systems. The name Fronius is also associated with revolutionary welding processes such as Cold Metal Transfer (CMT), intelligent seam detection sensors such as WireSense, and the brand-new DynamicWire wire feeder. Unfortunately, there is little awareness across all industries that Fronius Welding Automation supplies automated welding systems from a single source. Only in the oil and gas offshore sector do we have a strong profile among potential customers as a renowned manufacturer of cladding systems.

Technological Advantage

Ever since the invention of the “cold” MAG welding process Cold Metal Transfer (CMT), if not earlier, we have continuously achieved a technological edge in many welding-related areas, resulting in cutting-edge mechanized and automated welding systems. Advanced power source technology stabilizes the arc and ensures perfect welding results. Modern monitoring sensors optimize guidance of the welding torch and compensate for component tolerances. Last but not least, smart data documentation systems assist in perfecting the welding process.

We Solve Welding Technology Challenges. From a Single Batch to Series Production

Collaborative systems, smart sensor technology, software solutions for data management, and offline programming including welding simulation open up profitable welding opportunities for metal processing companies starting with a single batch. That is why our robotic welding cells prove profitable not only for large companies, but also for small and medium-sized enterprises.

Modular System and Project Management

Together with our customers, we analyze their specific requirements for welding technology. We then create a customized solution for them. To do this, we have an extensive construction kit of standardized components at our disposal. Starting with the feasibility study and continuing with planning, engineering, manufacturing, and start-up, the sale of welding systems is handled as a project. During this time, our customers have one main point of contact: the project manager. He or she takes care of the entire project process and acts as the interface between the customer and all the Fronius departments involved. In doing so, the project manager ensures that processes run smoothly, cooperation is effective, and projects are successfully completed.

Downloads

The platform concept is at the heart of our engineering process. We define this as an intelligent matrix of management, technology, modular system, partnerships, and service.

Automation from a Single Source

At the start of any project, our focus is on the feasibility study, which determines the entire engineering process. It forms the basis for a solution that is tailored both in terms of technical and commercial viability. The integration of our welding technology into the kinematic elements depends on the following factors: component conditions, process accuracy, and profitability. We source specialized components such as robots, sensors, clamping systems, and shelving systems from qualified cooperation partners.

Offline Programming and Welding Data Management

We rely on software solutions that enable a high degree of control and optimal interaction between all system components. Fronius Pathfinder provides our customers with an offline programming and simulation solution that significantly increases the profitability of welding systems. We have programmed WeldCube for the evaluation of welding data. The innovative software seamlessly records welding data, makes welds reproducible without any limitations, and supports users in identifying optimization potential and maintenance intervals.

All-inclusive Service

From the very beginning and throughout the entire service life of a welding system, we are by our customers’ side worldwide: with everything from planning to feasibility studies, welding trials, commissioning, user training, remote maintenance, calibration, predictive maintenance, and on-site maintenance work.

What We Offer

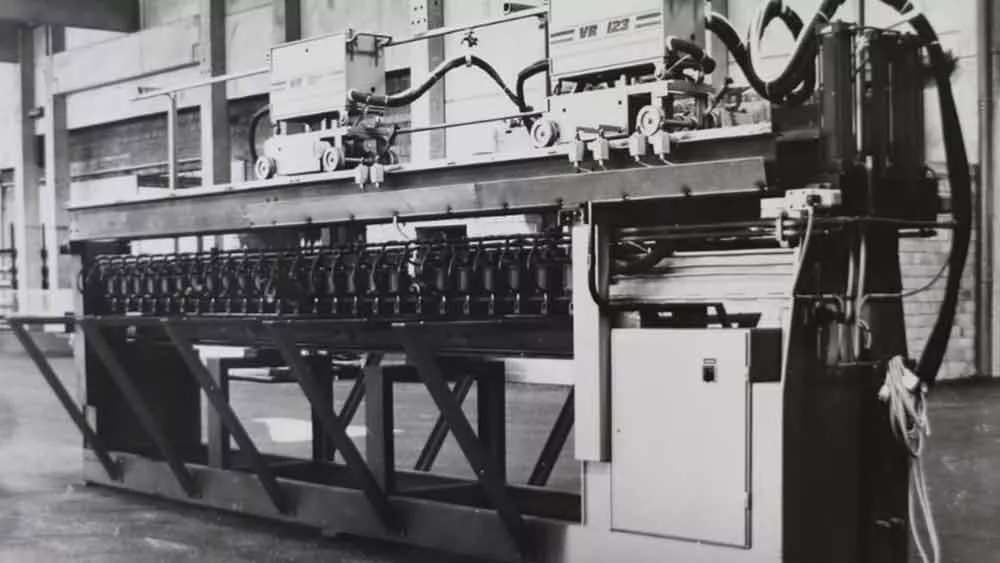

Mechanized Welding Systems (“Hard Automation Systems”)

Welding torch movements are controlled automatically without the use of robots. Examples include boiler welding systems, seam welders, orbital welding systems, and magnetic or rail-guided welding carriages.

Image title: FRW compact double-headed circular seam welding system

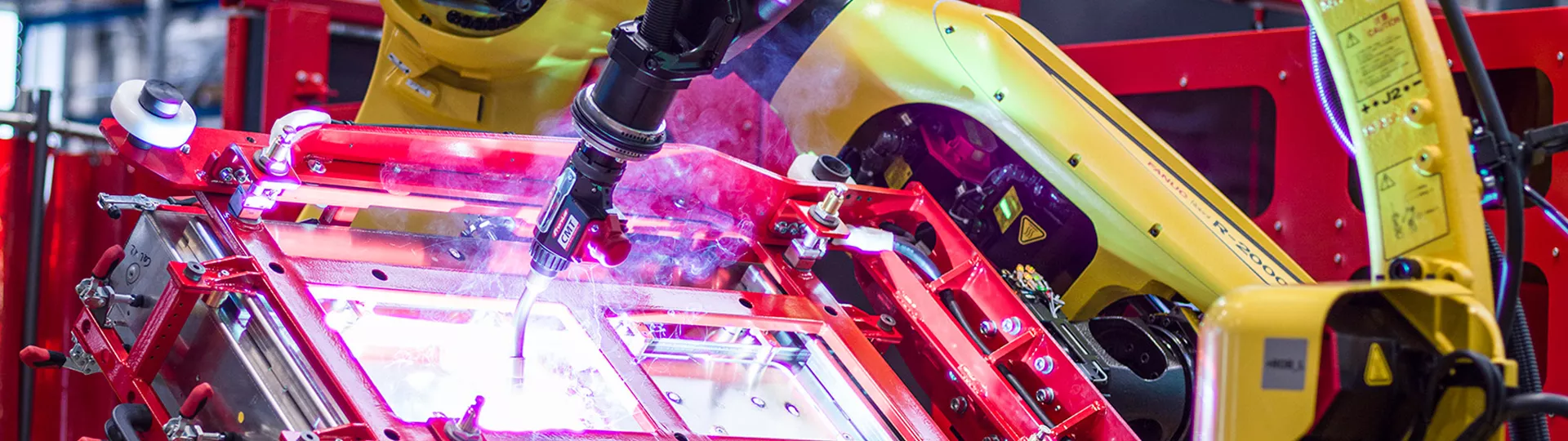

Robotic Welding Cells

Robots are used to control the movement axes. They are ideal for automating complex welding tasks on a variety of components. In combination with intelligent offline programming and simulation software for batch sizes as small as one.

Image title: LaserHybrid robotic welding cell

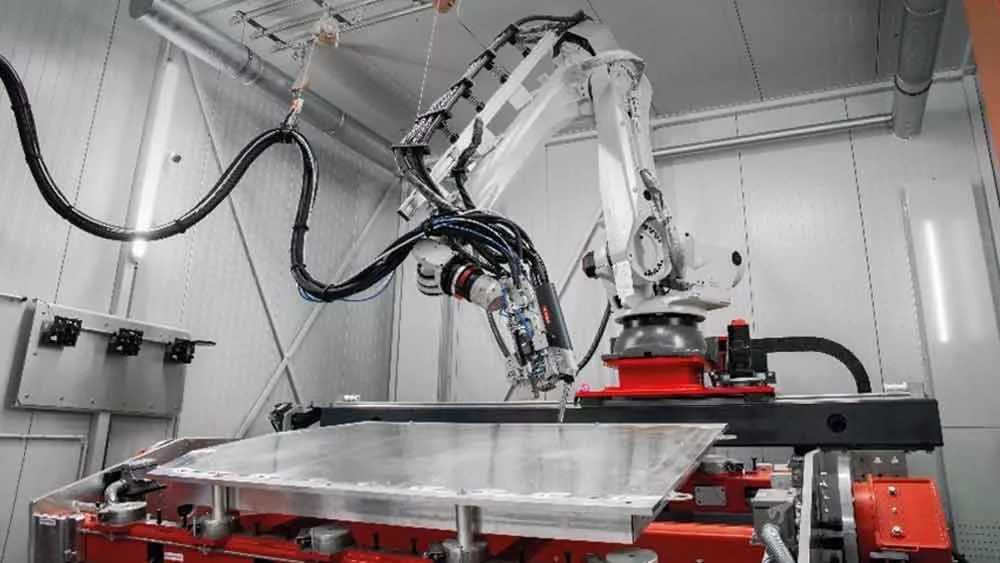

Overlay Welding Systems (Cladding Systems)

Overlay welding is used primarily in the cladding of metals to protect against abrasion and corrosion. Typical fields of application include rising pipes as well as valves for the oil and gas industry or membrane walls for power plants and waste incinerators.

Image title: Endless torch rotation cladding system (ETR) with SpeedClad welding torch