What makes the GEN24 Plus one of the most sustainable inverters? - part 2

Over the course of this life cycle analysis, data was collected and analyzed for a wide variety of scenarios: different countries, type of PV modules, inverters with different power classes, repair work, as well as recycling and disposal. In total, the team collected and analyzed around 16,800 data points.

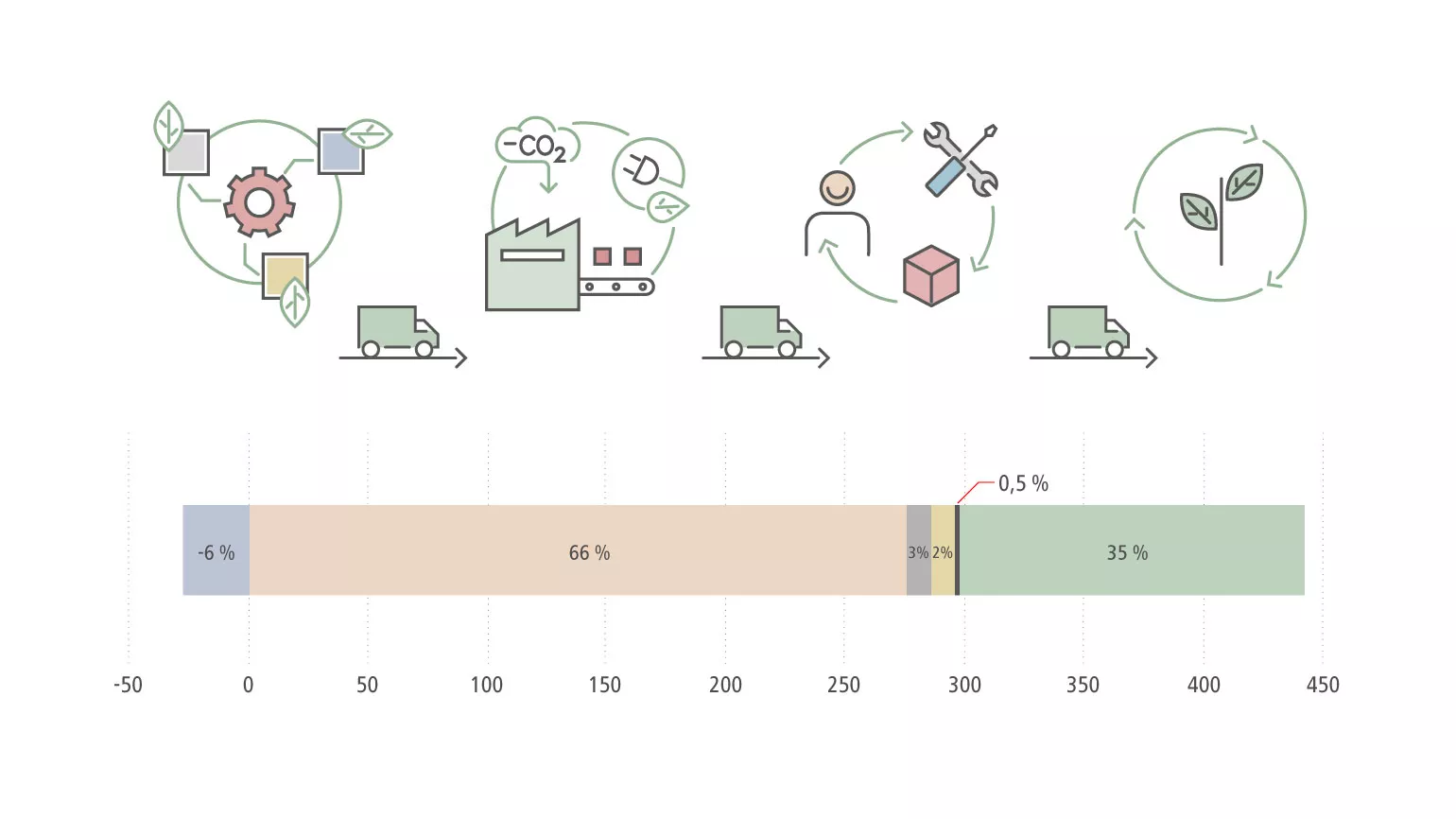

We are highlighting the following scenario in our series of articles: A Fronius Symo GEN24 5.0 Plus inverter installed in Germany with conventional modules, which has been in operation for 20 years and disposed of at the end of its life via metal recycling combined with waste incineration.

CLIMATE IMPACT OVER THE ENTIRE LIFE CYCLE

It was observed that the inverter’s product components have the largest impact on the climate impact (30.5%), the so-called CO2 footprint (more info in part 1).

This result underlines the importance of the procurement process in the entire life cycle and emphasizes the need to guarantee a sustainable supply chain.

SUSTAINABLE INVERTER - PRODUCTION & TRANSPORT ROUTES

What about the other phases? At 1.1%, the production of the inverter at the Fronius production site only represents a small portion of the overall climate impact. The production of the GEN24 Plus at Fronius production sites was mapped based on primary data, taking into account, for example, electricity consumption in the production line, solder paste requirements, potential waste generation and management, and packaging use.

For example, did you know that all electrical energy at the production site is provided by green power (own PV plant & green power purchased from the grid)? With the photovoltaic systems installed at the production sites, Fronius produces almost 2000 MWh of solar power per year.

At 0.8%, the transport of product components also represents only a very small share of the inverter's carbon footprint. This is even more relevant in the case of transport to the customer, which even has a smaller share at 0.3%.

And this does not only apply to this scenario in Germany because Fronius generally avoids air freight and relies on transport by train, truck, or sea freight. Here, too, you can see that sustainability is far more than just an empty phrase at Fronius, but has already found its way into many processes.

THIS IS HOW IT CONTINUES IN PART 3...

In the last part of our series of articles on our life cycle assessment, we will look at the usage phase and show why durability, repairs, and recycling are so important for the life cycle assessment.