Lowering energy costs

Reducing energy costs is a top priority for many companies, be it to reach company-wide benchmark values concerning the efficiency of a site, to ensure that operating costs remain constant even when turnover is higher and electricity prices are increasing, or due to incentives offered by energy suppliers, such as attractive tariffs for clients using energy sparingly.

Reducing energy costs

If energy consumption exceeds a certain level, company transformer stations may reach their limits - with expensive upgrades or new buildings the result. For this reason users are ever more frequently selecting new purchases based on their energy efficiency; from modern LED lighting to electrically-powered forklift truck systems. Whether purchasing a fleet or entering into a leasing contract, these concerns are the same.

Discovering potential savings

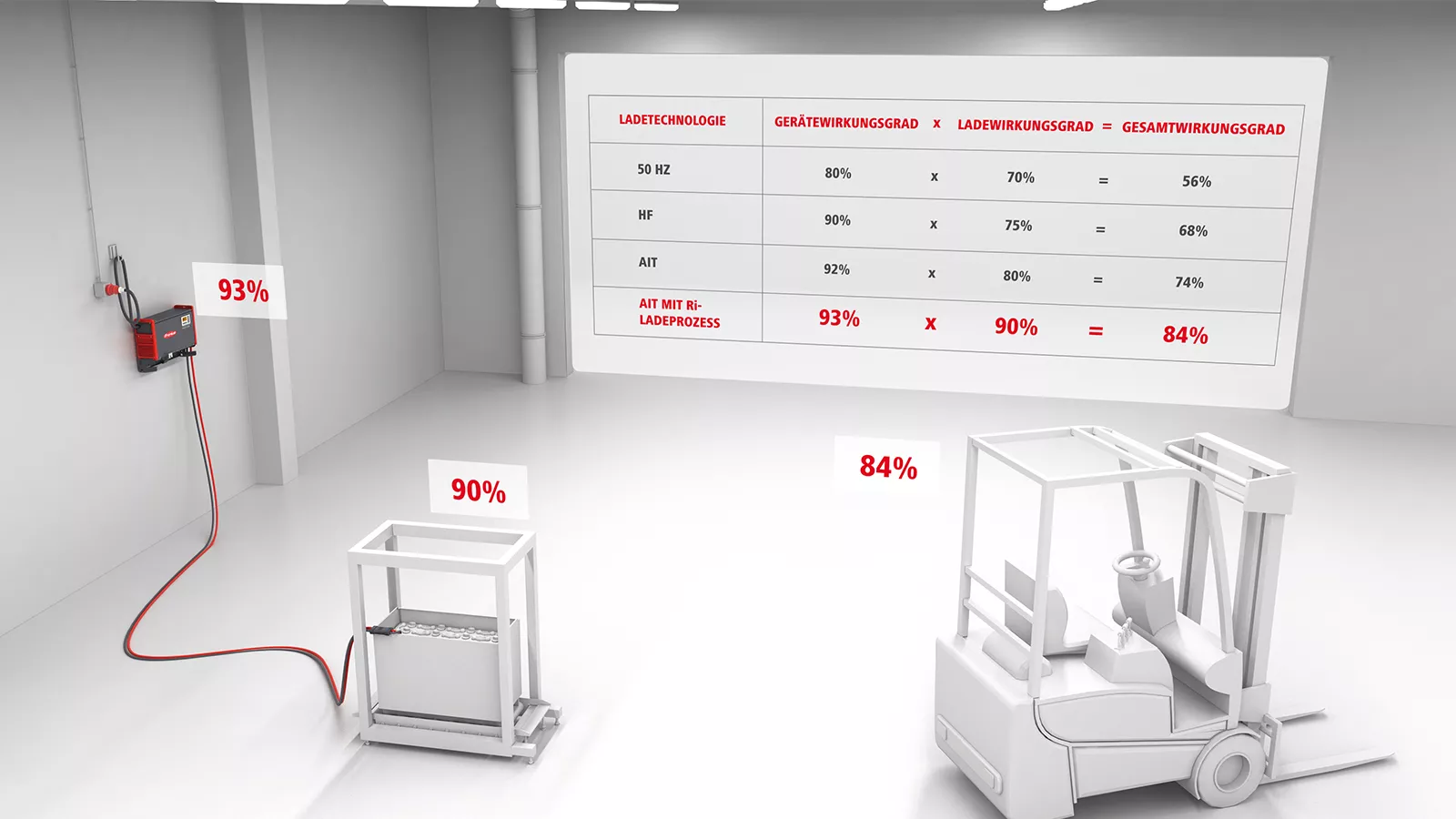

Considerable savings can be achieved here if users take a holistic approach to optimising the three-part system (forklift truck, battery and battery charging system), as the right battery charging technology plays an important role in making forklift truck systems more economical to operate.

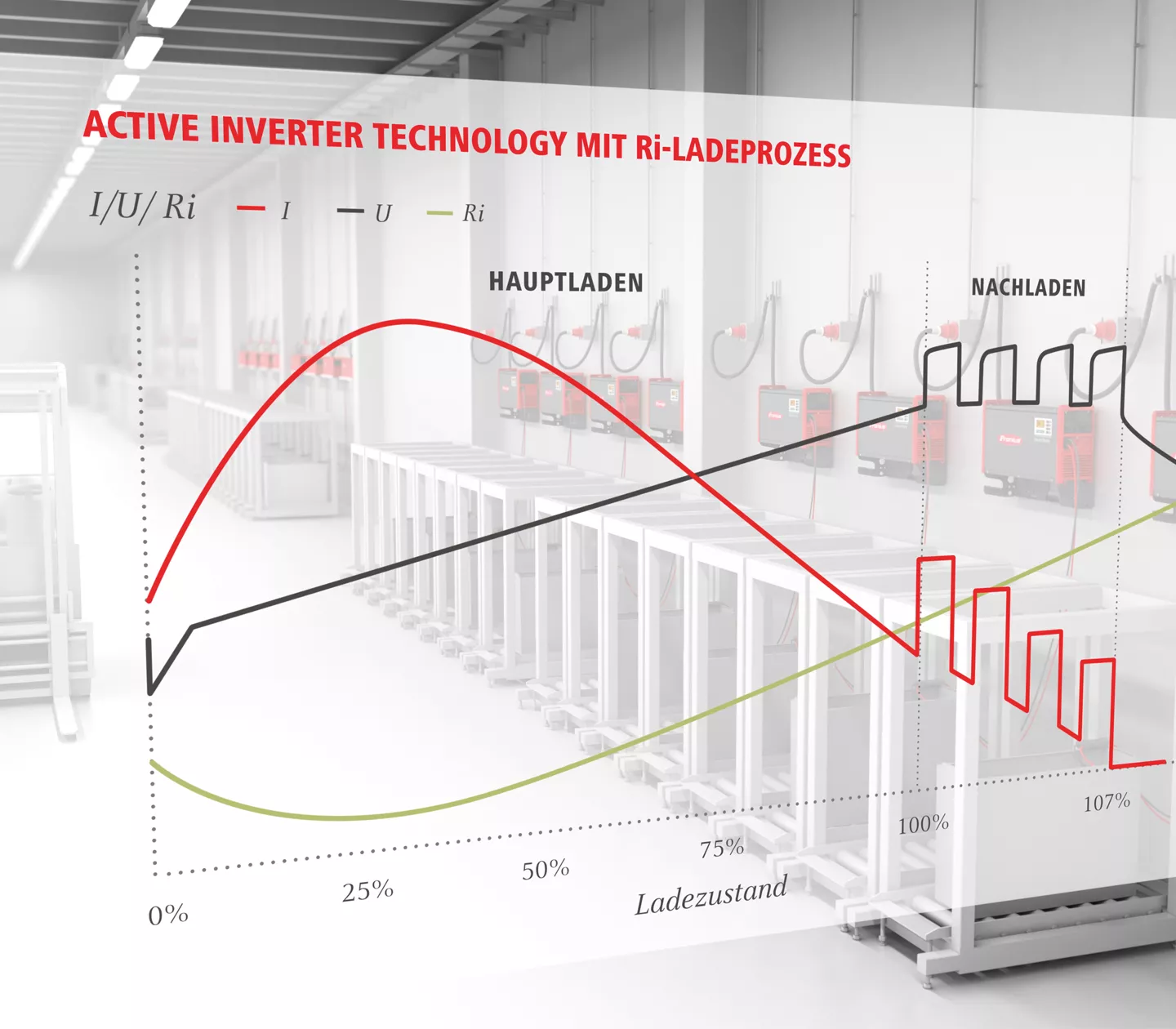

Selectiva charging systems from Fronius with the new Ri charging process offer a clear advantage. This charging process does not follow a fixed characteristic; instead it adapts according to the age, temperature and state of charge of the individual battery, reducing overcharging and thus energy losses during charging.

With a total efficiency of up to 84 percent, the Fronius devices reduce energy consumption considerably, helping the operator to achieve significant cost savings. Expensive investments in high performance transformer stations can be avoided too.

Analysis and energy consultation

Fronius also offers users a free analysis and energy consultation. Using the I-SPoT Calculator software tool, our experts calculate the total operating costs (“costs over lifetime”) and determine ways to minimise energy consumption using the Ri charging process – in detail and tailored to individual company sites and departments. This allows users to pinpoint the improvements that are most suitable for each location and the order in which to implement them.

Making the best use of electricity tariffs

Electricity tariffs are time-dependent in many places, and are much more expensive at peak times. This is a huge advantage for companies as they can set consumers (such as battery charging systems) to operate at times when the cheaper electricity tariffs are in force.

Fronius Selectiva battery charging systems have a calendar function which enables the start of the charging process to be defined. Even if an employee connects the battery too early, charging only begins at the set time. Companies can therefore control their energy consumption at exact times and benefit from the cheaper electricity tariffs, such as off-peak electricity.

Moreover, the devices automatically switch to daylight saving time or standard time in the summer or winter months. The user does not need to change the time on the devices manually, eliminating the fear of the one hour time shift generating charges for a more expensive electricity tariff.

Preventing peak currents

At the end of a shift, all forklift trucks are driven back to their charging stations and their batteries are charged at the same time. This leads to increased energy consumption - especially at the start of the charging process - which can result in expensive peak currents. Should this occur on a regular basis, consumption will exceed the annual quota agreed with the energy supplier. Expensive supplementary payments due to the additional consumption and supply costs will surely follow. Many companies respond by disconnecting production machines or even entire warehouses and production areas from the grid and shutting them down when peak currents occur. Disruptions to the company's entire operations can thus be traced to the simultaneous peak current consumption of the battery charging systems.

Thanks to the Ri charging process, Fronius battery charging systems have considerably lower energy requirements at the start of charging compared to other high frequency or 50 Hz devices: the current consumption of the battery is low to start with due to the high effective inner resistance.

The “delayed charging start” feature enables users to set the time at which the charging process begins, allowing individual charging processes (and thus the energy consumption) to be spread out over time so that peak currents do not occur. The start of the charging process can also be controlled using the calendar function on the battery charging systems. The user can set the desired charging start time on the device, irrespective of when the battery is connected.

Operators of large forklift truck fleets are able to start the charging process in individual departments or charging stations at different times, for example every 15 minutes. By avoiding the simultaneous peak current consumption of the battery charging systems in this way, energy costs are reduced.