TOP Marks in the Energy Storage Inspection 2022 — The Primo GEN24 Plus impresses with the highest System Performance Index

Fronius GEN24 PLUS SERIES THE TOP PERFORMER IN BOTH REFERENCE CASES

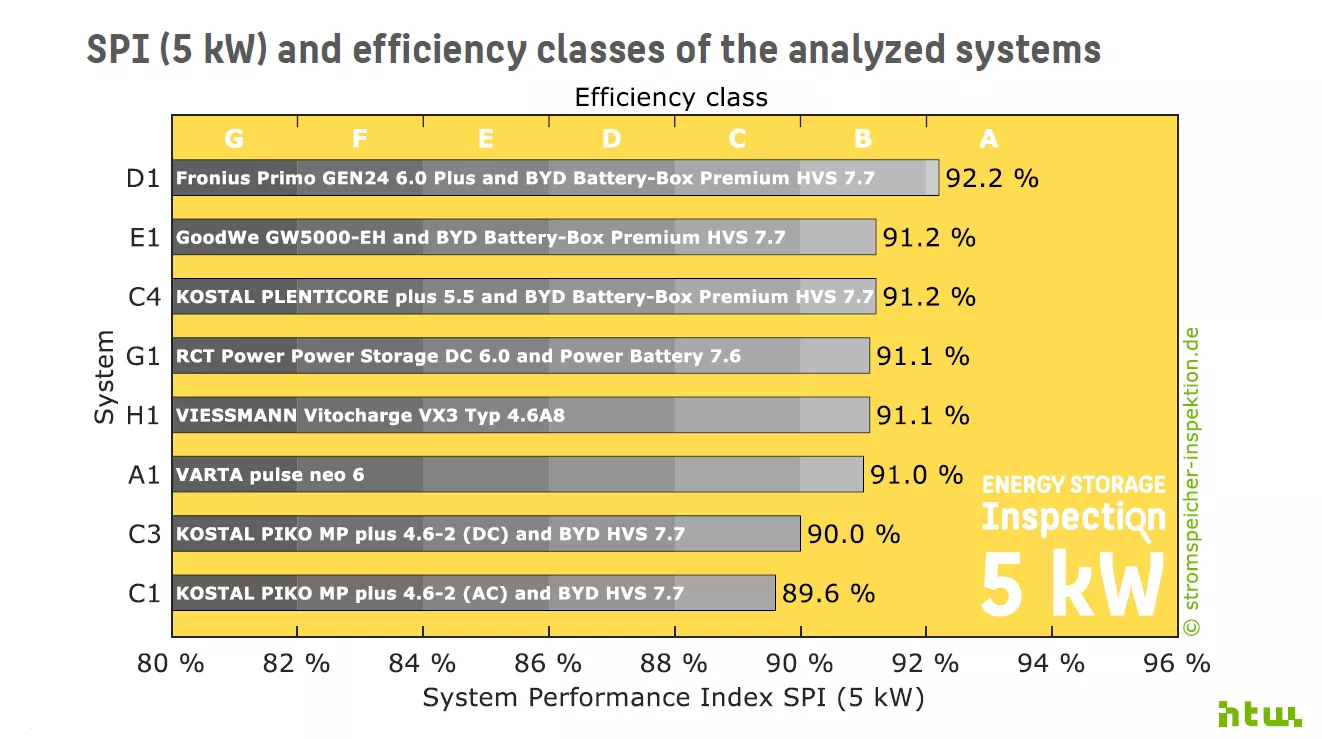

With an unbeatable System Performance Index of 92.2%, the new Primo GEN24 6.0 Plus, together with the BYD Battery-Box Premium HVS 7.7 secured first place in the 5kWp category.

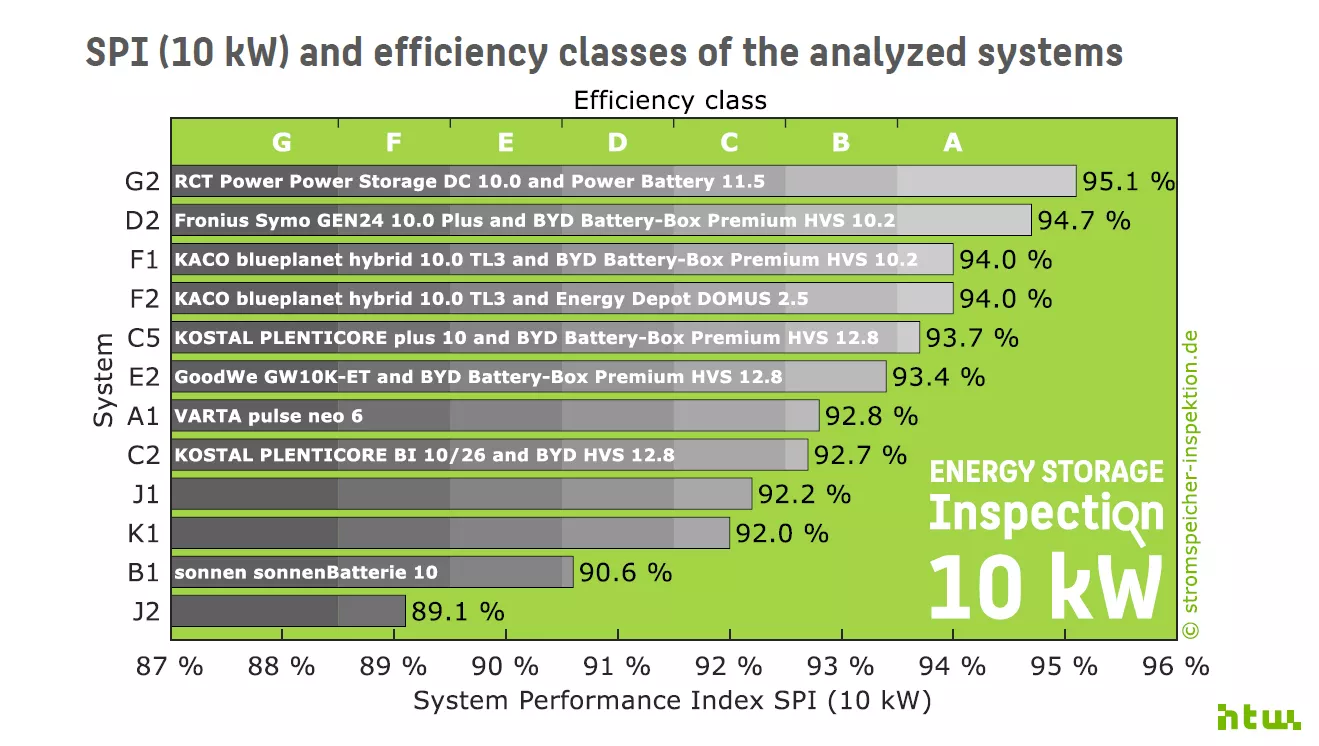

At the same time, the Symo GEN24 10.0 Plus with the BYD Battery-Box Premium HVS 10.2 was able to improve on its showing from last year with a system performance index of 94.7% (2nd place).

With the GEN24 Plus series and the BYD Battery-Box Premium, Fronius is also the only manufacturer to offer a complete system in the highest efficiency class A in both reference cases.

What exactly is the Energy Storage Inspection?Independent testing institutes tested the overall efficiency of home storage systems, analyzing the interaction of PV systems and battery storage.

Two different reference cases were used for the evaluation. The first analyzed the SPI (System Performance Index) of a 5 kWp PV system with an annual household consumption of 5,010 kWh/a, while the second reference case combined a 10 kWp PV system with a heat pump (2,664 kWh/a), an electric car (1,690 kWh/a), and an annual household consumption of 5,010 kWh/a. |

Discover how our inverters are so efficient in an interview with Susanne Lampl, Product Management, and Jürgen Wolfahrt, Systems Engineering:

What is involved in Energy Storage Inspection in general? Which parameters are examined exactly to determine the System Performance Index?

SL: The Energy Storage Inspection independently compares different complete systems, including inverters and storage, with regard to efficiency. This is unique and so important because not only are the individual components examined, but their interaction between components is analyzed in detail. Just as it is in reality in the customer's system on a daily basis.

JW: Starting from an ideal system without losses, the dimensioning, conversion, control, energy management, and standby losses are deducted, and the System Performance Index (SPI) is calculated from this.

How did Fronius compare with other manufacturers? What makes our GEN24 Plus series so unique?

SL: With the GEN24 Plus series, we were the only

manufacturer to achieve energy efficiency class "A" in both reference

cases. With scores of 94.7% and 92.2%, the 3-phase Symo GEN24 Plus and the

1-phase Primo GEN24 Plus were able to achieve very high scores.

JW: The greatest influence on the SPI is the conversion efficiency in the different energy paths, and here, the Fronius inverters, together with BYD, achieve by far the best values. On the one hand, this is due to the use of high-quality power semiconductors in our inverters, but on the other hand, of course, it is also due to the perfect interaction with the battery.

What exactly does the collaboration with BYD look like? How well are the inverters and the battery storage coordinated with each other?

JW: The close cooperation with BYD starts in the

development phase, which means that the two devices can be perfectly matched to

each other, thus achieving high system efficiency. Very few manufacturers of

complete storage systems from one manufacturer are able to achieve this high

system efficiency.

SL: The software of both components is also continuously adapted to each other and further optimized together over the entire product life cycle. As a result, not only can hardware improvements be achieved in the development phase, but the storage system can also be further developed in a continuous manner. In this way, we can even increase efficiency of systems that are already in operation.

How do we use the results of the Energy Storage Inspection?

SL: The Energy Storage Inspection is a very valuable study for us. It shows us clearly where we are already achieving the best results, but also where we still have room for improvement.

Fronius and BYD - Power Duo With Maximum Performance

The excellent coordination and cooperation with BYD was the key factor in helping us to achieve the top marks in this year's storage inspection.

In comparison with other manufacturers, it is clear from both reference cases that the BYD Battery-Box Premium with the Fronius GEN24 Plus inverters has the best compatibility and thus delivers the best performance.

For Fronius, it was important to find a reliable partner for batteries when it comes to holistic energy systems. We have clearly found this with BYD, with whom we have now been working closely since 2018. Starting from RnD to sales and service, the joint cooperation is closely coordinated and thus bears its fruits.

Martin Hackl, Global Sales & Marketing Director

The Symo GEN24 Plus — Particularly Robust Thanks to Silicon Carbide-Based Power Semiconductors

The increasing share of high-efficiency inverters is due, among other things, to the use of silicon carbide-based power semiconductors. These are incorporated into devices such as the Symo GEN24 Plus, allowing them to achieve high conversion efficiencies, even at small loads of a few hundred watts.

SiC modules can be used to build very energy-efficient, robust, and reliable inverters. The technology allows the switching frequency to be increased many times over. Compared to the previous generation, it has thus been possible to significantly increase functionality, without compromising on size. Each unit now has an emergency power output and backup power in addition to the usual connection options for a hybrid inverter.

Andreas Luger, Head of R&D Power Electronics SE