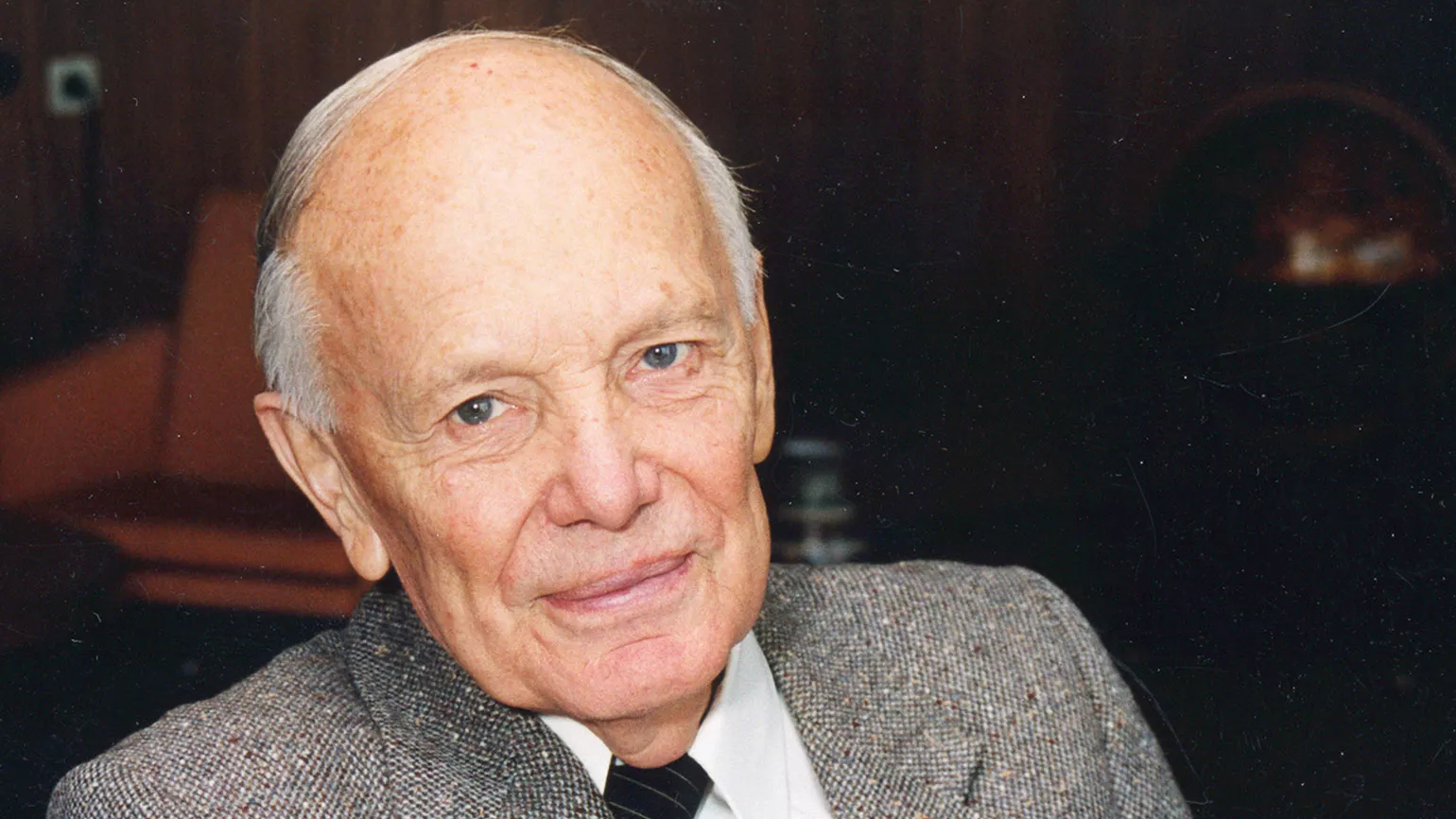

The constant need for innovationInterview with Borys Paton

Professor Paton, you are the son of the founder of one of the most important welding technology institutes in the world and have dedicated your own life to research in welding technology. What is it that fascinates you about welding?

Welding technology requires in-depth research whose results are hugely beneficial for society. Electric arc welding is extremely important for the development of humanity. I find this both inspiring and fascinating.

What do you consider to be the most important developments in arc welding over the past hundred years?

The most breathtaking changes have been brought about by manual metal arc welding, submerged arc welding, tungsten inert gas welding as well as metal inert and metal active gas welding. These welding processes were developed in the difficult times around the Second World War. These days, about two thirds of rolled steel around the world is used for producing welded structures. In most cases, arc welding is the only possible and most effective joining method.

Where do you see the role of industry in this development?

Industrial demand has shaped the development of the welding processes: the possibility of automating the manufacturing processes and the diversity of component geometries have taken a leading role in this regard. In response to constantly rising industrial requirements, welding technology has developed new methods for joining materials such as high-alloy or high-strength steels and non-ferrous alloys efficiently, in various material thicknesses. The origins of AC welding, from pulse processes to auto-correction settings and modern controlled processes, were derived to meet these industrial requirements. Currently, industry is pushing the development of combinations that are used in hybrid processes.

How important is the “old” TIG welding process with regard to its industrial application?

TIG welding remains the best choice whenever there are high demands on the quality of the weld seam – from stainless steel through to aluminum, titanium and nickel alloys. The use of pulsed TIG arcs improves the quality of the welded joint while simultaneously mechanically controlling the tungsten electrode. Moreover, groundbreaking developments enable considerable improvements in the cost effectiveness of TIG welding. These developments include the use of active substances (activating flux or A-TIG), high frequency TIG welding (high frequency pulse or HFP-TIG) and the use of an inert gas added to the active gas.

TIG welding will play an increasingly important role in joint welding in the future, especially in the production sector, particularly where robots are used. A key field of application is single-pass welding of thicker walls with thicknesses of ten millimeters and more. TIG orbital narrow gap welding also has great potential to improve performance, such as in the manufacture of pipelines or when joining dissimilar base materials.

These days, power electronics plays an essential role in welding technology. What were the effects of the development of digital welding current sources?

The digital power source, together with its intelligent control circuitry and sensor equipment, is having an impact on all industries that use welding technology, such as energy technology, the automotive industry and shipbuilding. The technology is significantly changing the quality requirements for welded products. The adaptive process control in digital welding systems enables residual welding stresses and component distortion to be reduced. This improves the quality of the manufactured products.

Digital technology is also changing the everyday life of users: welding is increasingly becoming associated with IT methods and instruments. This is reflected in the training of system specialists, technologists and operators - there needs to be a greater focus on software, hardware and IT skills. I believe that this will also increase interest in the welding profession among the younger generation.

Yet, in the past few years there has been a lack of young talent in the welding professions. How else can young people be attracted to starting a career in welding technology?

I think that attractive apprenticeship and training play a key role. Moreover, employers must create conditions in which employees can develop. Essentially, people strive for success – they will show commitment to areas in which they can achieve this success.

What do you consider to be the greatest welding technology challenges of our time?

There are an increasing number of structures and machines that have reached a critical service life. Repair welding is therefore an important topic, since reliable operation, for instance, in energy companies, transport companies and the chemical industry, must be ensured. It is important to establish reliable processes for determining the residual service life of welded structures. The design also needs to be further developed to facilitate maintenance and repair work. With regard to the different and often difficult conditions, this requires the further development of welding systems, processes and filler metals. This is the most urgent challenge that welding experts will need to overcome in the coming years.

So, the coming generation of welding experts will be faced with difficult tasks.

Certainly. But, in my opinion, the beauty of welding lies in precisely this constant need to search for fundamentally new solutions and the development of new technologies, materials and structures.