Welding Wiki

Welding technology by Fronius

What´s your welding challenge?

Welcome to the Welding Wiki!

The "Welding Wiki", a unique online encyclopedia developed by Fronius International, has been in existence since November 2019. The aim of the Wiki is to gather all relevant information on welding in one place and share it with all those interested in welding technology. The encyclopedia contains basic welding terms and definitions. The Welding Wiki has been created and is sustained by its welding community. The more information we can all bring together, the more expertise will be available to others. That's why we're asking you to actively support the project so that the Welding Wiki can keep on growing and developing.

A

AC balance

AC balance is a function on the welding system. It refers to the sine wave of the alternating current represented on a graph. The positive section of the curve is called the “cleaning half cycle”: opposite the parent material, the zone at the edge of the weld seam is cleaned. The “cooling half cycle” on the other hand, which describes the negative area of the curve, protects the tungsten electrode by preventing it from melting. The longer the cooling half cycle lasts, the better the penetration conditions are.

AccuPocket

AccuPocket is a grid-independent, portable electrode welding system that can also be used for TIG welding tasks.

AC frequency

Function to change the frequency of the alternating current in AC TIG welding. This setting determines the number of cycles per second.

AC wave shape

In AC welding, different wave shapes can be selected: sine, rectangle, and triangle, as well as mixed waves. This changes the arc properties accordingly, which is reflected in the noise level, for example.Additive manufacturing

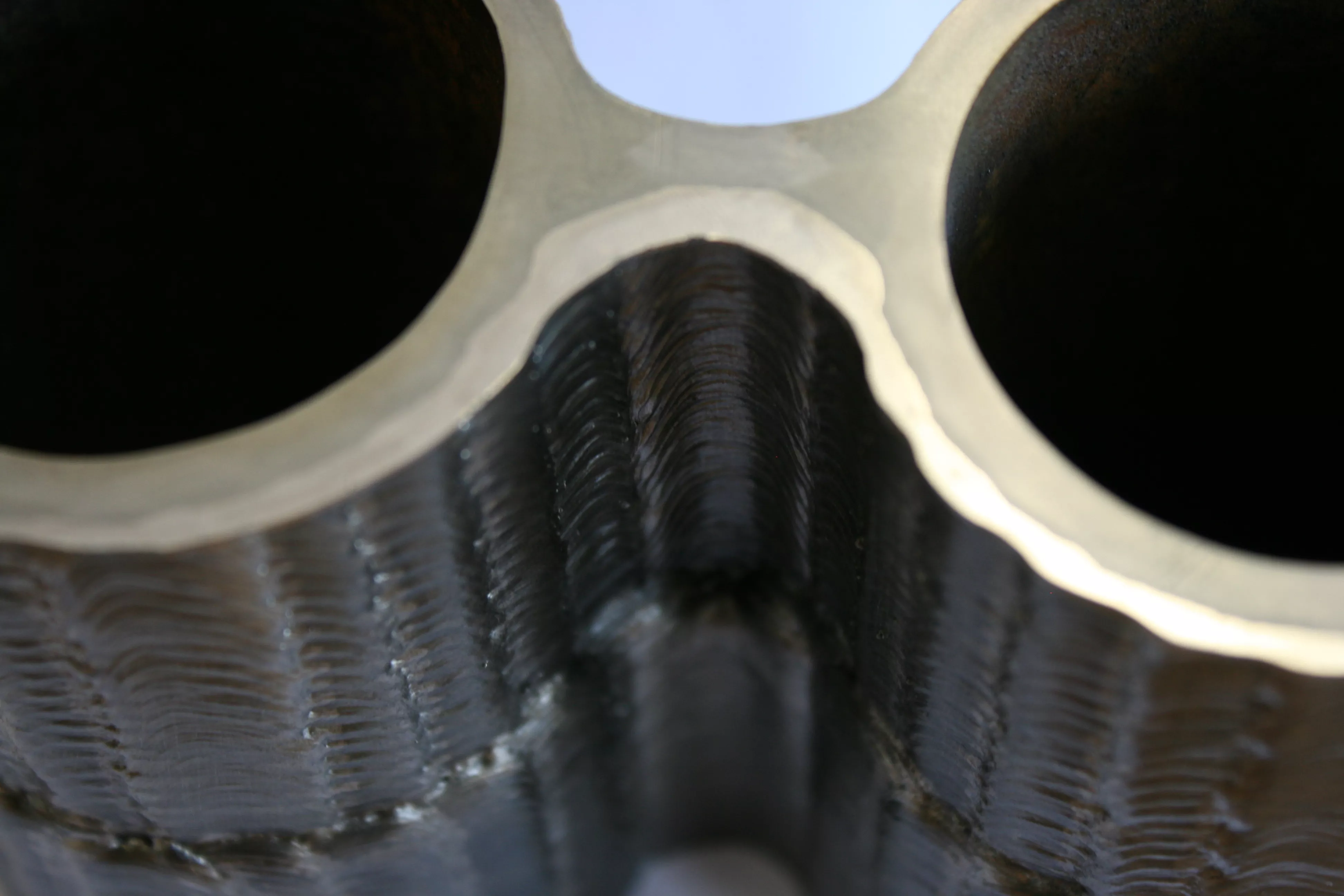

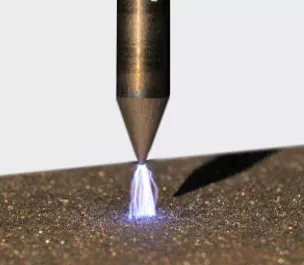

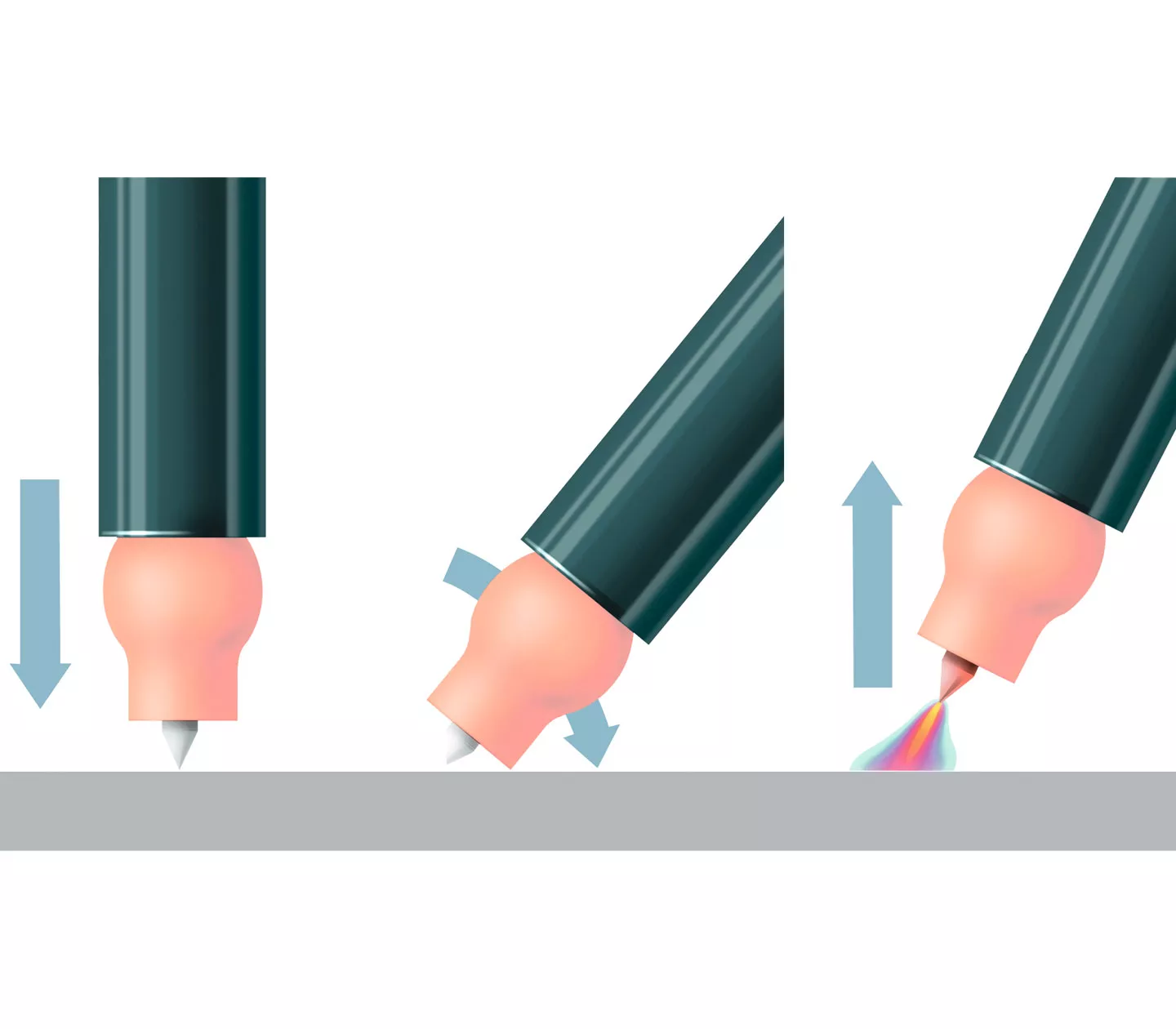

Additive manufacturing processes are all based on the same basic principle: a component is created by joining volume elements on top of one another or together in layers (filler metal). The parent material, which can either be in powder form, a fluid, or also a solid material (wire), is hardened by introducing energy. Complex geometries and components can therefore be manufactured without the need for tools. Conventional production would otherwise not be possible or would be very costly.

Air gap

This is the technical term for the distance between two sheets.Alternating current

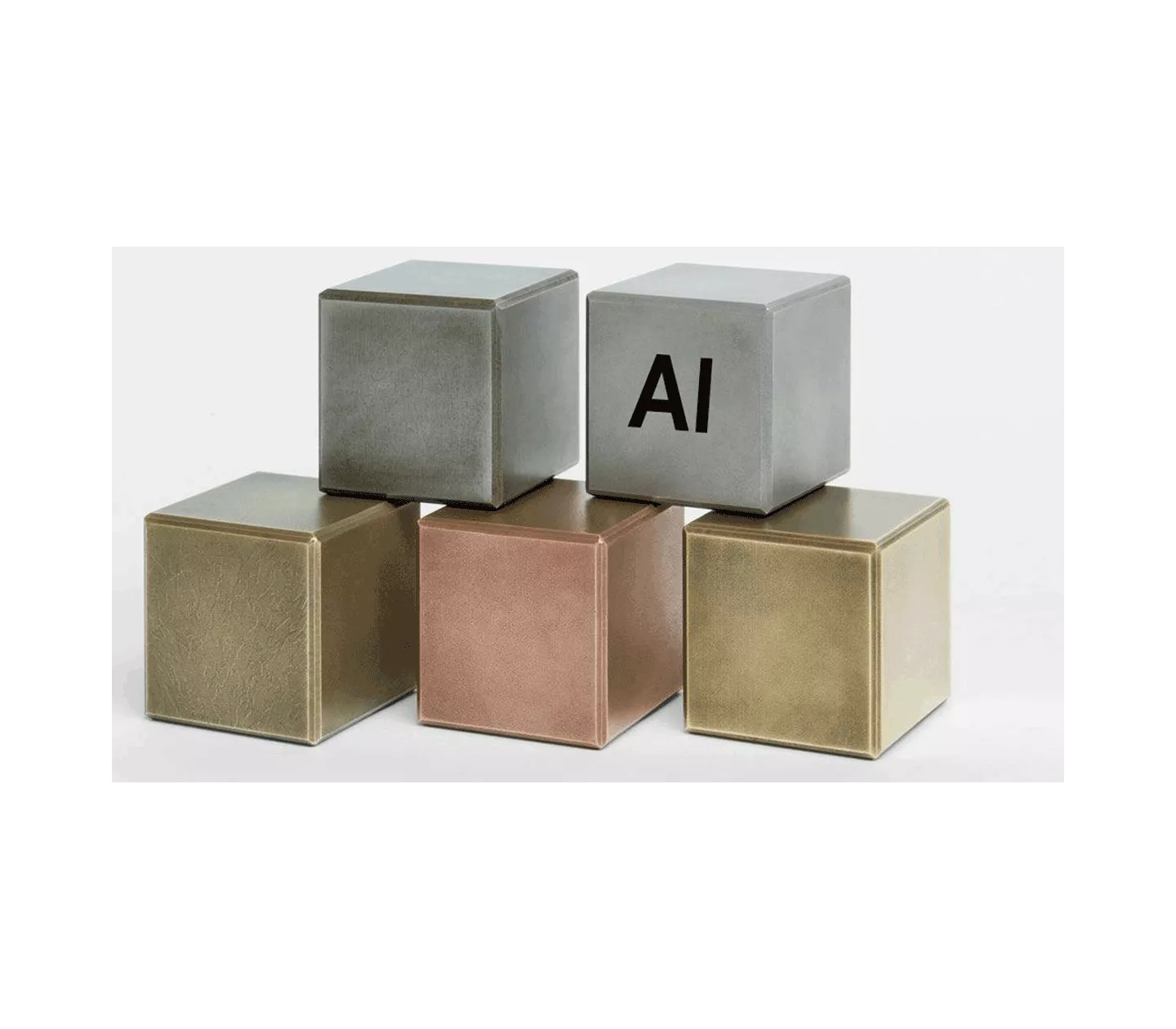

With alternating current (AC), amplitude and polarity change cyclically. Welding power sources are operated on a single or three-phase alternating current grid and usually supply direct current for welding. When TIG welding aluminum, an alternating current is also needed on the secondary side to break up the oxide film.Aluminium

This is a light metal that is silvery white in color. Its distinguishing features include corrosion resistance, electrical conductivity, and low weight.

Anode

By definition, an anode is the pole that receives electrons or the pole to which the electrons flow. For welding, this is therefore always the positive pole.

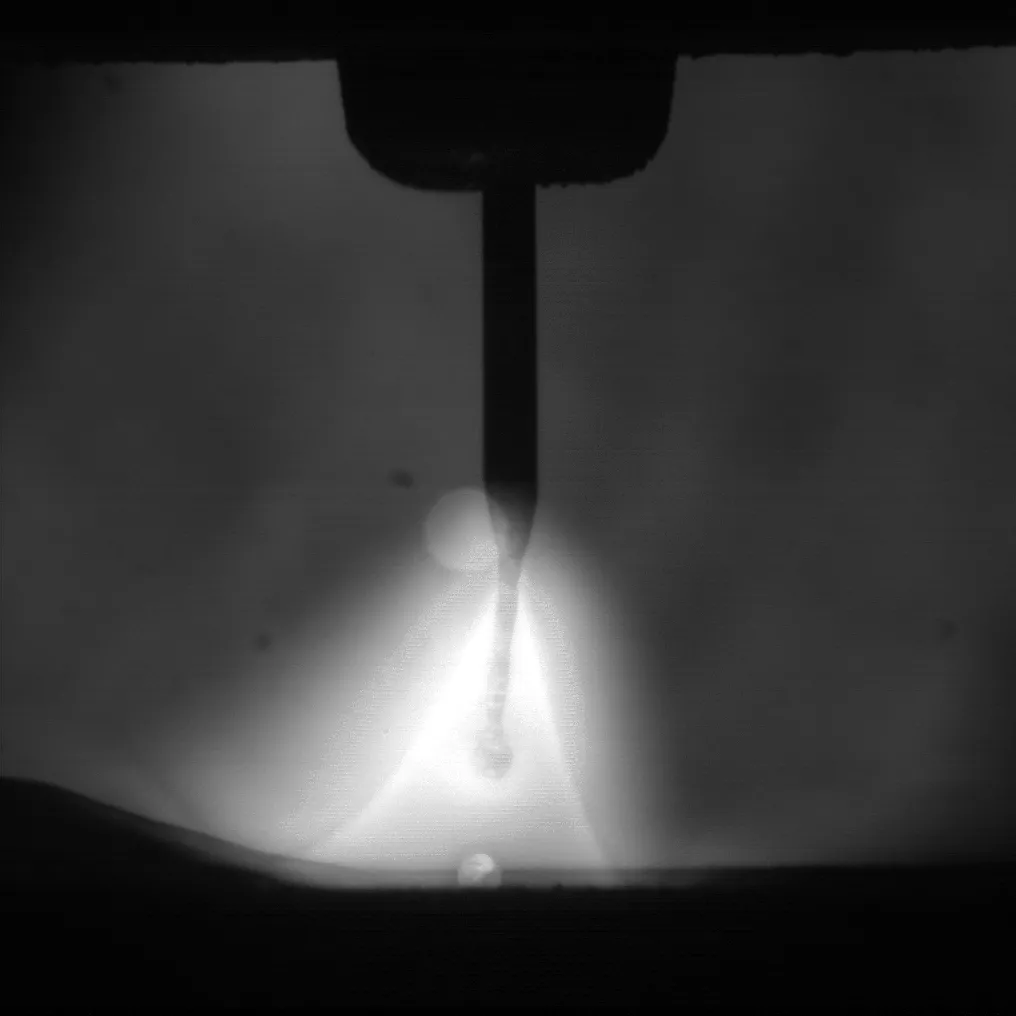

Arc

The arc burns during welding between the electrode and workpiece. Due to its high plasma temperatures, it fuses the parent material and melts away the filler metal.

Arc blow

The arc blow describes the irregular fluttering of the electric arc in an undesirable direction.

Arc break voltage

Refers to TIG welding torches without a torch trigger and stick electrodes: In both processes, the welding process is ended by lifting the welding torch or electrode off the workpiece. The required distance to the workpiece is defined in volts in advance by the arc break voltage.

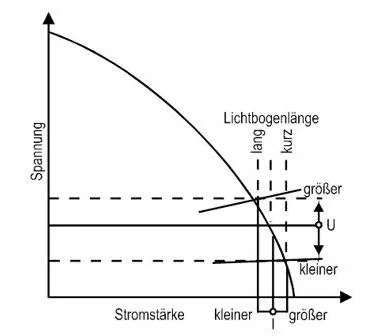

Arc characteristic

The arc characteristic indicates the relationship between the arc voltage and the arc current.

Arc length

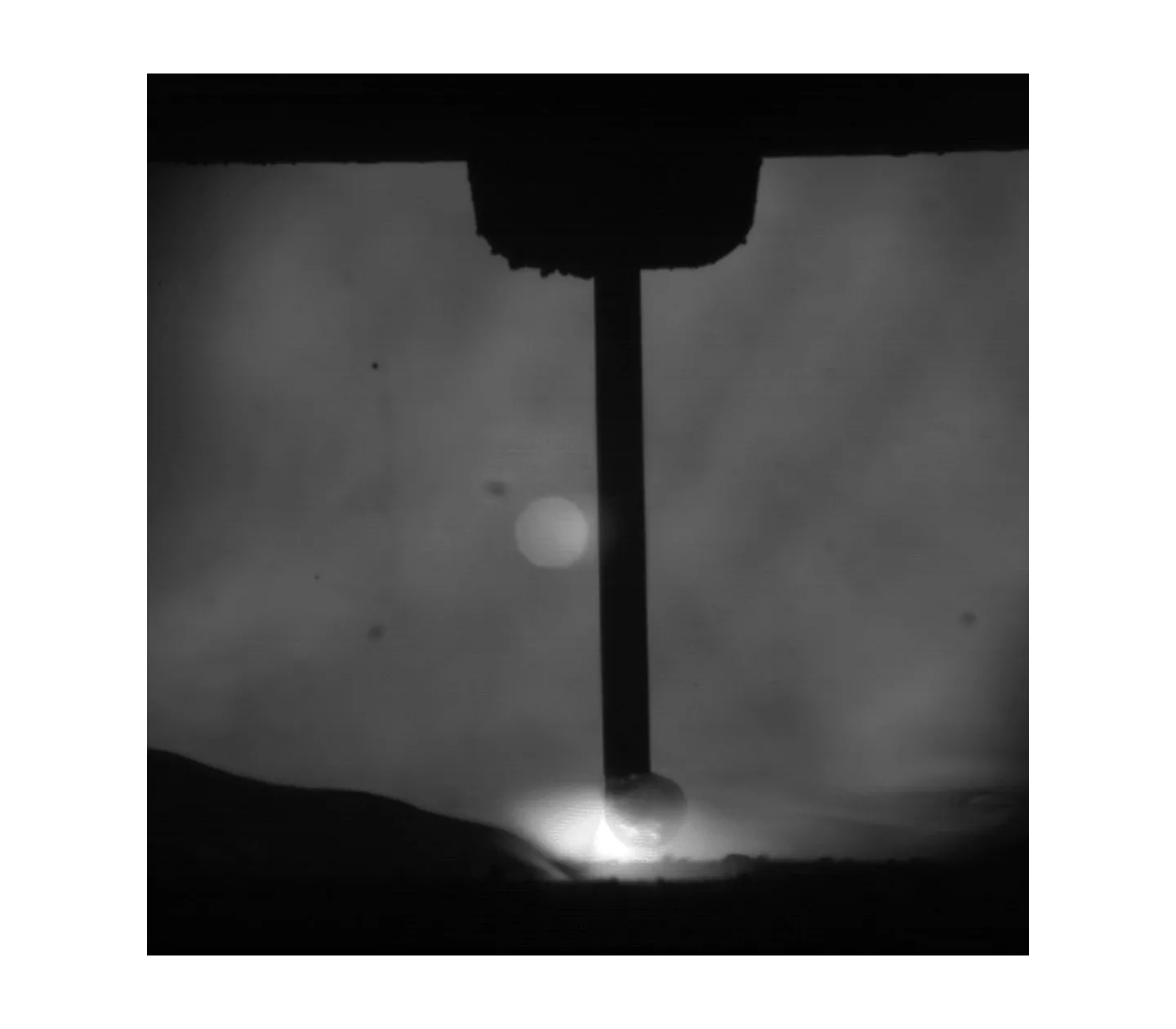

The arc length refers to the distance between the point where the arc touches the wire electrode until the point of reaching the workpiece. The voltage is a characteristic dimension for the arc length.ArcTig

ArcTig is a TIG keyhole welding process. The tungsten electrode is water-cooled, whereby significantly higher welding speeds can be achieved than in conventional TIG and plasma welding.Arc welding

In arc welding, an electric arc (welding arc) burns between the workpiece and electrode. Depending on the welding process, this can melt and act simultaneously as the filler metal or be non-consumable.B

Back-step welding

This is a welding technique where short weld seam lengths are welded in the opposite direction to the main welding direction so that the end of a weld seam length overlaps the start of the previous seam.

Balance

The balance is a parameter in aluminum welding. It influences the required cleaning effect and/or the penetration profile of the welding. During AC welding, the welder has the option to control the ratio between positive and negative polarity.

Base current

This is the lower current level of the pulse cycle. In TIG-MIG/MAG pulse welding, its main task is to cool the weld pool and maintain the arc.

Butt joint

Butt joints are used to join workpieces positioned on the same plane, that is, at an angle of 180 degrees to one another.C

Cap-shaping/cap

A cap refers to the rounded/molten end of a tungsten electrode, required for aluminum welding with alternating current. Modern welding systems have the function of automatic cap-shaping.

Cap-shaping mode

Cap-shaping mode is the function on the welding system that prepares the tungsten electrode for AC welding. Instead of the usual tip, the electrode is melted into a hemispherical cap.

Cathode

The cathode is the negative pole in the welding circuit.Central User Management

Central User Management is a piece of software that enables users and roles for TPS/i welding systems to be managed quickly and easily. Managing users centrally results in a time saving of up to 95% compared to conventional user management.

Characteristic

The characteristic of a power source is a material and shielding gas dependent combination of current and voltage across the entire power range.Chrome-nickel (stainless steel, Cr/Ni, Niro, Inox)

Stainless steel, also called NiRo, refers to alloyed steels with a special level of purity. NiRo has a chrome content of more than 10.5%, giving it the necessary corrosion and acid resistance.

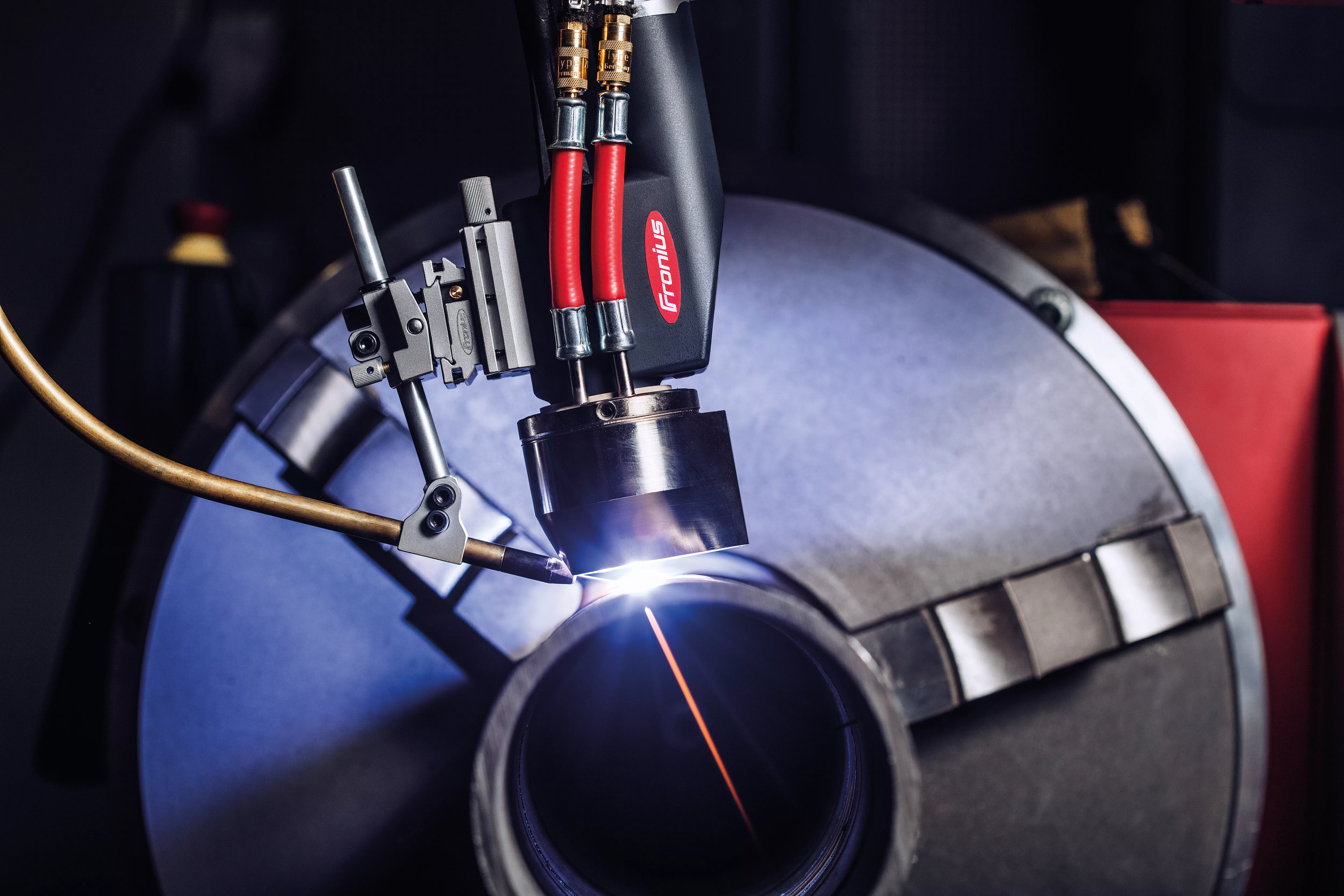

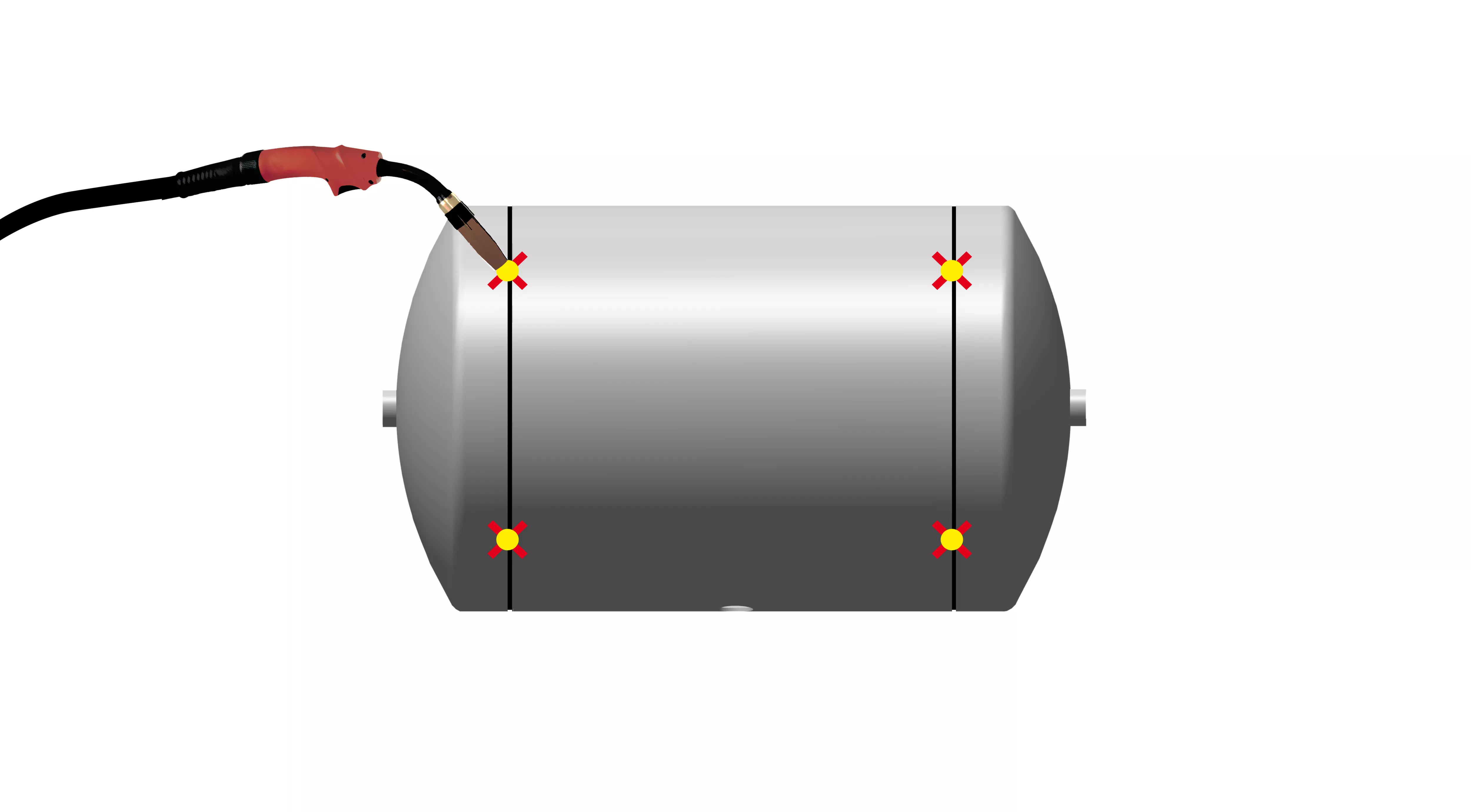

Circumferential welding

In circumferential welding, two cylindrical components are fully joined together.

Cleaning effect

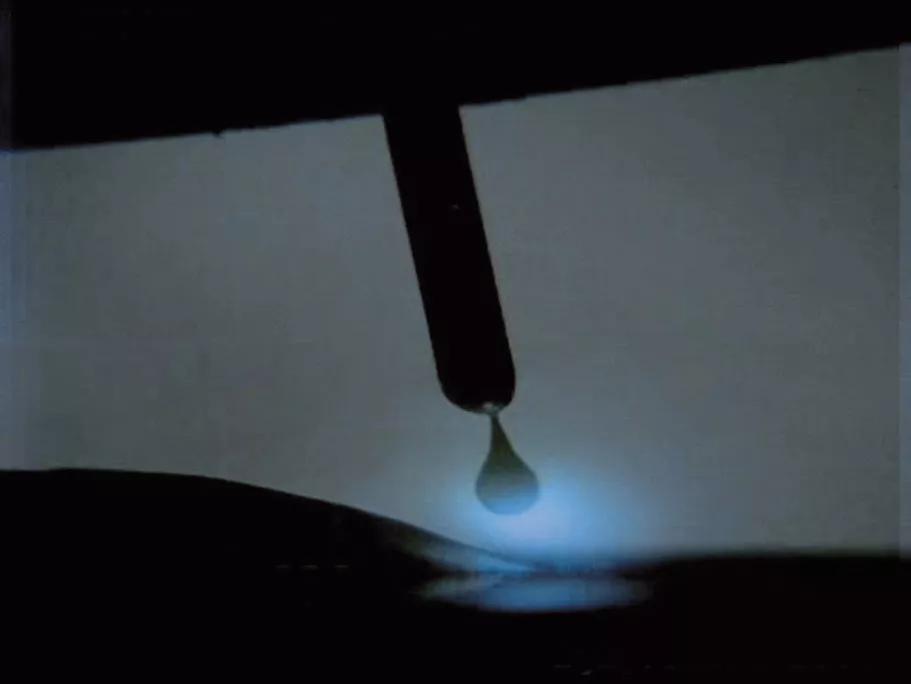

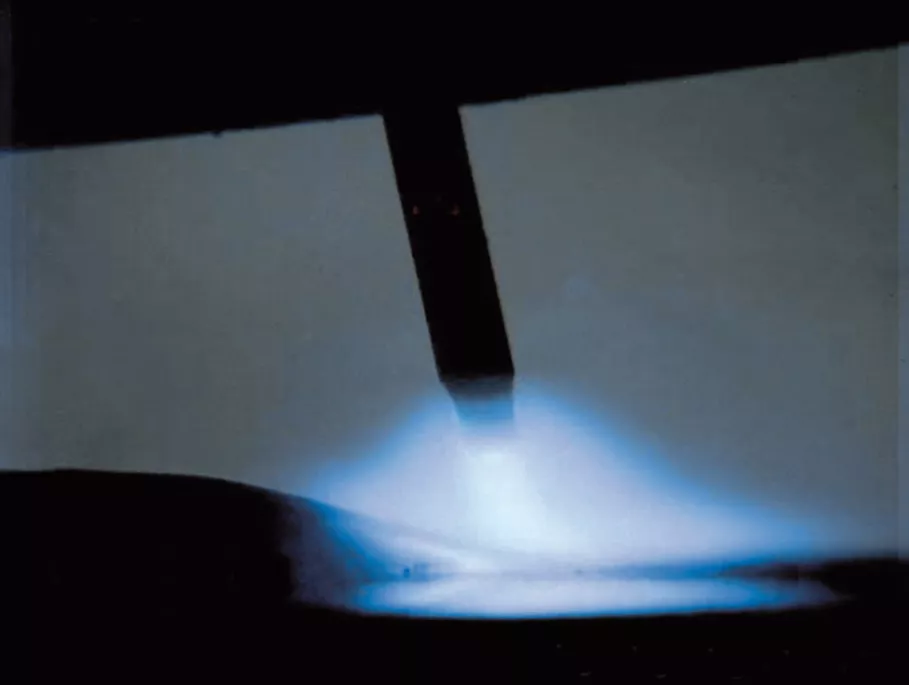

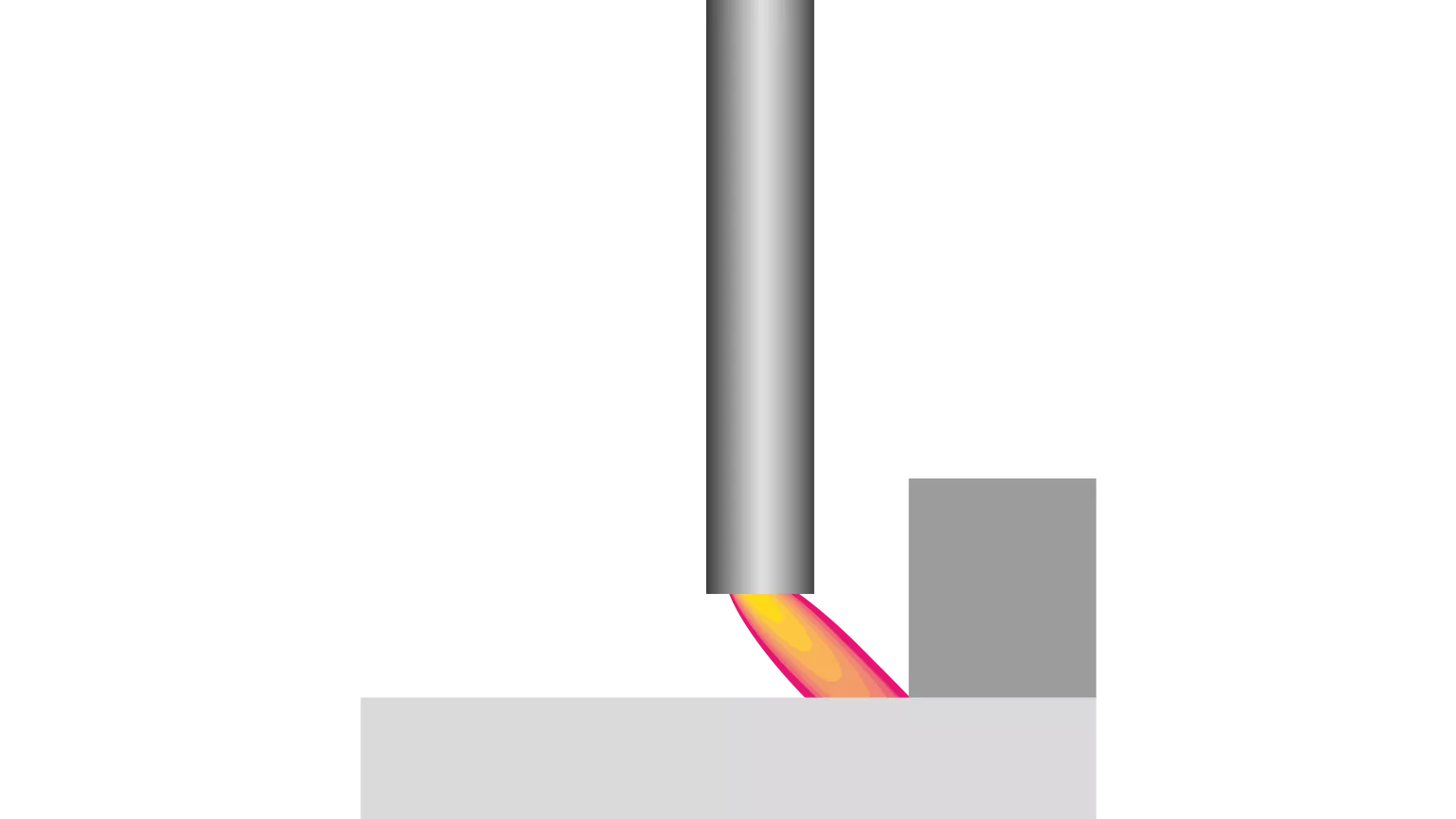

The cleaning effect in aluminum welding means the destruction of the aluminum oxide layer. This process is caused by the positive polarity of the tungsten electrode (during TIG welding).CMT – Cold Metal Transfer

Cold Metal Transfer (CMT) is a dip transfer welding process where the heat input is kept very low. Due to the reversing wire movement, the CMT process has a completely new type of droplet detachment. This leads to significantly improved dip transfer arc characteristics.

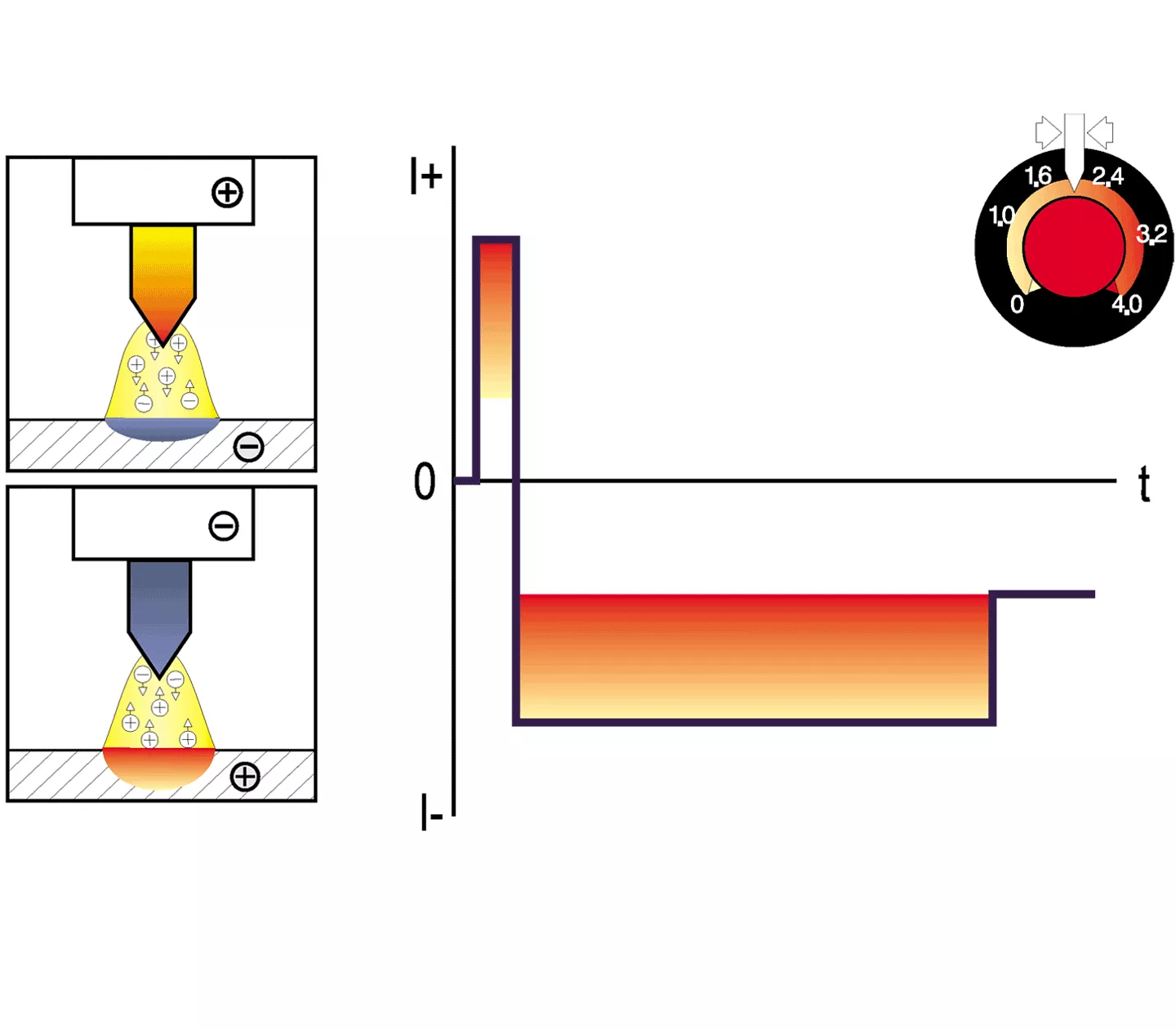

CMT Advanced

CMT Advanced is a variant of the CMT welding process. A cyclical change in polarity of the welding current takes place in the short circuit phase, in conjunction with the reversing wire movement. This additional degree of freedom allows the heat input to be reduced again.CMT Braze+

CMT Braze+ refers to a CMT brazing process that gains its benefits from the special Braze+ gas nozzle. The small outlet diameter and high shielding gas flow rate play a crucial role here.CMT Mix

CMT Mix combines the advantages of the CMT dip transfer arc and the pulsed arc. Depending on the operating point and corrections, several pulses are set between the CMT cycles. The heat input can be increased and the process window extended. For the TPS generation of devices, "CMT MIX" is called "CMT PULSE".

CMT Mix Advanced

This CMT process variant consists of a negative CMT phase with reversing wire movement (EN) and a positive pulsed arc phase with continuous wirefeed (EP). Process advantages can be achieved with this combination especially on aluminum.CMT overlay welding (CMT cladding)

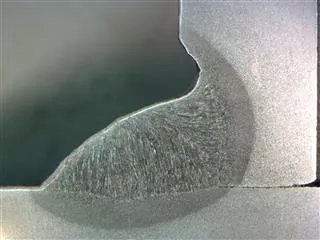

Overlay welding with CMT offers advantages due to the reduced heat input and high process stability. CMT allows for low fusion where there is a metallurgically perfect bond between the parent material and filler metal.

CMT Pin

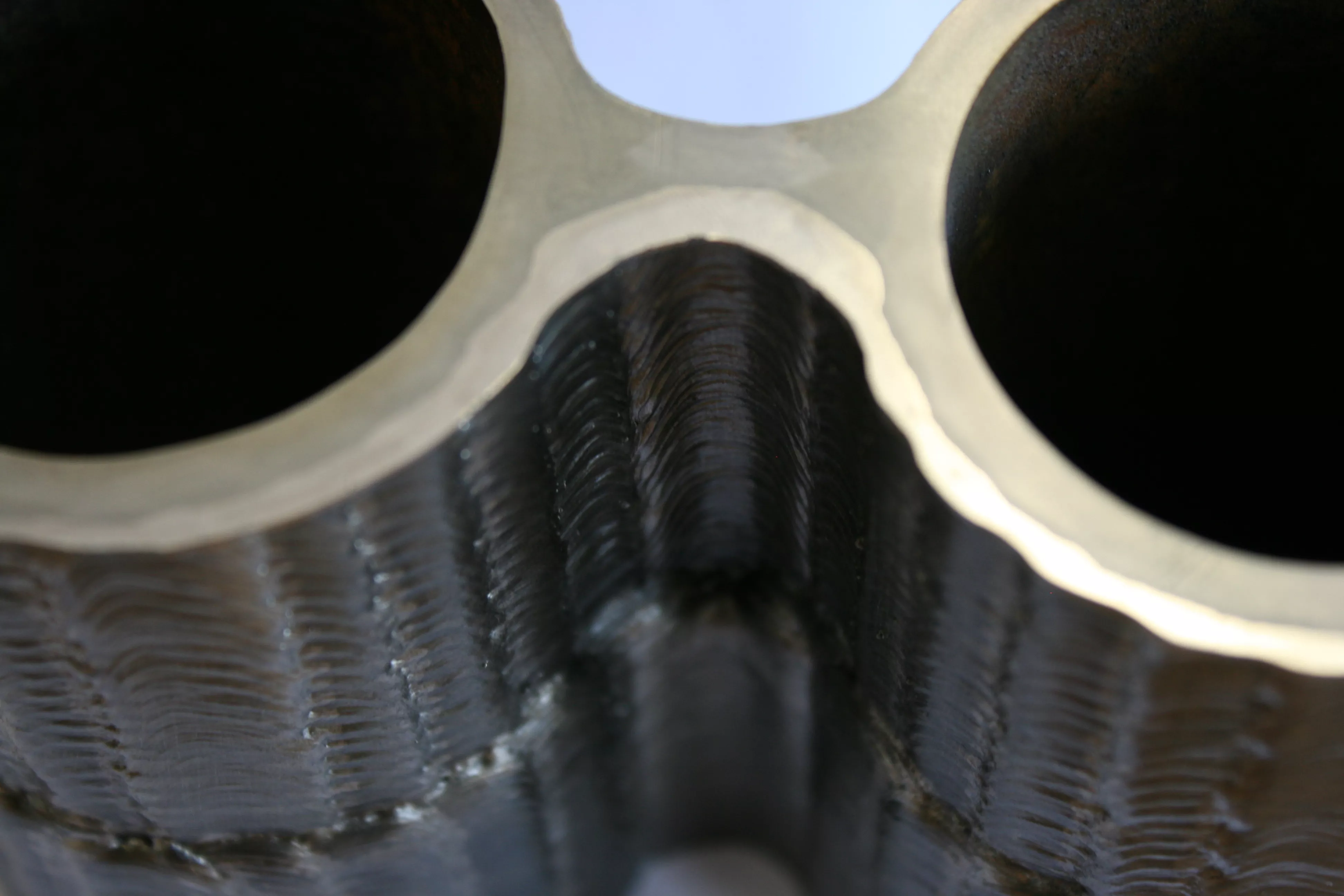

With CMT Pin, small wire pins are welded onto the metal surface. Depending on the level of current and force applied during wire retraction, the different forms "Ball", "Cylindrical", and "Pike" are created.CMT Twin

CMT Twin is a MIG/MAG tandem welding process based on the CMT process where two completely isolated wire electrodes come together in a common weld pool. The combination of a short pulsed arc for the "lead electrode" and a stable CMT dip transfer arc for the "trailing electrode" is advantageous here.

Corrosion

Corrosion describes a reaction of a material with its environment, which causes a measurable change in the material and can impair the function of a component or system. In metals, chemical corrosion is particularly significant. The best-known type of chemical corrosion in metals is rust, that is, the oxidation of iron.

Cracks

Cracks are weld seam faults that occur under tensile stresses. The two main groups are cold and heat cracks.

Crater crack

Crater cracks occur when a crater is not filled before the welding arc goes out. This causes the outer edges of the crater to cool down faster than the crater. This creates stresses, which can result in longitudinal splits, or transverse or radial cracks.

Crater shrink hole

The crater shrink hole is a hemispherical opening at the end of a weld seam. It occurs when the end-crater is not properly filled.D

DC voltage

DC voltage is an electrical voltage where the polarity does not change.

Degassing

Degassing refers to the escape of gases from liquid material during the welding process.

Demagnetization

Every object through which a current flows builds up an electromagnetic field. Demagnetization is a process used to break down the electromagnetic field.

Deposition rate

The deposition rate indicates how much filler metal melts within a specified period of time (kg/h). A higher deposition rate increases the welding speed and productivity. The increase can be affected by various parameters: parallel use of several welding wires or the use of special shielding gas combinations, flux core wires, and welding parameters. During TIG welding, the deposition rate can be increased by using hot wire. An additional welding system is required for this.

Device ID

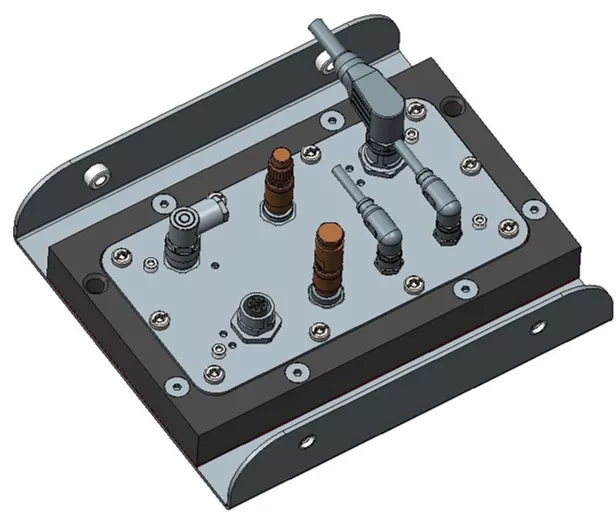

The device ID can be considered as a safety feature of DeltaSpot and DeltaCon. It is located on the sensor PC board directly on the gun. All gun-related data is stored on it for identification purposes. This is, amongst other things, to prevent damage to the system or component.Dip transfer arc

The dip transfer arc is a short-circuited arc with low power. It is suitable for ultra-light gage sheet, root pass, and position welding.

Direct current

Direct current (DC) is an electrical current where the amperage and polarity do not change.

Distance from contact tip to workpiece

“Distance from contact tip to workpiece” is another technical term for “stick out” or “free wire end”. It also describes the distance between the contact tip and the workpiece.

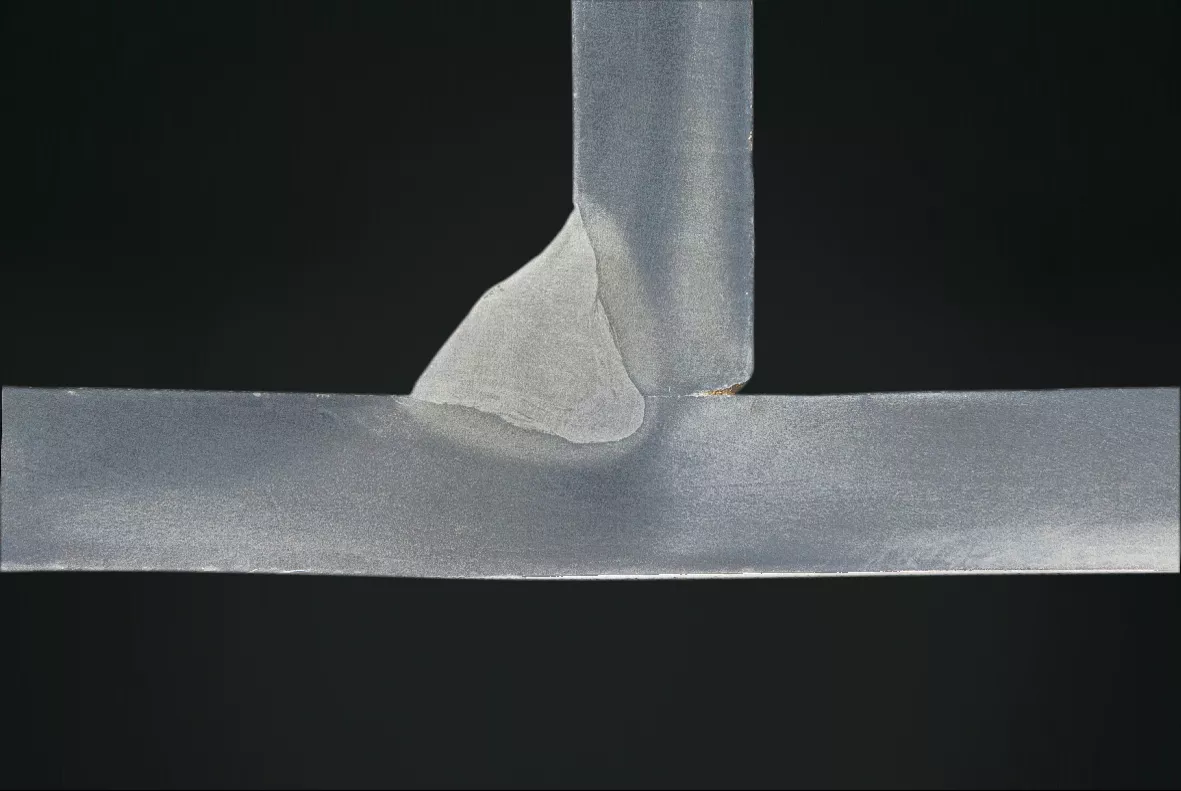

Double fillet weld

A double fillet weld is a T-shaped weld seam, welded on both sides.

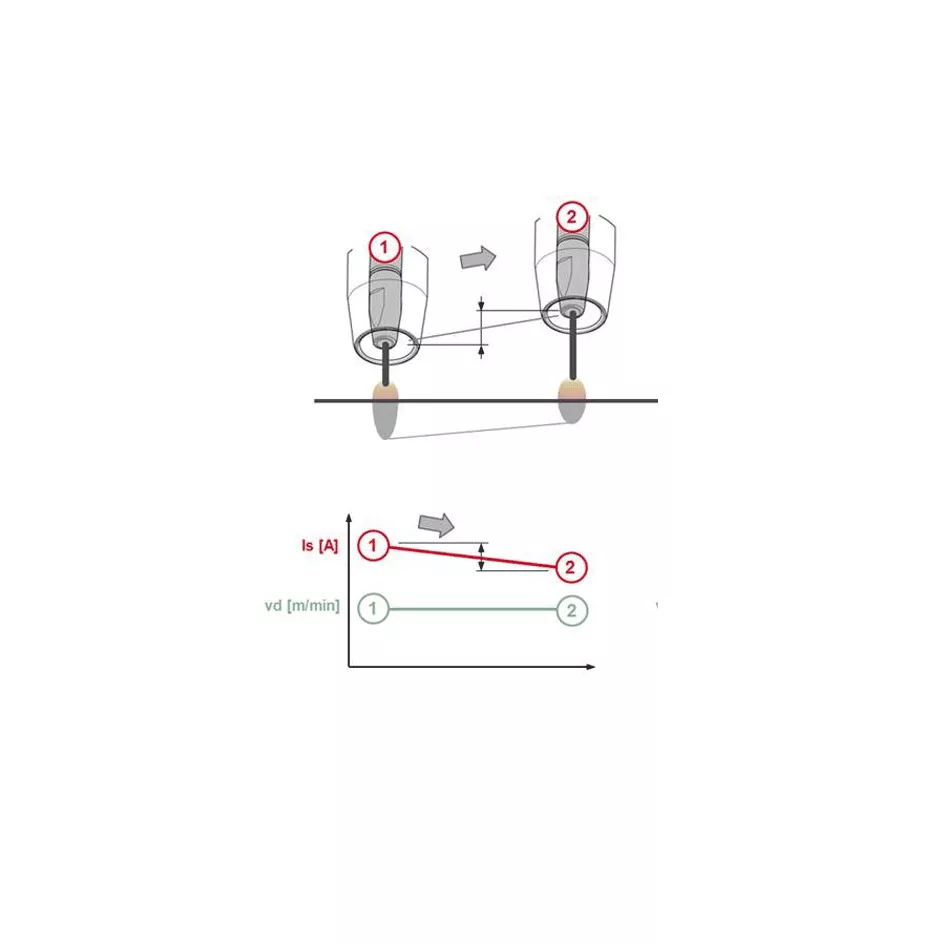

DownSlope

Period of time it takes to fall from the defined main current to the final current during TIG welding.

Duty cycle

Ratio of pulse duration to base current duration at a set pulse frequency. When the duty cycle is increased, the base current is increased. The weld pool therefore becomes hotter, which has a positive effect on the penetration.

Dynamic correction

Dynamic correction can be used to control the current increase behavior.E

Efficiency

The efficiency describes the relationship between the power input and power output. Examples include the electrical efficiency of a welding system or the thermal efficiency of the arc.

Electrical current

Electrical current is the directed movement of negatively charged charge carriers (electrons). The unit of measurement is an ampere (A). The formula symbol I describes the quantity of current that flows through a line within a given time period. In order for current to be able to flow, it requires an electrical voltage.

Electrical resistance

The electrical resistance indicates how much the electrons are slowed down while the electrical current is flowing. Its formula symbol is R and the unit of measurement is ohm (Ω).

Electrical voltage

The electrical potential difference is referred to as voltage and is between the positive and negative pole. The formula symbol for electrical voltage is U and the unit is volt (V).Electrode / Rod electrode

The rod electrode is a coated metal rod that is used for electrode welding. It acts both as a conductor for the arc and the filler metal at the same time. A distinction is made between basic (B), rutile (R), and cellulose (Cel) coating types.

Electrode holder

Secures the rod electrode during manual welding and allows the current to be transferred to the electrode.Electrode types

Rod electrodes for welding are made in numerous materials and with different coatings. The most common are rutile (R), basic (B), and cellulose (Cel) covered electrodes.Electrode welding (SMAW, manual arc welding, rod electrode welding)

Electrode welding is the oldest variant of arc welding. The arc burns between the workpiece and a covered rod electrode, which, by melting during the process, simultaneously acts as the filler metal.

End-crater

At the end of the welding process, the welding power is reduced rapidly. The weld pool cools down from the edge to the center. The molten mass that is still liquid has no strength to speak of and is distributed between the solidification fronts.

Result: A so-called end-crater forms in the middle.

Practical tip: At the end of the welding process, reduce the welding current slowly, move the welding torch back and forth or in a circle until the end-crater is completely filled.

EN ISO 1090

EN ISO 1090 is a European standard for structural steel and aluminum components, and affects all manufacturers, distributors, and suppliers. Since 07/01/2014, structural steel and aluminum constructions can only be brought onto the market in Europe if they comply with this series of standards and carry CE marking. Before CE marking, components were subject to self-monitoring by the manufacturer (factory production control), who then had to complete a declaration of performance for the guaranteed component properties.F

Fillet weld

The fillet weld is the most common weld seam and is usually found on the T-joint and lap joint.

Final current

Current value according to the defined DownSlope to end the welding process in a controlled manner and to avoid overheating the parent material at the end of the weld seam.

Forming

Forming primarily refers to a method used in TIG welding to protect the part of the weld seam facing away from the tungsten electrode from oxidation/temper colors. When welding pipes, these are flushed internally with gas (see figure: forming gas cylinder). When welding sheets, the underside is flushed with gas.

Fronius Xplorer

This is Windows-based software for the process monitoring of the digital series TPS and MagicWave. Welding data documentation, visualization, archiving, and parameter setting on a PC.

Fusion

Fusion indicates the mixture percentage of the parent material with the weld layer applied (e.g., steel with nickel-based alloy).G

Gas post-flow

Controls the time of gas flow after welding is completed. This prevents tarnishing and oxidation in the end crater area.

Gas pre-flow

The gas pre-flow is a way to obtain better shielding gas cover at the start of welding. A fixed period of time is defined here during which the gas solenoid valve should open before welding starts.

GMAW overlay welding

Gas metal arc overlay welding is used for cladding. A wear protection layer is applied over the base body using the MIG welding process. A characteristic of this is low penetration, low fusion, and a low ferrite content in the first weld layer.

Gouging

In gouging, the metal is melted with a special carbon electrode. The liquid material is purged by a stream of compressed air. Joins can be produced, defective weld seams removed, weld backups cut off, or very thick pieces of metal cut through. A special electrode holder is needed here with an integrated compressed air supply (see figure).

Grounding cable

The grounding cable is the current return cable in the welding circuit. It is secured to the component.

Grounding clamp

The grounding clamp is a quick-release mechanical connection between the workpiece and the current-return cable in the welding circuit.H

Heat-affected zone (HAZ)

The heat-affected zone emerges during welding and includes the material area next to the weld seam, in which structural changes due to the welding process can be detected by means of metallographic examinations. These changes also affect the properties of the material, so the welder is striving for the smallest possible HAZ. This is achieved with low energy input, i.e., heat input that is as concentrated as possible at a high welding speed – for example in laser welding.

Heat input

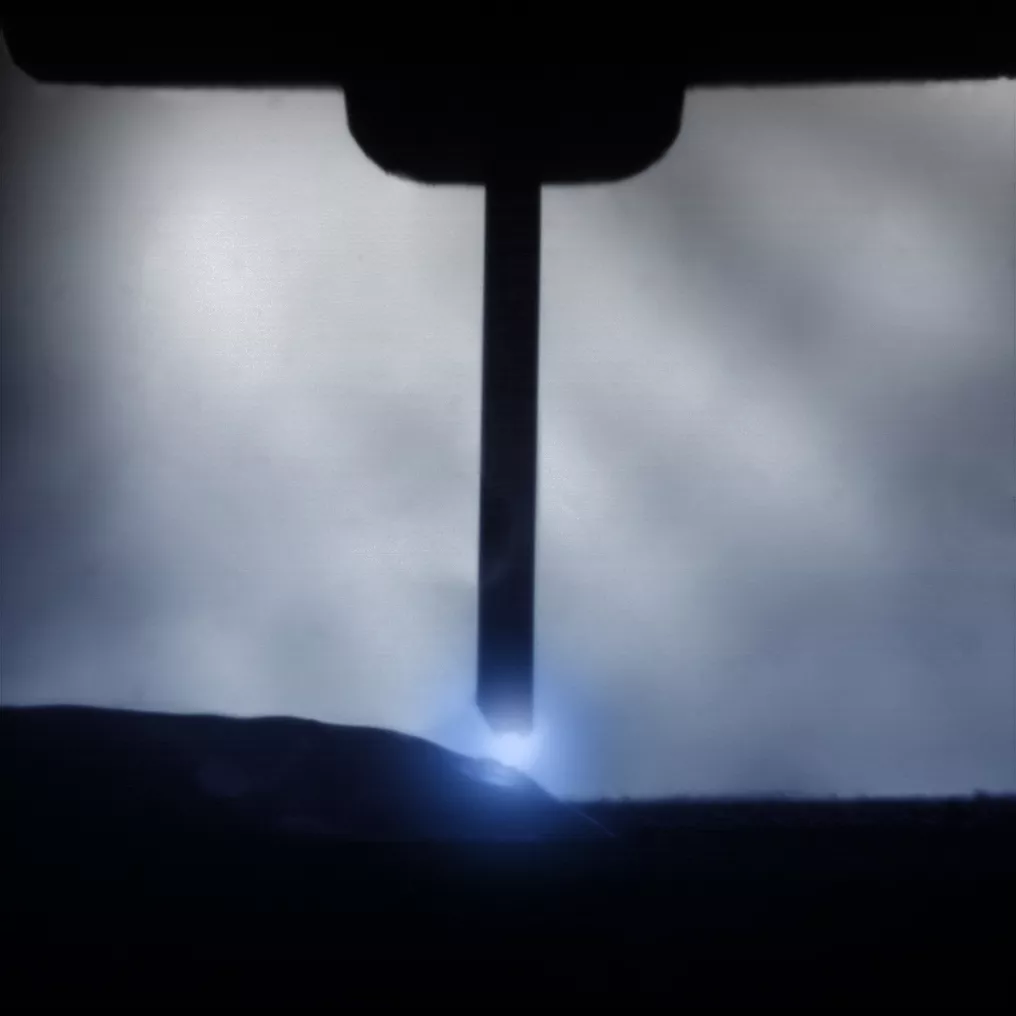

Heat input refers to the energy that is introduced into the component during welding. The heat input is calculated based on the electrical energy input per weld, reduced by the total efficiency. The unit of measurement is kilojoules per centimeter (kJ/cm).High frequency ignition (HF ignition)

In TIG welding, the arc is usually ignited touchlessly. Here a high-voltage source that is temporarily connected is used for ignition – this is referred to as high frequency ignition.

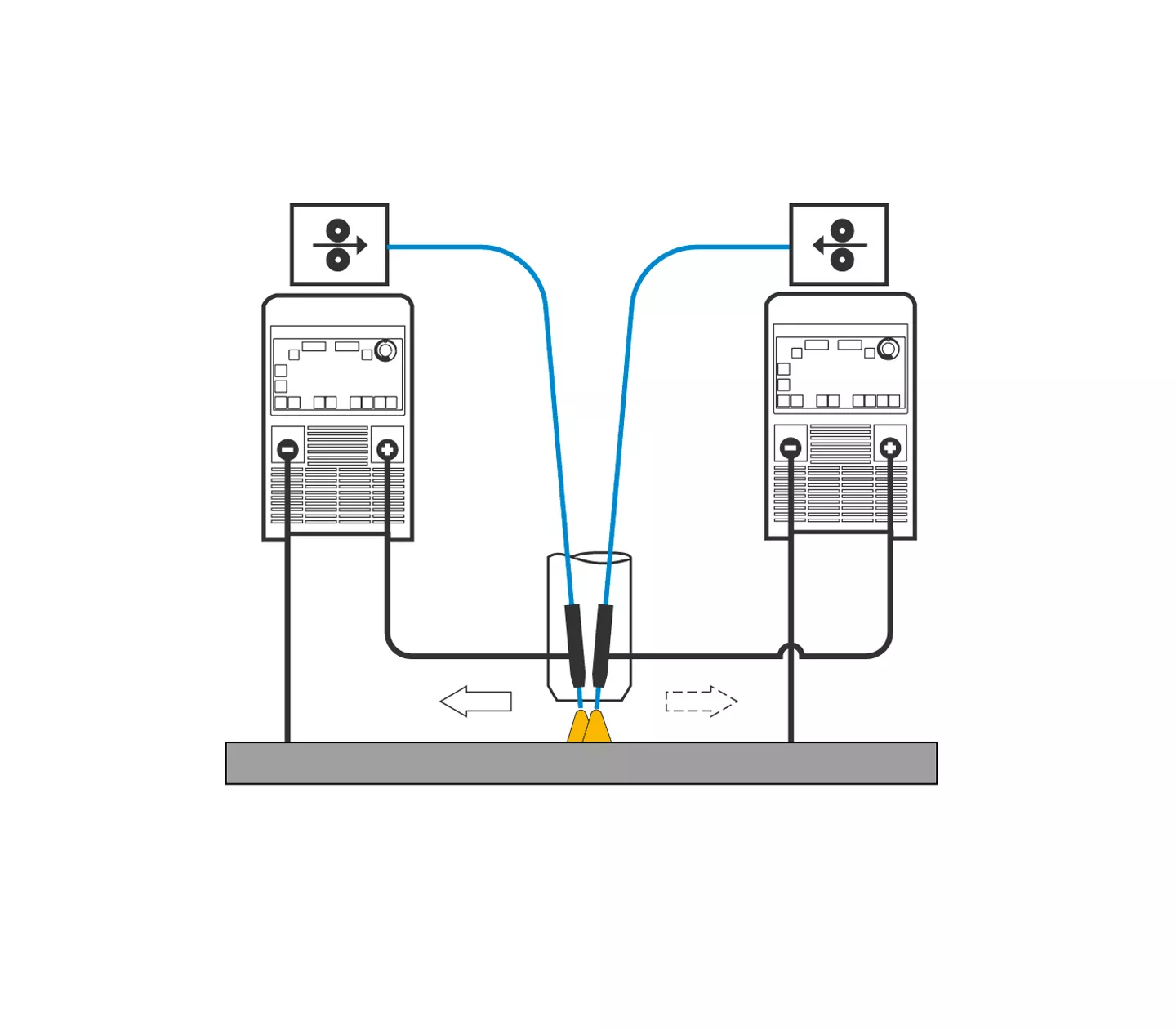

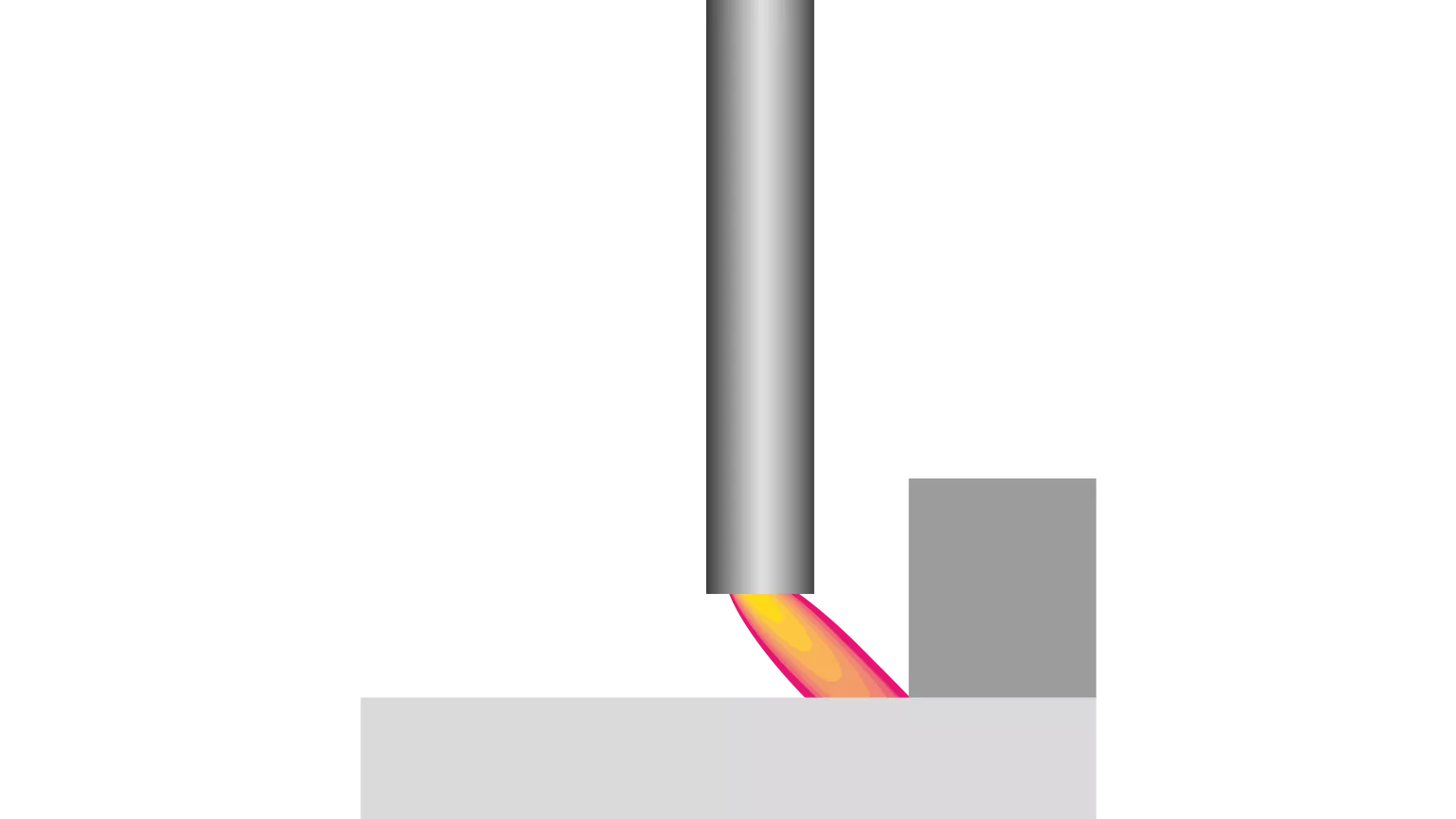

High-performance welding

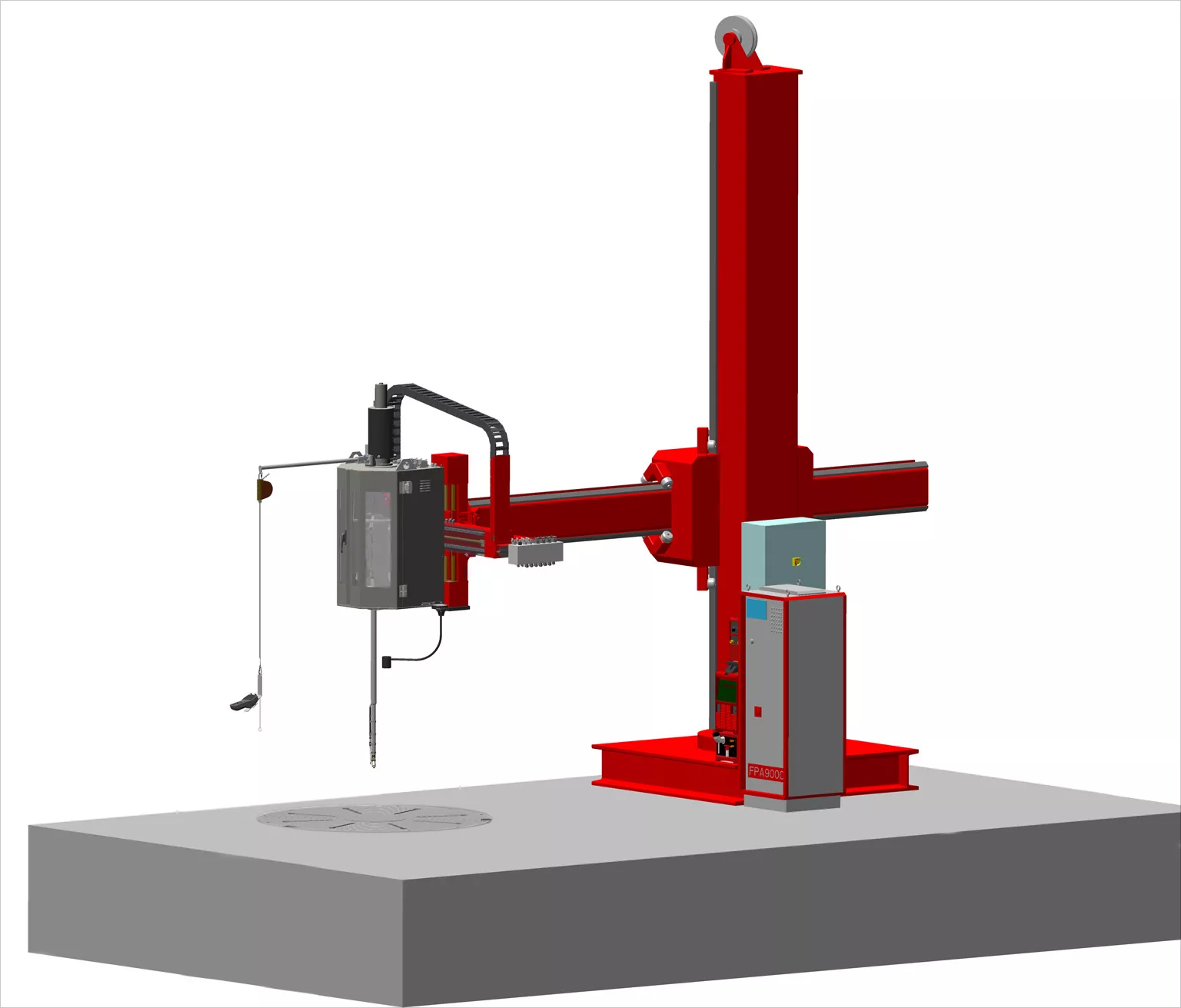

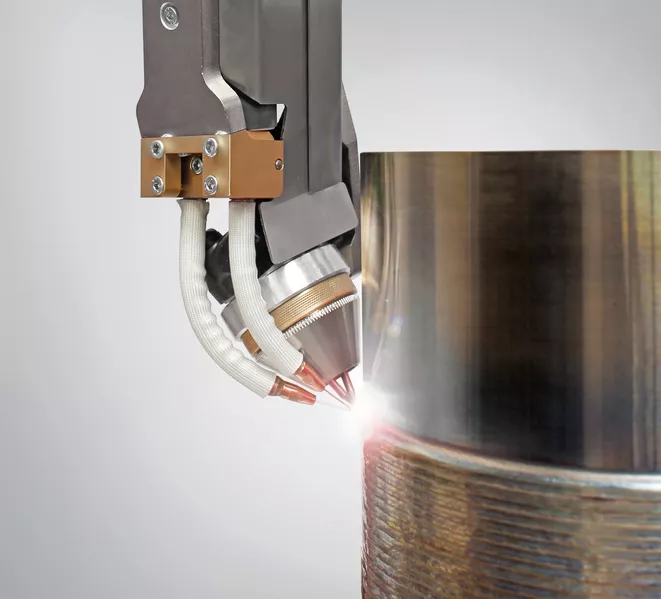

The term high-performance welding is commonly used as of wire speeds of 15 meters per minute (with a wire diameter of 1.2 mm) or an 8 kg per hour deposition rate. If several wire electrodes are used, there is an increase in the deposition rate (see figure).

Hot wire

The hot wire welding process can increase the productivity and quality of overlay welding (cladding).I

Inert gas

Inert gases are non-reactive noble gases. They are used in metal inert gas welding (MIG) and tungsten inert gas welding (WIG). Inert gases include argon, helium, and mixtures of these.

Inner control

For the inner control, constant-voltage characteristics or slightly drooping characteristics are used. The result is that when the welding amperage is changed, the voltage barely changes or does not change at all. Inner control improves process stability, even if the distance between the welding torch and the workpiece changes.

Intermediate arc

The intermediate arc is characterized by a coarse droplet, short-circuited droplet transfer. The advantages include positional freedom and relatively deep penetration. In contrast, however, is the increased spattering.

Interval mode

In interval mode, both the arc time and pause time can be set.

Inverter

Inverting means transforming. This concerns converting DC into AC current and vice versa. In the case of the inverter power source, the transformer is driven by a very high frequency, whereby the volume of the transformer can be kept extremely low. This reduces the weight and the power source is mobile. In addition to direct current, inverters can also generate sinusoidal and square wave alternating current for special requirements.

IP rating

The abbreviation IP stands for International Protection and is also called protection class. It defines the protection of electrical equipment against the penetration of foreign objects and water, and their impact resistance.J

JobMaster

The JobMaster welding torch with integrated digital display allows the welder to change and check the welding parameters on the handle of the welding torch.

Joining / joining process

In production engineering according to DIN 8580, joining is the permanent connection of two or more materials. Some of the most important joining processes include welding, brazing, bonding, riveting, and screwing.L

Lack of fusion

Lack of fusion occurs if there is no secure join between the weld metal and the parent material, or in multirun welding.

Lap joint

A lap joint is a weld joint where several parts lie (parallel) on top of each other and overlap, whereby one workpiece protrudes beyond another.LaserHybrid

LaserHybrid welding combines the laser and MIG welding process. Characteristic features are deep penetration, a high welding speed, and low heat input.

Lines of force

Components that are mainly subject to dynamic loads need homogeneous weld seam transitions (line of force progressions) to avoid a notch effect.

Longitudinal seam welding

In longitudinal seam welding, components are joined together lengthwise.

Lowering/intermediate current

Temporary higher/lower welding current by means of a controlled change on the torch button to the set value.LSC

Low Spatter Control (LSC) is a spatter-reduced dip transfer arc with early detection of the short circuit breakup and a corresponding reaction.LSC Advanced

The LSC Advanced process characterizes the accelerated drop in current that is facilitated by an electronic switch in the welding circuit. The result is improved weld properties with increased inductivity.M

MagicWave

The MagicWave is a fully digitized TIG series and can be used with both alternating current (AC) and direct current (DC). The operator can adapt the waveforms to various conditions.

Magnetic arc blow

Every metallic object that has current flowing through it builds up an electromagnetic field. This magnetic field can deflect the electric arc and cause weld seam faults. Larger masses of steel attract the electric arc.

Main current

Adjustable welding current.Manual welding

Manual welding is a manual joining process for producing inseparable metal joints.

Mechanical properties

The mechanical properties of a parent material or a welded joint act as the basis in the static calculation for supporting structures. They are crucial for choosing the parent material and filler metals to be used. Mechanical properties are: hardness, tensile strength, impact energy, toughness, etc.Mechanical welding

Mechanical welding is a mechanized joining process. Among other things, this involves using trolleys or robots.MIG/MAG welding

Metal inert gas welding (MIG) and metal active gas welding (MAG) are variants of gas metal arc welding (MSG). Here an endless wire electrode melts under a shielding gas cover. MIG/MAG welding is characterized by a wide range of different uses and a high level of cost effectiveness.

Misalignment

This is the technical term that describes the deviance from accuracy, for example between two sheets.Multiprocess welding systems

Multiprocess welding systems refer to welding power sources where the common welding processes, such as MIG/MAG, SMAW, and TIG, are available.

Multivoltage power source

Multivoltage power sources can be connected to electrical grids with different voltage levels. Single-phase and three-phase multivoltage power sources are available.O

Open circuit voltage

This is the voltage that is applied to the welding sockets prior to welding, for example from the ignition of the rod electrode.

Operating point

The operating point is the intersection between the power source characteristics and the physical arc characteristics.

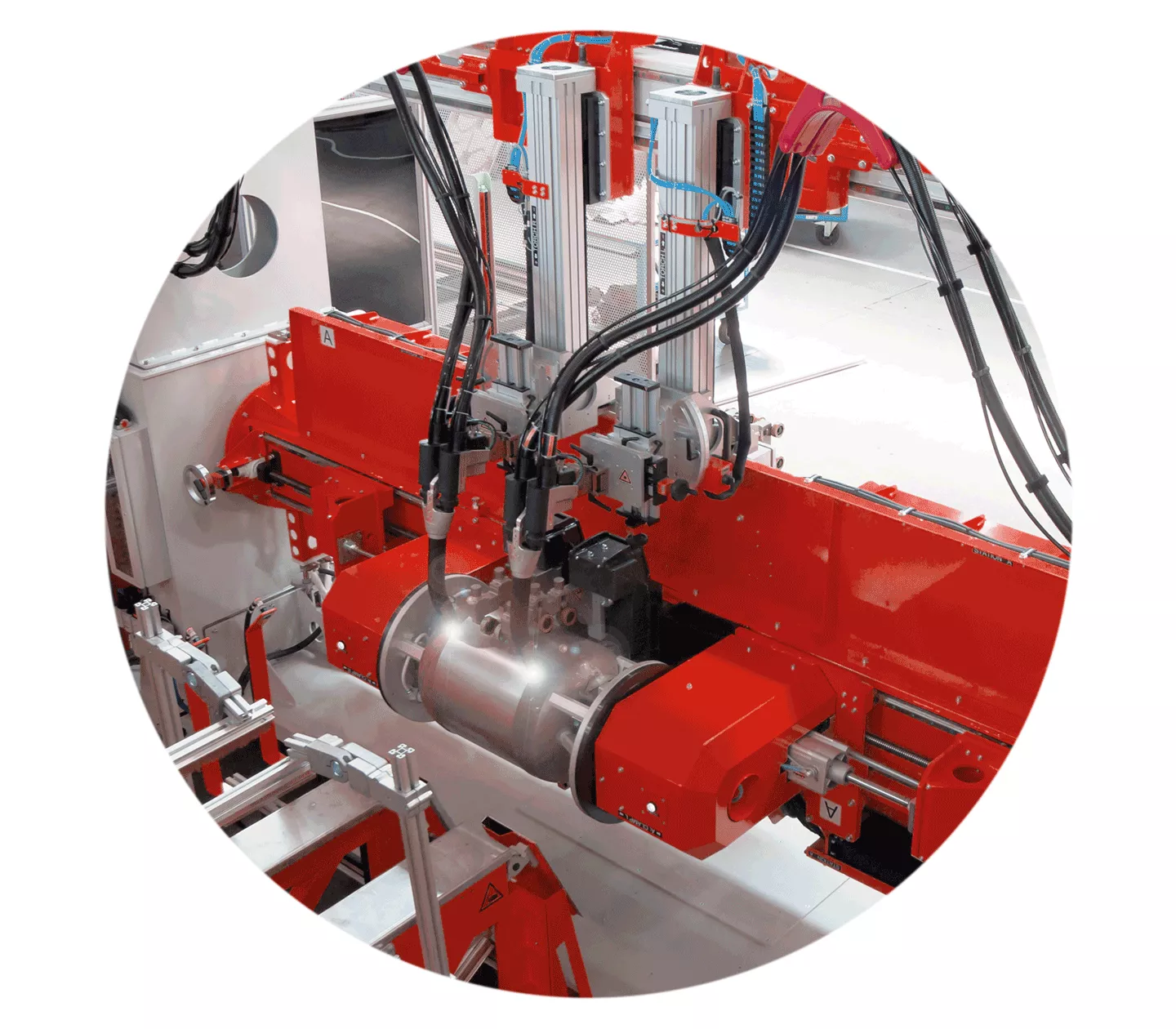

Orbital welding

Orbital welding is a mechanized welding process in which the arc is guided by machine and without interruption around pipes or other round objects.

Outgassing

Outgassing refers to the escape of gases from liquid or solid material during the welding process.

Oxide film

Aluminum forms a protective layer that is called an oxide film. The oxide film has a destructive effect during welding and must be broken up. This is done during TIG welding with alternating current (AC). The melting point of the oxide film is approximately 2100°C, in contrast to aluminum that has a melting point of approximately 660°C depending on the alloy.

Oxide formation

Surface scaling is called oxide formation. This occurs especially during the manufacturing of steel or slightly in the case of poor shielding gas cover.P

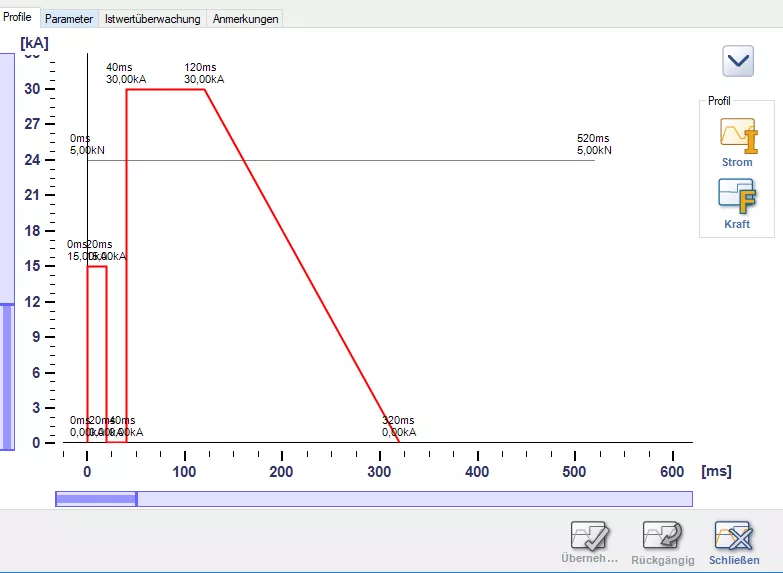

PCS - Pulse Controlled Spray Arc

The PCS (Pulse-Controlled Spray Arc) characteristic is a modified pulsed arc that transfers to the higher power range in a short spray arc. Dynamic correction enables a pulse profile to be superimposed onto the spray arc. The result is a welding process with a high deposition rate, deep penetration, lower heat input, and low spattering.

Penetration

Penetration refers to the depth of the melted zone in the parent material.

Phase synchronization

Synchronization of two power sources for simultaneous TIG welding on both sides, also with alternating current.

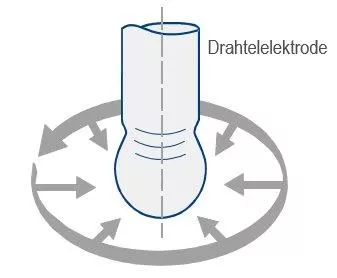

Pinch effect

In welding technology, the term pinch effect refers to the detachment of the droplet at the wire end caused by the effect of the magnetic constriction due to high currents.

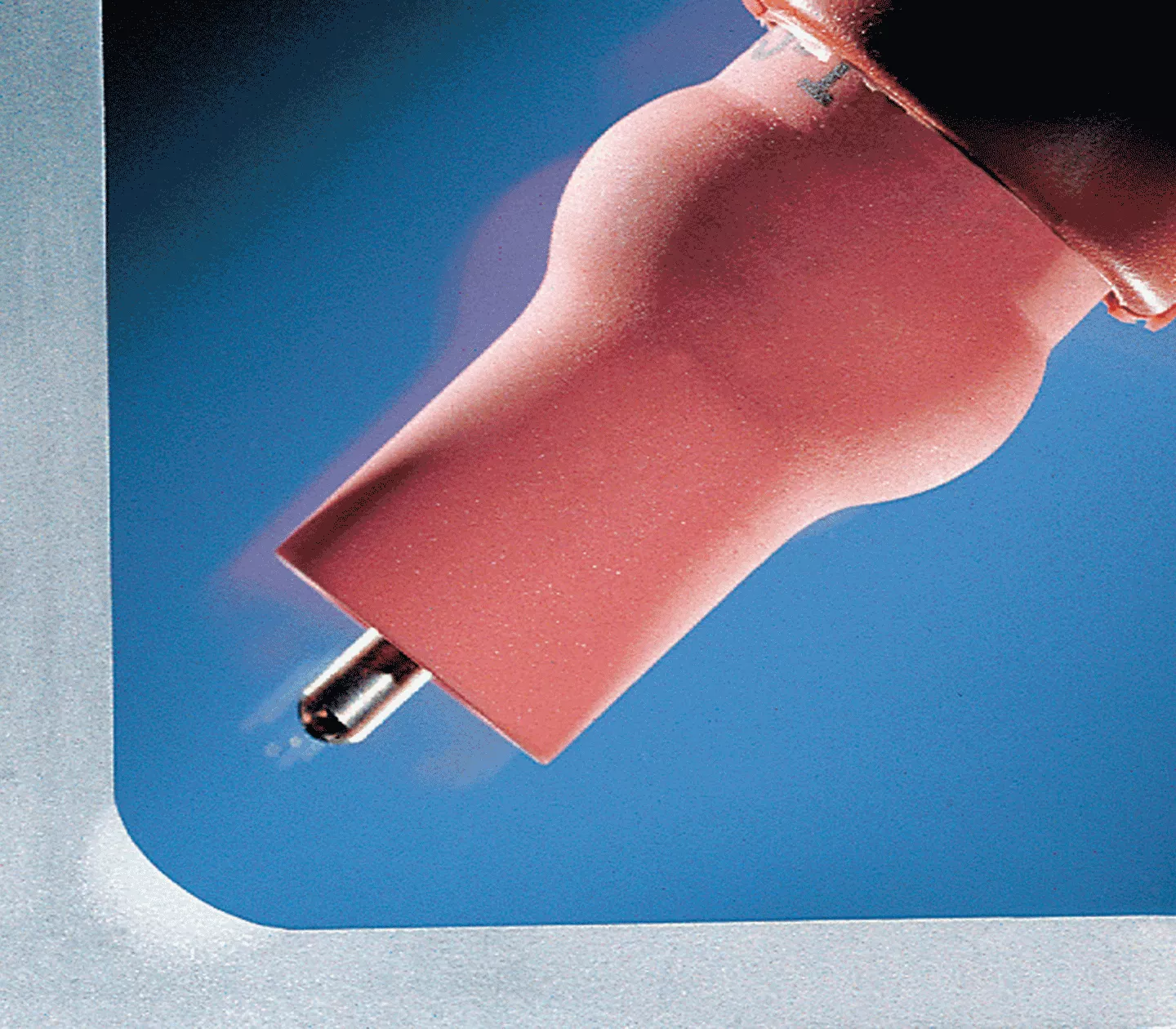

Plasma welding

In plasma welding, the welding or main arc burns between a tungsten electrode and the workpiece, just as in TIG welding. In addition, the constricted plasma gas acts as a process-determining factor. It is determined by the nozzle diameter, plasma gas quantity, and plasma flow. A distinction can be made between micro plasma, soft plasma, and plasma keyhole. In comparison with the TIG process, a higher welding speed, narrower weld seam appearance, and deeper penetration can be achieved.PMC - Pulse Multi Control

All further developments in the pulsed arc are implemented at Fronius in the Pulse Multi Control (PMC) characteristic package. This currently includes additional control variables and stabilizers and different characteristics that make things easier for the user.

Pore formation

Pore formation refers to the gas inclusions in the weld seam. Pore formation is a welding fault that is caused by contamination or insufficient shielding gas cover.

Power source

The function of a welding power source is to convert a high input voltage into a low welding voltage and high welding current. There are different types of models, whereby the controlled type inverters have mostly established themselves.

Power source characteristic

The characteristic of a power source is a material and shielding gas dependent combination of current and voltage across the entire power range.

Preheating

With preheating, the components are heated up and then kept at a specific temperature in order to influence the cooling speed during welding.

Protection from welding fumes

Weld outdoors if possible. Extract the welding fumes at their source using a welding fume extraction system (stationary or mobile) and/or on-torch extraction (MIG/MAG or TIG). Welding helmets with a fresh air supply, such as the Vizor Air, provide further protection from welding fumes.

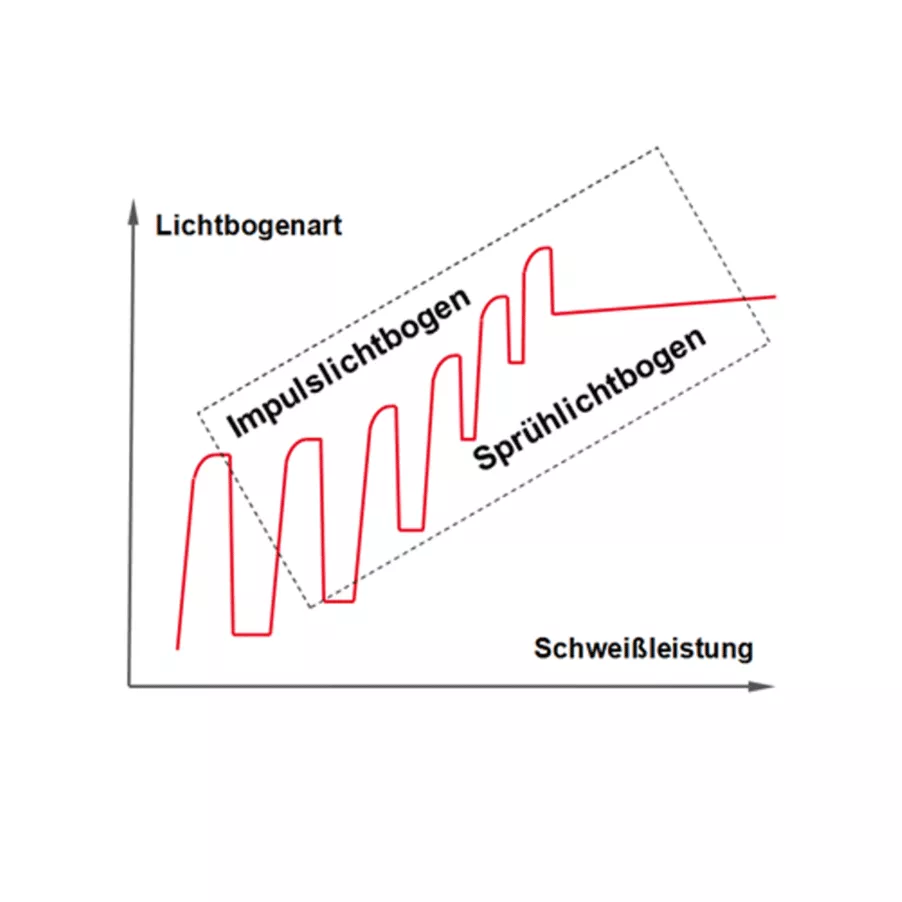

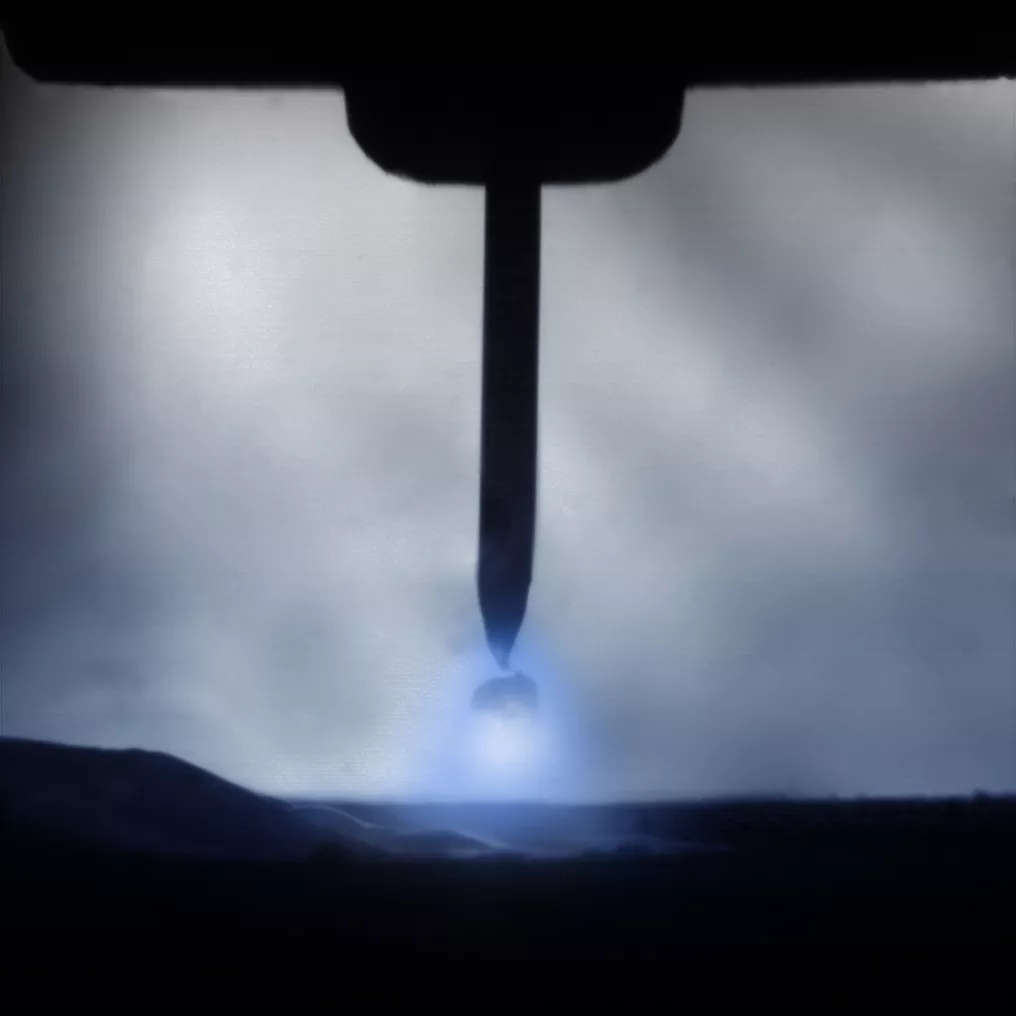

Pulsed arc

When welding with pulsed arcs, there is a switch from base current to pulse current. The frequency and pulse time are specified here. This causes the pinch effect that allows a short-circuit-free droplet transfer across the entire power range.

Pulse frequency

Specifies how many pulse cycles per second (Hz) are generated.R

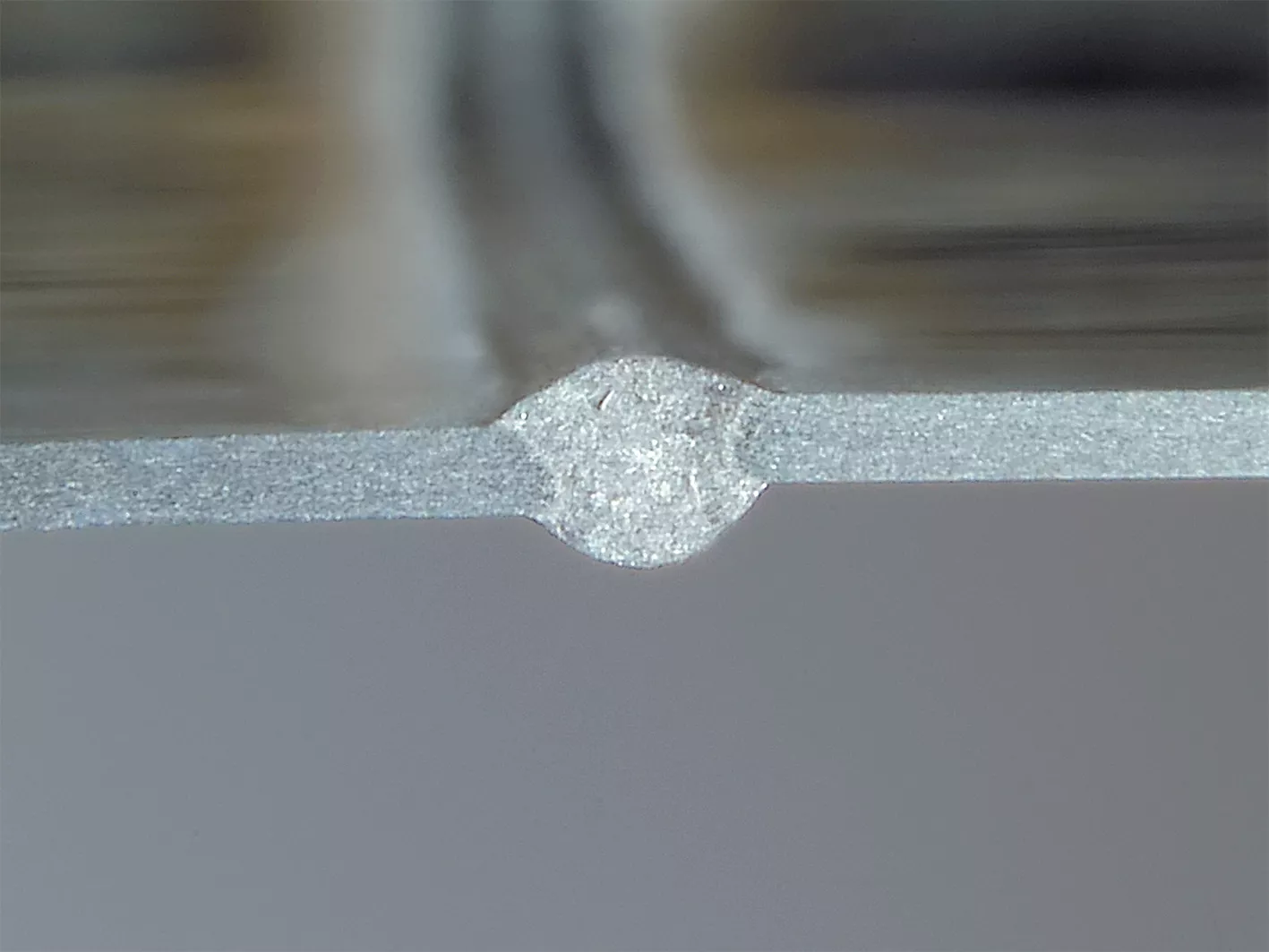

Resistance spot welding

The principle of resistance spot welding is based on current, resistance, and time. When maximum resistance is applied, the material fuses. Due to the high contact pressure, exerted by the effect of the electrode force, the components are welded together at their points of contact.

Reversed polarity ignition (RPI)

A reversed polarity ignition is a polarity reversal of the tungsten electrode to the positive pole in the ignition phase, in order to achieve a more accurate and stable ignition.

R/L alignment

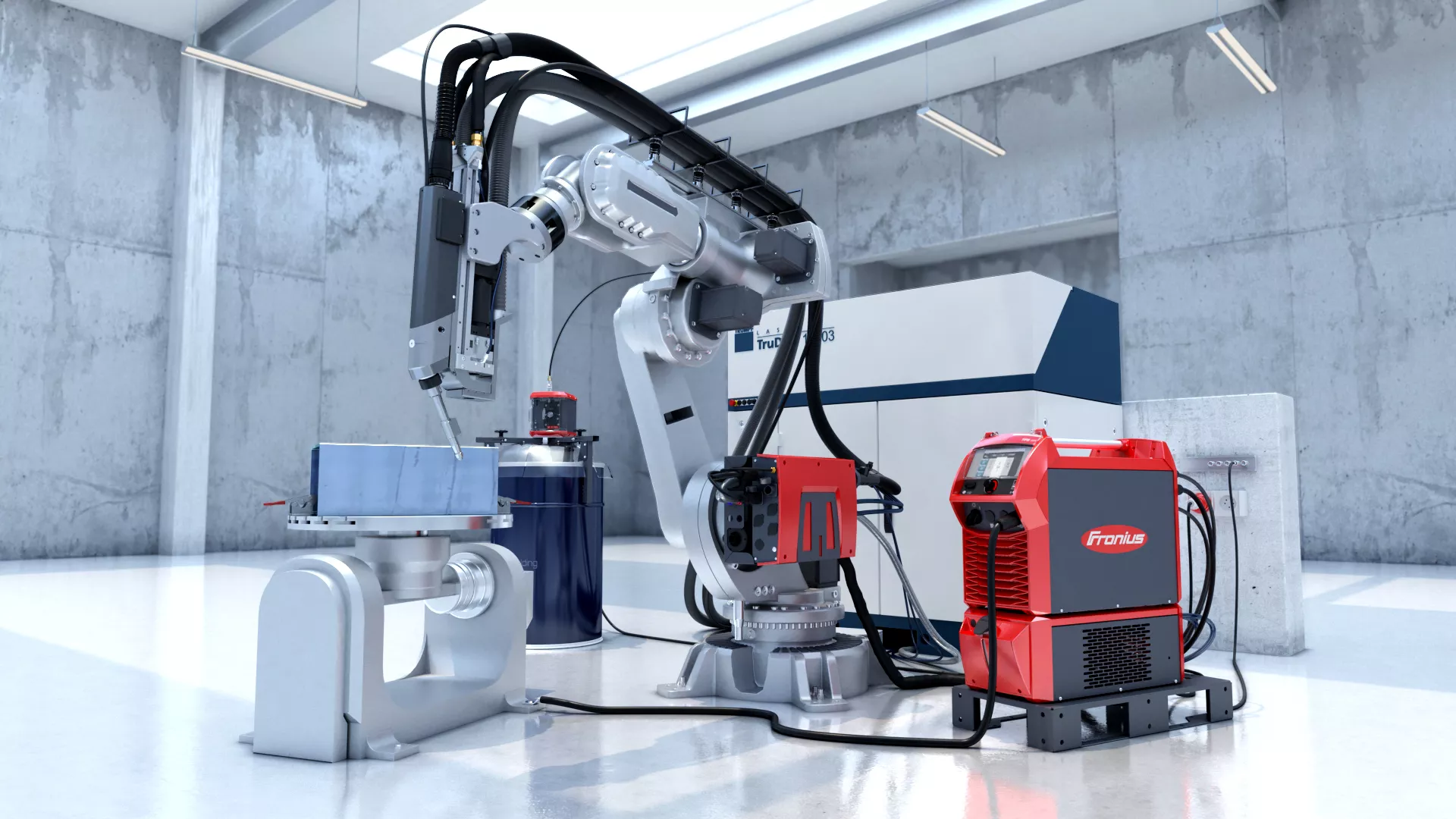

R stands for resistance in mΩ (milliohms), L for inductivity in µH (microhenrys). Aligning the welding circuit resistance and the welding circuit inductivity is a function on the welding system. This compensates for losses with long hosepacks or grounding cables. It enables consistent, optimal welding results to be achieved.Robotic welding

In robotic welding, an industrial robot guides the welding torch within a preprogrammed track.Rod electrode / electrode

The rod electrode is a coated metal rod that is used for electrode welding. It acts both as a conductor for the arc and the filler metal at the same time. A distinction is made between basic (B), rutile (R), and cellulose (Cel) coating types.

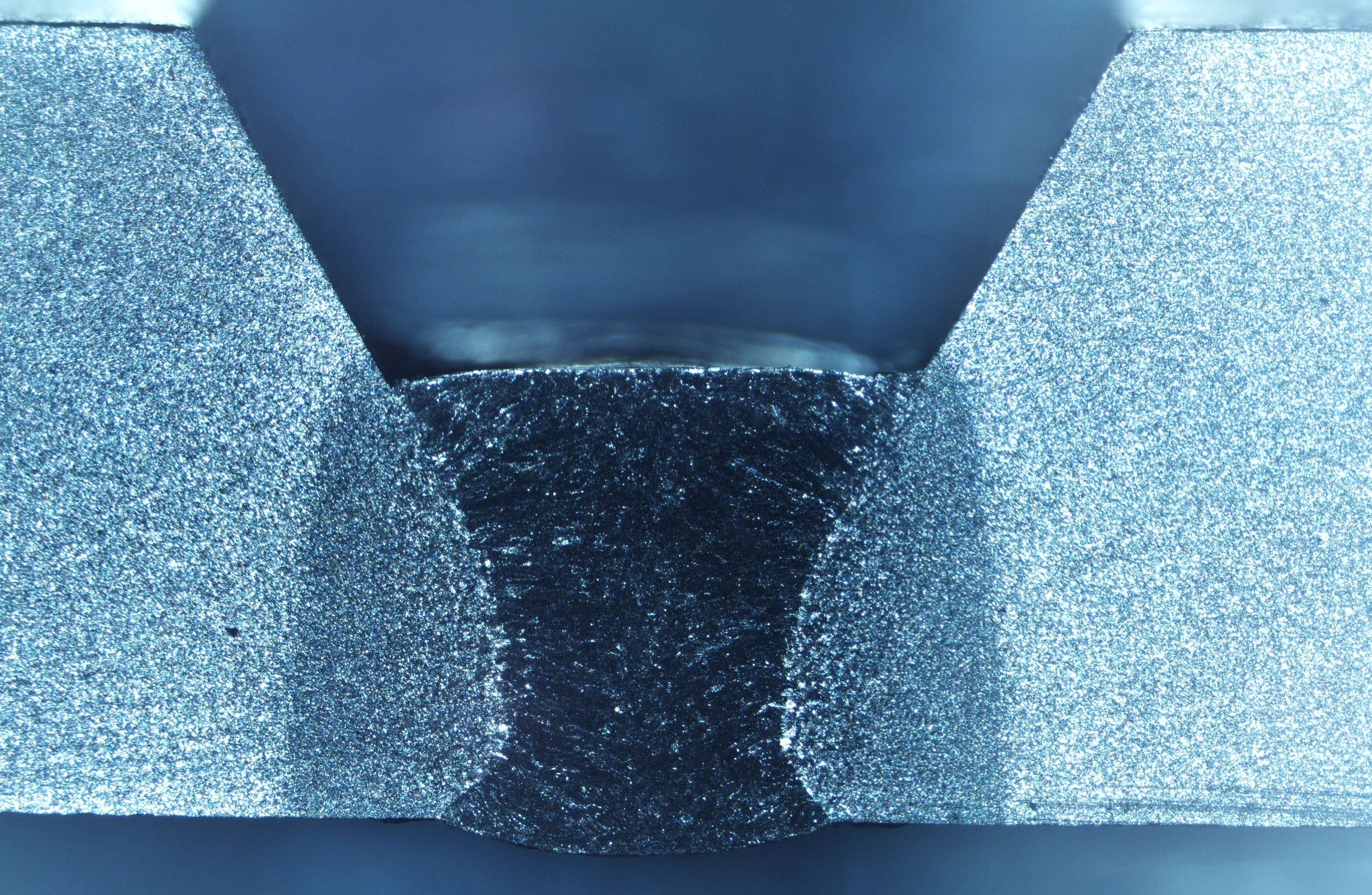

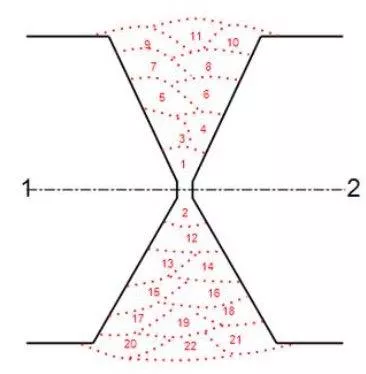

Root pass

The root pass refers to the first bead that is introduced into the join during multirun welding. Fronius offers special characteristics with the ROOT characteristic for this purpose.

Run-in and run-off plates

These are metal pieces that are attached directly to the workpiece before the start of the weld seam and at the end of the weld seam. This ensures full penetration is achieved from the start of the weld seam to the end, without resulting in restarts of welds and end-craters.S

Shielding gas

Shielding gas refers to a gas or gas mixture that is designed to suppress the air in the earth's atmosphere during welding. Shielding gases influence the penetration form, penetration, and welding speed and need a corresponding characteristic during MIG/MAG welding.

Short circuit

If during MIG/MAG welding, the wire electrode or during SMAW, the rod electrode hits the surface of the material, this produces an electrical short circuit. This must be overcome at the start of welding and broken up during continuous welding by means of a short circuit treatment.

S identifier

The S label (Safety) is required to be able to use the welding system to perform welding where there is an increased electrical risk (e.g., in boilers). It refers to the open circuit voltage of the system. The maximum permitted open circuit voltage where there is an increased electrical risk is 113 V DC (peak value) or 68 V AC (peak value)/48 V (effective value). The system must however not be located in such areas.<br>The S label replaces the former K labels (DC range) and 42 V (AC range).

Slag

Rod electrodes have a coating that melts away in the arc and partially vaporizes. It forms shielding gases and slag. The slag protects the weld metal from the atmosphere and rapid cooling speed, covers the weld seam, and must be removed after cooling. Certain flux core wires contain a welding powder that also forms a slag when it melts.

Slag inclusions

Slag inclusions are weld seam faults caused by fixed inclusions made up of slag residues that were not washed to the surface. They affect the strength of the connection.

Smart Manager

Smart Manager is the TPS/i welding system website. It is decentralized and comes with WeldCube Light and Basic. You can manage your welding system on Smart Manager.

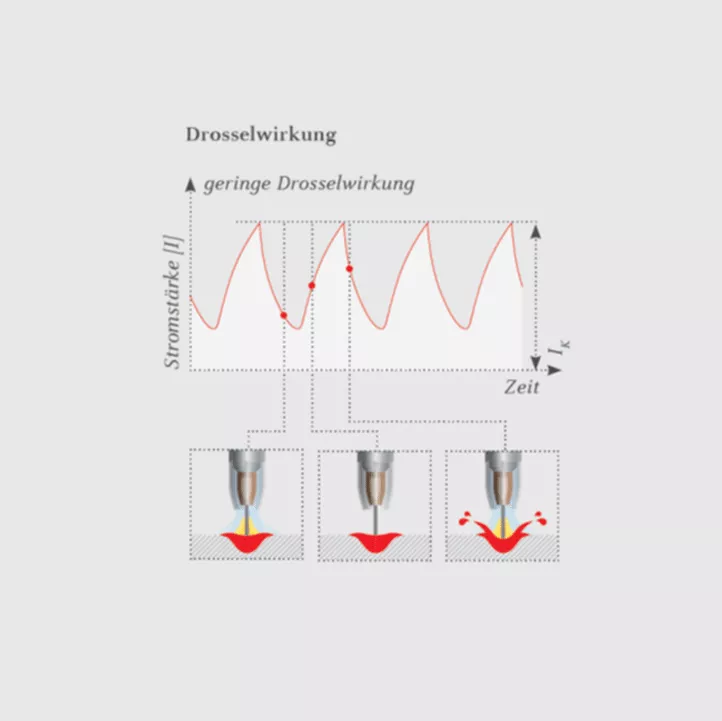

Smoothing choke

The smoothing choke slows down the current rise rate. For stepped welding systems, this is a coil with different choke draw-offs. The weld properties such as the ignition of the arc, handling of short-circuit incidents and faults are affected directly here.

SoftStart

Contact ignition during TIG welding - The ignition takes place by touching the tungsten electrode with the workpiece.

Spot welding time

Set value for the spot welding time in spot welding mode. Corresponds to the actual arc time.

Spray arc

The spray arc is a type of arc with short-circuit-free droplet transfer. It is characterized by high amperages and high deposition rates. This type of arc is used for thicker materials.

Starting current

Current value at the start of welding for a “gentle” start and thus controlled heat input into the workpiece. At the same time, this protects the tungsten electrode against high loads during the start of welding.

Steeply drooping characteristics

When welding with rod electrodes and TIG, it is important to keep the welding current as constant as possible, even when the distance between the electrode and the workpiece changes. This is achieved by what are known as the drooping characteristics of the power source, whereby the amperage (ampere) does not change and the voltage (volt) rises/falls due to a change in distance.

Stick out

Is the technical term which describes the distance between the contact tip and the workpiece. It is also referred to as “free wire end”.

Synchronized welding

This is a technical term from the discipline of TIG welding. Two welders join the workpiece in sync on both sides of the required joint. This practice is primarily used in pipeline construction, i.e., for circumferential welding.

Synergic welding

Synergic operation is the single-button operation of a welding power source. Here, the welding current, welding voltage, and wirefeeder are linked together in a synergy. This function helps the user achieve a welding result very quickly and easily.T

TAC

During tacking with TAC, a TIG pulsed arc causes the liquid weld pool to begin moving. This leads to accelerated merging of the elements and therefore to a shorter tacking process.

Tacking

Tacking refers to the joining of the components prior to the actual welding process.

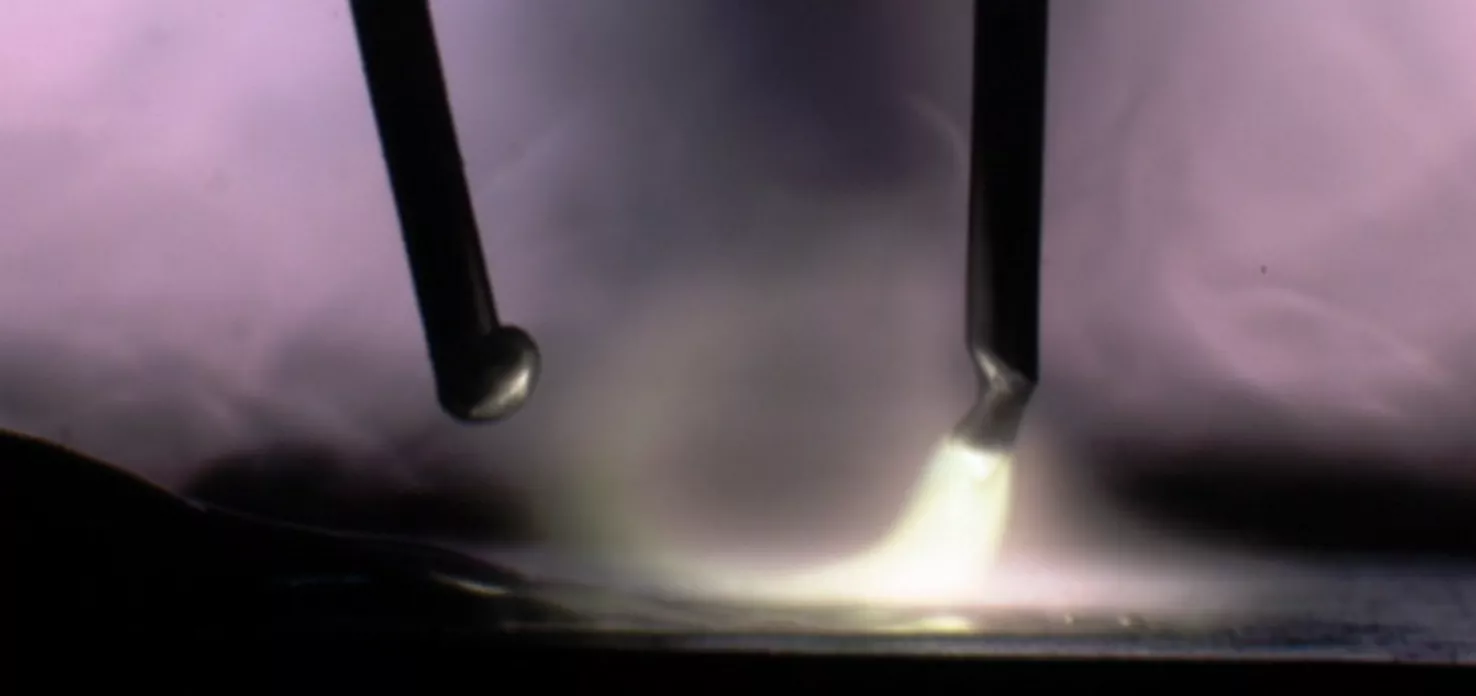

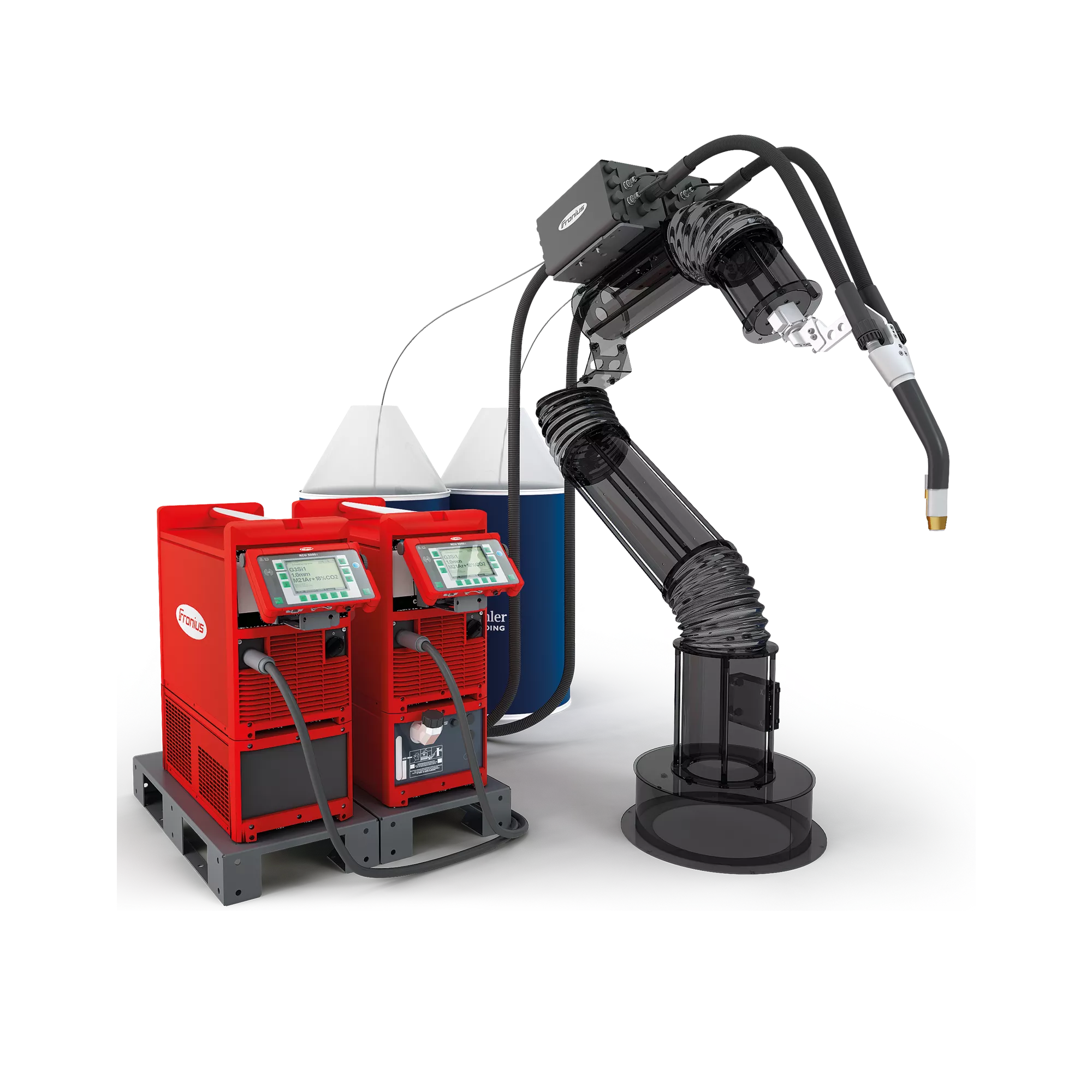

Tandem welding

In tandem welding, two completely isolated wire electrodes are melted in a welding torch and a common weld pool. The process allows a particularly high deposition rate, which can be converted to welding speed or volume filling. This welding process is known at Fronius under the brand name TWIN.

Temper colors

Temper colors are superficial, bright colorings on metals, generally caused by thermal heat input and oxidation. These can be avoided by using various forming and shielding gases.

Thermal conductivity

Thermal conductivity is a material value that describes how well a material conducts heat. Materials with high thermal conductivity are difficult to weld and need a special welding start treatment (e.g., aluminum) or require a high preheating temperature (e.g., copper).

Thermal joining processes

Thermal joining processes refer to the connecting of materials by introducing heat and/or using force. They include press welding and fusion welding.

TIG AC

This is TIG welding using alternating current, whereby the polarity of the electrode changes quickly between positive and negative. It is mainly used in aluminum welding.

TIG Comfort Stop

Stopping the welding process without a torch trigger by briefly lifting and lowering the electrode.

TIG contact ignition

With conventional TIG contact ignition, the tungsten electrode is lifted off the workpiece. The preset welding start sequence then takes place.

TIG DC

TIG welding with direct current, where the polarity of the electrode is negative throughout the entire welding process. In exceptional cases, DC plus can also be used.

TIG overlay welding

Tungsten inert gas overlay welding is universally applicable and is ideal for surfacing high-alloy metals and steels. The welding process provides high-quality surfaces that are clean and exact, with little spatter.

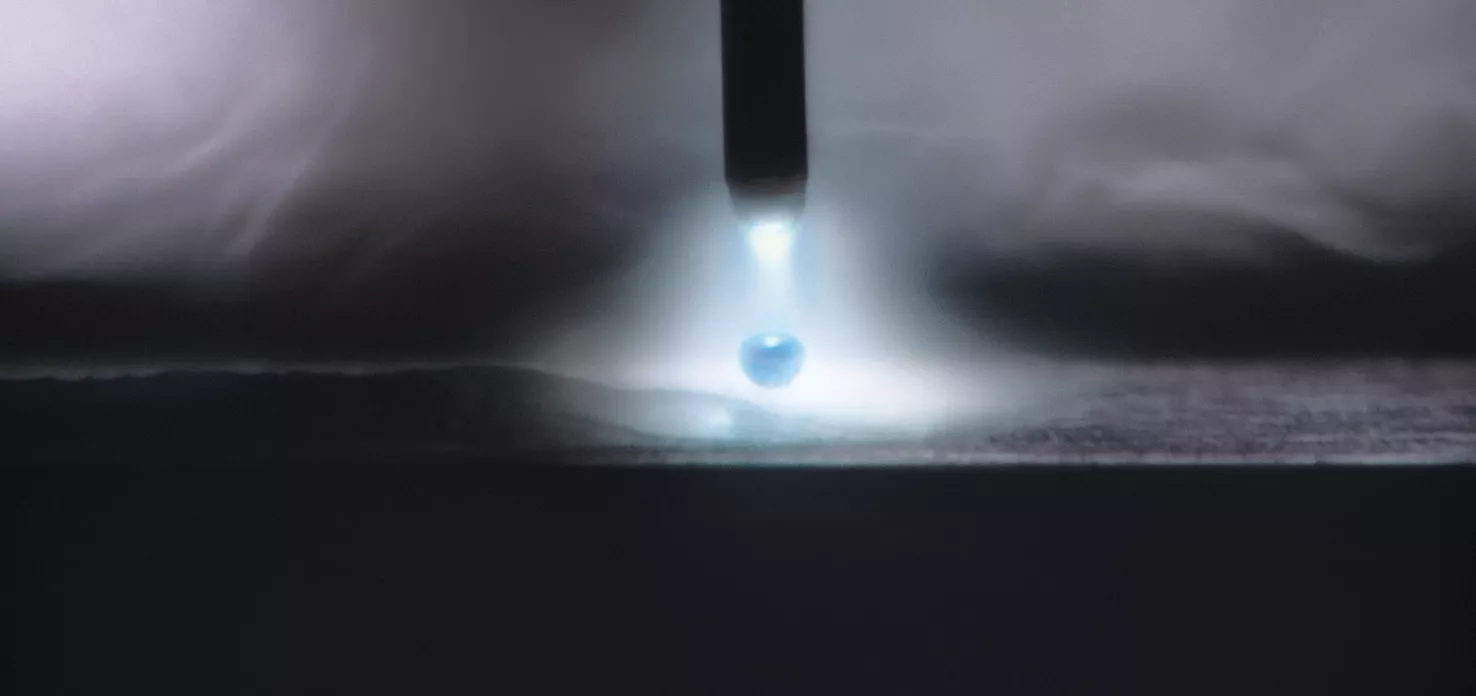

TIG touchless ignition (HF ignition)

In TIG welding, the arc can be ignited touchlessly. Here a high-voltage source is used that is temporarily connected with high frequency and low power.TIG welding

Tungsten inert gas welding is a shielding gas welding process. Here the arc burns between a non-consumable tungsten electrode and the workpiece.

TIME process

TIME stands for Transferred Ionized Molten Energy. The TIME welding process is synonymous with MAG high performance welding with a wire.

Time Twin

With Time Twin, two digital power sources that can be controlled separately work in a single gas nozzle and in a common weld pool. Both wire electrodes are completely isolated. This shortens cycle times and increases weld quality and cost effectiveness in high-performance welding.

Tolerance

This is the technical term for the gap between two sheets in the longitudinal direction and/or the height of the plates.

Torch to workpiece distance

The torch to workpiece distance is the distance between the gas nozzle and workpiece. To achieve optimum results, the correct distance must be chosen and remain constant during welding.

Torch trigger logic

Two alternative operating modes can be set: 2-step and 4-step (the difference is the way the torch trigger works). Choosing between these two step modes allows the welder to decide whether they want to hold down the torch trigger permanently or only do so to start and stop welding. In 2-step mode, the torch trigger is held down during welding and released to end it. In 4-step mode, the trigger is pressed and released again (the same action is repeated to end welding). This makes torch guidance/handling more relaxed for the welder, which has a positive effect, especially when longer weld seams are involved.

TouchHF

Ignition via high-voltage pulses triggered by touching the workpiece.TPS/i

The devices are fully digitized, microprocessor-controlled inverter power sources. A universal controller controls the entire welding process. The actual data is measured continuously and the device responds immediately to any changes. Special rule algorithms ensure that the desired target state is maintained. The software system is the decisive factor for the weld properties of the power sources, not a rigid hardware system that can barely be changed. This results in high accuracy in the welding process, exact reproducibility of the welding results, and excellent operating characteristics.

TPS/i TWIN Push

This is the latest welding system in tandem welding based on the Fronius TPS/i system platform.

TransPocket

The TransPocket series includes power sources for electrode welding with fully digital inverter technology. User-friendliness, durability, high performance, and mobility are the characteristics of these welding systems.TransSteel

The TransSteel is a fully digitized, microprocessor-controlled inverter power source. The modular design and internal software system make system add-ons or updates very easy. The main application is GMAW steel welding. The central control unit is linked to a digital signal processor. They control the entire welding process. Actual data is measured continuously so that the device can respond immediately to any changes. Special control algorithms control the entire welding process and ensure that the desired target state is maintained. The software system is the decisive factor for the weld properties. This provides the opportunity to make ongoing improvements and adaptations.

TransTig

The TransTig is a fully digitized TIG series and can be used for direct current (DC) applications.Tungsten electrode

The tungsten electrode is a non-consumable electrode for TIG welding.

Tungsten inclusions

If the tungsten electrode touches the weld pool during TIG welding, particles of the electrode can get into the molten mass and cause welding faults or tungsten inclusions.

Types of radiation in the electric arc

The electric arc emits visible radiation, invisible infrared or heat radiation, and invisible ultraviolet radiation.U

Ultraviolet radiation

Ultraviolet radiation is an electromagnetic radiation with wave lengths that are shorter than visible light and that are invisible to a person. When welding, UV radiation is generated by the arc plasma – the greater the amperage, the longer the arc and therefore the stronger the radiation.

Undercuts

Undercuts are depressions at the side of the weld seam, which can cause the welded joint to break. They are caused either by an incorrect welding torch or electrode position, and incorrect welding parameter settings. A reduction in the cross section of the material can cause a notch effect (starting point for cracks).

UpSlope

Period of time it takes to rise from the defined starting current to the main current during TIG welding.V

Virtual Welding

Risk-free welding: Virtual training offers a safe, affordable, and resource-conserving way to realistically simulate complex welding processes. Those new to welding can repeat jobs as many times as necessary, improve their skills in a safe environment, and learn from their mistakes as a result. Alongside the associated Welducation Campus platform, the Welducation Simulator offers trainees and trainers a complete teaching concept consisting of theoretical content and virtual training units with the simulator.

VRD - Voltage Reduction Device

On MMA devices, there is a relatively high open circuit voltage at the sockets for igniting the electrode. To increase safety for the user the open circuit voltage is limited to 12 V by the VRD (Voltage Reduction Device) option. The welding system identifies whether welding is taking place or not by measuring the welding circuit resistance. If the welding circuit resistance is greater than 200 ohms, the welding system assumes that no welding is taking place (open welding circuit) and reduces the open circuit voltage to 12 V for safety reasons. If, however, the welding circuit resistance drops below 200 ohms (i.e., closed welding circuit), the welding system assumes that welding is to take place (electrode makes contact with the workpiece, and the welding circuit resistance of course drops). Detection takes the welding system just 0.3 seconds.W

WeldConnect

WeldConnect is a platform for smartphones with integrated applications (apps) for the exchange of data. This is realized with the TPS/i series and to find parameters for MIG/MAG and TIG processes.WeldCube

WeldCube is a piece of software used by welding companies to monitor production. This browser-based application allows all relevant data to be evaluated and analyzed on all digital terminals (responsive design).

WeldCube Premium

WeldCube Premium is the intelligent, centralized welding data management tool from Fronius. The browser-based software collects all welding data generated during the joining process and provides a wide range of functions to subsequently analyze the welding data. This enables companies to optimize their production processes.Welding equipment

Welding equipment consists of different tools, such as a face guard, welding gloves, wire brushes, chipping hammers, electrodes, and grounding cables.

Welding filler metals

The welding filler metals melt during the welding process and form the weld seam. The selection of welding filler metals is primarily dependent on the parent material and use of the component. The corresponding characteristic must be selected in a material-specific and diameter-dependent way in MIG/MAG welding.

Welding fumes

When processing metals during welding, cutting, and related processes, fumes and gases are produced that are classified as hazardous substances according to current regulations. Welding fumes are therefore hazardous to health and can even be carcinogenic in some cases.

Welding of similar materials

When welding similar materials, the parent material and the filler metal have the same composition. Consequently, welding behaves similarly to the process of welding the parent material.

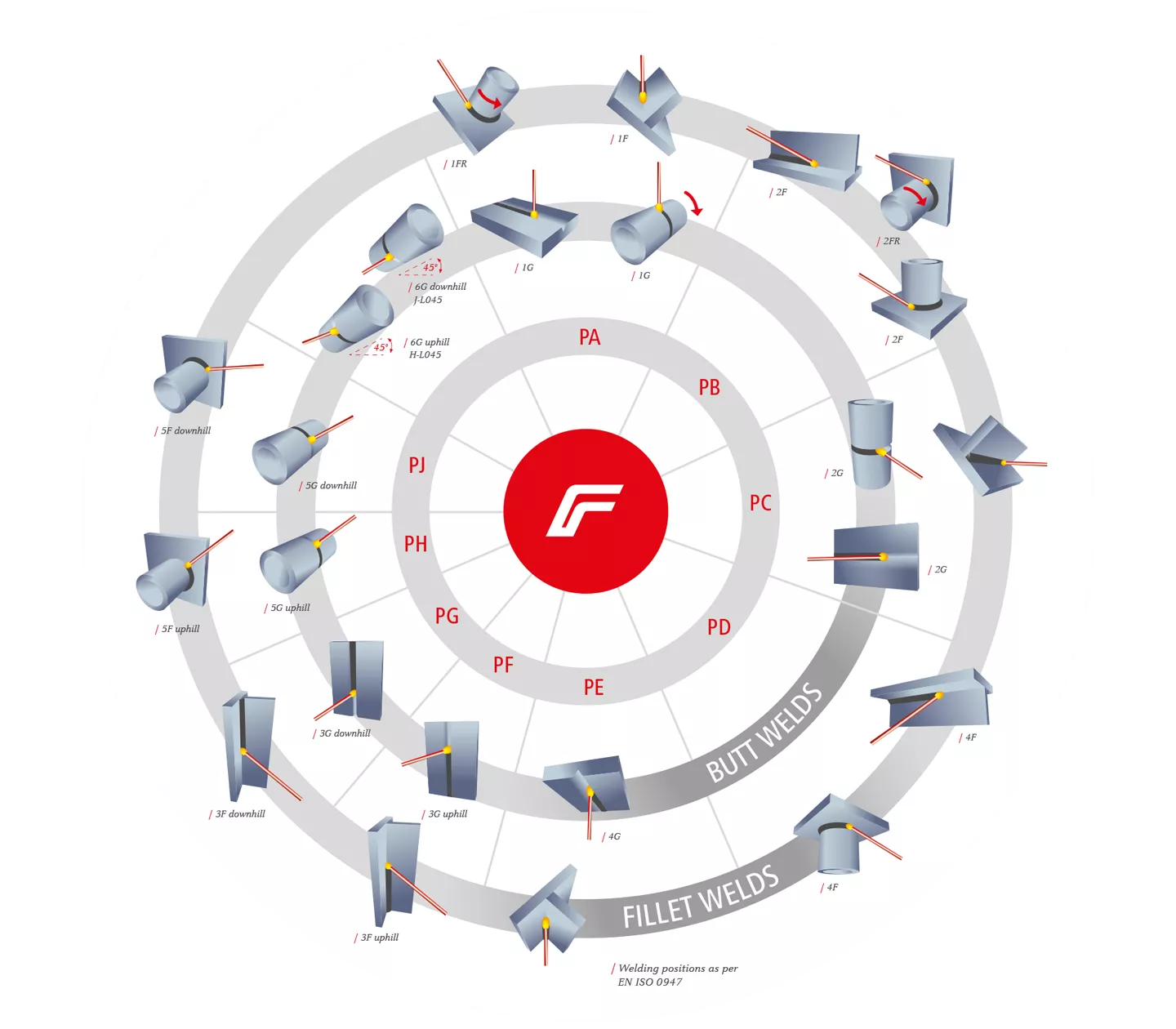

Welding positions

In the discipline of welding there are different welding positions (PA – PJ) that indicate the position of the weld seam.

Welding Procedure Specification (WPS)

For certification purposes, welding procedure specifications (WPS) for sample applications are a key prerequisite.

Welding rectifier

A welding rectifier converts alternating current (three-phase current) into direct current for welding. In general, older welding power sources with no power electronics are called welding rectifiers. (see figure)

Welding sequence

The welding sequence refers to the sequence in which the weld seams of a structure are created.Welding torch

The welding torch consists of a handle with connections, controls, valves, and replaceable gas nozzles. It is connected to the power source by a hose. The welding torch is used to transfer the welding current, and to transport the gas and the filler metal to the workpiece.

Weld pool backing

This is an aid made of suitable material that prevents the weld pool from dropping through during welding. It can also be used to form the root pass. The weld pool backing may consist of a ceramic material for manual welding, and stainless steel or copper for mechanized processes, depending on the application.Welducation Basic

The Welducation Basic app includes a quiz and a game that conveys theoretical principles. It provides virtual training in practical skills at the same time.

Wirefeeder

The wirefeeder is an automatic unreeling device for the welding wire. It feeds the wire through the welding torch into the arc range, where it melts.