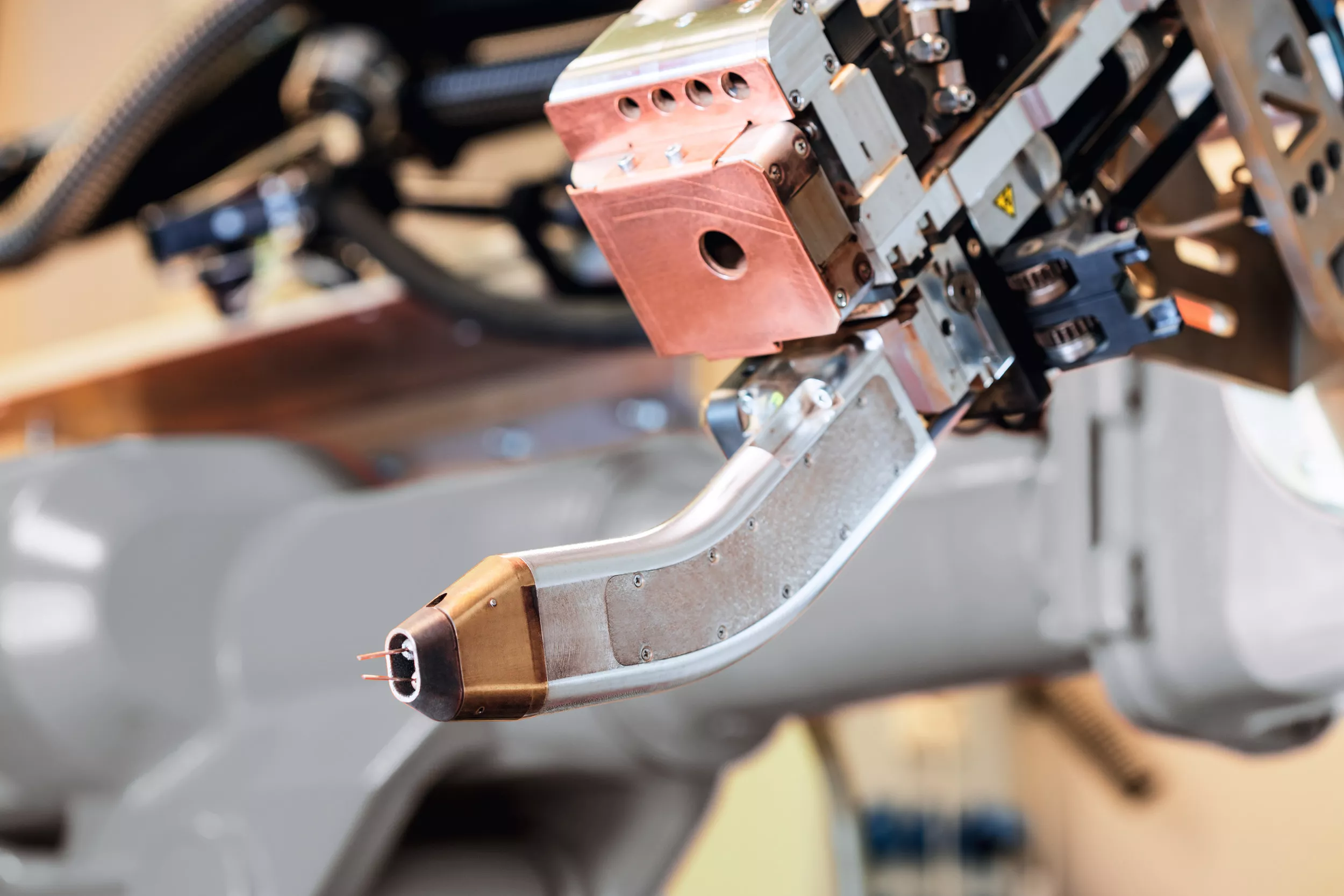

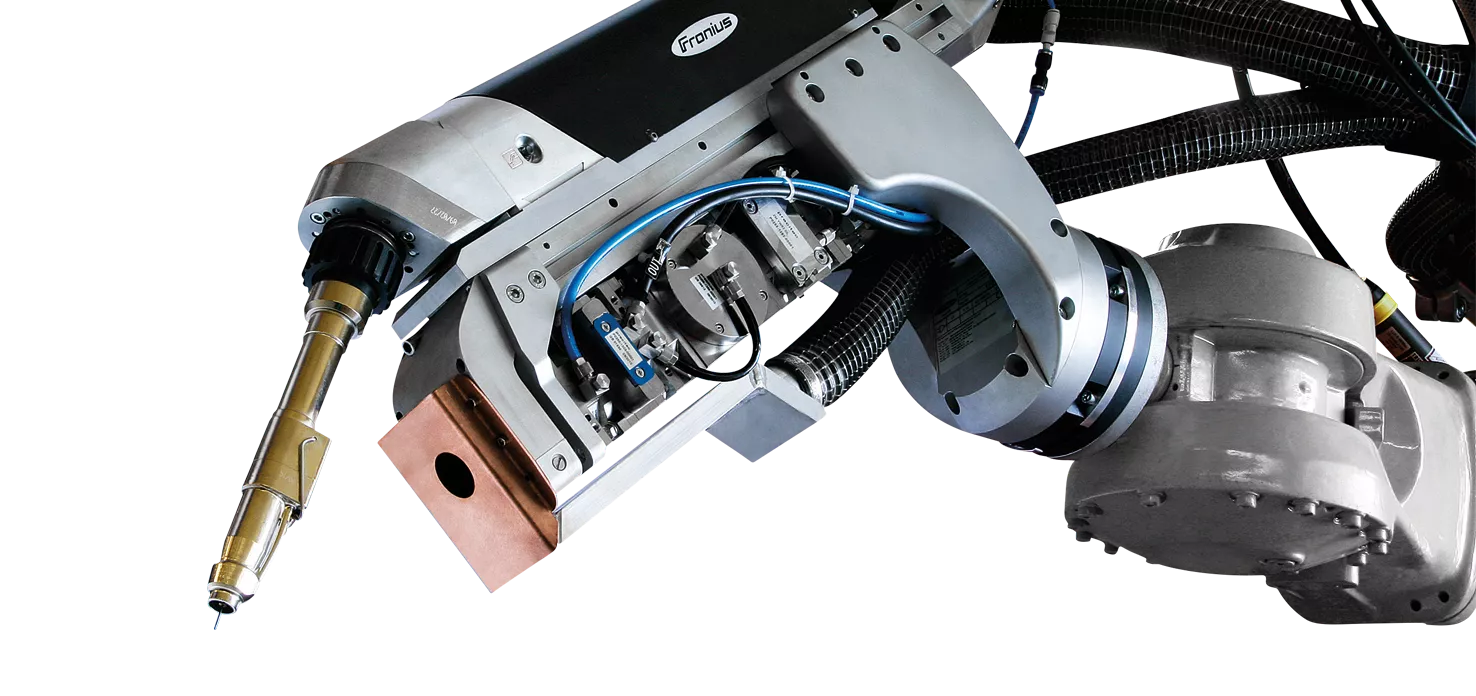

LASERHYBRID TWIN: MAXIMUM WELDING SPEED & MAXIMUM GAP-BRIDGING ABILITY

LaserHybrid Twin welding combines the conventional laser-beam process with the GMA Twin welding process. In joining technology, two factors play a key role: high welding speeds and good gap-bridging ability. However, conventional welding processes do not allow both of these at once. Although classic laser welding achieves extremely high welding speeds, the gap-bridging ability is very low due to the small focus diameter. The established MIG welding process, on the other hand, is characterised by good gap-bridging ability, but does not generate the required speed. Laser Hybrid Twin exploits the advantages of both technologies to achieve top-quality results. Maximum welding speeds prevail with sheet thicknesses of up to 4 mm, which is of particular interest to customers in the automotive and component supply industries.

CUSTOMER BENEFITS

- Maximum speeds on sheets up to 4 mm thick

- Better gap-bridging ability

- A smaller weld pool means lower heat input and thus a smaller heat-affected zone. This results in less distortion and rework on the component

- Shorter production times