Does bigger always mean better and cheaper when it comes to inverters?

If you are looking for a high return on investment (ROI) from your project in the long term, it‘s not enough only to look at the purchase costs of the inverter. The initial costs of the whole system and the operating costs over its entire service life are what really make the difference. The comparative study about a PV-system in northern Italy revealed what will be surprising results for many.

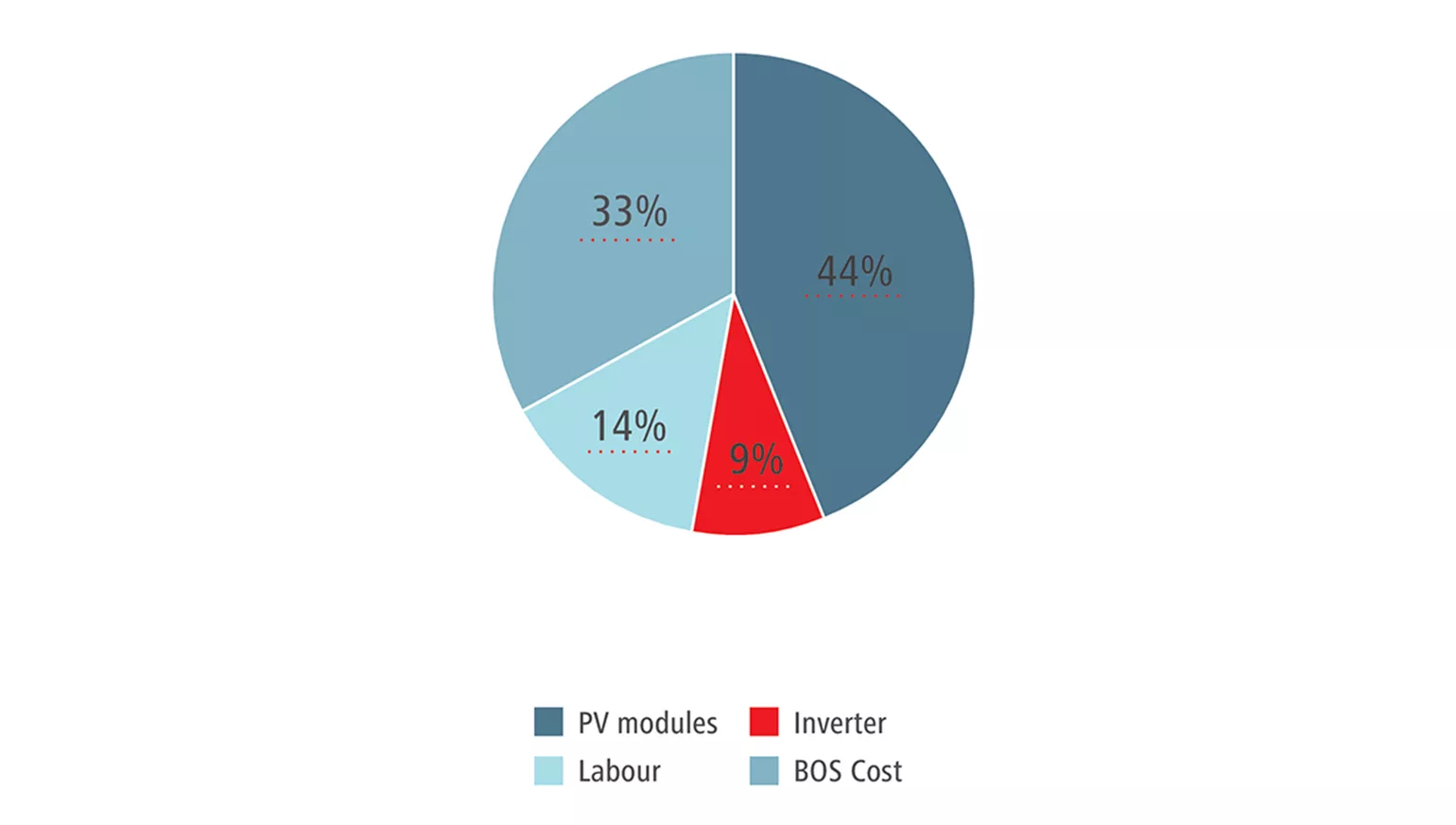

A PV project always begins with system design. During this process, the planner takes a series of technical decisions, both general and relating specifically to the system components. CAPEX (capital expenditure) plays a key role here. CAPEX for a PV system includes the costs for inverters, PV modules, labour and BOS (Balance of System) costs etc. Here, the inverter usually makes up less than 10% of the CAPEX, but, nonetheless, does have a significant influence on the operating costs and the ROI of the PV system.

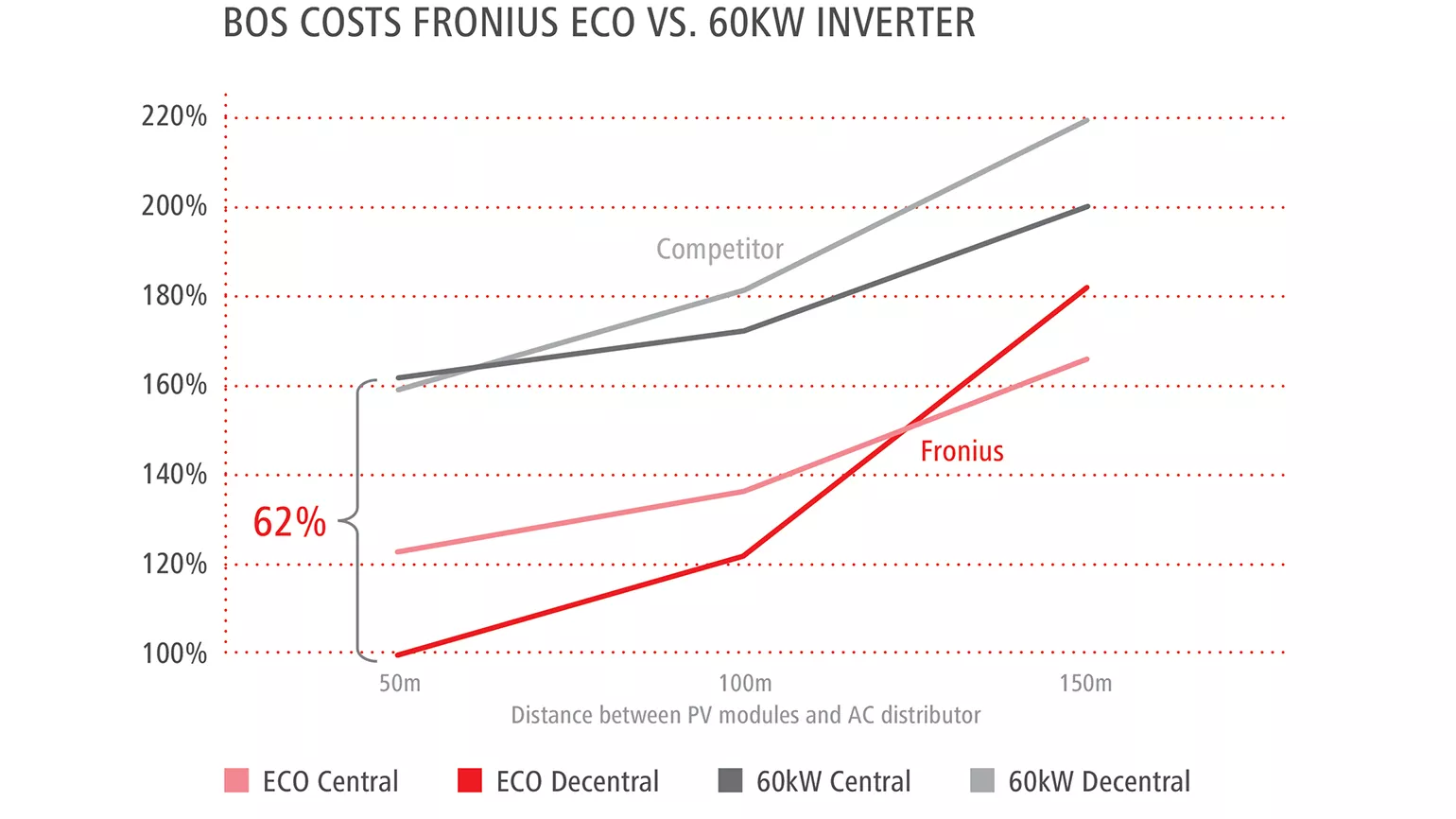

BOS cost advantages of up to 62%

This is also evident in the present case, where it shows that the Fronius Eco 27.0 (27 kW), compared with a competitor’s 60kW device, can achieve a cost advantage of up to 62% in some aspects of BOS costs. The saving is the result of differences in cabling design and the components required for the AC and DC distribution. The Fronius Eco does exceed the 60 kW unit in a cent-per-watt comparison, however, the saving in the overall system costs that can be realized through reducing BOS costs make the Eco the more cost effective choice.

On top in terms of OPEX

The Eco also comes out on top in terms of the OPEX costs (operational expenditure). Among other things, this is attributed to its active cooling technology. Compare the Eco to passively cooled devices that need to have the cooling element cleaned at least twice a year (if this is not done, owners risk invalidating their warranty). For the Fronius Eco, just one maintenance is recommended once a year. This is an important factor given the costs of servicing. This can also be seen in the event of technical problems, where the Eco is again a significantly better value. While faults with the Fronius device can be rectified immediately and on-site by a Fronius Service Partner replacing the PC board, the heavy 60 kW device needs to be replaced in its entirety. A full replacement is already expensive, but the weight of the device also means that at least two service technicians and, depending on the installation location, tools such as lifting platforms are required. This can lead to considerable cost increases.

Fronius Eco impresses with a higher yield

Ultimately, the expected energy yield is an important factor and the Eco doesn’t fail to impress here either! Accordingto the yield forecast, over the course of 15 years in a 400 kW system, the Eco generates up to EUR 41,000 more yield than a competitor’s passively cooled 33 kW device subject to the same monitoring. In this case, the additional yield is attributed to the Fronius Eco’s considerably superior power derating behaviour in summer temperatures.

Bigger is not always better

This clearly shows that bigger is not automatically better, and is often more expensive. System planners that - instead of focusing on the inverter price only - take into account CAPEX, OPEX and energy yield can significantly increase the system’s ROI.