ArcTig

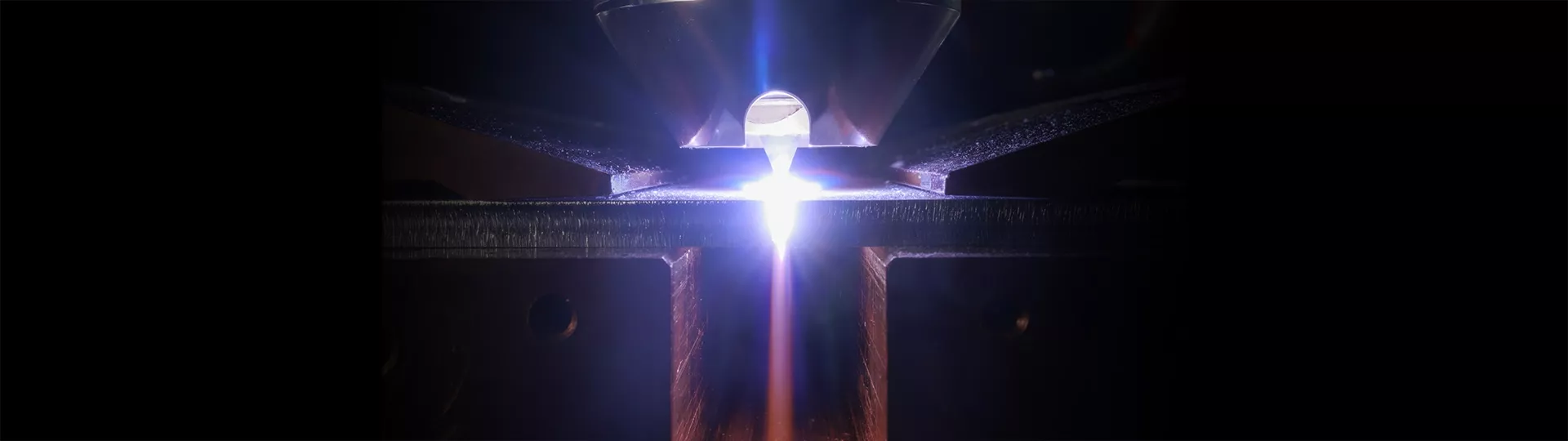

The revolution in TIG keyhole welding

ArcTig: maximum weld seam quality and high cost efficiency

ArcTig is a TIG keyhole welding process for mechanized welding of longitudinal seams. A special electrode clamping system delivers optimal cooling for the tungsten electrode, creating the conditions for significantly higher welding speeds compared to conventional TIG welding and welding depths similar to plasma welding.

Whether it’s for the construction of pipes or containers, or for use in aerospace technology—ArcTig offers the optimal solution for everyone who is looking for the very highest quality from their welds as well as a simple and, above all, cost-effective solution. If you’re working with mechanized and robot-assisted applications, you can weld materials of up to 10 mm in a single pass without prep work.

Experience the perfect balance between top quality and profitability with ArcTig, our innovative TIG welding process.

The advantages of ArcTig from Fronius for you

Fast. Straightforward. Profitable.

- Increase your welding speed by up to 100% compared to the conventional TIG process and boost efficiency by reducing prep work and rework

- High weld seam quality

- No time-consuming weld preparation for material thicknesses of up to 10 mm

- Single-pass welding up to a material thickness of 10 mm for CrNi and 8 mm for steel thanks to the focused arc

- Minimal dilution due to lower heat input

- Spend less on filler metal thanks to a lower weld volume, including single-pass welding at high speeds

- Simple handling/parameterization

- More flexibility in terms of applications compared to plasma

- Quick changeover between TIG and ArcTig welding torches possible

- Improved access thanks to freely adjustable electrode end

ArcTig – Technical overview & components