Plasma welding

Ultimate quality and efficiency

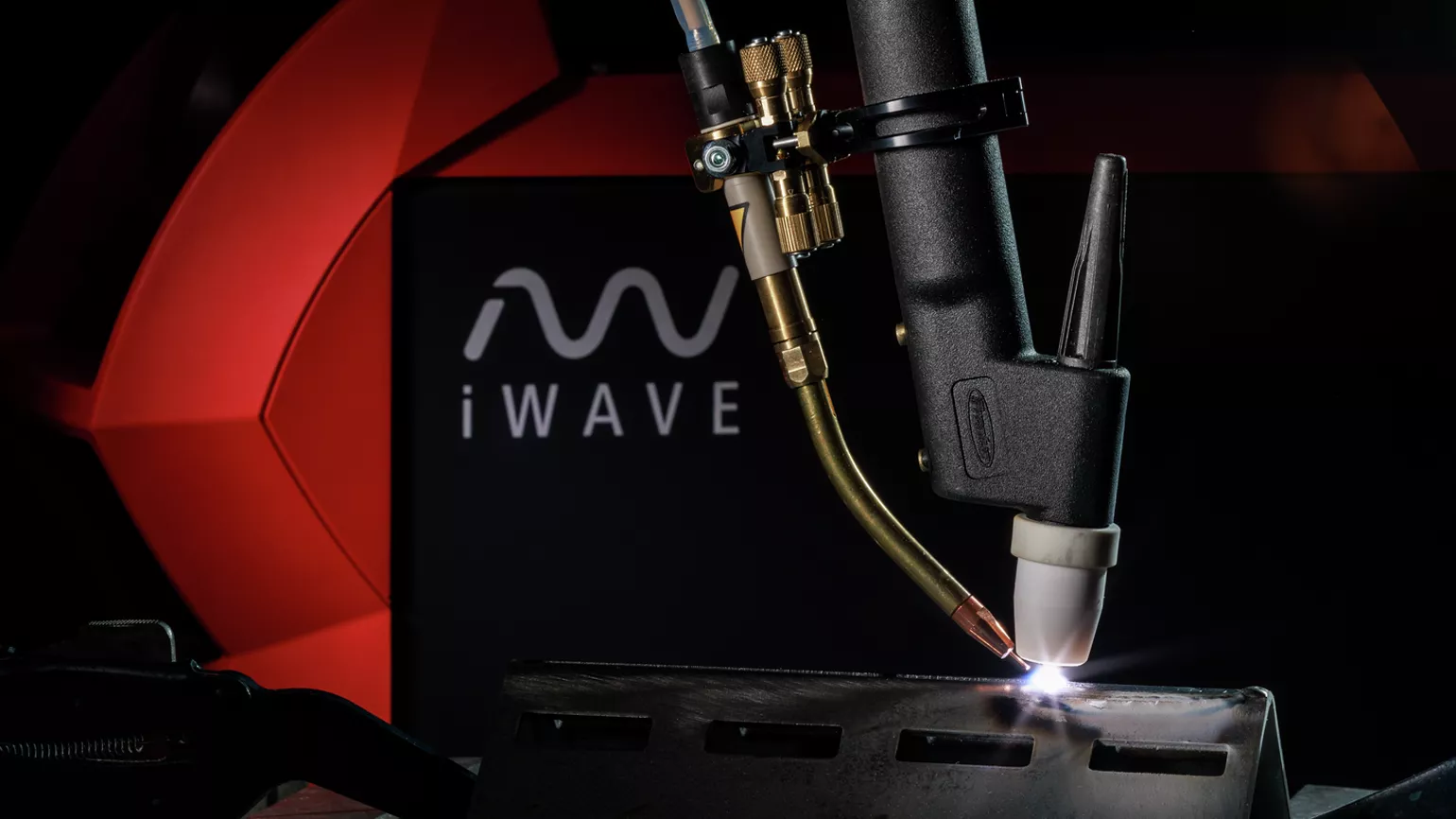

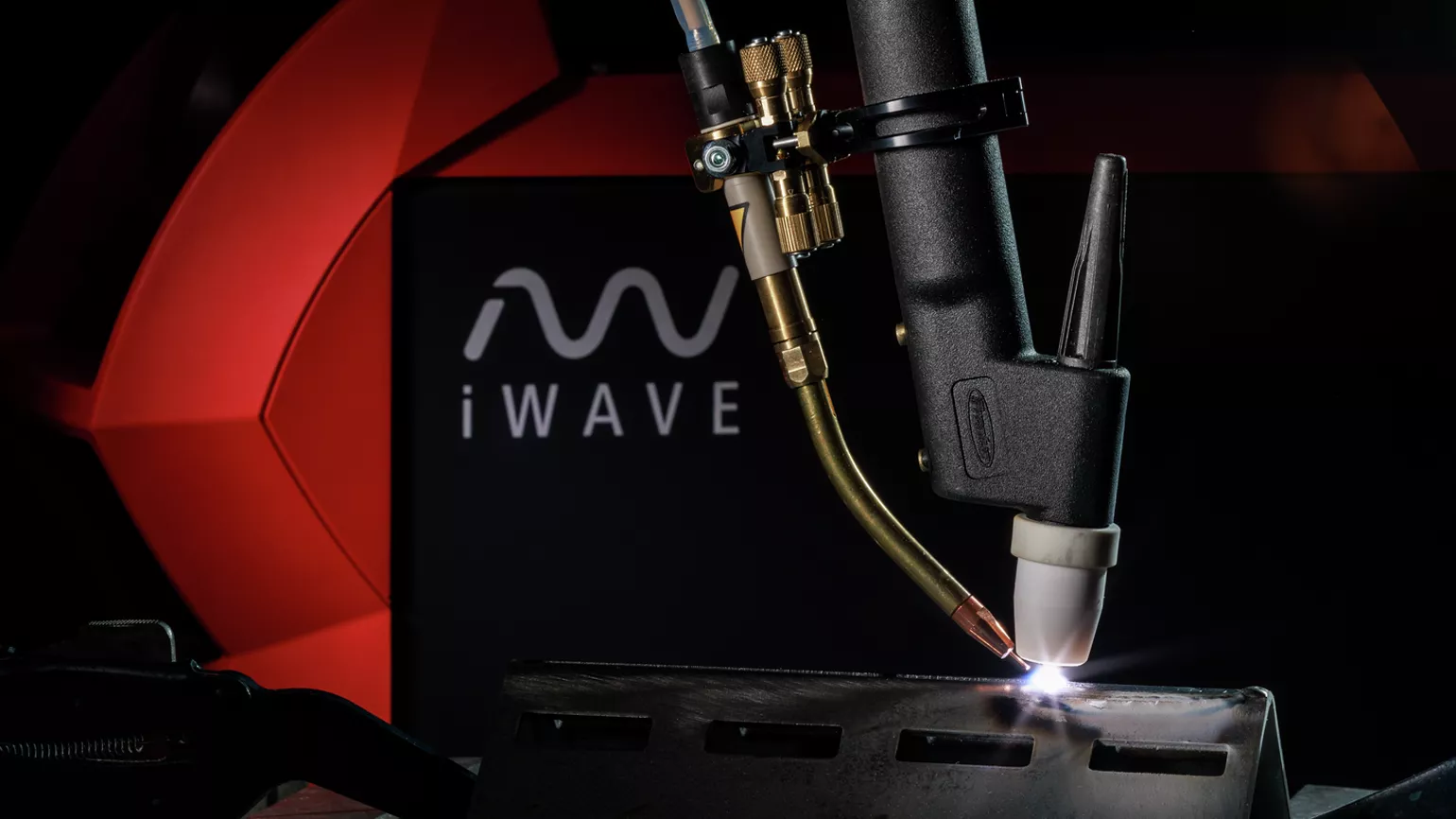

Experience the ultimate in plasma welding with the iWave!

The iWave impresses with a sophisticated device concept that takes the general advantages of plasma welding to the next level by offering significant improvements in parameterization and handling.

Existing TIG systems can be easily upgraded to a plasma system—all you need is the OPT/i Plasma hardware option, a plasma welding torch, and the plasma welding package.

The result is outstanding weld quality and maximum efficiency in every welding process.

What are the advantages of plasma welding?

Higher welding speeds

Soft plasma enables up to 20% higher welding speeds compared to conventional TIG welding—and increases the speed by as much as 100% for the plasma keyhole process.

No weld preparation

Save time and effort by eliminating the time-consuming process of weld preparation.

Less filler metal

Up to 30% less filler metal needed.

Completely spatter and pore free

Achieve maximum quality with spatter-free and pore-free welds.

Higher penetration

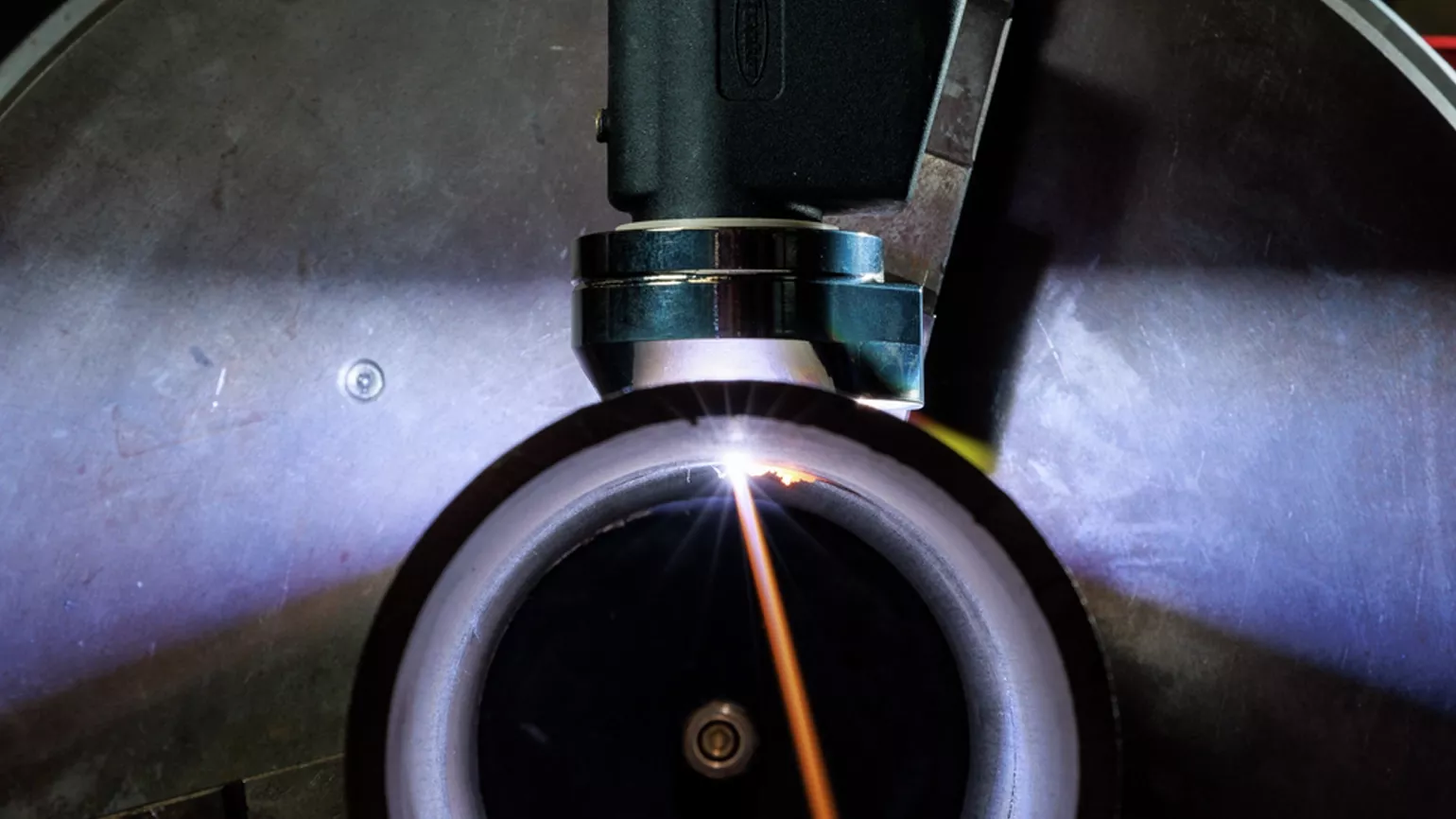

Achieve higher penetration with minimal distortion compared to conventional TIG welding.

Larger tolerance/process window

Plasma allows for tolerance compensation (air gap/offset) of up to 10% of the material thickness.

Longer electrode service life

The electrode is located inside the torch body, where it is less exposed to environmental influences. This also gives the product a significantly longer service life.

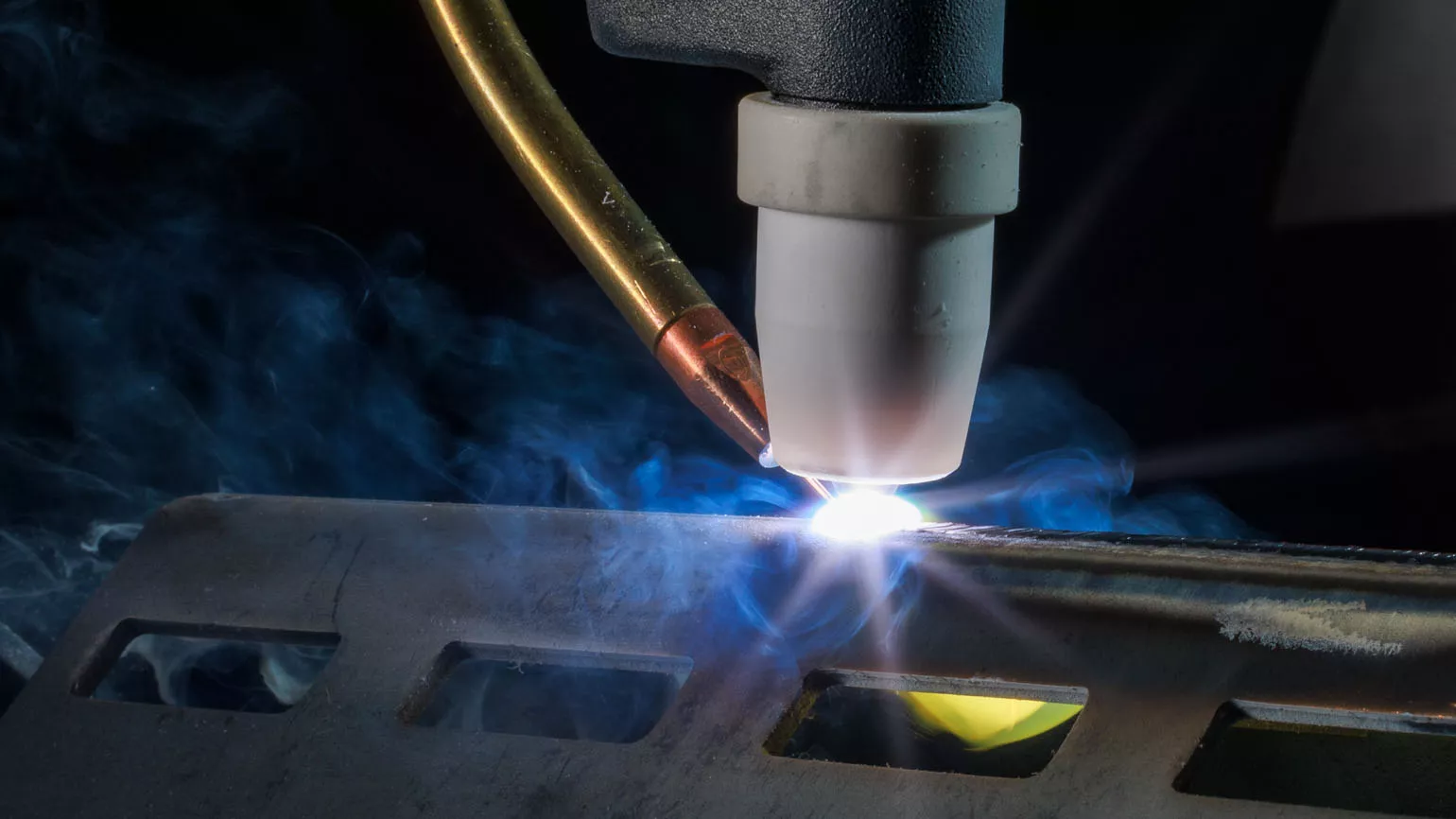

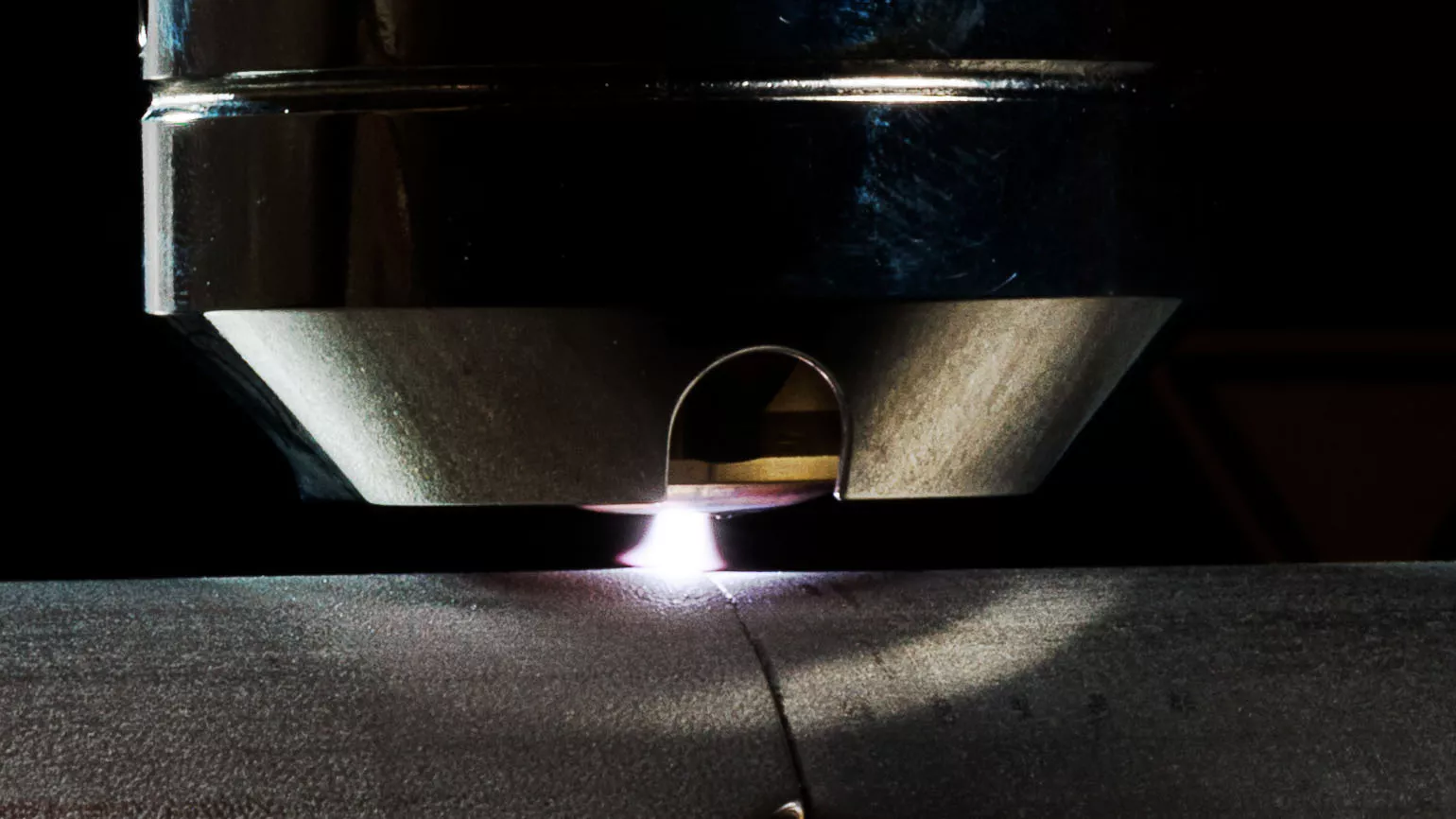

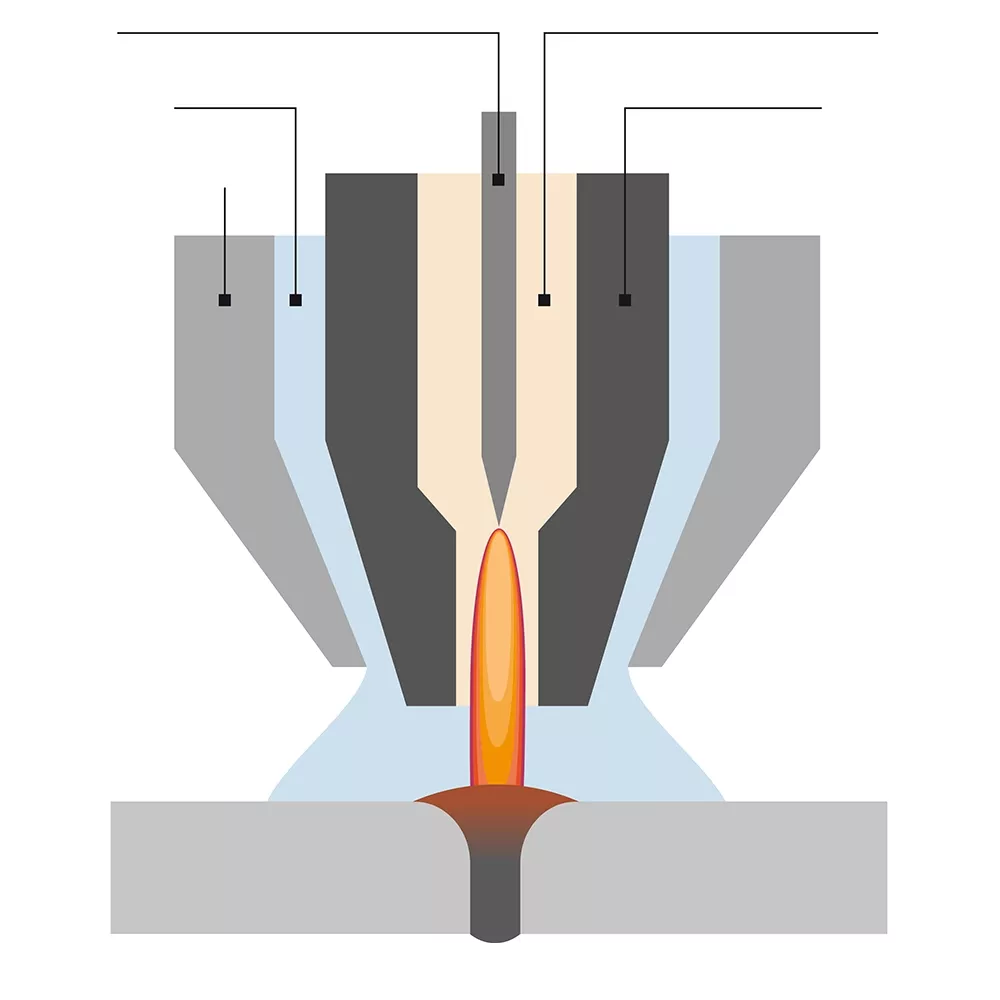

The plasma principle

Plasma welding is similar to TIG welding, with the key difference being that the arc is significantly constricted by a cooled gas nozzle (4) through which the plasma gas (3) flows. The shielding gas (1) passes through the external gas nozzle (5) to create an optimal gas shield for the weld. The result is a concentrated arc with maximum energy density.

Why plasma welding with iWave is the right choice

All-in-one welding machine

We build the hardware components required for plasma welding directly into the welding machine. This means that all parameters can be controlled centrally via a single interface.

Universal hosepack for TIG and plasma welding

This hosepack can be used for both TIG and plasma welding. Switching between processes is particularly easy, as only the torch body needs to be replaced—no need to change the hosepack itself before continuing work.

Easy upgrade

Existing TIG systems can be quickly and easily upgraded to plasma.

Precise plasma gas control

Precise gas control is guaranteed with an accuracy of ± 5%.

Improved gas shield

The newly designed torch components and wear parts increase the gas shield by around 30%.

iWave plasma welding system—technical overview and components

Plasma welding vs. TIG welding—a direct comparison of the welding processes

| TIG | Plasma | |

| Weld quality and appearance | ●●●● | ●●●● |

| Small heat-affected zone | ● | ●●●● |

| Gap-bridging ability | ●●● | ●● |

| Brazing of coated materials | ● | ●●● |

| 3-8 mm material thickness without weld preparation (steel) | ● | ●●●● |

| 3-10 mm material thickness without weld preparation (CrNi) |

● | ●●●● |

| Fillet welding |

●●● | ● |

| Welding speed | ●● | ●●● |

| Service life of wear parts (tungsten electrode) | ●● | ●●● |

Materials

|

|

TIG | Plasma |

| Aluminum and aluminum alloys | ●●●● | ● |

| Unalloyed or low-alloy steels | ●● | ●●● |

| Coated steels | ● | ●●● |

| High-alloy steels | ●●●● | ●●●● |

| Nickel-based materials | ●●● | ●●● |

| Copper materials | ●●● | ●● |

iWave—The all-rounder in automated welding

New technologies and innovations, such as DynamicWire and CycleTIG or the iWave’s unlimited multiprocess capability, bring numerous advantages and open up new possibilities for automated welding applications.