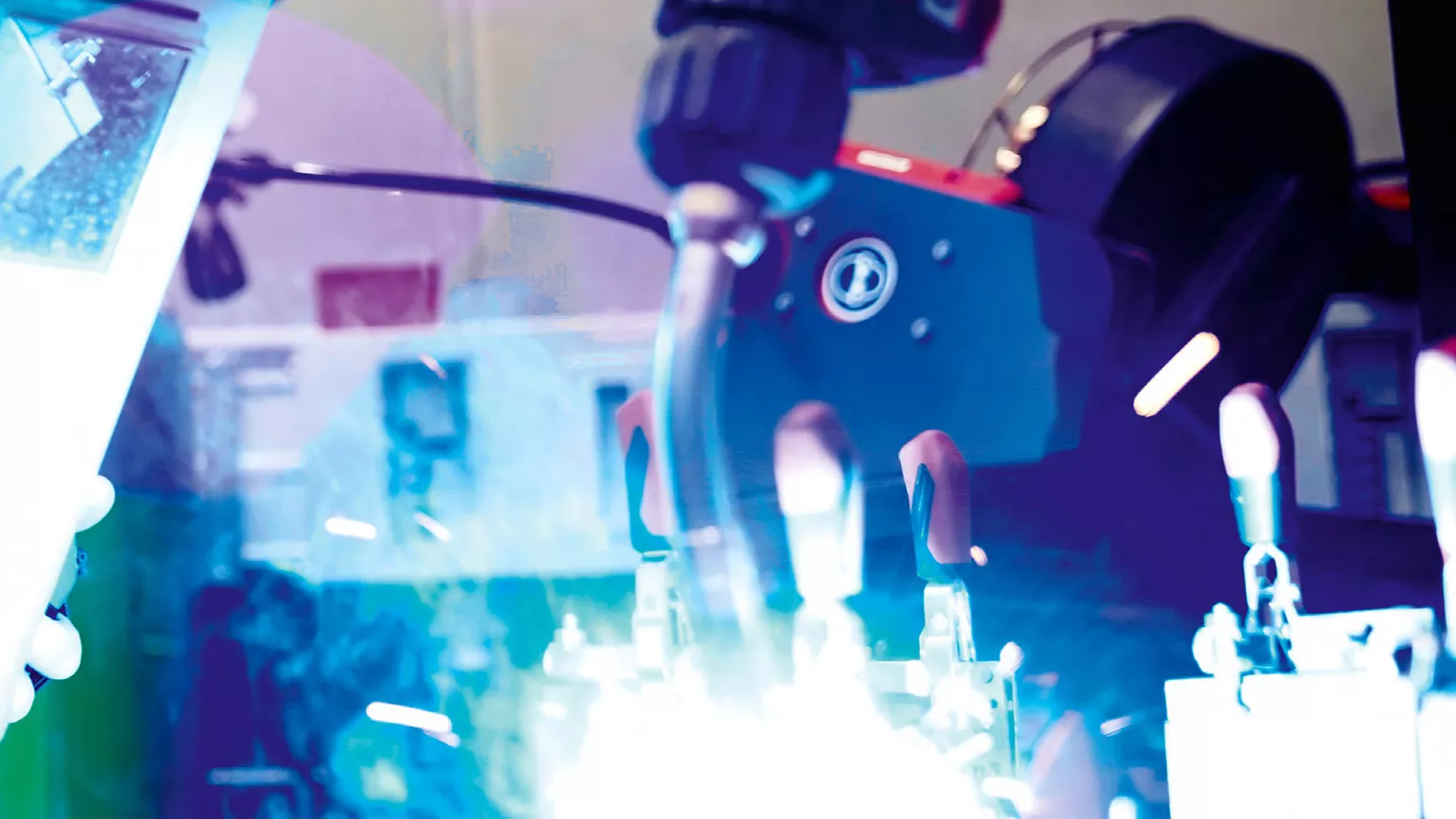

Customer intimacy in actionAn interview with Fronius technician Stefan Höglinger about the WireSense development with Magna Steyr

Stefan, as an application technician for Fronius Technical Support Austria, what exactly does your role involve?

As an application technician, I mainly support key accounts with the commissioning of robotic welding systems, particularly in the automotive sector. My main tasks include creating and optimizing welding parameters.

In regard to WireSense – when and why were you assisting automotive supplier Magna at that time?

As a technician for Fronius Technical Support Austria, the Magna Group is one of my core customers. At the end of 2017, I was tasked with assisting a robot integrator. The production line for a new vehicle range was being installed. As part of this, production tolerances which could lead to a lack of fusion and in turn, greater resource expenses, needed to be addressed. All potential error sources had already been investigated when they asked me to take an outside look at the issue. I soon realized that the limits were really being tested in all areas, even in relation to our extremely tolerant arc – there was nothing more to give.

How did Fronius help solve this?

In such cases, you have to simply accept minimal deviations in the component position. These tolerances are also allowed for in the design. Nonetheless, the Magna Group is always striving to improve its production systems in all areas. So now it’s about ensuring that the robot reliably finds the edge of the upper sheet of the lap joint – despite the deviation. As I used to work in R&D at Fronius, I knew that we had carried out successful trials in the past, which used the touch signal of the intelligent TPS/i power source to search for the edge. At the time, we wondered whether the whole thing could be positioned somehow as a product for the welding market – but it wasn’t pursued. I then talked to my R&D colleagues and quickly installed a prototype at Magna.

The WireSense product is not very tangible – how can we best picture this prototype?

Magna put me in touch with the technician of the robot integrator, to whose system our wire sensor was to be connected. We then met in Magna’s production facility near Graz where we were able to complete the project work together in just one day. Basically, we integrated a specific repertoire of TPS/i signals into the robot controller. In doing so, I told the technician the time points at which the robot should activate teach mode and when the touch signal is expected. Everything else is a fairly simple, technical process.

From then on it was possible: if we stared a search operation towards the upper sheet and the touch signal was then output from the TPS/i, the edge had been detected.

And so WireSense was born?

Well, at that point, we had only called it an edge search function. But the resulting, absolute position precision – which should reduce rework at Magna to zero – revealed the need for such a product. Since it had all gone so well at Magna, my colleagues in R&D were very keen to extend the functional scope. For example, the height signal output by the TPS/i was also evaluated, which ultimately made it possible to determine the gap.

It’s hard to comprehend the brilliance of this discovery upfront or understand who played the greater role – the robot manufacturer or Fronius. How do you see the relationship and what ultimately led to the product being developed?

I think the deciding factor, the inventive spirit, clearly lies with Fronius due to the high-precision signaling through CMT Ready. And how did this all become a product?

All the functions possible today were already known to the developers, way before my prototype was installed at Magna. The desire to make WireSense into a salable product that has a manual and is user-friendly has been there for a while. The developer’s task was also to make this clear and understandable to the decision-makers at Fronius and Product Management. To pitch it internally so to speak, indicating what is promising and that is it worth bringing it to market. Of course, when there is such a successful field trial, with an important major customer such as Magna to boot, then this can grease the wheels internally and pave the way.

The WireSense technology seems to be amazingly simple. So maybe you might wonder if the discovery is worth the money. Are you ever put on the spot and have to justify it?

If you want to sell WireSense, it has to be a coherent package. Of course we can’t simply give the idea away and leave others to potentially pick up the business.

First, you have to consider what other options – aside from WireSense – our customers have for solving such robot welding challenges. Normally these take the form of optical measuring devices, which can cost ten or twelve thousand euros. Also, have a look at how quick, robust and maintenance-intensive such competitor systems are. So our comparatively cheap yet high-precision Fronius solution is suddenly justified in all regards – and the product is on its way.

Fronius services

The journey you took is almost more exciting than the product itself. You really helped Magna Steyr and Fronius WireSense – a pioneering development in the field of robot assistance systems – to get going. Is this a remarkable achievement in comparison to competitors?

As far as Fronius is concerned it is not unusual. This process is exactly what Fronius know-how transfer is all about and therefore it is a prime example of our principle of customer intimacy, which is a firm part of the Fronius strategy. When you buy a Fronius product, you are not just buying exceptional device performance. We believe in looking after customers after the sale by providing an extensive range of services to choose from. If a customer decides to make use of these and grant us a deeper look into their work, we can then become a problem solver. In particular, we can also develop customized solutions – which is exactly what led to the creation of WireSense. I really enjoy this kind of work!

In the case of WireSense, Fronius was really able to benefit from the collaboration with Magna Steyr. Thinking about Fronius Technical Support in general, how can our welding expert be at an advantage over the customer’s employees?

Well, welding is not witchcraft. Out there – and of course at Magna too, there are well-trained and extremely capable welders. However, Fronius welding technicians are particularly knowledgeable about our products. Our devices have an immense amount to offer and we are trained on every last detail. Internally, we are also divided into various business units, so that we can truly commit to finding solutions. Whether it is application technology, system technology or welding data documentation – Fronius technicians are complete specialists in their fields and can therefore focus 100% on their tasks.

If a customer opts for a Fronius product, are they also purchasing such support with it?

Experience shows that at the start, customers mainly want to try things out themselves and get relatively far – however they can also do that with competitor devices too. If you look at the overall performance of our devices, welders reach about 60% of what is possible, due to the extremely wide range of functions. That final bit is achieved with expert support. The Fronius technician is usually called upon at a later point to get 100% out of the device. One thing is clear, if you invest in a Fronius system, we will guarantee this offer – this is something which we are very proud of!

Let’s talk about welding performance – what exactly is this?

It can be the optimization of welding parameters, various characteristics or the installation of some kind of equipment which makes welding faster, better, and more reliable. The WireSense is one example. We are often asked about this in regard to light gage sheets, where welding can become a bit of a balancing act.

So, this brings us back to the question: Do you as a Fronius technician bring better knowledge to the table than the customer’s welding experts?

When working with the customer, we have the opportunity to understand or track their production line from the ground up. This often enables us to act as a problem solver. By this, I do not mean that I know more than the customer. However, as well as having an insight into the customer’s know-how, I also understand how to handle our power source very well. Then there’s the fact that I have built up a wealth of experience working with a diverse range of customers and I bring this to the table for the benefit of each individual customer. The problems are often very similar. So if I have already been able to find a solution for a specific challenge somewhere else, I can make best use of this experience for the next customer.

The work of Fronius Technical Support is a fee-based Fronius service, which comes at a price. Can this always be justified for the customer?

There are customers who admit to me that sometimes they have difficulty requesting my services internally – as the resulting costs are not exactly low. The workshop or line manager’s argument however is almost always the same: “You don’t realize how much Höglinger could save us!” If there is a failure or shutdown, it can quickly result in a mid five-figure sum. When I am visiting customers, I also always let them know about any upcoming technology which could make life easier for them.

So are Fronius technicians also ambassadors to customers?

No, not directly. But in addition to our day-to-day technical problem solving tasks, we are a mouthpiece – on the one hand from R&D to the customer and on the other we try our best to feed the requirements and conditions of the market back to our development team. If better, and above all, more efficient solutions pop up for the customer and Fronius can expand its technology leadership at the same time, then that’s perfect. A complete win-win situation!