CONTEC MD FROM FRONIUS: A LONGER SERVICE LIFE FOR WELDING TORCHES USED IN AUTOMATED WELDING

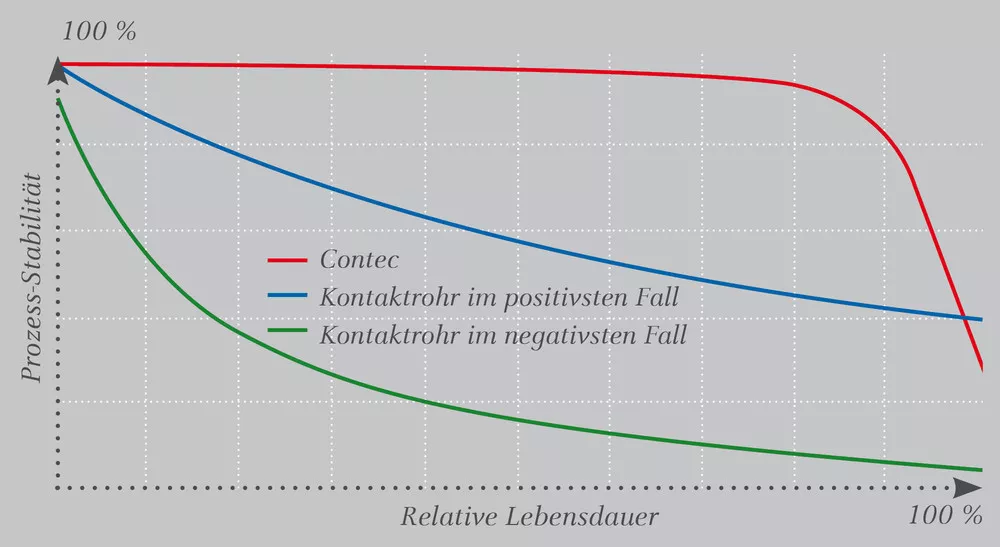

The Contec MD contacting system allows the user to prolong the service life of their welding torch several times over during automated welding compared to conventional nozzles. This applies to the joining of both aluminium and steel. With conventional welding systems, disturbance variables such as abrasion, and the tendency for abraded particles to burn onto the tip, are caused by the straightening of the wire in the contact tip. This causes the contacting points to change, resulting in faulty weld seams and higher outage costs. With Contec MD, two moveable split tips keep the contacting surfaces and contact forces between the contacting system and the welding wire exactly in the defined target range – even in the face of increasing wear. This results in even wear of the contact tip, minimising incalculable adverse effects on the process. The user enjoys steady and even contact, high process stability and a lower probability of failure due to contacting faults. Contec MD is suitable for all materials and wire diameters from 0.8 to 1.6 mm.

Downloads

EFFICIENCY & PRECISION

THE BENEFITS OF USING CONTEC

- 100% consistent contacting

- Much longer service life

- Enhanced process stability