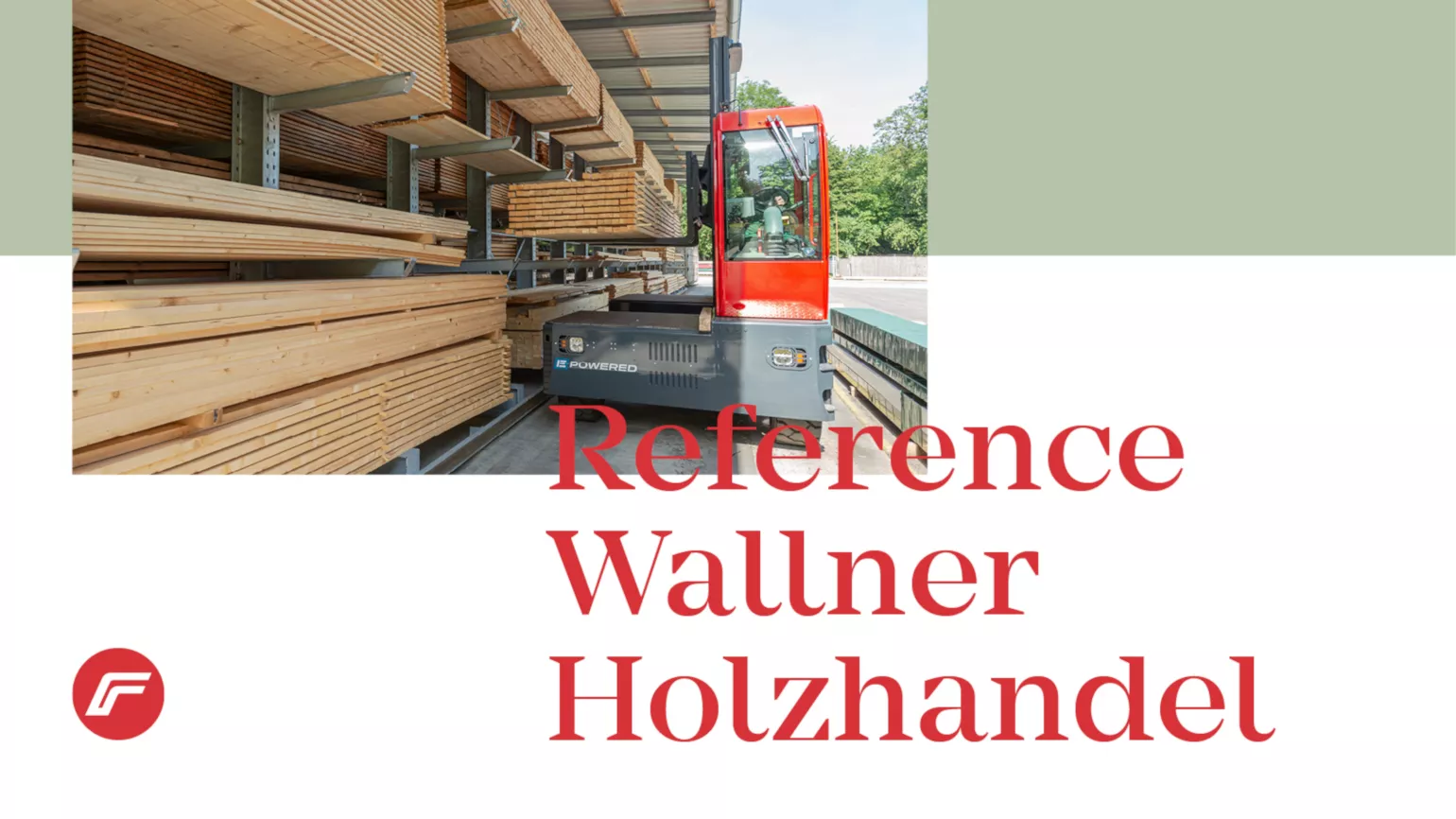

Wallner Holzhandel

The 60,000m2 premises of Wallner Holzhandel GmbH in St. Pölten are located next to a forest with an impressive tree population. For more than 80 years, the family business founded by Mr. Wallner has been dealing with the versatile and natural material of wood. In addition to the wholesale of timber, Wallner also operates a modern cutting and edging centre for individual customer requirements.

More than 80 employees ensure that the timber products reach the customer in the desired form on time. In order to load and unload the heavy and bulky panels of wood onto the company’s own fleet of trucks, a large number of electronically operated heavy-duty forklifts are used. The intralogistics are coordinated by the warehouse manager at the location, Herbert Baumgartner. „We are currently operating 11 sideloader trucks, which were specially manufactured according to our requirements. Many years ago the fleet was changed to electric drive and is now powered by large lead-acid batteries.“

For charging these traction batteries, the company relied on a 50 Hz technology in the past. The chargers regularly caused high power peaks and an overload of the company network. A disruption of the charging process often led to downtimes of the forklift trucks as no exchangeable batteries are used due to the single-shift operation. A problem that presented a major challenge for the timber trading company, where smooth operations are essential.

With the expansion of the site and the planning of a new warehouse, also the charging infrastructure was completely renewed. Baumgartner had no doubt that Fronius was the right partner for the job: in close collaboration with the customer the Fronius Perfect Charging team developed the ideal charging concept. Individually designed charging stations were planned, to suit the special requirements and dimensions of the heavy-duty forklifts. High reliability and particularly efficient and gentle charging of the powerful traction batteries were also a priority. The charging concept sustainably reduces peak loads, which previously led to high costs. Thanks to the unique Ri charging process and the possibility to delay the start of charging by half an hour, no more power peaks occur at Wallner. Failures in the company network are also a thing of the past.

The smart possibilities for optimisation, the local contact person and the peace-of-mind Fronius quality have convinced the customer all along the line: „Since we started using the Selectiva chargers, our batteries are always fully charged at the beginning of the shift. We have been able to reduce energy consumption by about 30%.“

Mr Baumgartner is also impressed by the integrated deep discharge characteristic. Thanks to this, even a set of older lead-acid batteries could be regenerated and returned to its original use. „We had already depreciated the batteries in our minds, as charging with the old chargers was no longer possible. With the Selectiva deep discharge characteristic we were able to use the batteries for several more months - a sustainable and cost-efficient solution that helps us enormously as a family business“.

Download the reference sheet now

Since we started using the Selectiva chargers, our batteries are always fully charged at the beginning of the shift. We have been able to reduce energy consumption by about 30%.