Simplifying battery handling

Even utilisation of the battery pool extends the useful life of each individual battery. Yet in many cases the reality is often somewhat different: employees frequently select the wrong battery, which in the long term can lead to damaged batteries and expensive new purchases. To counteract this, Fronius offers solutions for optimising battery handling.

Fronius battery charging systems provide maintenance instructions on the display, one of which reminds the user to top up the water in good time. The content of the messages and their time intervals can be configured as required. All this helps the forklift truck operator to keep the batteries in the best condition possible, thereby ensuring an extended service life and increased capacity.

Fronius can equip its Selectiva battery charging systems with the Aquamatic control option as required, which allows the user to control automatic water filling systems. These systems automatically fill the individual battery cells with distilled water after every charging process. By preventing damage and a loss of capacity, this allows the user to benefit from an extended battery life and increased availability.

Even utilisation of the battery pool extends the useful life of each individual battery. Yet in many cases the reality is often somewhat different: employees frequently select the wrong battery, either for convenience or because the state of charge is not visible or is difficult find out. This means that some batteries are almost always in use, leading to an increase in battery temperature and a reduction in the service life of the battery. In contrast, other batteries remain unused for days or weeks, which can lead to acid stratification - and subsequent plate damage. The consequences are a reduced service life and considerable costs for purchasing new batteries.

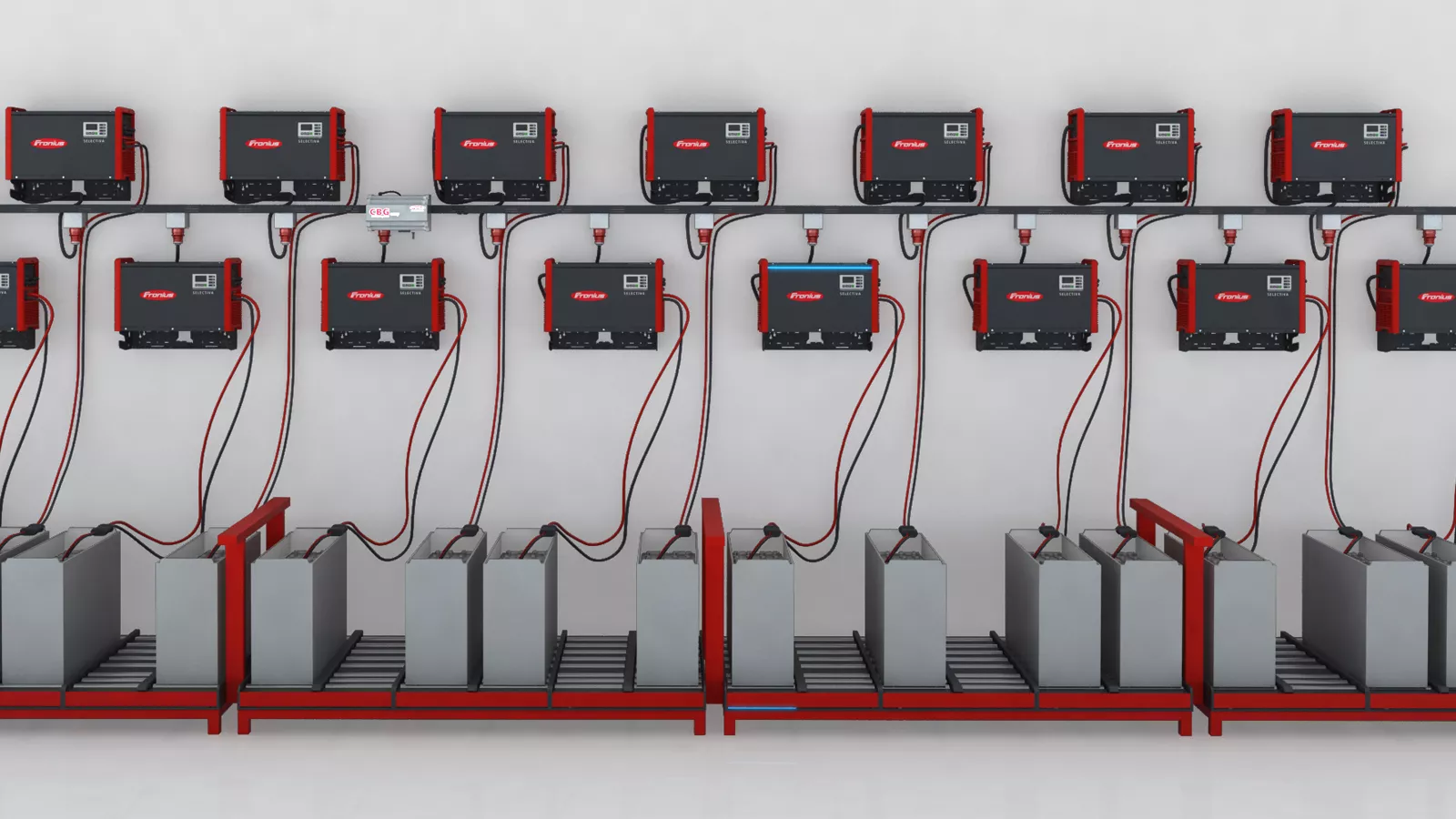

Fronius Selectiva battery charging systems have different coloured LEDs that show the status of the charging process at a glance. A minutes counter on the display indicates how long the battery has been fully charged for.

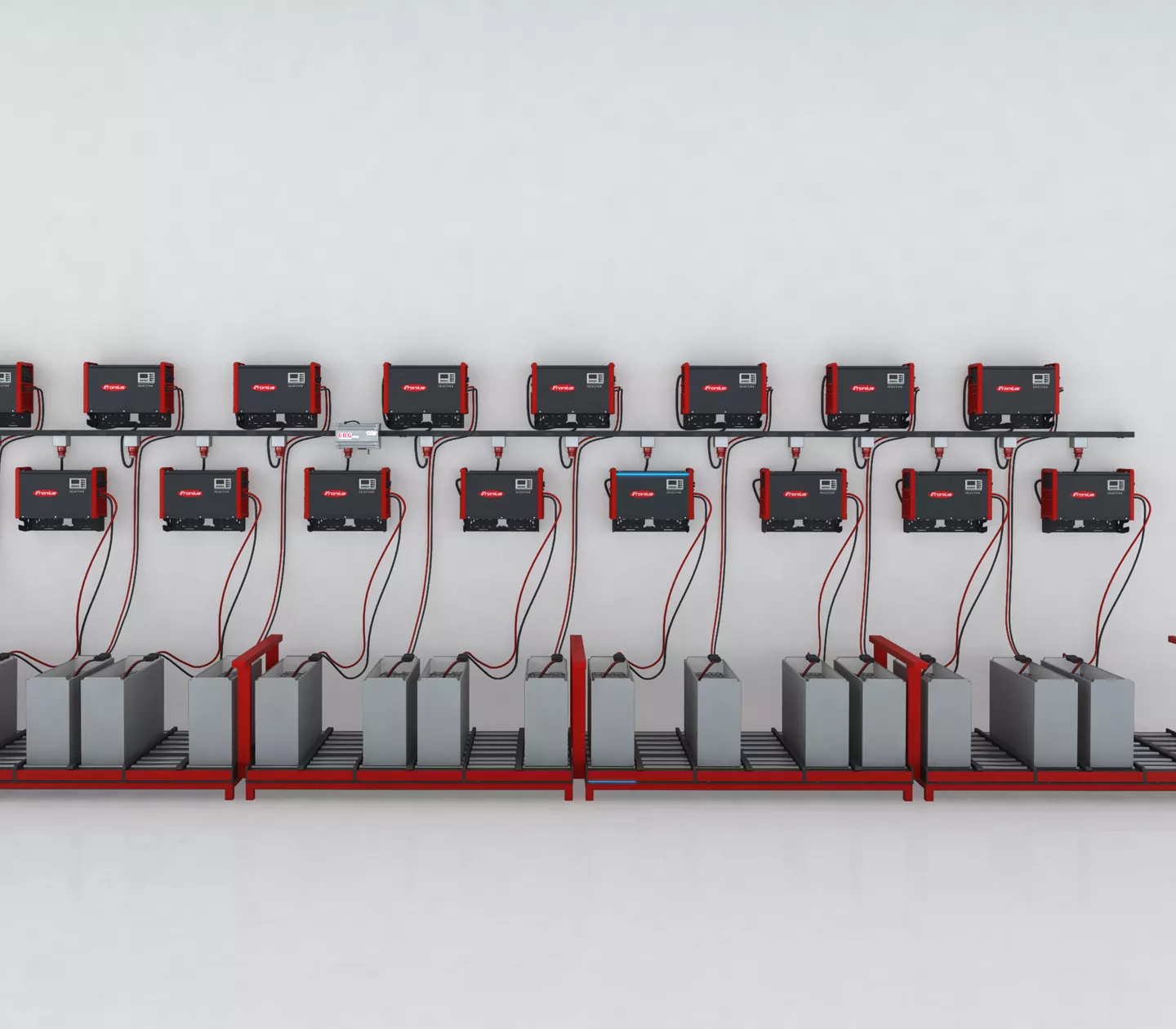

The “Cool Battery Guide Easy” and “Cool Battery Guide Premium” information and management systems further improve the utilisation of the battery pool: a control unit shows the user which battery has been fully charged for the longest and is therefore the coolest, intuitively guiding the user to the correct battery. Incorrect decisions made by employees become a thing of the past. The service life of the batteries is thereby increased and operating costs are reduced.

Manufacturers and distribution centres often employ a multi-shift working environment. Forklift truck batteries are therefore in constant use and rarely have the chance to cool down before and after charging. Every day the internal temperature of the battery continues to increase, and battery temperatures well above 50 degrees Celsius are not uncommon. This effect is intensified when the forklift trucks have to move heavy weights, for example in the beverage or paper industry. Over time this causes damage to the batteries and reduces their service life considerably.

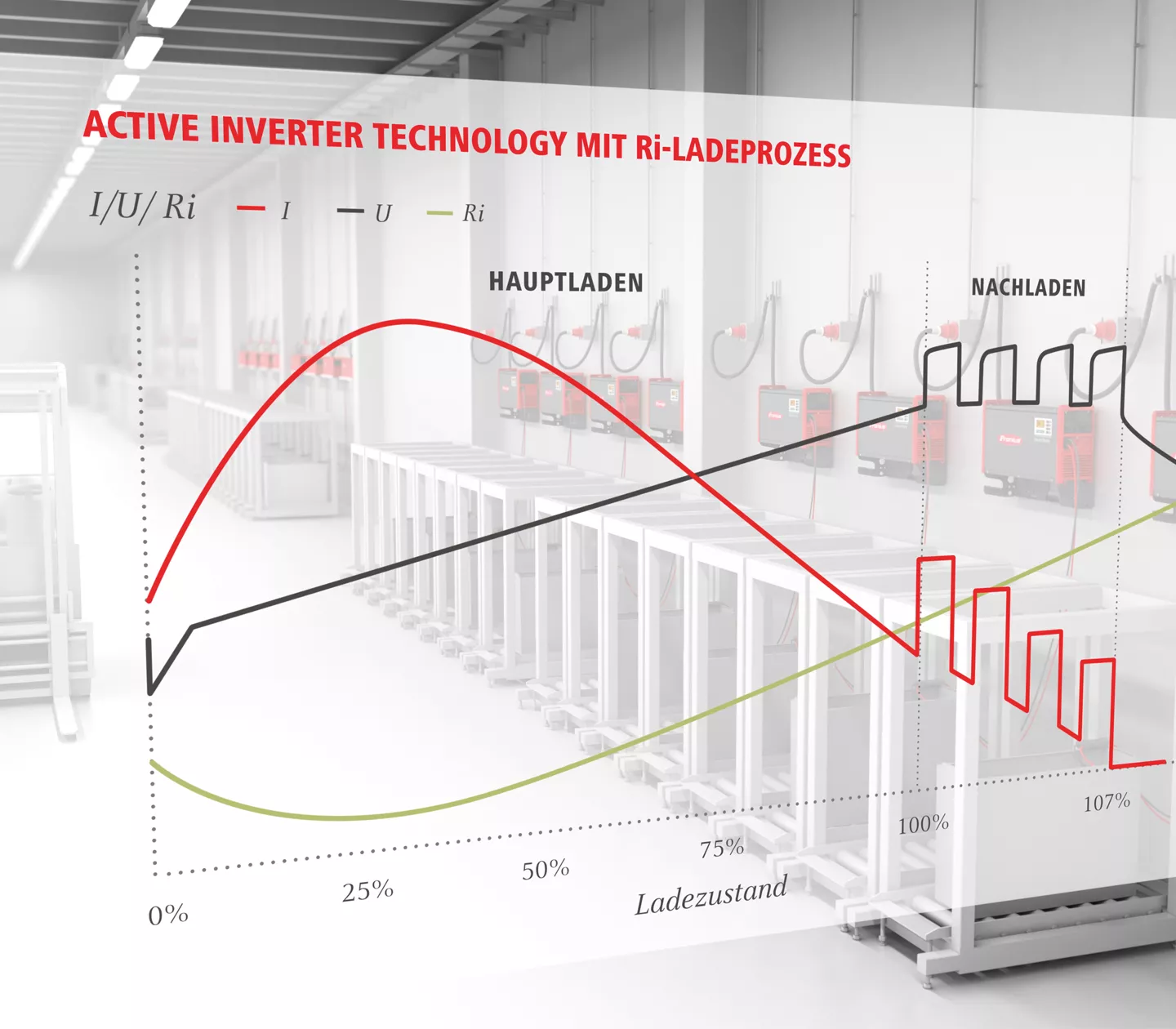

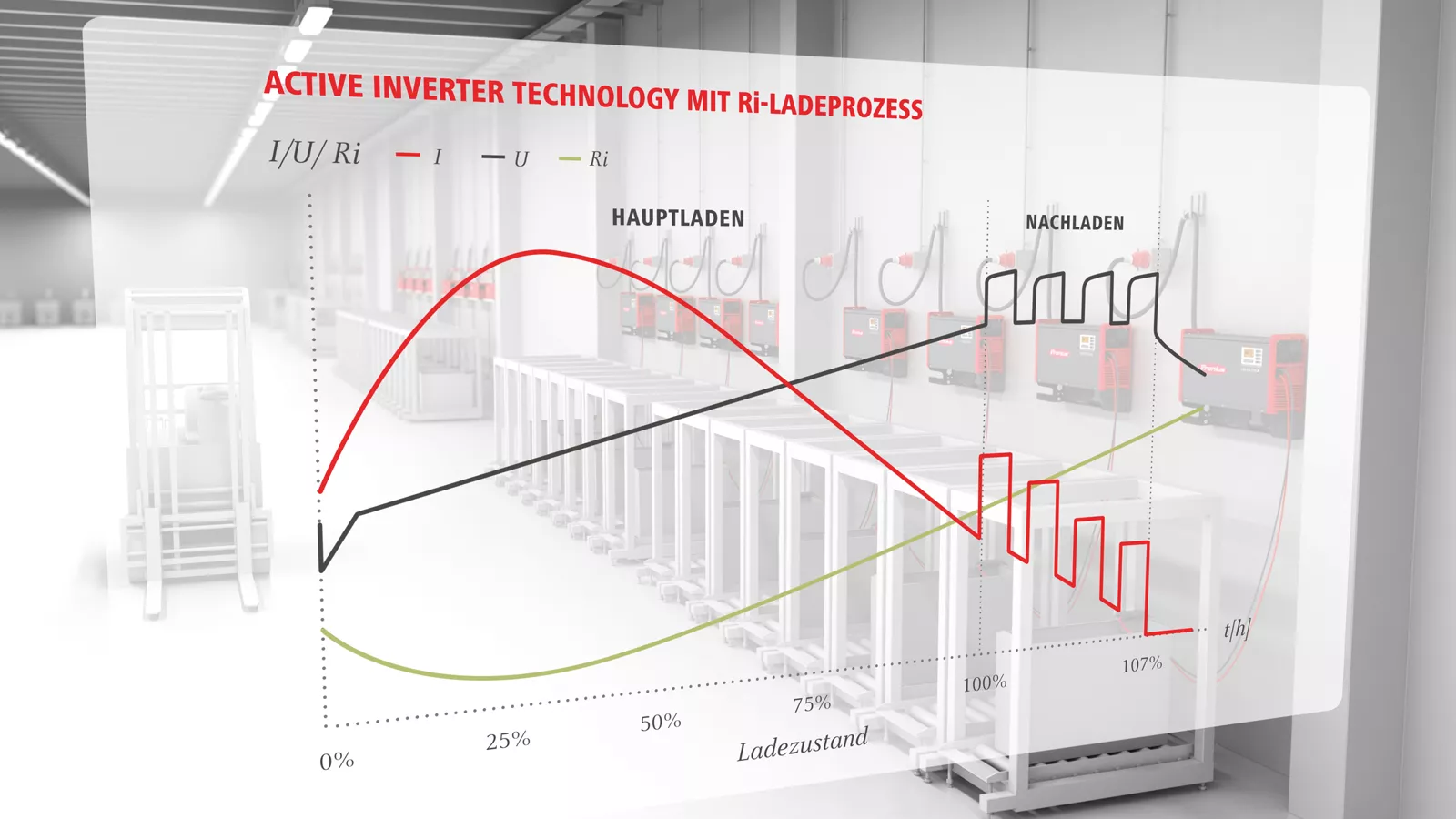

Fronius battery charging systems have a calendar function that allows the start of the charging process to be delayed, giving the battery enough time to cool down before charging starts. Moreover, the Ri charging process of the Selectiva battery charging systems ensures ultra-gentle and significantly cooler charging of the battery compared to other technologies. A blue LED and a minutes counter on the device display show if and for how long the battery has been cool enough to be returned to use.

Clearly visible LED strips are also available as an option, as well as the “Cool Battery Guide Easy” and “Cool Battery Guide Premium” information and management systems. These show the user which battery has been fully charged for the longest and is therefore the coolest, intuitively guiding the user to the correct battery. The service life of the batteries is thereby increased and operating costs are reduced.

Extreme loads result in an increase in the temperature of traction batteries. This is a particular challenge for industries in which heavy weights must be moved by forklift trucks, for example in the paper industry or in breweries. The temperature of the battery often increases to above 50 degrees Celsius - too high to simply charge once the battery has been changed, since high temperatures during the charging process reduce the service life of the battery and generate unnecessary costs. For this reason, most battery manufacturers specify an ideal temperature at which the battery should be charged.

The “delayed charging start” feature also enables users to set the time they want the charging process to begin for each Selectiva battery charging system. This gives the battery enough time to cool down before charging begins. Forklift truck operators can thus significantly extend the service life of their traction batteries without employing any additional technology.

Fronius can equip battery charging systems with the “temperature-controlled charging” feature on request. This means that a temperature sensor is installed between the cells in the cell case. When charging begins, the innovative Ri charging process permanently records the temperature of the battery and adapts the charging characteristic accordingly. The user also has the opportunity to set limit values for the maximum temperature of the battery. If the temperature is close to violating one of these limit value, the battery charging system outputs a warning. If the critical temperature is exceeded, the device stops the charging process so that the battery does not become damaged. This increases the service life of the battery and makes the entire forklift truck system substantially more cost effective.

With the aid of the I-SPoT Viewer software tool, a user can analyse every charging process and optimise the process where necessary, for example by extending the charging time. A cooler and gentler charge is thus established, which in turn extends the service life of the battery.

When not in operation over the weekend or on public holidays, lead batteries often cool down and fall below the ideal operating point for the battery. On the next working day, the output of the battery is not enough for a complete shift - an effect known as Monday morning syndrome. Consequences include opportunity charging or time-consuming changing of the battery, lower availability of the forklift trucks and reduced efficiency of the intralogistics operation.

With Fronius Selectiva battery charging systems, users can set a date-controlled automatic equalising charge for the weekend to ensure that the batteries are fully charged before the start of the shift, thus avoiding Monday morning syndrome.

When charging lead batteries such as traction batteries for forklift trucks, gas forms as the result of chemical reactions: the water inside the battery is electrolysed into hydrogen and oxygen. The electrolysis produces oxyhydrogen, which is not only explosive, but also has an unpleasant odour and contaminates the surface of the battery. This has a significant impact on the working environment in the immediate vicinity of the charging stations.

The innovative Ri charging process of the Fronius battery charging systems reduces overcharging of the battery to a minimum. This also reduces gas formation, which in turn reduces contamination and unpleasant odours. The result: an improved working environment around the charging stations.

The output of a lead battery changes over time. According to the standard, batteries have a service life of around 1,500 charging cycles. Their capacity must not fall below 80 percent of the nominal capacity during this time. However, the actual service life - the useful life - is much lower under real operating conditions. On average this amounts to 1,200 charging cycles, and sooner or later considerable wear and loss of power become apparent.

Operators must compensate for this loss by increasing the number of opportunity charges or by using back-up batteries. Longer and more frequent downtimes and reduced availability of the forklift trucks are the consequences, along with a less efficient logistics landscape. Users also fall back on more expensive batteries with the highest possible capacity in an attempt to counter this effect.

Fronius battery charging systems with the Ri charging process ensure ultra-gentle charging of the traction batteries, which reduces wear. Reaching the maximum service life of the battery is not unusual; and the battery even remains efficient for much longer. To counter capacity losses after several years of use, Fronius devices also have special charging characteristics. In many cases, these improve the efficiency of the battery, ensuring longer driving times and increased availability of the forklift trucks.

It is important to ensure that a residual capacity of 20 percent remains in a lead battery. The deep discharge that results if this falls below 20% leads to excessive sulphation, which can damage or even destroy the battery. In addition, many standard battery charging systems cannot recharge deep discharge batteries, and it is not possible to change the characteristic on most devices without a laptop or the help of a technician.

The battery is therefore unusable, and purchasing a new battery or recharging the sulphated battery incurs significant costs.

Fronius Selectiva battery charging systems have a special characteristic as standard that permits the recharging of deep discharge batteries. The user can set this characteristic directly on the device itself at the touch of a button. The capacity and efficiency of the battery can be restored to a large extent, increasing the service life of the battery and reducing procurement costs, as the batteries do not need to be replaced as often.

All-round battery charging system for the workshop or as a replacement device

Be it as an all-rounder for the maintenance and servicing of forklift truck systems or as a replacement device, having a flexible battery charging system for all types of traction battery (irrespective of size, voltage, capacity or charging plug) is a huge advantage in countless applications. However, many suppliers are struggling to achieve this: battery charging systems are often designed for specific types of battery only and cannot be used as a universal tool.

Fronius is offering a truly all-purpose solution with the Selectiva 8090 battery charging system: it enables flexible charging of batteries with a voltage of 12 to 80 volts and is suitable for battery capacities of 225 to 1,500 ampere hours. Users will enjoy a universal battery charging system for all types of electrically-powered forklift trucks. Its compact dimensions and low weight mean it is easy to transport, while the comprehensive range of accessories allows it to be adapted to the individual needs of the user.