A Pulsating Time at EuroBLECH 2018

The WeldCube Data management system records information such as current, voltage, and wire speed, enabling users to optimize their processes. Visitors had the opportunity to familiarize themselves with this software at EuroBLECH.

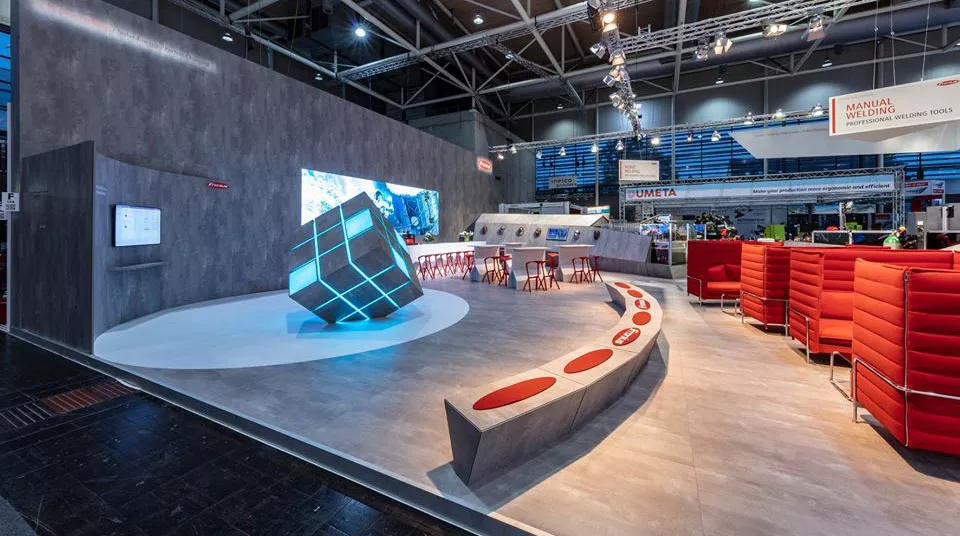

“Many exhibitors at this trade show claim to be drivers of digitization, but unfortunately it’s often just a lot of hot air. However, I was pleasantly surprised when I visited the Fronius stand,” said one visitor. Aside from the WeldCube, Fronius also presented various apps and digital functions. Visitors to the stand were given the chance to try the Welducation Basic app for themselves, which allows users to test their welding knowledge and practice their torch guidance skills on the touchscreen.

Live welding demonstrations from Fronius also drew quite a crowd. Manual welders were impressed with the versatility of the TransSteel 2200, the compact multiprocess welding system. Visitors also had the chance to see the MagicWave 230i live in action – the ideal tool for TIG AC welding in aluminum applications. “We received a lot of interesting questions regarding the connectivity of our new generation of TIG devices. The MagicWave 230i and TransTig 230i are equipped with Bluetooth and can be connected to other devices, such as the Vizor Connect welding helmet or a smartphone. This enables the use of various apps,” explained one of the manual welding experts on the Fronius stand. “Nevertheless, it is ultimately the welding behavior of a device that is the primary concern for welders. This remains the most important aspect.”

Visitors that prefer to weld without an arc were able to learn more about the new DeltaCon spot welding gun for resistance spot welding. The spot welding gun is extremely flexible due to its modular design – the user benefits from having various gun geometries at their disposal from the same main components. The compact design makes for ideal access to the component. DeltaCon is particularly well-suited to aluminum spot welding and optimizes productivity thanks to minimal downtimes.

See our Instagram page or watch the fair video for more insights into the Fronius trade show experience. You can find more information on the individual products in the press area of our website.