Exento LowVac

Mobile low-vacuum extraction system

Exento LowVac: More filter surface area, maximum safety

The flexible filter options include a disposable filter with a 25 m² surface area fitted as standard, which can be replaced by an extra-large 42 m² version if required. In addition, the filter is changed without contamination for maximum safety during handling.

The Exento LowVac is EN ISO 21904-1 W3-certified and therefore meets the highest quality and occupational safety requirements.

Your advantages at a glance

The equipment impresses with practical details that make everyday work easier and ensure greater efficiency:

- Automatic start/stop function for automatic activation and deactivation

- Workplace lighting with integrated on/off switch that can be controlled directly on the extraction hood

Other particularly noteworthy features include:

- 360° rotatable extraction hood with throttle valve for maximum flexibility

- Robust, stable design for industrial use

Altogether the system is ideal for:

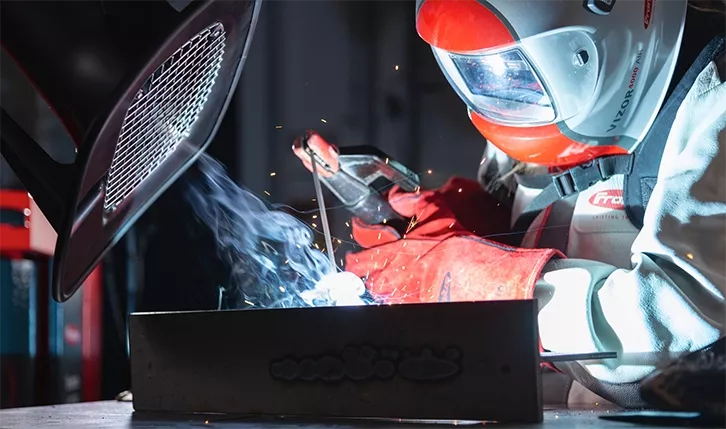

- MMA, MIG/MAG, and TIG welding

- Regular jobs

- Changing workplaces

Great versatility

Whether MIG/MAG, TIG, or MMA welding, the mobile Exento LowVac plays to its strengths during all common welding processes thanks to the flexible extraction arm with flow-optimized extraction hood. The Exento LowVac extraction system is the perfect choice especially where a fume extraction torch cannot be used, such as with manual arc welding.

Exento LowVac technical data

| Exento LV 230V/EF | Exento LV 115V/B | Exento LV 230V/B | Exento LV 400V | Exento LV 460V | Exento LV 600V | ||

| Mains voltage -10/+10% | 1x 230 V / 50 Hz | 1x 115 V / 60 Hz | 1x 230 V / 60 Hz | 3x 400 V / 50 Hz | 3x 460 V / 60 Hz | 3x 600 V / 60 Hz | |

| Motor power | 1.5 kW / 2.04 hp | ||||||

| Nominal current | 9.1 A | 17 A | 9.2 A | 3.1 A | 2.6 A | 1.9 A | |

| Max. extraction capacity | 1,100 m³/h / 647 cfm | ||||||

| Max. negative pressure | 2,250 Pa / 9.04 in wc | ||||||

| Sound pressure level | 70 dB(A) | ||||||

| Protection class | IP 21 | ||||||

| Dimensions l x w x h | 836 x 795 x 1,169 mm / 32.9 x 31.3 x 46.0 in | ||||||

| Weight | 127 kg / 280 lb | ||||||

| Filter stages | 2 | ||||||

| Filter process | Depth filter | ||||||

| Filter area | 25 m² / 38,750 in² | ||||||

| Filter type | Safe change filter | ||||||

| Filter material | Polyester fleece | ||||||

| Extraction efficiency rate | ≥ 99.5% | ||||||

| Filter class | E12 | ||||||

| Additional filter | Pre-filter (aluminum mesh) | ||||||

| Fan type | Centrifugal fan | ||||||

| Extraction arm type | Flexible hose design | ||||||

| Extraction arm lengths | 2 m / 3 m / 4 m | ||||||

| IFA approval | W3-tested | ||||||

Downloads

Exento LowVac Clean: Self-cleaning filter system

The Exento LowVac Clean is based on the proven Exento LowVac and offers an extra-large filter cartridge with automatic cleaning.

This means that regular filter changes are no longer necessary—for maximum efficiency with minimum maintenance. W3 certification in accordance with EN ISO 21904-1 has already been applied for.

The Exento LowVac Clean is available with practical extras such as an automatic start/stop function or an illuminated extraction hood for even greater convenience.

Exento LowVac Clean technical data

| Exento LV Clean 400V | Exento LV Clean 460V | Exento LV Clean 600V | ||

| Mains voltage -10/+10% | 3 x 400 V / 50 Hz | 3 x 460 V / 60 Hz | 3 x 600 V / 60 Hz | |

| Motor power | 2.2 kW / 2.99 hp | 2.2 kW / 2.99 hp | 2.2 kW / 2.99 hp | |

| Nominal current | 4.4 A | 4.4 A | 2.9 A | |

| Max. extraction capacity | 1,450 m³/h / 853 cfm | |||

| Max. negative pressure | 3,300 Pa / 13 in wc | |||

| Sound pressure level | 73 dB(A) | |||

| Protection class | IP 21 | |||

| Dimensions l x w x h | 973 x 834 x 1,350 mm / 38.3 x 32.8 x 53.2 in | |||

| Weight | 197 kg / 435 lb | |||

| Filter stages | 2 | |||

| Filter process | Surface filter | |||

| Cleaning process | Rotary nozzle | |||

| Cleaning trigger | Automatic | |||

| Filter area | 15 m² / 23,250 in² | |||

| Filter type | Filter cartridge | |||

| Filter material | ePTFE membrane | |||

| Extraction efficiency rate | ≥ 99.9% | |||

| Dust class | M | |||

| Additional filter | Pre-filter (aluminum mesh) | |||

| Fan type | Centrifugal fan | |||

| Compressed air supply | 5-6 bar / 73-87 psi | |||

| Extraction arm type | Flexible hose design | |||

| Extraction arm lengths | 2 m / 3 m / 4 m | |||

| IFA approval | W3 certification applied for | |||