Fronius Ignis Battery

The mobile battery-powered welding machine

Ignis Battery—for welding with the mobile battery-powered welding machine

Fully autonomous electrode welding and TIG welding

Whether you’re working on exposed installations and construction sites, in the great outdoors, or in an open field: These and many other situations pose a particular challenge for welding specialists. Complex grid leads often have to be laid to the welding point or a heavy and noisy generator used—both very costly and time-consuming measures.

With the Ignis Battery, a mains power connection is not required. Thanks to complete independence from the energy supply, you can rely on a stable and high-performance welding process for both manual arc and TIG welding with innovative battery technology. Leaving you to focus fully on the task at hand.

Highlights of the Ignis Battery

Welding electronics meets intelligent battery technology

Operating modes

Battery mode

Perfect welds in every position

The welding energy is drawn exclusively from the battery. One battery charge is sufficient for around thirty-one 2.5 mm or twelve 3.25 mm electrodes. Alternatively, 30 minutes of continuous TIG welding can be performed (at 100 A).

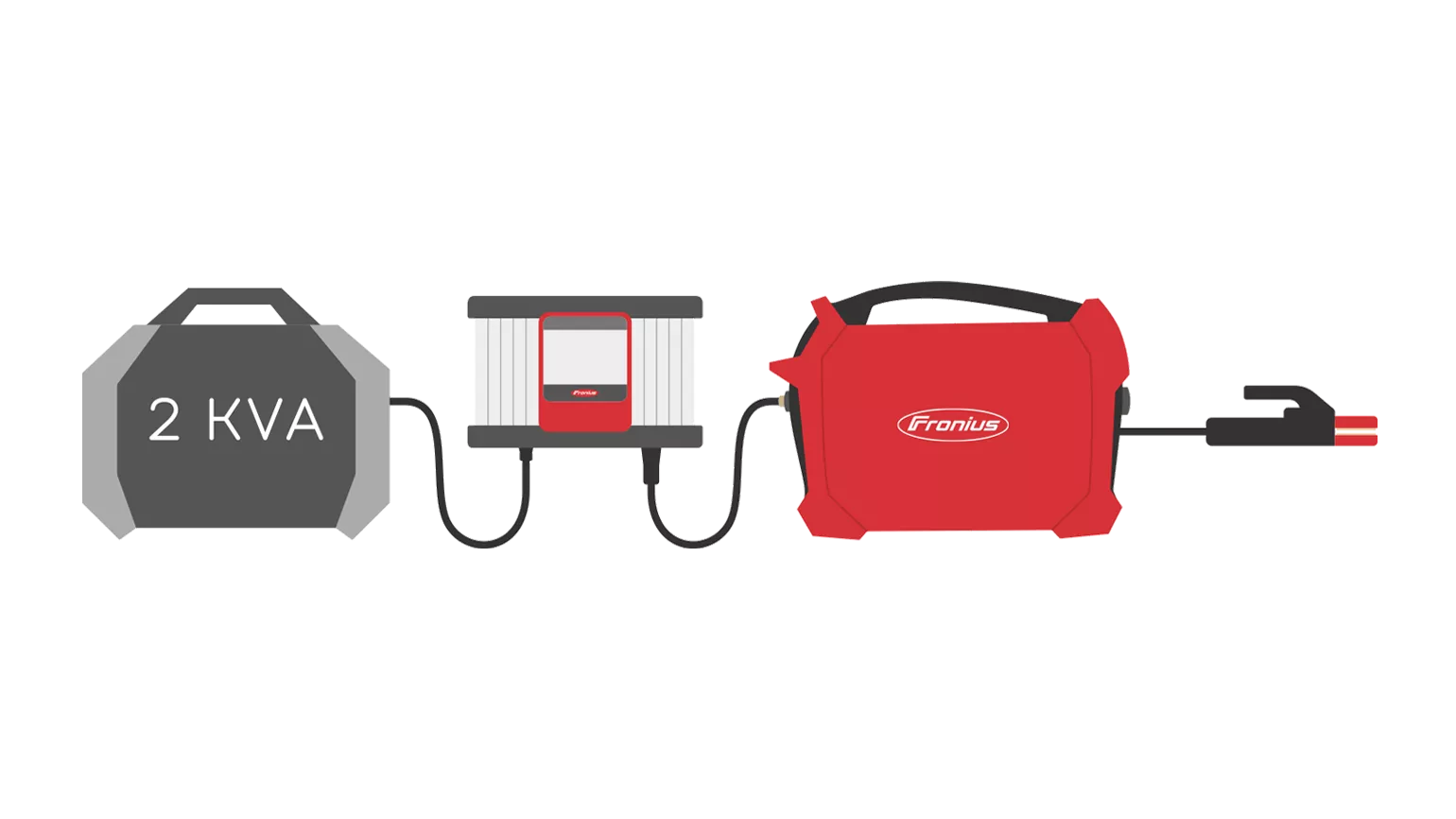

Hybrid mode—charging and welding simultaneously

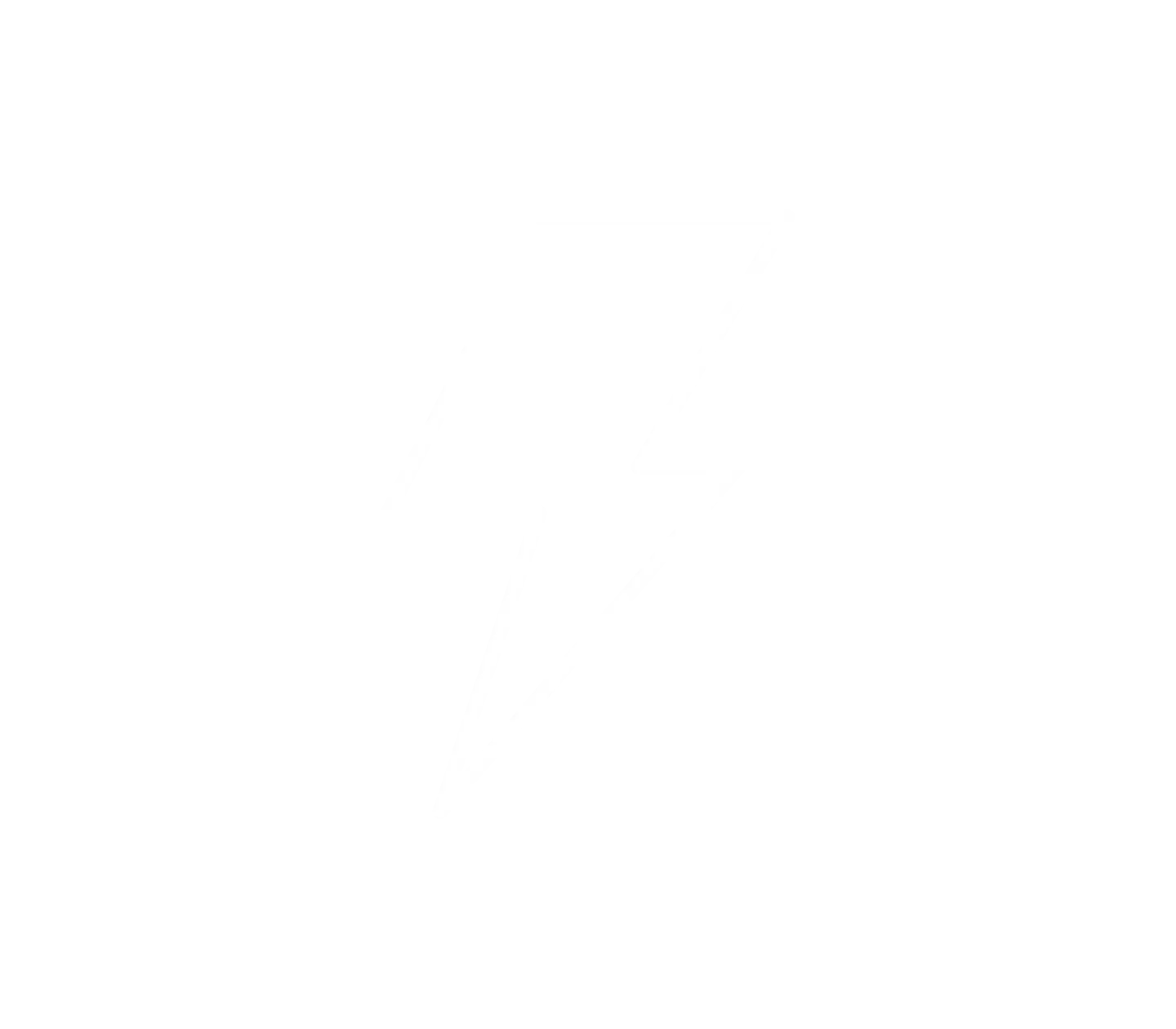

Generator-powered operation

Facilitates mobile applications and saves investment costs: Due to the low current consumption, a much smaller generator (2 kVA) can be used than with grid-connected devices—without compromising on welding power or arc quality.

Full output power of 150 A even with a 120 V mains supply: The battery’s integrated power reserve guarantees a constant arc even in the event of mains voltage fluctuations and prevents the mains fuse from tripping in case of power surges.

The MMA welding functions

The TIG welding functions

Intuitive operating concept

The clear operating concept and 7-segment display make it possible to quickly read the parameters and simplify handling.For today, tomorrow, and beyond

It’s in your hands

Durable

Boasting a long service life, repairable, and with many components suitable for recycling. A high-quality stainless steel filter inside the device, robust housing, and 3.5 cm ground clearance guarantee the welding machine will have a long service life.

Low-noise welding

The Ignis Battery allows you to weld very quietly in battery mode, especially compared with larger generator-powered devices. If a generator is required for longer welding jobs, a compact 2 kVA device is sufficient.

Energy-efficient welding

The energy stays exactly where it is needed: In addition to voltage monitoring, the innovative Battery Management System also watches over the charging process and ensures protection against overcharging and deep discharge. The optionally adjustable automatic time shutdown (0,5h - 4h) ensures that valuable energy is not wasted including in standby mode.