Neviditelné nebezpečí při svařování

I chvilka neopatrnosti může mít vážné následky: Zazní neočekávaný výkřik, následuje reflexivní otočení a nechráněná ruka se dotkne obalené elektrody. A následek? Tělo se stane součástí elektrického obvodu. Izolační pracovní obuv nebo podložka pro svařování z nitrilové pryže v takových případech přerušují průtok proudu a poskytují spolehlivou ochranu.

Elektrický proud si v těle vždy vybere nejkratší cestu mezi místem vstupu a výstupu. Pokud proud například protéká oběma rukama, prochází nejen pažemi a horní částí těla, ale také životně důležitými orgány, jako je srdce, což může mít smrtelné následky (náčrt 1).

Pozor na napětí naprázdno

Zatímco u běžných elektrických spotřebičů jsou části pod napětím chráněny proti dotyku, při obloukovém svařování existuje zvýšené riziko: Napětí naprázdno se může proměnit v nebezpečné dotykové napětí, zejména pokud se současně dotknete svařence (uzemnění) a elektrody nebo neizolovaných částí držáku elektrody. V takovém případě mluvíme o „průchodu proudu“ lidským tělem.

Pro napětí naprázdno platí, v závislosti na provozních podmínkách, stanovené maximální limity. Ohrožení elektrickým proudem začíná již při střídavém napětí nad 25 V (efektivní hodnota) nebo stejnosměrném napětí 60 V za předpokladu, že je současně možný dostatečně vysoký průtok proudu.

I malé velikosti proudu jsou životu nebezpečné

Když elektrický proud protéká lidským tělem, působí dráždivě na svaly, nervy a kardiovaskulární systém. Možné následky sahají od svalových křečí a zástavy dechu až po malé bodové popáleniny v místech vstupu a výstupu proudu. Již při velikosti proudu 30 miliampérů hrozí akutní ohrožení života. „Mez uvolnění“ je mezi 10 a 15 mA pro střídavý proud a asi 50 mA pro stejnosměrný proud. Při překročení této hranice mohou být svalové křeče tak silné, že postižené osoby nejsou schopny bez cizí pomoci uvolnit díly pod proudem, a to pro svářeče při každodenní práci představuje obzvláště vysoké riziko.

Střídavý proud je považován za výrazně nebezpečnější než stejnosměrný proud, protože může narušit srdeční rytmus a vyvolat fibrilaci komor. Často se také podceňuje, že i malé velikosti proudu mezi 1 a 10 mA stačí k vyvolání nevědomých reflexních pohybů, které často vedou k sekundárním nehodám. Takovéto nekontrolované reakce mohou například vést k pádu ze žebříku nebo k jiným zraněním.

Kromě velikosti proudu hraje z hlediska rizika poranění rozhodující roli také doba působení na lidský organismus. Čím delší je průtok proudu, tím závažnější jsou zdravotní následky. Z tohoto důvodu je pro svářeče nezbytné vždy používat vhodné osobní ochranné prostředky. V Evropě musí svářečské rukavice splňovat požadavky normy EN 12477 a pracovní obuv by měla odpovídat třídě ochrany S3 podle normy EN ISO 20345.

Jak se určuje nebezpečí?

Velikost proudu (I) závisí na použitém napětí (U) a odporu (R) a řídí se Ohmovým zákonem (U = R x I). Chcete-li určit velikost proudu, lze předpokládat odpor těla (bez osobních ochranných prostředků) 1 000 ohmů mezi rukou a nohou nebo druhou rukou. Pokud má svařovací přístroj podle výkonového štítku napětí naprázdno 50 V, může podle Ohmova zákona (I = U / R) tělem protékat životu nebezpečný proud 50 mA.

Pozor při svařování s několika svařovacími přístroji

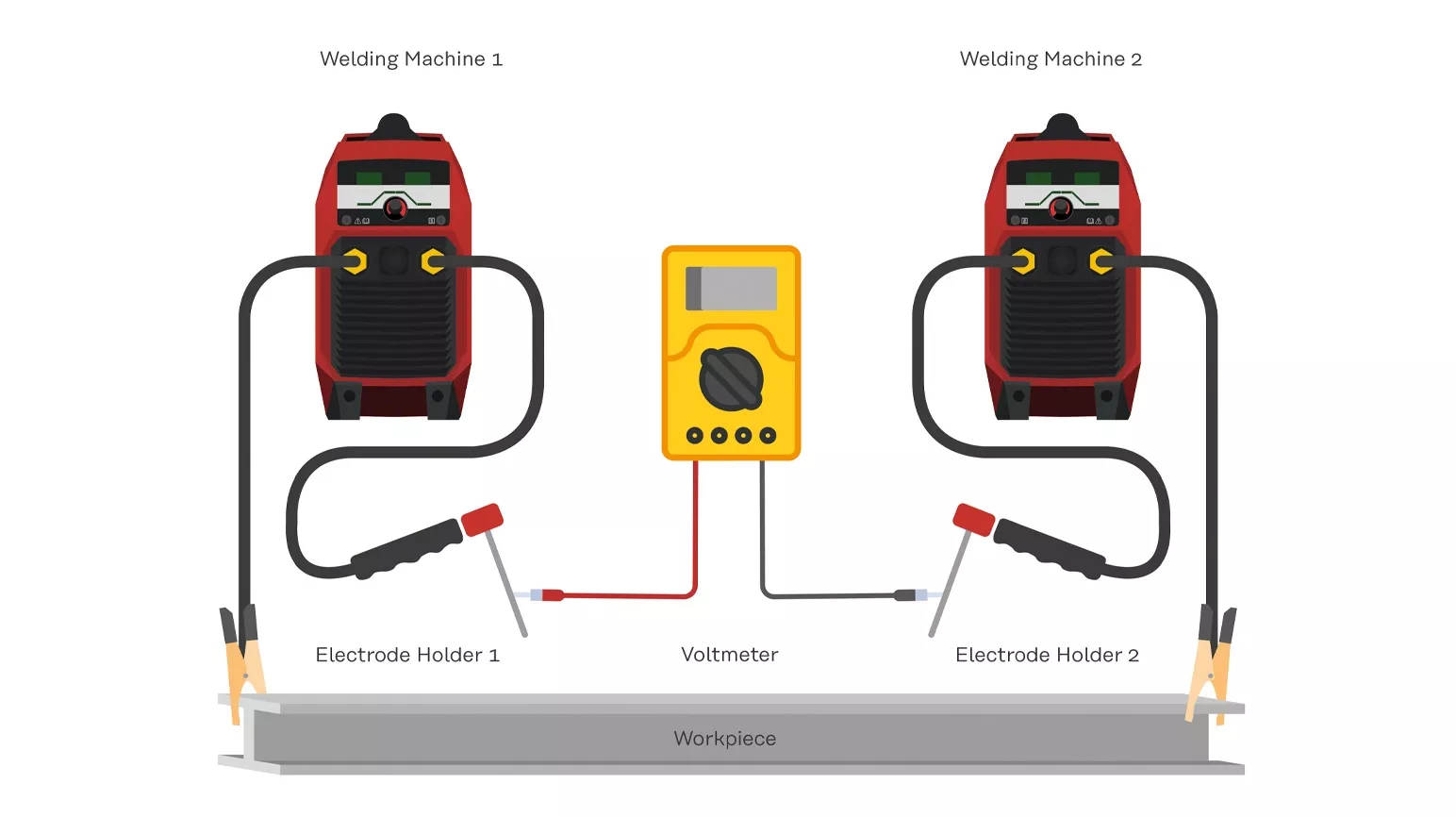

Pokud svářeči pracují současně s více svařovacími přístroji na jednom svařenci nebo na vodivých dílech, může vzniklé dotykové napětí – zejména napětí naprázdno – dosáhnout nepřípustně vysokých hodnot. Tento nebezpečný stav často není okamžitě rozpoznatelný.

Zvláště kritická situace nastává, pokud se svařuje současně s různou polaritou: Při svařování stejnosměrným proudem (DC) se v tomto případě napětí naprázdno všech příslušných svařovacích přístrojů sčítají, což může vést k nebezpečně vysokým hodnotám napětí.

„Zejména na staveništích taková situace není nijak výjimečná,“ říká Franz Bichler, školitel svařování ve společnosti Fronius International GmbH. „Dříve jsme často svařovali metrové díly po dvou nebo po třech – u složitých komponent i s různou polaritou, abychom dosáhli optimálních výsledků. Pokud je v takových situacích uzemnění vadné, může součtové napětí procházet tělem svářeče – s život ohrožujícími následky, jako jsou úrazy elektrickým proudem, srdeční arytmie nebo těžké popáleniny.“

Při svařování střídavým proudem (AC) ovlivňuje výsledné napětí naprázdno jak polarita elektrických obvodů, tak připojení přístroje k síti. Za nepříznivých podmínek může dotykové napětí dosáhnout součtu napětí naprázdno u všech použitých zařízení. Proto je před zahájením prací nezbytné měřit napětí mezi svařovacími hořáky nebo držáky elektrod. Měření se provádí multimetrem, přičemž oba měřicí hroty se přiloží přímo na svařovací hořáky (držáky elektrod) – viz náčrt 1.

Zaměstnavatelé mají povinnost zajistit ochranu a informovat

Účinná ochranná opatření mohou zabránit pracovním úrazům. Odpovědnost za jejich zavedení nese v zásadě zaměstnavatel. Mezinárodní normy a předpisy – jako jsou normy ISO (International Organization for Standardization), ASME (American Society of Mechanical Engineers), AWS (American Welding Society) a DIN (German Institute for Standardization) – tvoří základ pro bezpečné pracovní podmínky.

Svářeči musí být v každém případě informováni o potenciálních nebezpečích. Vzdálenost mezi konci svařování musí být zvolena tak, aby byl vyloučen současný kontakt se dvěma svařovacími hořáky nebo držáky elektrod. Pokud to není možné, musí být pracovní prostory odděleny izolačními příčkami. Kromě toho je třeba vhodnými měřeními zajistit, aby součtové napětí nepřekročilo přípustnou maximální hodnotu napětí naprázdno.

Co je třeba při svařování dodržovat?

Před zahájením prací musí svářeči zajistit, aby použitý svařovací přístroj byl v perfektním stavu. Přístroje, které se nepoužívají nebo jsou ponechány bez dozoru, je třeba vypnout a odpojit od elektrické sítě. Provoz musí být vždy v souladu s krytím uvedeným na výkonovém štítku a s příslušným návodem k obsluze.

Přístroje s krytím IP21 lze používat pouze v suchých vnitřních prostorách. Pro použití ve venkovním prostředí je vyžadováno minimálně krytí IP23. Svorky zemnicího kabelu musí být upevněny co nejblíže oblasti svařování – buď přímo ke svařenci, nebo k jeho podpěře.

V případě závad musí být napájení okamžitě přerušeno, a to buď vypnutím přístroje, nebo vytažením síťové zástrčky. Poškození svařovacího přístroje, elektrického vedení nebo hadicového vedení je nutné neprodleně nahlásit svářečskému dozoru. Vadné přístroje nesmí být v žádném případě dále používány ani otevřeny bez povolení – zejména nesmí být odstraněn ochranný kryt.

Nebezpečí v důsledku bludných svařovacích proudů

Nesprávná manipulace se svařovacími přístroji může představovat značné nebezpečí. Zvláště kritické jsou nesprávně připojené zemnicí kabely nebo nedbale odložené držáky elektrod. Takové závady mohou způsobit propálení ochranných vodičů, svařovacích přístrojů nebo jiných elektrických zařízení. Vzhledem k tomu, že přerušení ochranného vodiče obvykle není zvenku rozpoznatelné, představují značné riziko pro všechny, kteří pracují s poškozenými přístroji.

Nejčastějšími příčinami přerušení ochranných vodičů a následných nehod jsou nedbalost a nepozornost. Typickým příkladem jsou neizolované držáky elektrody odložené na svařovacím přístroji, nebo elektrické ruční nářadí, které během svařovacích prací zůstává na svařovacím stole (náčrty 3 a 4).

Dodržování ochranných opatření uvedených v platných normách však umožňuje účinnou ochranu před bludnými svařovacími proudy. Zpětné vedení svařovacího proudu (uzemnění) by mělo probíhat přímo na svařenci nebo jeho podpěře – pomocí přípojných svorek nebo zemnicích magnetů. Jiné části, jako jsou kovové tyče, řetězy nebo jeřábová lana, nesmějí být v žádném případě používány jako zpětné vodiče.

Pokud je výjimečně nutné svařovat svařence zavěšené na jeřábovém háku, je nutné důkladné odstínění, například suchými textilními lany nebo izolačním závěsem. Pokud se při svařování používají závěsné pracovní koše, musí být vybaveny vhodnou izolací. Pokud se současně svařuje a pracuje s elektrickým nářadím, smí se používat pouze zařízení s ochrannou izolací.

Práce pod zvýšeným elektrickým napětím

Na pracovištích s omezenou volností pohybu existuje zvýšené riziko elektrického nebezpečí. To platí zejména v případě, že svářeči musí pracovat v nucené poloze, například vkleče, a přichází tak do kontaktu s elektricky vodivými díly. Nebezpečí představují také oblasti, které jsou zcela nebo částečně obklopeny elektricky vodivými materiály. I náhodný nebo nevyhnutelný dotyk může vést k úrazu elektrickým proudem.

Pro zjednodušení posouzení, zda při obloukovém svařování hrozí zvýšené nebezpečí, slouží následující obecné pravidlo: Pokud je volný prostor mezi protilehlými vodivými částmi menší než dva metry – na délku, na šířku, na výšku nebo v průměru – je třeba předpokládat zvýšené elektrické nebezpečí.

Zvláštní opatrnost je nutná na mokrých, vlhkých nebo horkých pracovištích. V takovém prostředí může být elektrický odpor pokožky, ochranného oděvu a používaných pomůcek výrazně snížen vlhkostí nebo potem. Za „mokrá“ se považují pracoviště, na kterých je oděv vlhký a stává se vodivým, což výrazně zvyšuje riziko úrazu elektrickým proudem.

Ochranná opatření při zvýšeném elektrickém nebezpečí

Při práci se zvýšeným elektrickým nebezpečím smí být používány pouze schválené svařovací přístroje označené symbolem [S]. Kromě toho jsou nutná zvláštní ochranná opatření: Svářeči musí být před elektricky vodivými díly a vlhkými podlahami a stěnami chráněni izolačními podložkami nebo mezivrstvami.

Pokud takové odstínění není možné z důvodu dalších nebezpečí, jako je například riziko pádu, nebo z důvodu stísněných prostorových podmínek, smí být práce prováděny pouze v suchém a nepoškozeném pracovním oděvu. V situacích, kdy nelze trvale zajistit suchý oděv, například v horkém prostředí, je pro ruční obloukové svařování povoleno používat pouze zařízení na stejnosměrný proud.

Napětí naprázdno by u použitých zařízení mělo být v závislosti na svařovacích úkolech a vlastnostech zařízení co nejnižší a nesmí překročit 75 voltů. Svařovací přístroje nesmí být umístěny v bezprostřední blízkosti oblasti ohrožení. Pro dálkové ovládání těchto přístrojů musí být použito ochranné velmi nízké napětí.

Kromě toho je třeba zajistit, aby svářeči nebyli při těchto pracích sami – je povinný odpovídající svářečský dozor. Svařování při zvýšeném elektrickém nebezpečí je vyhrazeno výhradně kvalifikovaným odborníkům.

Shrnutí a závěr

Bezpečnost je při svařování nejvyšší prioritou. Nesprávná manipulace se svařovacím přístrojem může mít vážné následky – zejména kvůli vysokému napětí naprázdno, bludným svařovacím proudům nebo práci při zvýšeném elektrickém nebezpečí. Tato rizika však lze výrazně snížit důsledným dodržováním vhodných ochranných opatření.

Zvláštní pozornost je třeba věnovat mokrým, vlhkým nebo horkým pracovištím, protože tam může být ochranný účinek oděvů a vybavení snížen. Pokud se vyskytnou závady, je třeba okamžitě přijmout vhodná opatření, aby se zabránilo zranění osob a poškození majetku.