Trial license for TPS/i and iWave

Discover the full potential of our welding systems

When is a trial license for the TPS/i or iWave the right answer?

If you are asking yourself any of the following questions, then we recommend that you obtain a trial license:

What production benefits would I see if I were to invest in welding packages such as PMC or LSC?

Is it really practical to use OPT/i Jobs?

Can I improve quality by using OPT/i Limit Monitoring?

The Welding Packages

Depending on your needs, the welding systems can be equipped with different welding packages, from entry-level options all the way up to high-end solutions. Each of the welding packages has different process characteristics that are designed to meet the diverse requirements of different welding tasks.

Standard

The standard package includes the dip transfer arc and spray arc. Easy to handle and suitable for the entire power range of unalloyed, low- and high-alloy materials.

Pulse

The pulse package from Fronius facilitates welding with the pulsed arc. This ensures low spattering as well as a variable working range (thin sheets to thick sheets).LSC – Low Spatter Control

LSC is a MIG/MAG welding process with high arc stability and reduced spattering in the dip transfer arc. In addition, despite the possible stick out change, the penetration stabilizer enables constant penetration in the spray arc.PMC – Pulse Multi Control

PMC is a modified pulsed arc for MIG/MAG welding. When in use, the penetration and arc length stabilizers included guarantee both higher weld seam quality and higher welding speeds.CMT – Cold Metal Transfer

This highly specific type of droplet detachment minimizes the heat input. The reversing wire electrode movement also reduces spattering.Software options

The trial license also gives you access to all software options for the welding systems. This means, for example, that you can edit jobs and access all data logging functions.

The Trial License includes the following software options:

OPT/I Jobs

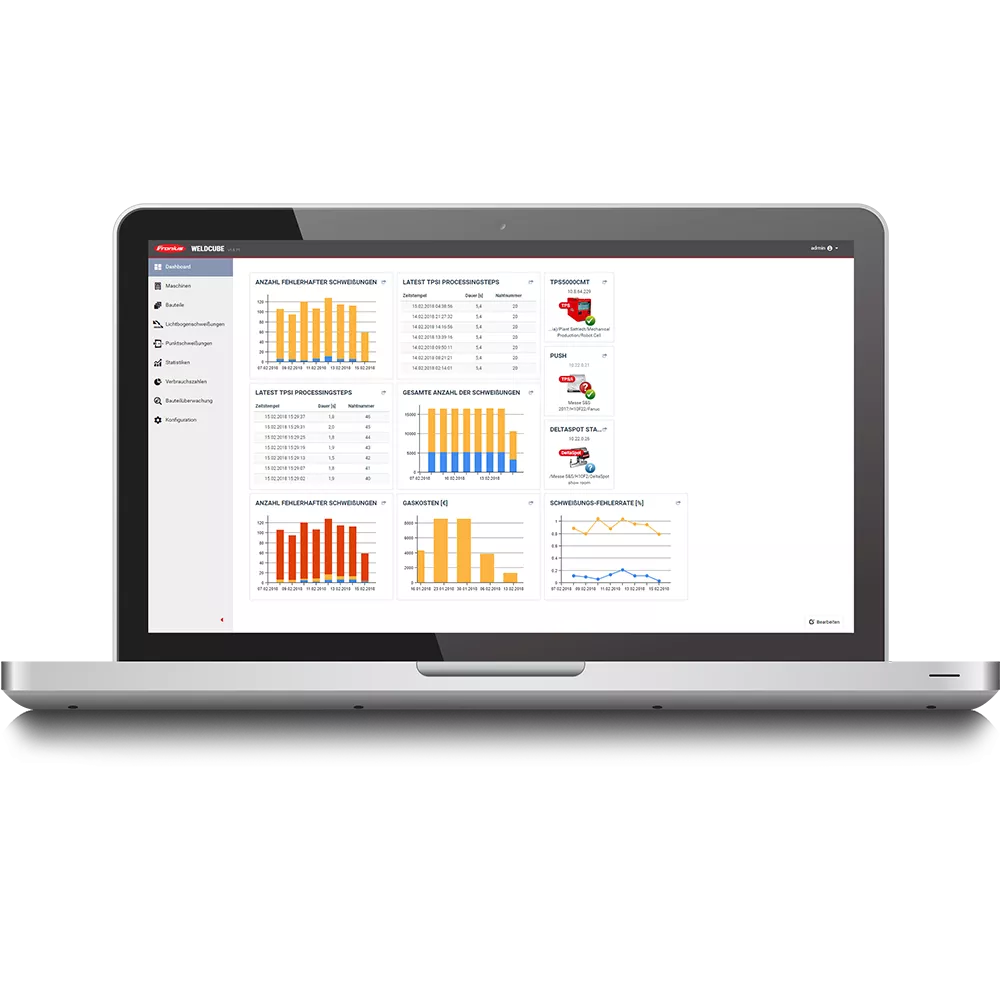

With TPS/i and iWave, you can save up to 1000 jobs—these are predefined welding parameters for a particular welding task. The Opt/i Jobs option offers additional functionality for SmartManager, a web-based application: now, jobs can be visualized and edited on all end devices.

OPT/I Documentation

With OPT/i Documentation, actual values (current, voltage, wire speed) and consumption data (gas, wire, energy) are recorded in the memory of the welding system. This makes it possible to visualize the data via web views.

OPT/I Limit monitoring

This function is used for monitoring limit values of individual welding parameters and thus for detecting weld defects. The parameters monitored are current, voltage, wire speed, welding duration, and heat input into the weld. It is also possible to determine whether a warning or an error message should be issued if a limit value is exceeded.

OPT/I Gun trigger

This special function allows you to make additional settings on the JobMaster welding torch, such as operating mode, SynchroPulse, or gas test.

OPT/I CMT Cycle Step

CMT Cycle Step is a variant of the CMT (Cold Metal Transfer) welding process. What’s special about it is that you can set the number of individual droplets per welding spot as well as the pause time between cycles. This enables maximum precision and reproducibility as well as a flawless seam appearance.

OPT/I CUSTOM NFC – ISO 14443A

This OPT/i allows you to use your existing NFC system for TPS/i user management. This means that existing user IDs can be reused.

OPT/I Wire Sense

WireSense uses the wire electrode as a sensor, which scans the component with pinpoint accuracy and delivers appropriate signals to the robot before welding begins. This means that, for instance, edges can be detected and gap sizes determined.

OPT/I OPC-UA

OPC-UA is a standardized protocol that is transmitted via the data interface of the welding system. With this option, a defined data set is output live at a defined sampling rate or in the event of changes via the OPC-UA standard. The data includes set values, actual values, process information, and system information. In the other direction, specific process and traceability parameters can be transmitted to the welding system via OPC-UA.

OPT/I MQTT

MQTT is a standardized protocol that is transmitted via the data interface of the welding system. With OPT/i MQTT, data (set values, actual values, process and system information) can be output live at a defined sampling rate or in the event of changes and transmitted to a message broker.

OPT/I Synergic lines

This software function activates all the special characteristics of a particular welding package. The main features are the characteristics for special filler materials and gas combinations.

TIG software options

The iWave trial license gives you the opportunity to test two additional TIG software options.

OPT/I Puls Pro

All iWave power sources offer standard functionality for pulsing. The pulse current and pulse frequency are adjustable as standard; the pulse frequency is limited to 2 kHz. The Puls Pro option activates additional functions as needed, meaning that the base current, duty cycle, and DC waveforms can also be configured. With OPT/i Puls Pro, the upper limit for the pulse frequency is increased to 10 kHz.

OPT/I CycleTIG

CycleTIG is a process variant for DC minus welding and is based on interval welding. Through combinations of different parameters (e.g., with pulse or tacking), CycleTIG simplifies TIG welding for a flawless seam appearance. One of the major advantages of CycleTIG is that it can be used for highly targeted heat input, which is very useful when welding light gage sheets, conducting repair welding, and so on.

TPS/i Trial License

50 arc hours to evaluate the potential of TPS/i

By activating the TPS/i trial license, you will be able to enjoy the full functionality of TPS/i during the trial period.This gives you access to all the welding packages and software options described above.

If you are still unsure which functions you need, you can use the trial period of 50 arc hours to test out all the options and decide which TPS/i configuration meets your needs.

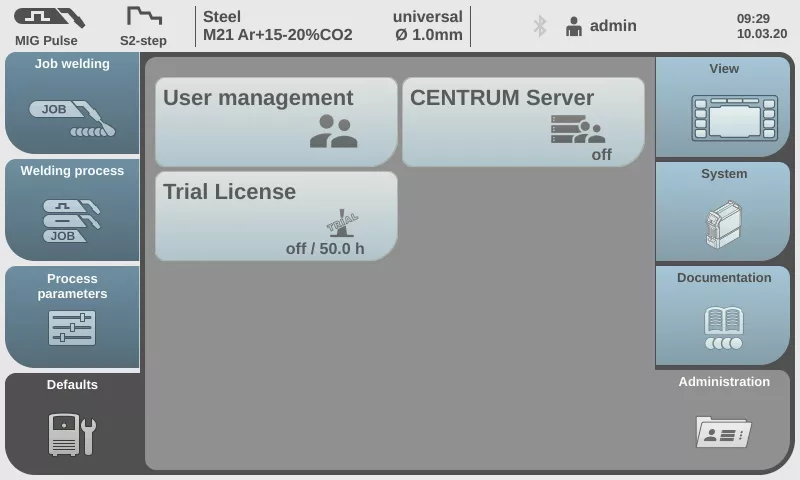

Activating the TPS/i Trial License

The license can be activated directly in TPS/i in a few easy steps. We have prepared a quick guide to help you activate all welding packages and software options in a one-time process.

Step 1

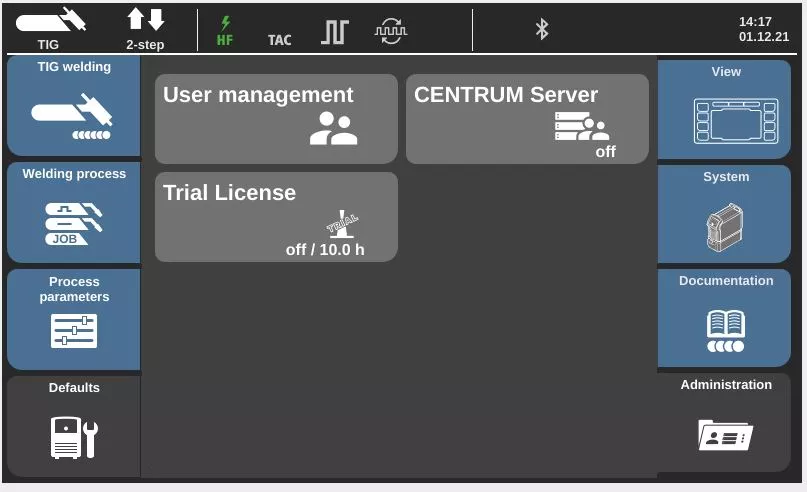

Under “Settings” you will find the “Trial License” button. Clicking on it will start the activation process.

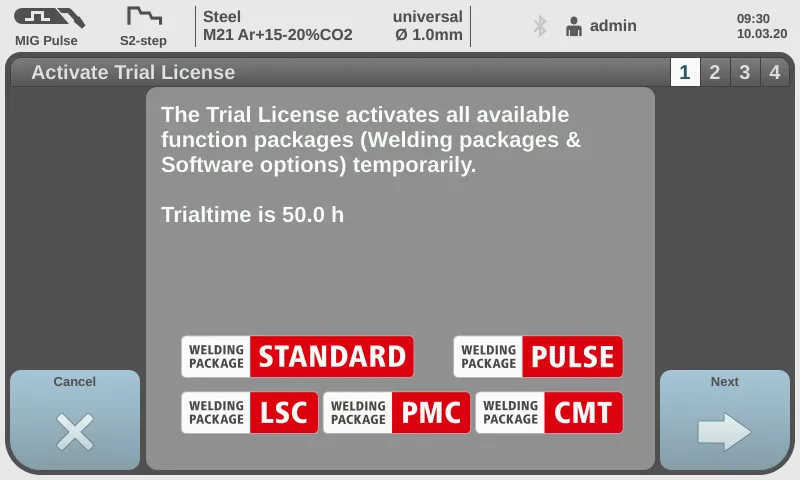

Step 2

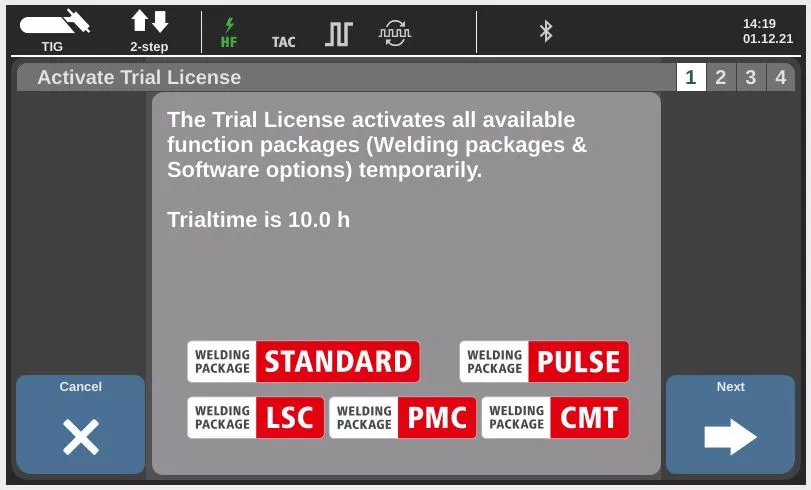

A quick reference to the available welding packages that are enabled for 50 arc hours with the Trial License.

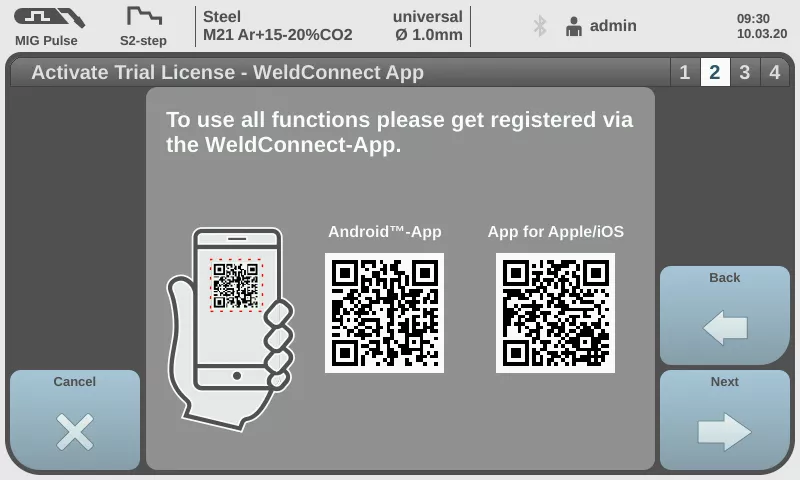

Step 3

To take full advantage of the enabled functions, we recommend using the WeldConnect app. Simply scan the QR code and download the app.

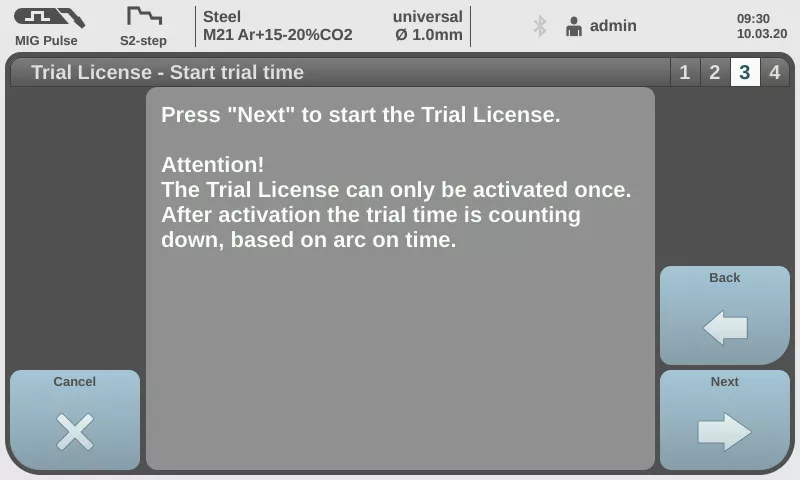

Step 4

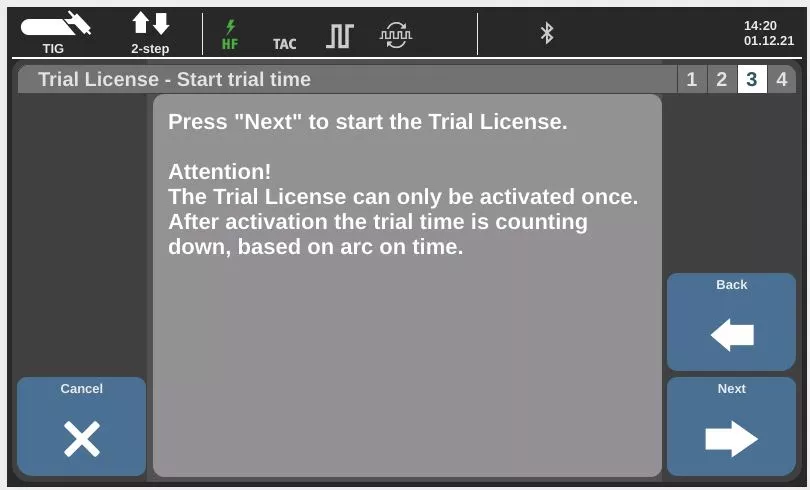

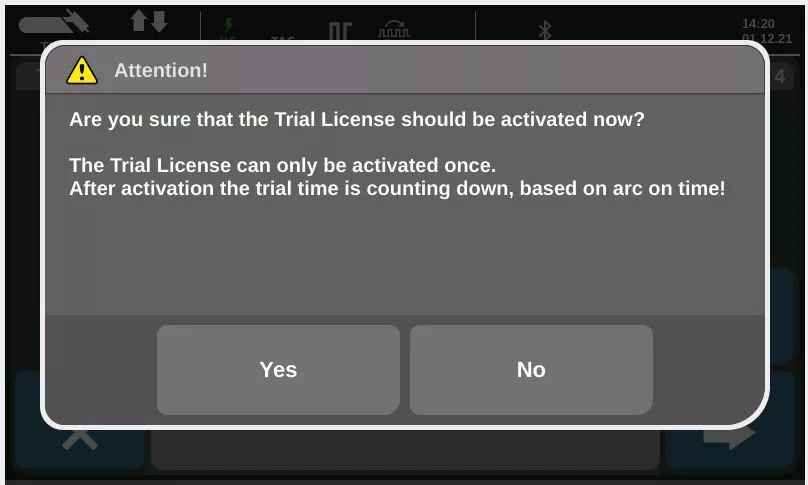

A final note: the Trial License can only be activated once per device.

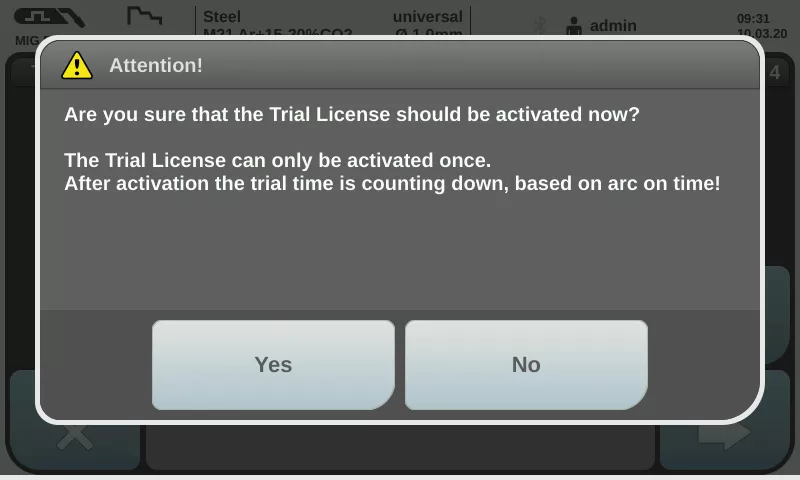

Step 5

Last step: once this message is confirmed, the Trial License is active.

Step 6

Done! You now have 50 arc hours to discover the full range of TPS/i services.

iWave Trial License

10 arc hours to evaluate the potential of iWave

Activating the iWave trial license gives you access to the following functions during the trial period:

iWave 190i-230i:

/ OPT/i Jobs

/ OPT/i Documentation

/ OPT/i Limit Monitoring

/ OPT/i Custom NFC

/ OPT/i OPC-UA

/ OPT/i MQTT

/ OPT/i Puls Pro

/ OPT/i CycleTig

iWave 300i-500i:

/ all welding packages described above

/ all software options described above

/ all TIG software options described above

If you are still unsure which functions you need, you can use the trial period of 10 arc hours to test out all the options and decide which iWave configuration meets your needs.

Activating the iWave Trial License

The license can be activated directly in iWave in a few easy steps. We have prepared a quick guide to help you activate all welding packages and software options in a one-time process.

Step 1

Navigate to “Settings” and click on the “Trial License” button to begin the activation process.

Step 2

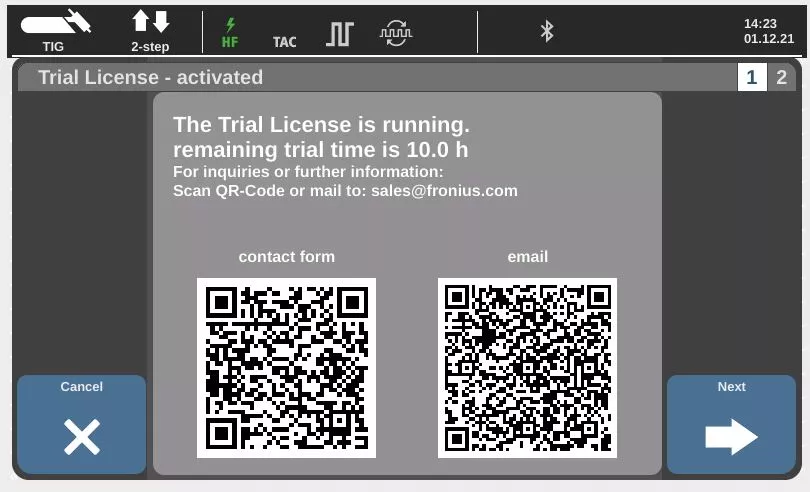

You will see a brief note about the available welding packages that will be activated for 10 arc hours with the trial license.

Step 3

In order to get the most out of the activated functions, we recommend that you use the WeldConnect app. Simply scan the QR code to download the app.

Step 4

One final note: the trial license can only be activated once on each system.

Step 5

The final step: acknowledge this message to activate the trial license.

Step 6

All done! Now you have 10 arc hours to discover everything that iWave has to offer.