Safety inspections

Contact

Would you like to find out more about the product?

Electrical Inspection of Welding Systems

The safety inspection or electrical inspection is a mandatory measure that is stipulated by occupational health and safety. The aim of the inspection is to protect people from the dangers of electrical current. The employer must ensure that the inspection is carried out at regular intervals.

Why is the electrical inspection so important?

An electrical inspection provides you as an employer with legal protection in the event that an electricity-related accident results in a dispute. It makes it possible to rule out the notion that you are operating equipment with faulty safety devices in a manner that is totally verifiable.Inspection scope

The inspection by our Fronius technicians includes the following steps:

/ Cleaning (internal cleaning of the device, removal of metal dust)

/ Visual inspection (condition, damage, labels, fuses, etc. )

/ Mechanical inspection (housing, covers, mounting, cables, etc.)

/ Electrical safety check (measurements according to IEC 60974 - 4) Germany: section 5 of the DGUV Vorschrift 3, Austria: ÖVE/ÖN 8701-1, Switzerland: SR 832.30 section 32b

/ Check for correct functioning (manufacturer's specifications or state of the art)

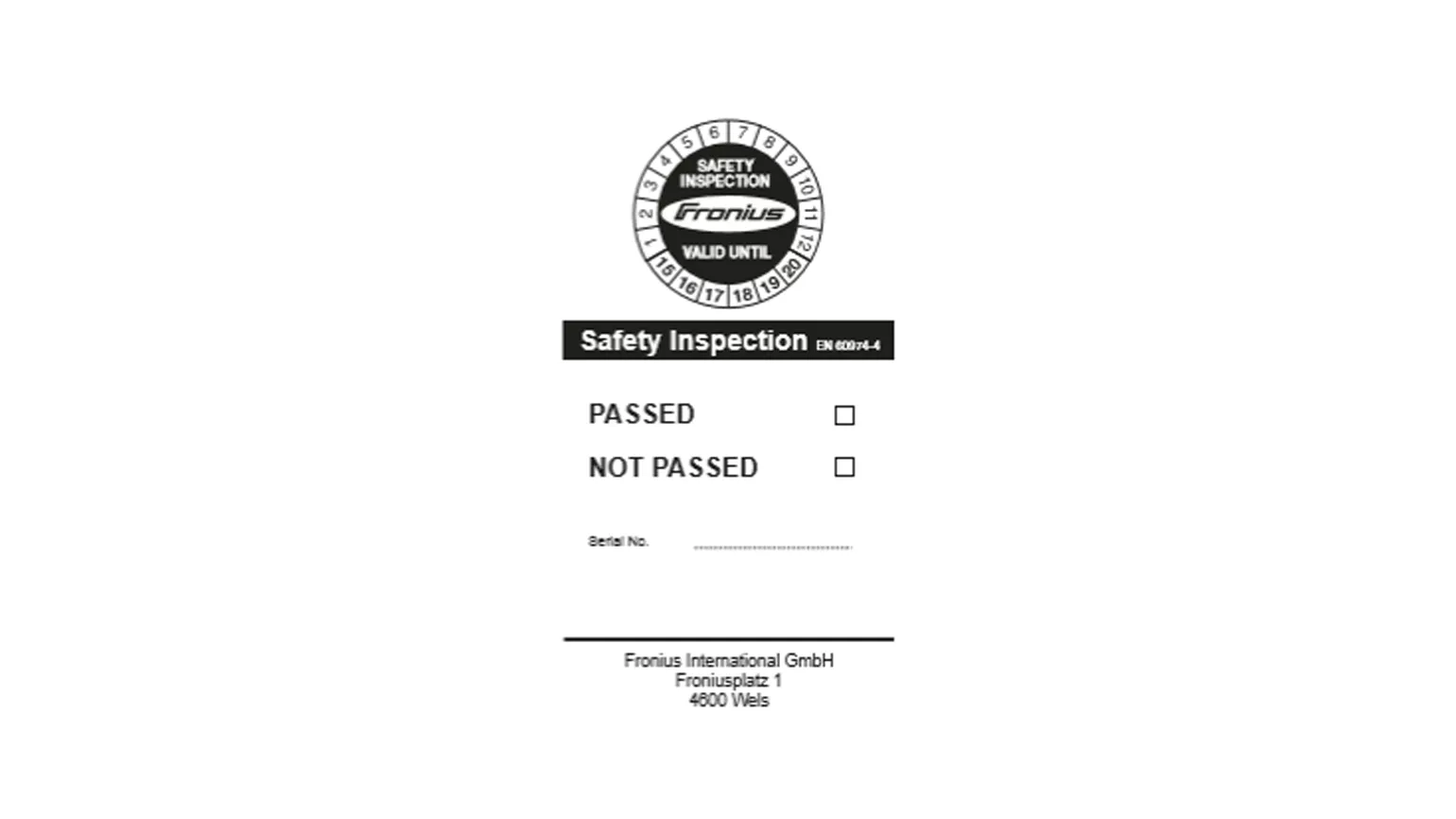

Labeling with a test label

The label is affixed to the successfully tested welding system and includes the date that the inspection was completed (month/year).

When and how often does a welding system need to be inspected?

Electrical systems must be checked by an electrician before initial commissioning and after any changes or repairs prior to the machine being operated again. Generally speaking, the equipment must also undergo repeat testing every five years. We carry out the first inspection ex works in combination with a calibration.

Downloads

Minimum interval for welding systems

Inspection scope