The Superhero of all welding processesSecure connections with tungsten inert gas welding

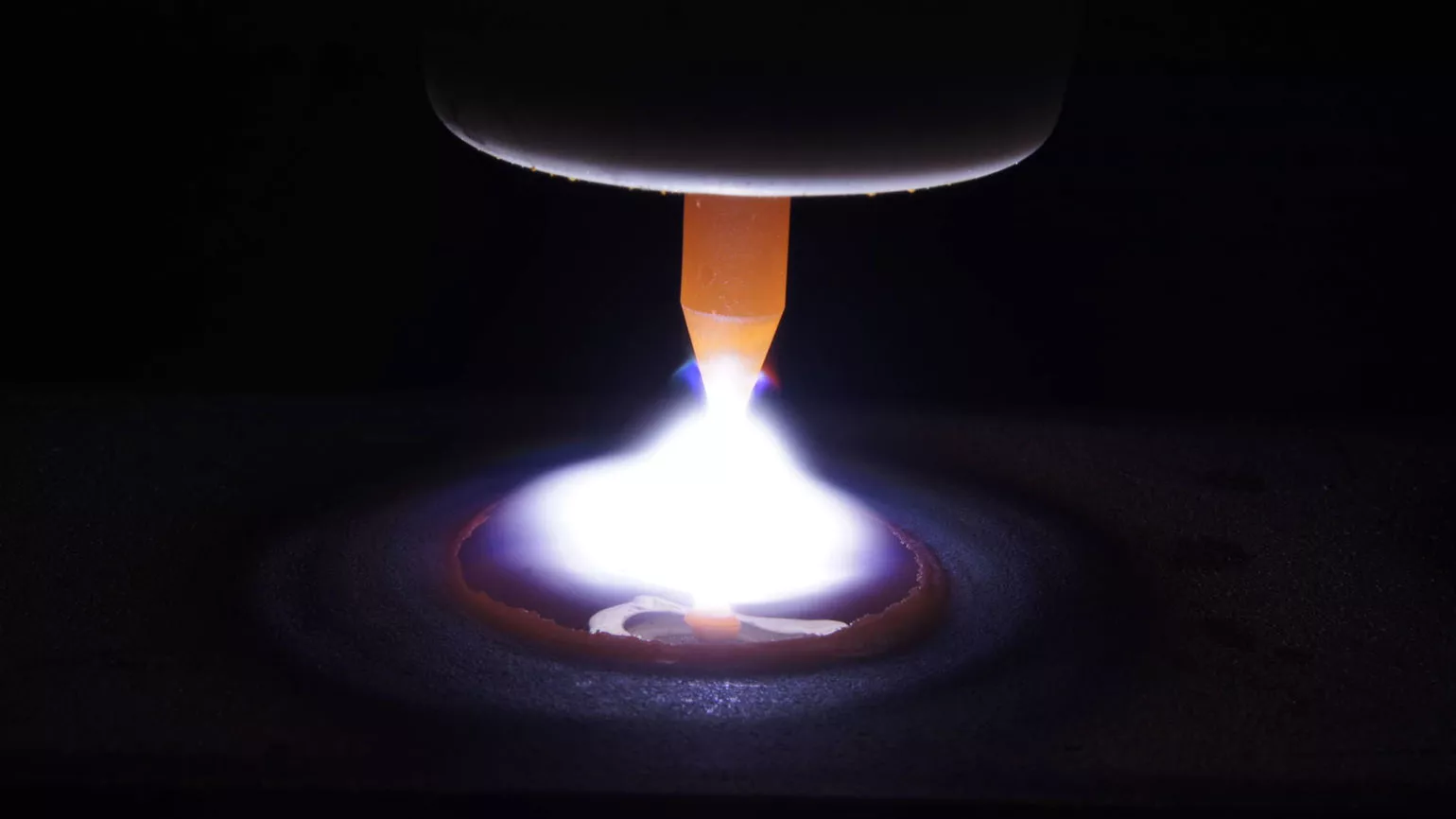

TIG welding is a process that enables top-quality weld seams. The arc burns between a non-melting tungsten electrode and the workpiece in an oxygen-free gas atmosphere. The inert shielding gas prevents chemical reactions with the liquid weld pool. This results in smooth, level, and non-porous weld seams.

FOR HYGIENIC FOOD

An example of a way the process is used is in the manufacture of food containers out of high-alloy chrome-nickel steels. No annealing colors should be visible on the tanks. These are a result of oxidation of the metal surface and contaminate the contents. In this case, the manufacturer has to stain the surface. This is harmful to the environment and very costly. It is more advantageous to keep the annealing colors as low as possible – they can be reduced to a minimum with TIG welding.

For hygiene reasons, it is also important that the weld seams are clean, smooth, and spatter-free. This is the only way that the manufacturer can ensure that the containers are corrosion resistant and easy to clean. When joining stainless steel, gas metal arc welding results in spatters and high welding reinforcement, which takes time to sand down. This is not the case with TIG welding.

SECURE EVEN UNDER HIGH PRESSURE

Even containers made of aluminum alloys have high requirements for weld seams. These include being helium-tight. Helium is light and diffuses particularly quickly when there is a leak in a container. TIG welding is one of the few processes that makes containers helium-tight.

When used in turbines for the aviation industry or power plants, the weld seams must also be X-ray safe, meaning that they do not have any pores or cracks. Gas turbines have to withstand temperatures of up to 700 °C, so they are manufactured using nickel-based alloys or titanium. With TIG, it is possible to weld these materials to be X-ray safe. Each weld seam is also X-rayed in pipeline construction for power plants. The pipelines and particularly the weld seams have to withstand high pressure. The TIG process guarantees the high quality levels necessary to keep them secure during this process.