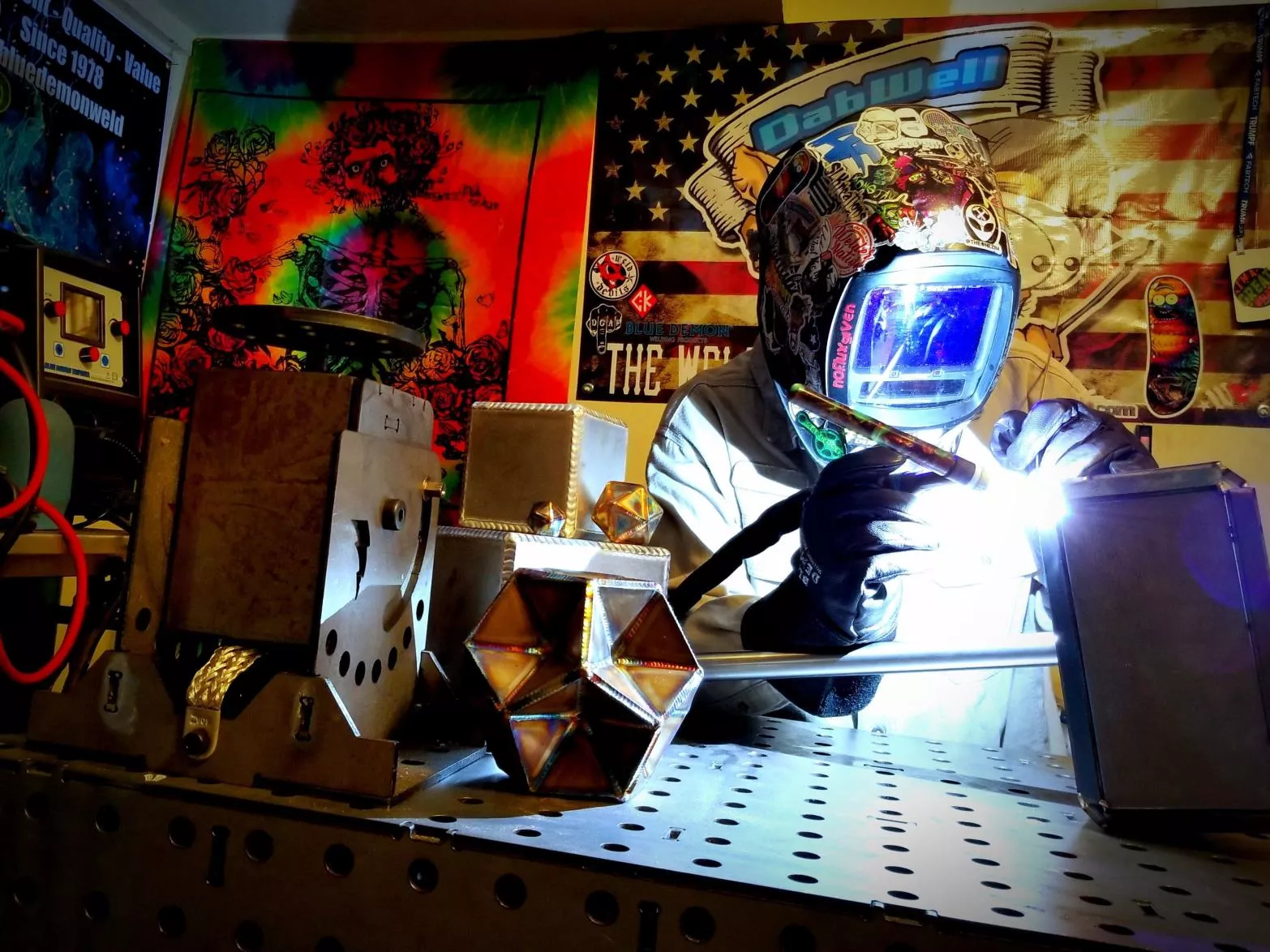

The artful welder

Sean Flottmann is a full-time production welder with two decades worth of experience. In his off hours, he is a social media influencer with more than 86,000 followers on Instagram, where he shares his unique stainless steel welded art.

How does one get to this point in their career? The answer is a whole lot of practice -and the right equipment, including a new Fronius MagicWave 230i TIG welder.

Flottmann took a winding path to learn welding. it all started when he was attending college for business management and began working in a fabrication shop as a temp. At first, Flottmann did the repair work and other jobs the experienced welders didn't want to do. He learned from anyone willing to teach him or answer his questions. Many tradesmen were more than happy to share their knowledge and appreciation of welding. The shop performed mostly TIG welding on stainless steel, which is where Flottmann's love for the alloy and the process began.

The day job

Like most young welders, he worked his way up through the ranks, honing his craft. Now, almost 20 years later, he is still welding, but he's the one sharing the tips with newer welders. TIG welding and stainless steel have their own challenges, but that's what Flottmann says keeps welding interesting. "When working with stainless," Flottmann says, "initially you have to worry about the heat input and layout. Stainless is prone to warping, and you have to walk a fine line between attaining proper fusion and burning right through the stainless finish." Flottmann walks that line daily. On the job, he welds base assemblies for conveyor systems, which require proper layout and spacing of the cross beams to support the meta lin order to get a solid weld without warping the end product. One of his favorite projects at work is welding“wash down” machines for the food packaging industry. “Some of these machines are 20 ft. long,” he begins. “I can spend 8 to 12 hours a day doing my best work to produce a nice and clean with a #4 finish. It makes the day fly by.”

The off hours

In his home shop, Flottmann’s favorite projects are what he refers to as plate artwork. The pieces are typically square often with a mirror finish or patterned with a decorative grind background. The central image is a TIG welded design or character often with a rainbow finish in the weave. These days, most of his artwork is done on commission. As he tries out new designs, he offers giveaways or raffles for the “test” pieces. A recent example includes an auction for a cobra plate on his Instagram page. Flottmann is known as Dabs Wellington on Instagram. The name is a clever play on words, referring to the adding of filler metal to the weld pool. His Instagram page showcases his artwork, welding related posts and pictures from a welder’s life, such as broken TIG cups. Beautiful rainbow welds and fancy weaves abound. He recently finished and shared photos of a colorful mandala design, which took three solid hours of welding, using a chill block to help dissipate the heat. As the chill block heats, he needs to weld faster to get the look he wants. “You get a feel for how the colors will come out in your shop,” he says. “Tiny factors, such as a breeze, can affect gas coverage and change the colors you end up with. Practice is key. I can’t guarantee which color I’ll end up with, but I can do things like add heat or go slower to get closer to the color I want.”

To continue reading: http://bit.ly/2ml4h6a

Written by Rhonda Zatezalo, published by Welding Productivity Magazine.