Cobot Welding

Eight powerful arguments for purchasing a CWC-S

- Low Total Costs of Ownership

- Cost-effective from batch size 1

- High level of flexibility for component geometries

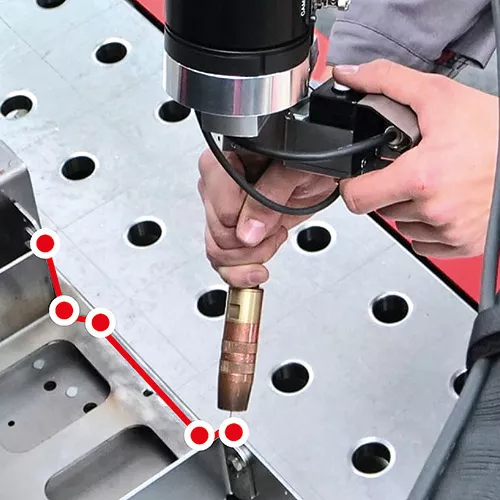

- Easy, intuitive operation

- Consistent, reproducible weld quality—hour by hour

- High-tech Welding Packages for application-optimized results

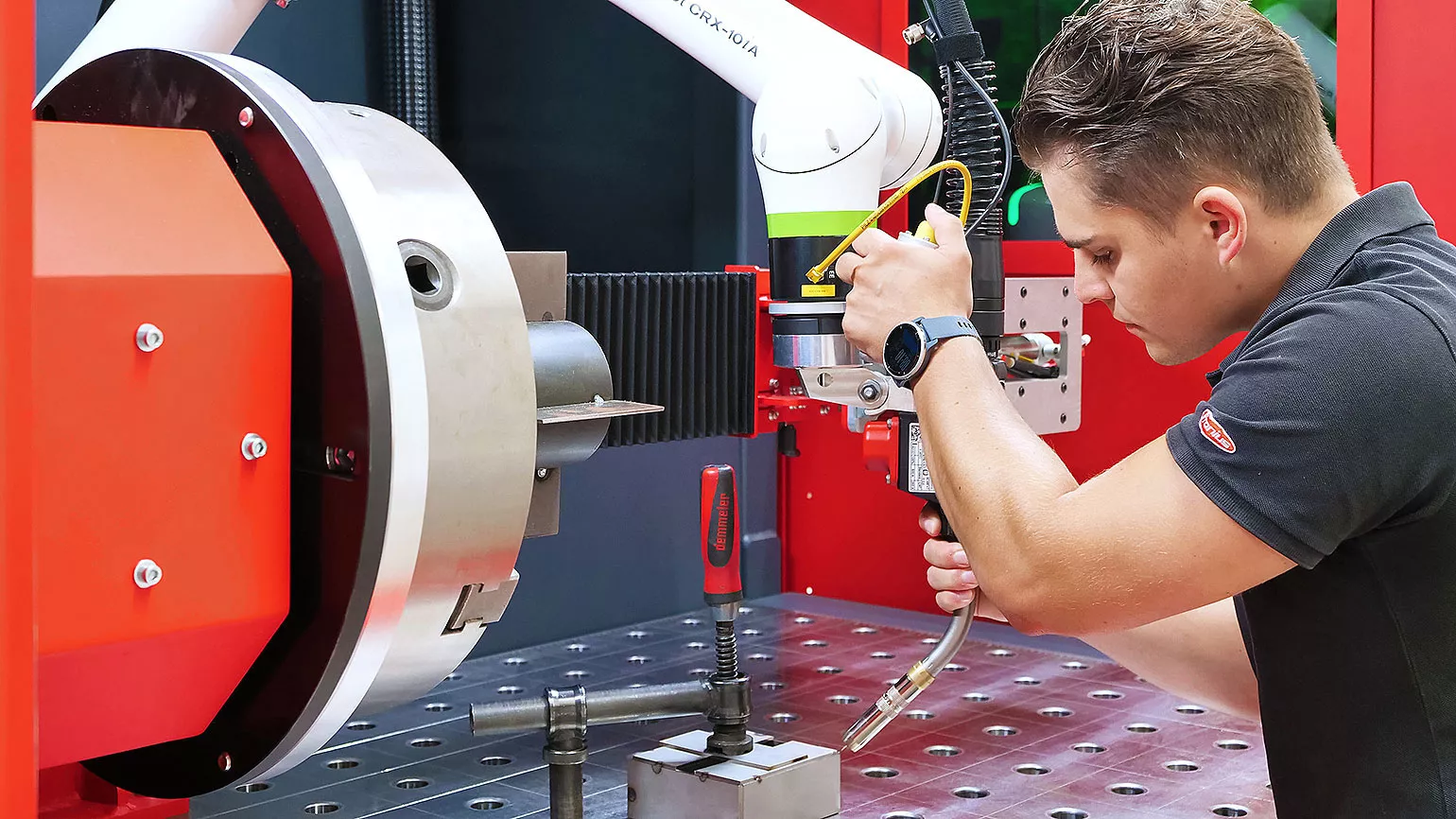

- Control of external axes possible (rotary unit)

- CE-compliant safety housing

Cobot equipment

Standard weld configuration

Welding system: Fronius TPS 320i Pulse, Welding Package Standard

Cooling unit: CU 1100i

Wirefeeder: WF 25i

Torch hosepack: MHP 700i

Torch body: MTB 400i

Easy maintenance: When performing maintenance work, the welding system can be easily lifted out of the welding cell without great effort, taking the strain off your back.

Features

Technical Data

Dimensions & weight

- L/D/H: 1680 x 2100 x 2240 mm

- Weight (standard configuration): 2500 kg

Working area (max. component size)

- Without rotary unit: 1500 x 1000 x 700 mm

- With rotary unit: L = 860 mm, Ø = 450 mm

Robot

- Fanuc CRX-10iA

- Range: 1249 mm

- Repeatability: +/- 0.04 mm

- Max. load: 10 kg