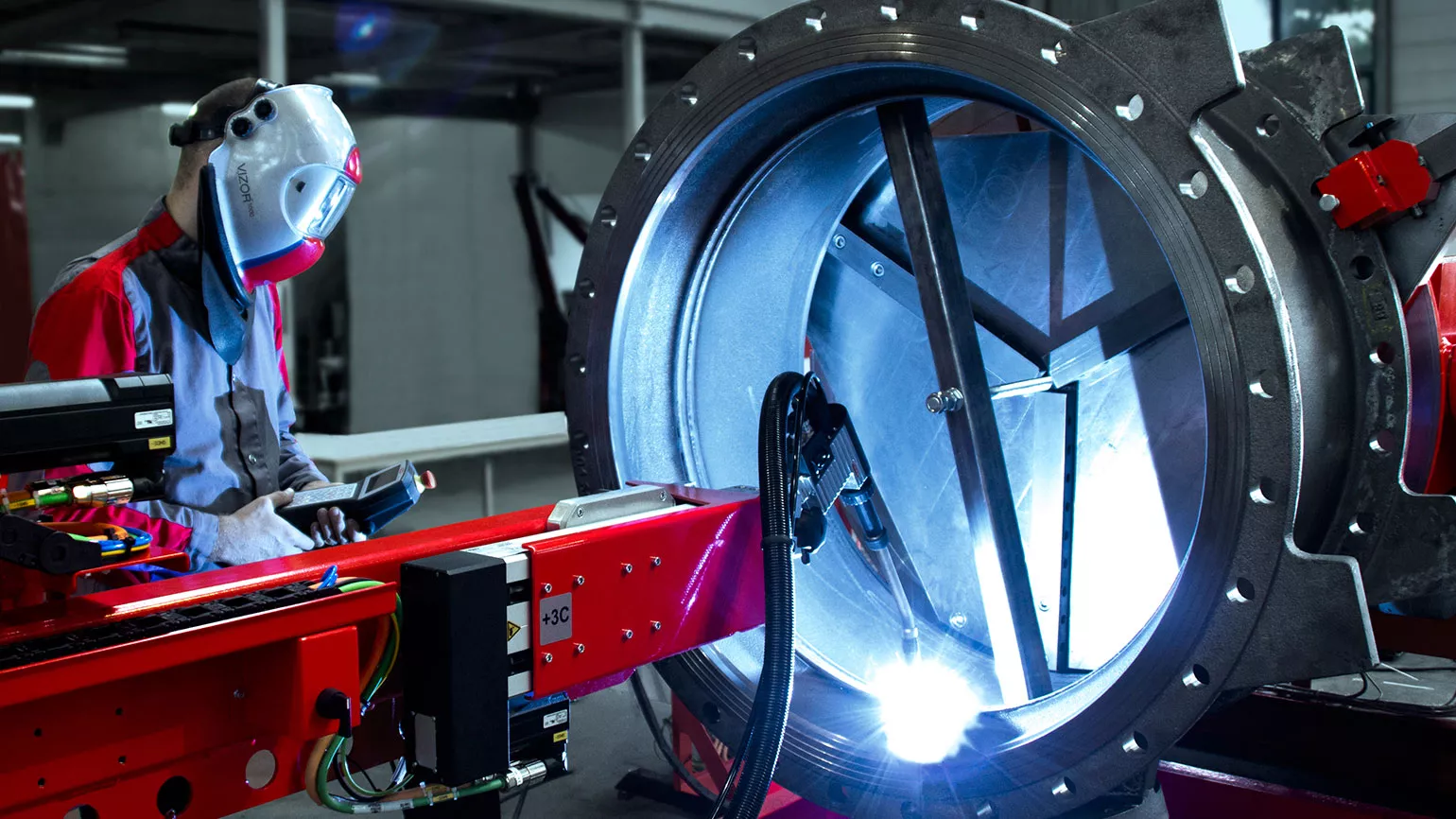

FCH 3-21 / 3-38 / 6-76 / 9-114 welding heads

Mechanised orbital welding

WELDING PROCESS: TIG

Closed welding heads for the mechanised TIG orbital welding of thin-walled pipe joints (external diameter 3 - 114 mm, wall thickness up to 3.5 mm) made of stainless steel, titanium, nickel-based alloys, aluminium and other materials without the use of filler wire.

Please choose your desired product.

Contact

Would you like to find out more about the product?

Product details

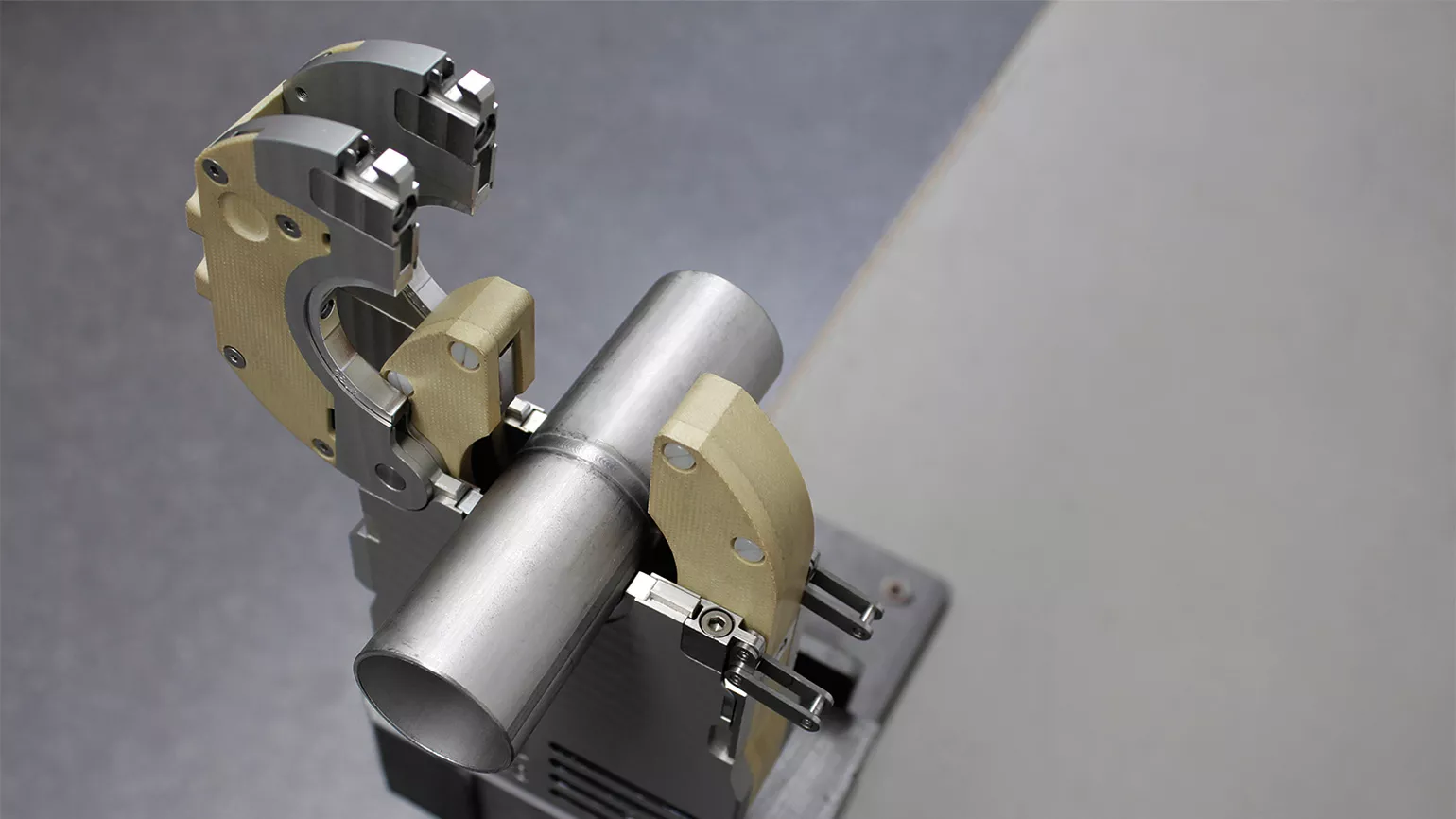

FCH welding head with component

Spot-on versatility

- FCH welding head with 8 m hosepack

- High duty cycle due to effective water cooling

- Integrated servo motor

- Automatic movement to the opening position

- Freely definable start position

- Automatic switch-off of the motor current in the event of overloading

- Compact design – optimum accessibility in confined areas

- Best possible gas shield and low level of temper colouration

- Clamping system for secure fixation and centring on the component

- Quick changeover system for clamping shells

- Highly user-friendly thanks to control buttons integrated in the handle

- Transport case with trolley function

FPA 3020 system controller

Standard equipment:

- Lightweight, compact design – ideal for portable use

- Integrated microprocessor control

- Integrated 200A, single-phase inverter power source

- Generator-compatible

- Integrated water cooling with water detector

- Integrated gas flow detector

- Intuitive touchscreen control panel with colour graphical process diagram

- Choice of languages (De/Gb/Fr/It/Es/Pb/Ru/Cz/Tr/Pl)

- Storing of programs onto USB flash drive

- Data backup onto USB flash drive

- Control of welding current, axis of rotation, forming gas and external wirefeeder

- Measuring and recording of heat input

- SynergicMode (material, pipe external diameter, wall thickness, gas, etc.)

- Auto-diagnosis system (error code display)

- Welding data documentation on USB flash drive

- USB port for data transfer/recording

- Integral printer for welding data documentation

- FRC-FPA 3020 remote control with 10 m cable

- 1 x 8 GB USB flash drive

Programming welding parameter:

- 200 programs can be stored and loaded

- Three tacking programs with up to 20 tacked spots

- Ten sectors/program with freely definable parameters

FRC-FPA 3020 remote control functions:

- Program selection

- Start/stop with slope, immediate end of welding

- Emergency Stop button

- Manual positioning of the movement units

- Manual wire feed and retract

- “On-the-fly” parameter changes during the welding cycle

- Shielding gas test button and forming gas on/off

Values displayed during the welding cycle:

- Welding current (A)

- Arc voltage (V)

- Torch position (degrees)

- Welding speed (cm/min)

FPA 3020 system controller

Standard equipment:

- Mounted on trolley

- Integrated microprocessor control

- Generator-compatible

- Integrated digital gas sensor

- Easy to program following intuitive operator guidance

- Remote support via internet connection

- Colour touchscreen with colour graphical process display

- Choice of languages (De/Gb/Fr/It/Es/Pb/Ru/Cz/Tr/Pl)

- Control of welding parameters for digital Fronius TIG power sources

- Control of axis of rotation using encoder

- Control of wirefeeder and forming gas

- Welding data recording onto USB flash drive

- SynergicMode (material, pipe external diameter, wall thickness, gas, etc.)

- Auto-diagnosis system (error code display)

- Ethernet and RS232 interface for servicing

- Storing and loading of programs onto/from USB flash drive

- Data backup onto USB flash drive

- Built-in printer prints 40 characters per line

- FRC-FPA 3030 remote control with 10 m cable

- 1 x 8 GB USB flash drive

Programming welding parameters:

- 200 programs can be stored and loaded

- Three tacking programs with up to 20 tacked spots

- Ten sectors, program with freely definable parameters

FRC-FPA 3030 remote control functions:

- Program selection

- Start/stop with slope, immediate end of welding

- Emergency Stop button

- Manual positioning of the movement units

- Manual wire feed and retract

- “On-the-fly” parameter changes during the welding cycle

- Shielding gas test button and forming gas on/off

Values displayed during the welding cycle:

- Welding current (A)

- Arc voltage (V)

- Torch position (degrees)

- Welding speed (cm/min)

- Wire speed (cm/min)

- Heat input (kJ)

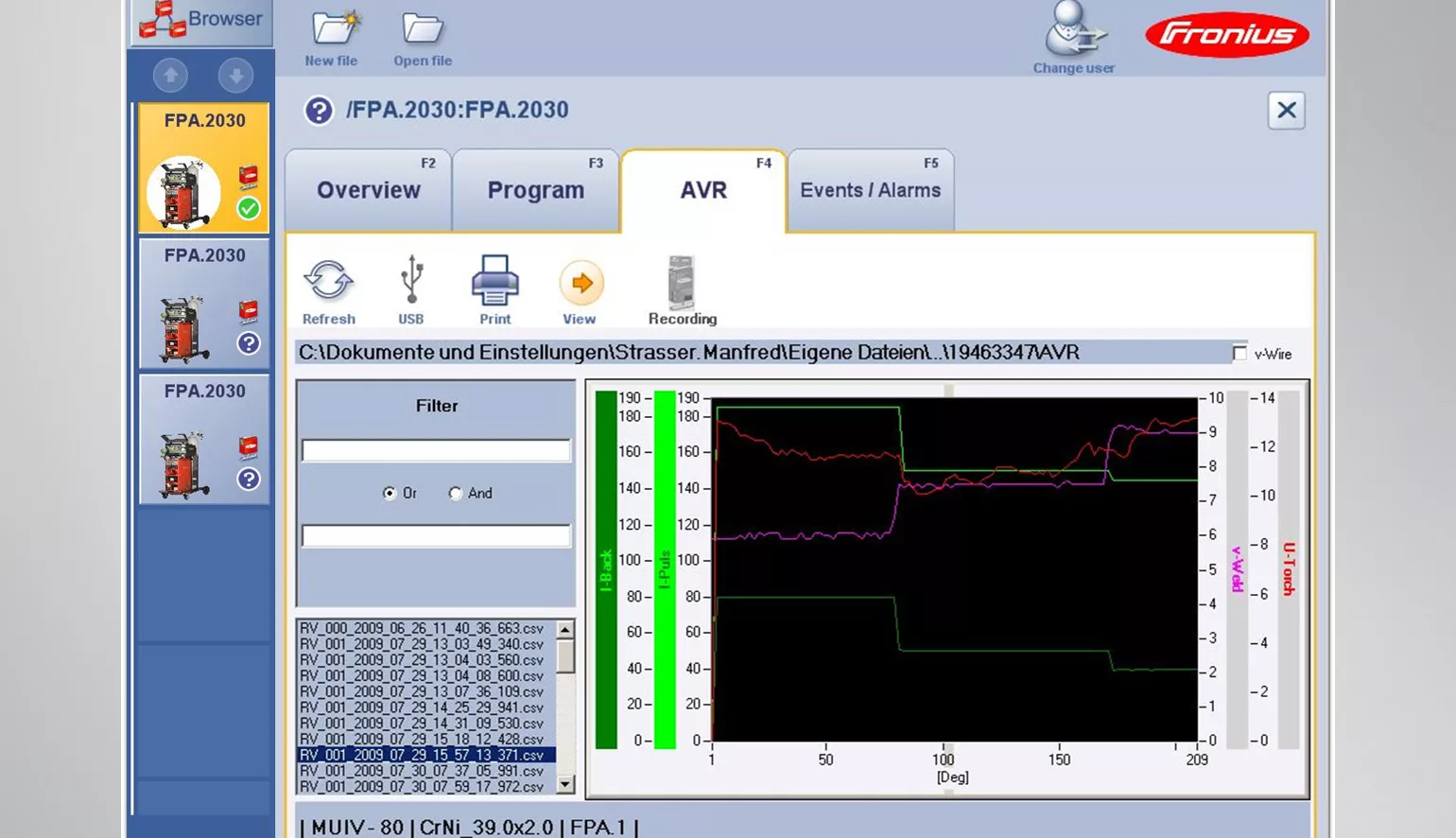

FPA Xplorer screenshot

Welding data documentation, visualisation, archiving and parameter creation on a PC

- View the properties of all managed devices

- Manage, edit and archive welding programs

- Overview of managed devices with status indicator

- AVR (Actual Value Record): visualise, evaluate and archive recorded actual values – via USB flash drive or in real time via the network connection (online version)

- Load log book data from USB flash drive or by downloading it directly from the control unit via the network connection (online version)

- Live display of alarm signals (online version)

Pipe welding with closed welding head

For FCH welding heads:

- Clamping shells for a wide variety of pipe diameters

- Customer-specific clamping shells

- Offset electrode holder (FCH 6-76/9-114 only)

- Tiltable electrode holder (FCH 6-76/9-114 only)

- FCH/FOH 10 m extension hosepack

- FPA 3020/3030 orbital system controller

For FPA 3020 system controller:

- Grounding cable, gas hose

- PickUp trolley with console and toolbox

- Pressure regulator

- Open welding heads with/without welding wire

- Hosepack extension

- Manual welding torch

- Printer paper

For FPA 3030 system controller:

- FPA Xplorer software for offline/online use (data documentation/archiving)

- Ethernet cable

- TIG power source, cooling unit, KD supply

- PickUp trolley

- Hosepack extension

- Printer paper