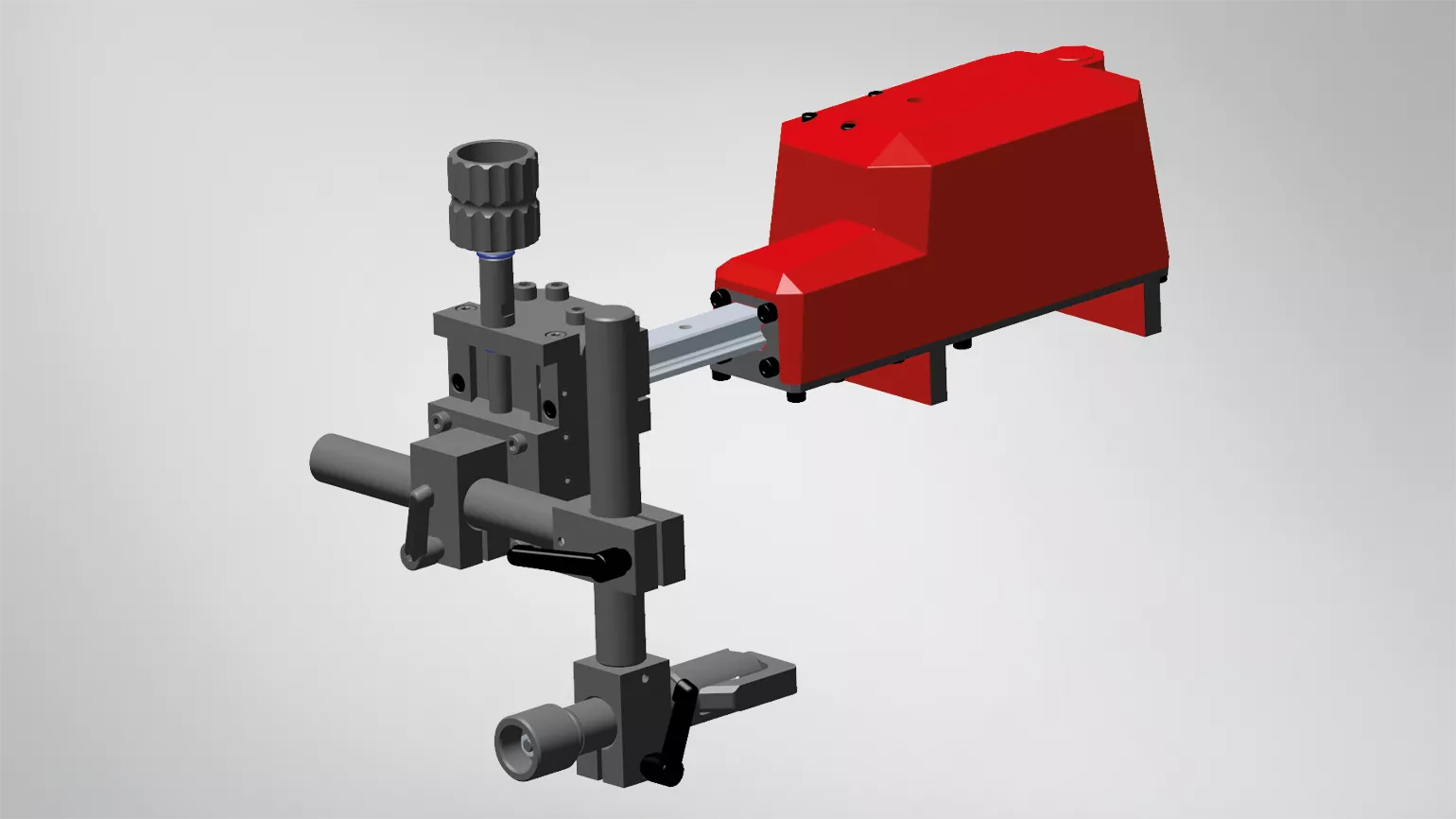

FlexTrack 45 Pro

Rail guided welding carriage for mechanised orbital welding

WELDING PROCESSES: MIG-MAG / CMT

The compact welding tractor can be used in a wide range of applications. Depending on the requirements, one of three different rail types can be selected. FlexTrack 45 Pro welding tractors are perfect for all-round use in industries where surface geometries vary, for example in shipbuilding or container construction.

Please choose your desired product.

Product details

Welding tractor FlexTrack 45 Pro, oribital welding

FLEXTRACK 45 PRO STANDS FOR:

- Flexibility for orbital and longitudinal seam applications

- Fast production processes

- Improvements in output quality

- Reduced costsIncreased competitiveness

SYSTEM HIGHLIGHTS.

- Flexibility: Modular rail concept for different welding applications on different component geometries

- Comfort: Quick and easy set-up of rails and carriage

- Precision: Precise movements and constant welding speed

- Quality: Perfect reproducibility of welding results, particularly in conjunction with TPS/i power sources

- Robustness: Compact cast aluminium housing, ideal for use under harsh conditions

MORE FLEXIBILITY + MORE QUALITY = MORE COST EFFECTIVENESS = FLEXTRACK

FRC-45 Basic remote control

FRC-45 BASIC.

- Robust housing

- Easy to operate

- Compatible with "old" FlexTrack

Equipment and functions.

- Numerical display (metric/imperial)

- Welding mode (with/without arc)

- Communication with TPS/i power sources

- Direction of travel

- Speed of travel

- Offset

- Oscillation mode, oscillation speed, oscillation path, dwell time

- End-crater filling

- Arc length monitoring (ACC - Arc Current Control)

- Segment welding of orbital and longitudinal seams

FRC-45 PRO Remote Control

FRC -45 PRO.

- Robust housing

- Easy to operate

- Compatible with "old" FlexTrack

Equipment and functions.

- Numerical touch display and function wheel

- 5 languages (DE, EN, ES, FR, PL) and further languages on request

- Welding mode (with/without arc)

- Communication with TPS/i power sources

- Adjustable power source parameters

- Direction of travel

- Speed of travel

- Offset

- Oscillation mode, oscillation speed, oscillation path, dwell time

- End crater filling

- Arc length control (ACC - Arc Current Control)

- Segment welding of orbital and longitudinal seams

Fronius Welding unit TPS/i, the intelligent revolution

AUTOMATIC COMPONENT DETECTION FOR GREATER CONVENIENCE (PLUG & WELD)

- Tool-less plug-in

- TPS/i detects all available components

- Warns of any incompatibility

Better control and analysis of the welding process (SpeedNet)

- High-speed bus for 200-times faster communication between system components

PEERLESS LOW SPATTER CONTROL (LSC) REDUCES COSTS

- Extremely low-spatter dip transfer arc process

- Including with long hosepacks

- Less rework, lower costs

MASSIVELY IMPROVED DROPLET DETACHMENT PULSE MULTI CONTROL (PMC) FOR INCREASED QUALITY

- Excellent stability and consistent penetration

- Even at high welding speeds

- Greater welding quality

- More competitiveness

SIMPLE DEVICE UPDATE

- Easy upgrades with USB flash drive or via Internet

- For new welding process, characteristics, applications, firmware updates, etc.

FUTURE-PROOF

- Upgrade functions and high-quality hardware

- State-of-the-art welding processes for years to come

CUSTOMER FRIENDLY WITH COST-SAVING REMOTE MAINTENANCE

- Remote maintenance and system Analysis via Internet

FlexTrack 45 Pro, linear oscillation

LINEAR OSCILLATION MODES.

- No oscillation, rectangular, trapezoid, triangular

FlexTrack 45 Pro, radial oscillation

RADIAL OSCILLATION MODES.

- No oscillation, rectangular, trapezoid, triangular

- The radial oscillation is used specifically for fillet welds

FlexTrack 45 Pro, ACC module

GREATER ARC CONSTANCY – PERFECT WELD SEAM.

- Automatic adjustment of the distance between the welding torch and the workpiece

- Optimum welding results– including on off-centre rails or uneven surfaces

EASE OF USE AND SAFETY.

- Compact design

- Quick and easy installation

- Spatter guard

Flexible rail ring, FlexTrack 45 Pro

FLEXIBLE GUIDE RAILS.

Can also be mounted as a ring for internal and external pipe welding. Different segment lengths (1130/1695/1884 mm) cover a wide diameter range.

Rigid rail ring, FlexTrack 45 Pro

RIGID GUIDE RAILS.

Ring with rigid aluminium profiles. The rails are connected using a hinge and catch for quick and easy set-up.

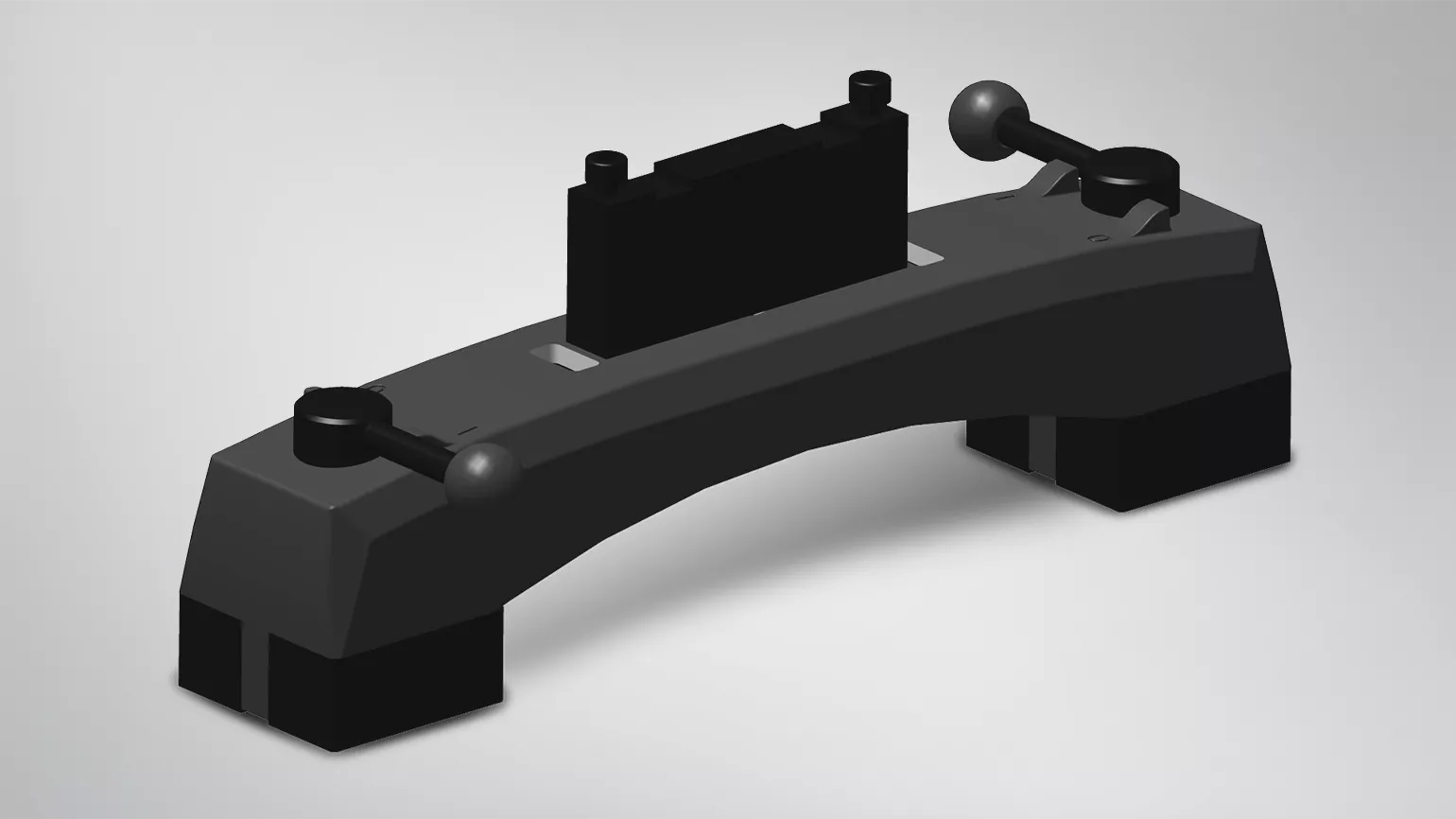

Magnetic bridge for FlexTrack 45 Pro

MAGNETIC BRIDGE.

- For magnetic components. Heat-resistant to 180 °C.

- The magnetic force is controlled by a lever.

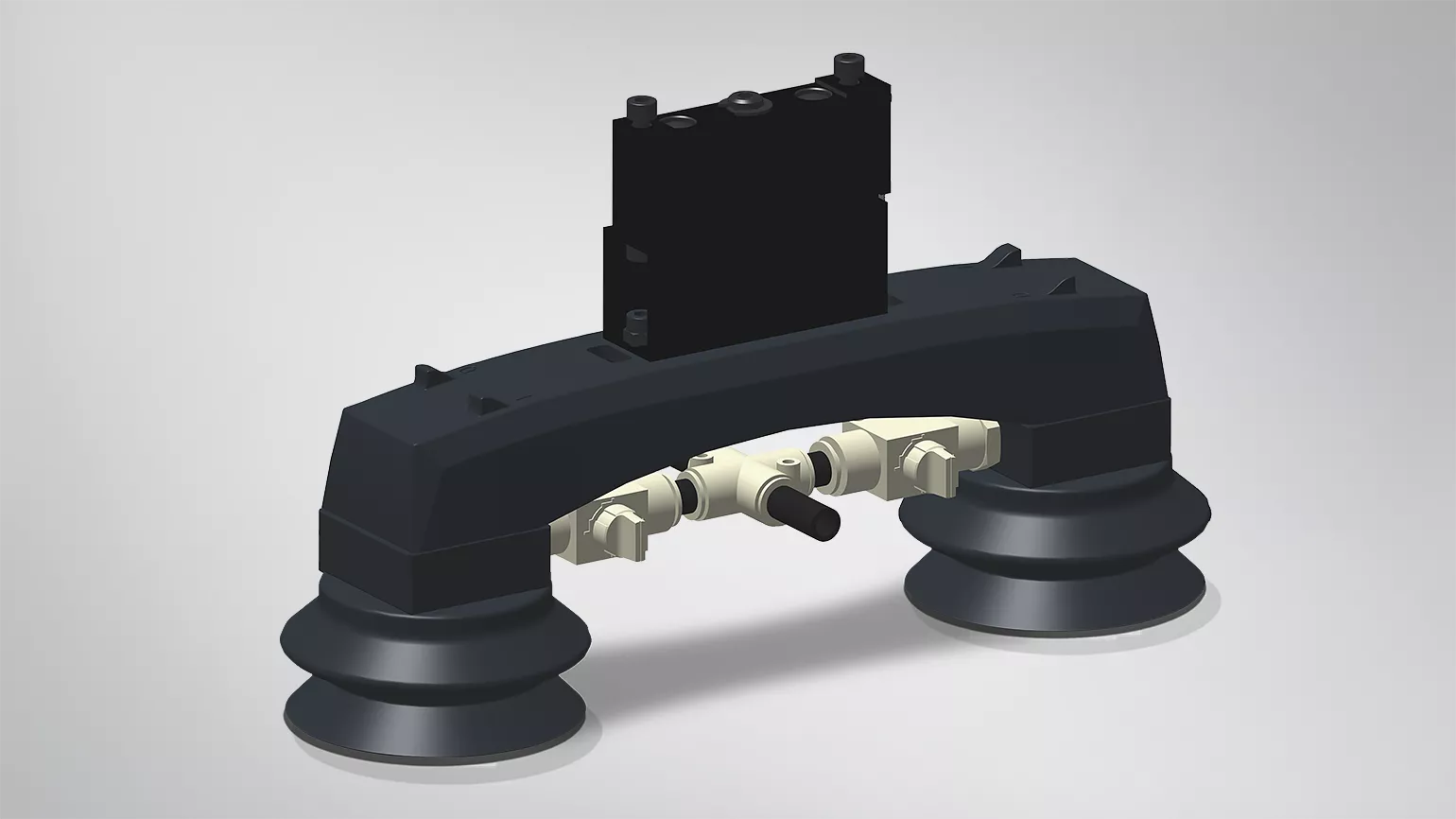

Vacuum bridge for FlexTrack 45 Pro

VACUUM BRIDGES.

- For non-magnetic components with smooth surfaces, such as aluminium or stainless steel.

- Operating temperature of 0 to 120 °C (optional from -30 to 250 °C).

Bridge with adjustable foot for FlexTrack 45 Pro

BRIDGE WITH ADJUSTABLE FOOT.

- Recommended for rigid rings up to 840 mm in diameter.

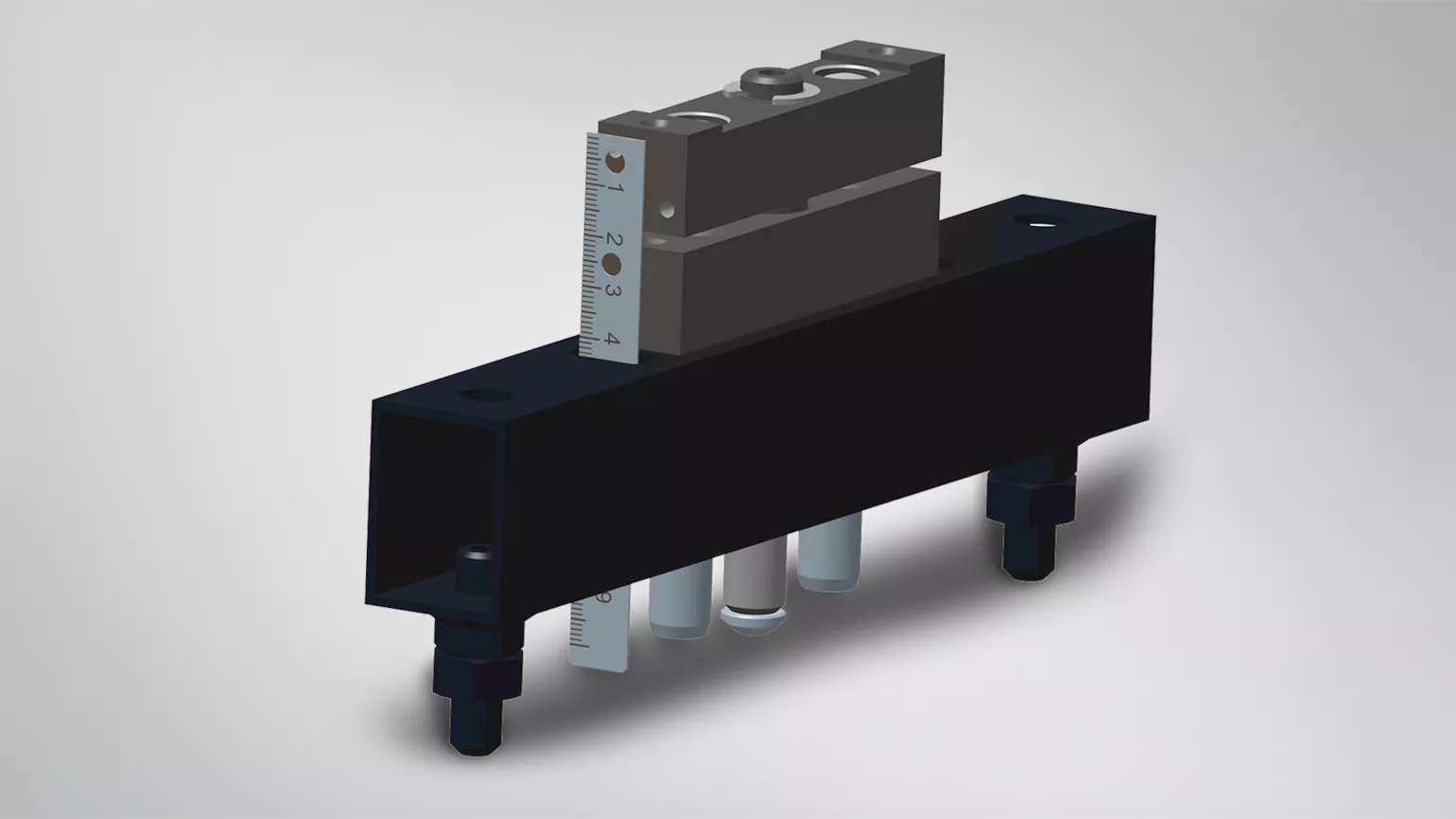

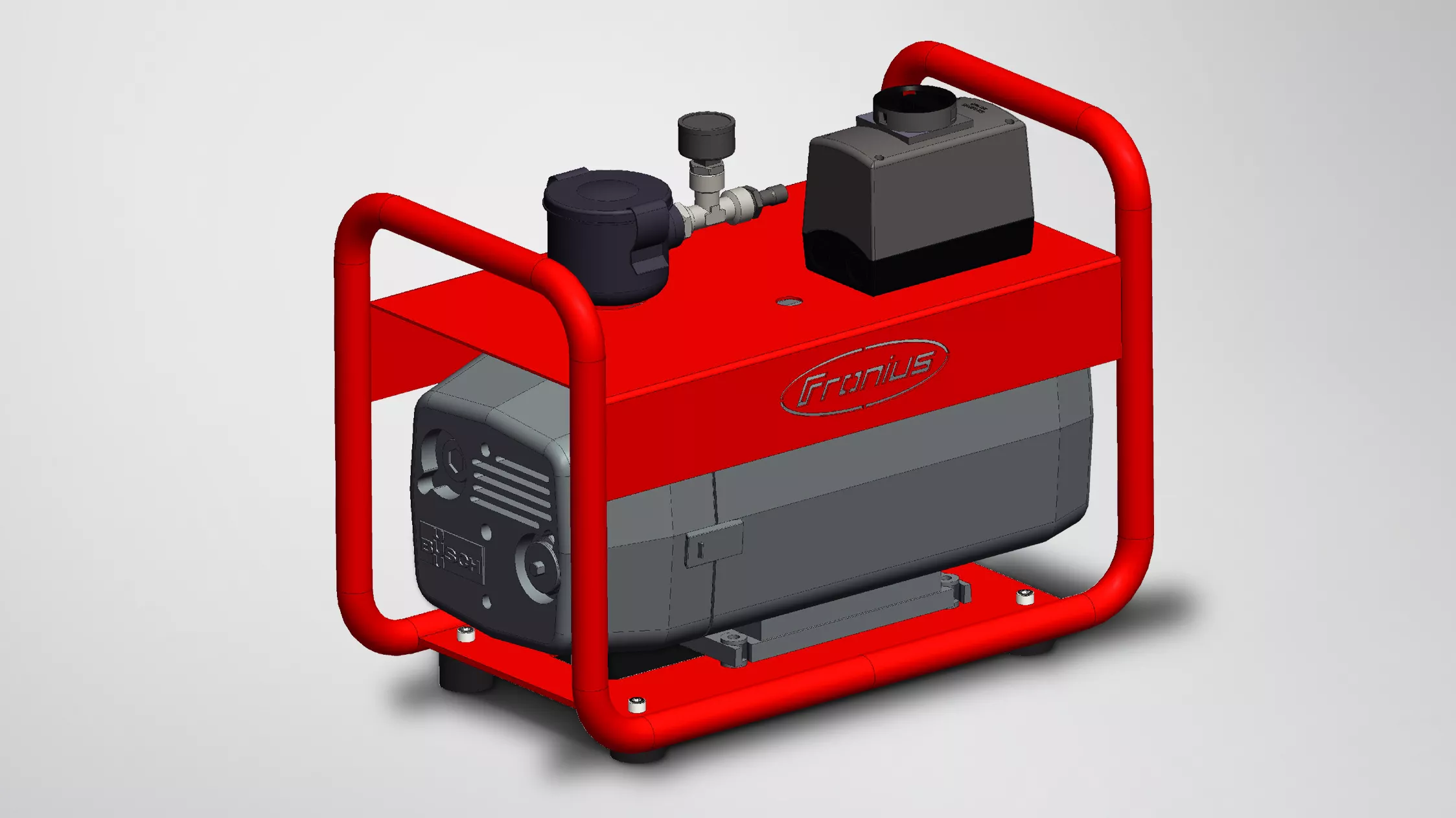

Vacuum pump for FlexTrack 45 Pro

VACUUM PUMP.

- In the case of non-magnetic materials, vacuum bridges are used to attach the guide rail. These require a suitable vacuum pump.

- Pump is integrated into robust steel tubing frame, suction power for maximum 13 vacuum bridges, suction power can be regulated with stop valves.

STANDARD EQUIPMENT.

- Dry-running, oil-free, rotary vane vacuum pump

- Portable base frame

- Direct-on-line starter

- Suction filter

- Pressure manometer

- Mains cable with plug, 5 m