Fronius Fortis

The next-gen manual MIG/MAG welding machine

MIG/MAG welding with the Fortis

As flexible as your work

Welding tasks are often a challenge, especially for small and medium-sized companies. Some of the tasks change on a daily basis, as do the required welding processes. This calls for a welding machine that can be adapted perfectly to these dynamic conditions.

With up to 240 optimized characteristics that have been specially developed for the requirements of steel construction, the Fortis series impresses with its reliable welding performance. In addition to steel, the MIG/MAG welding machine also masters materials such as aluminum and stainless steel effortlessly, especially in combination with the pulsed arc.

Highlights of the Fortis

Sophisticated device concept

The overall design of the Fortis is based on a compact system with a maximum output current of up to 500 A.

Space for the optional cooling circuit is also provided in the housing, enabling space-saving setup and use, even in environments with limited space.

In addition to the Compact version, models with an external wirefeeder are also available to extend the operating range.

The all-in-one system: one device, countless possibilities

- Compact welding machines up to 500 A

- Retrofitting of water cooling for 320, 400, 500 A versions possible at any time

- Split versions with external wirefeeder for an extended operating range

- Duo version: compact welding machines from 320 A can be combined with an additional wirefeeder

- One user interface for all versions

Fortis welding machine versions at a glance

| Fortis 270 | Fortis 320 | Fortis 400 | Fortis 500 | |

| Compact | ✔* | ✔** | ✔ | ✔ |

| Split | - | ✔ | ✔ | ✔ |

| Duo | - | ✔*** | ✔ | ✔ |

| Gas-cooled | ✔ | ✔ | ✔ | ✔ |

| Water-cooled | - | ✔ | ✔ | ✔ |

| 400 V | ✔ | ✔ | ✔ | ✔ |

| XT 200-600 V | ✔ | ✔ | ✔ | ✔ |

| 600 V | - | - | ✔ | ✔ |

* Fortis 270 only available in low housing;

** Fortis 320 all-in-one available in low (gas-cooled only) and high housing (optional water cooling or ToolBox);

*** Duo configuration only possible in high housings

Fortis Duo and Fortis XT

Duo option: Fortis 320-500 C

The Fortis Duo option combines a compact welding machine from 320 to 500 A with an additional, external wirefeeder. Software activation is also required.

Advantages

- Maximum flexibility for frequently changing applications or wire diameters

- Two different materials can be processed

- Less space required (2-in-1 solution) and lower purchase costs

- Faster process changes (switching via welding torch button)

- Ideal for small and medium-sized companies with frequently changing welding tasks

XT version: Fortis 270-500

A true all-rounder. XT stands for Extended, as the Fortis Extended version is designed for mains voltages from 200 to 600 V and can therefore be used around the world. Depending on the power category and the mains fuse, up to 320 A is possible in single-phase operation.

Special features of the XT version

- Available in all power categories (270-500 A)

- Can be used worldwide

- Single-phase operation up to max. 320 A (depending on mains fuse available)

- Full generator compatibility

- Optimized welding performance due to higher output characteristic

- Energy savings of up to 16% compared with the standard version

The MIG/MAG welding functions

Welding Packages and software options

Standard

The Fortis Standard package allows you to weld all common materials reliably and efficiently across the entire power range, from root passes and thin sheets to thicker sheets.

Pulse

The Fortis Pulse package uses the pulsed arc for clean and efficient welding. It ensures minimal spattering and flexibility on thin to thick sheets.

Pulse/Standard

The best of both worlds at a set price.

Software options

- Duo: For Fortis 320, 400, and 500 Compact

- Jobs: For all Fortis power categories

- Documentation: For all Fortis power categories

- Trial: Available for all Fortis devices ex works for 10 h arc time

- Pulse/Standard Mix: Ideal for vertical-up seams

MIG/MAG, TIG, and MMA welding

TIG pulse welding

Pulse welding is used primarily for welding in tight spaces or for welding particularly thin materials. The result is an improved seam appearance.

Touchdown ignition

As an alternative to high frequency ignition, highly accurate touchdown ignition helps to improve user-friendliness. In addition, there are no restrictions in terms of the area of application.

TAC tacking function

Pulse currents are used to make the weld pool oscillate. This makes it easier to tack components together and reduces tacking time. The pulsed arc optimizes the process on very thin materials.

HotStart

The HotStart function was specially developed for welding with rutile and cellulose electrodes. In order to make the electrode easier to ignite, the current is increased for a split second during ignition on the welding machine.

Anti-stick

If a short circuit occurs (electrode sticks during electrode welding), the welding process is interrupted. This prevents electrode burn-out and/or serious weld defects.

Dynamic

If basic electrodes are welded with coarse droplet material transfer at a low current (underloaded), there is a danger of sticking. When the arc-force dynamic is set accordingly, the electrode burns freely, preventing sticking.

CEL (XT versions only)

When using cellulose electrodes (CEL), a specially selectable operating mode ensures perfect welding results.

Operating the Fortis welding machine

Simple, clear, customizable

The display is divided into three segments and is operated using the three rotary and push buttons below it. These can be used to adjust the main parameters and two custom parameters.

All important working and welding parameters are also visible on the first menu level. Dynamic visualizations, animations, and the status LED provide additional support for the user.

Intuitive menu navigation

Welding parameter wizard

This reduce errors, rejects, and rework while significantly increasing efficiency and quality.

The welding parameter wizard is indispensable, especially for tasks with constantly changing variables. The self-explanatory graphics make it easier to understand the settings so that even complex tasks can be mastered with ease.

Further highlights

Wireless accessories

Maximum connectivity

WeldCube Navigator

The WeldCube Navigator helps to standardize manufacturing processes, avoid errors, and increase production quality.

Welders are visually guided through the job at the workplace and predefined parameters are set automatically. In the event of an error, alarm messages or the locking of the welding system prevent rejects and rework.

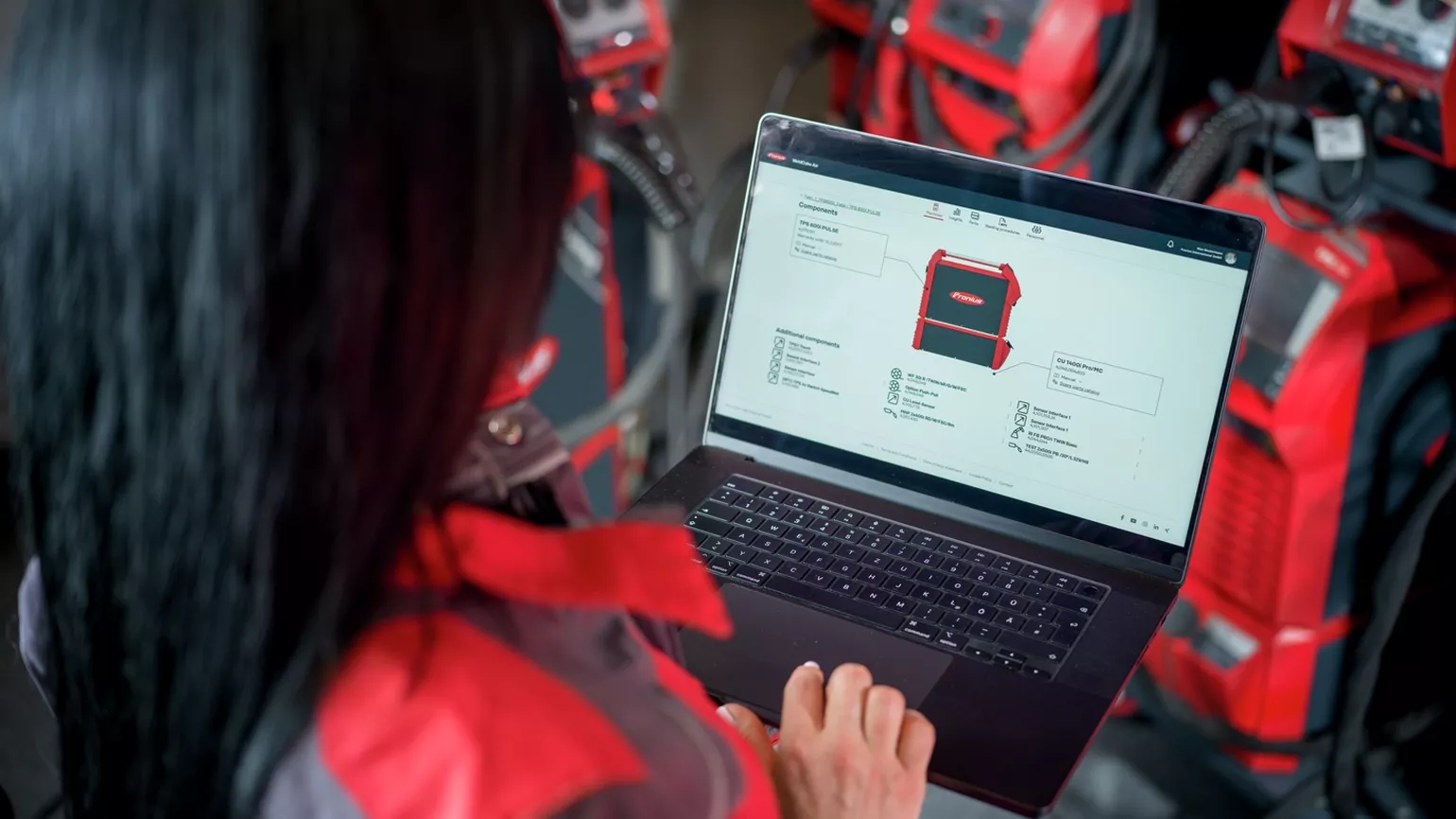

WeldCube Air

WeldCube Air is the cloud-based software solution for companies of all sizes. Users not only have the option of managing their welding machines connected via the Internet, but also receive an overview of welding procedure specifications, qualifications, and the most important welding key figures.

All this makes WeldCube Air the perfect companion to help welding companies go digital.

WeldCube Premium

WeldCube Premium is the ideal tool for ensuring your production processes are stable and verifiable. Welding equipment management simplifies the efficient management of multiple welding systems and the monitoring of welding parameters.

Component documentation and analysis functions increase the efficiency and quality of your welding operations. The number one solution for industrial welding companies.

Accessories

Minimize welding errors

The clear user interface and welding parameter wizard in particular assist the welder throughout the entire welding process. This minimizes errors and improves the welding quality, reducing the reject rate.

Recycle instead of disposal

Thanks to the new housing concept, a significant proportion of the plastic components have been replaced by recyclable aluminum. As a result, we have increased the proportion of recyclable material to a total of 53%. The majority of the components can therefore be recycled and help to conserve natural resources.

Fix it, don’t pitch it

The easy accessibility of the components, especially the mains cable and connection panel, makes repairs quick and easy, which minimizes downtime. The high proportion of replaceable components also enables the devices to be used for a long time.

Save electricity with the XT version

The Fortis XT version is perfect for anyone who wants to save even more power. It boasts a higher power factor, making it 16% more energy-efficient than conventional versions.

FAQs: Fortis versus TransSteel

“Trans…” (derived from transistor) has been a part of our naming system for over 40 years. We are now setting new standards by renaming the successor generation of the TransSteel as Fortis. The name Fortis stands for strength, stamina, and flexibility.

We are presenting the Fortis in a completely new industrial design for the very first time. Our development work on the new housing centered on welding specialists and their needs, so user-friendliness and improved ergonomics were the key focus for us.

You can also see a major change from the outside: the new design highlights the durability of the Fortis in conjunction with a streamlined look. The color layout has been completely changed, further enhancing the devices’ visual profile and making them easier to recognize.

- Compact device design in 400/500 A power category

- XT versions in all power categories

- Plain text display with wizard and dynamic visualizations in over 30 languages

- Multiprocess also available for 400/500 A power categories (only for compact devices)

- Duo configuration available for 320-500 A power categories

- Connectivity as standard (WiFi and Bluetooth as standard, NFC optional)

- Welding Packages and software options

- New system components (wirefeeders, trolleys, remote controls, and more) and new manual welding torches

“XT” stands for “extended”. The XT versions offer an extended range of functions and were so named due to the repositioning of these models on the market. These functions include:

- 200-600 V continuous input voltage range (-10 / +6 %)

- Full generator compatibility

- Energy-saving due to the higher power factor compared to the 3-x-400 V version

“s” stands for “smart and steel”— smart operation and smart welding with a focus on steel applications, a particular strength of the Fortis. Of course, the Fortis can handle many other materials.

Our new series is a technical innovation, so existing TransSteel components are not compatible with the new Fortis.

New components and hardware interfaces are also available with the new design. With regard to welding torches, all FSC welding torches can be used through to the U/D functionality. Poti, JobMaster, and PullMig do not work with the Fortis.