Robotics Change Stations

Fully Automated Contact Tip and Torch Body Changeover

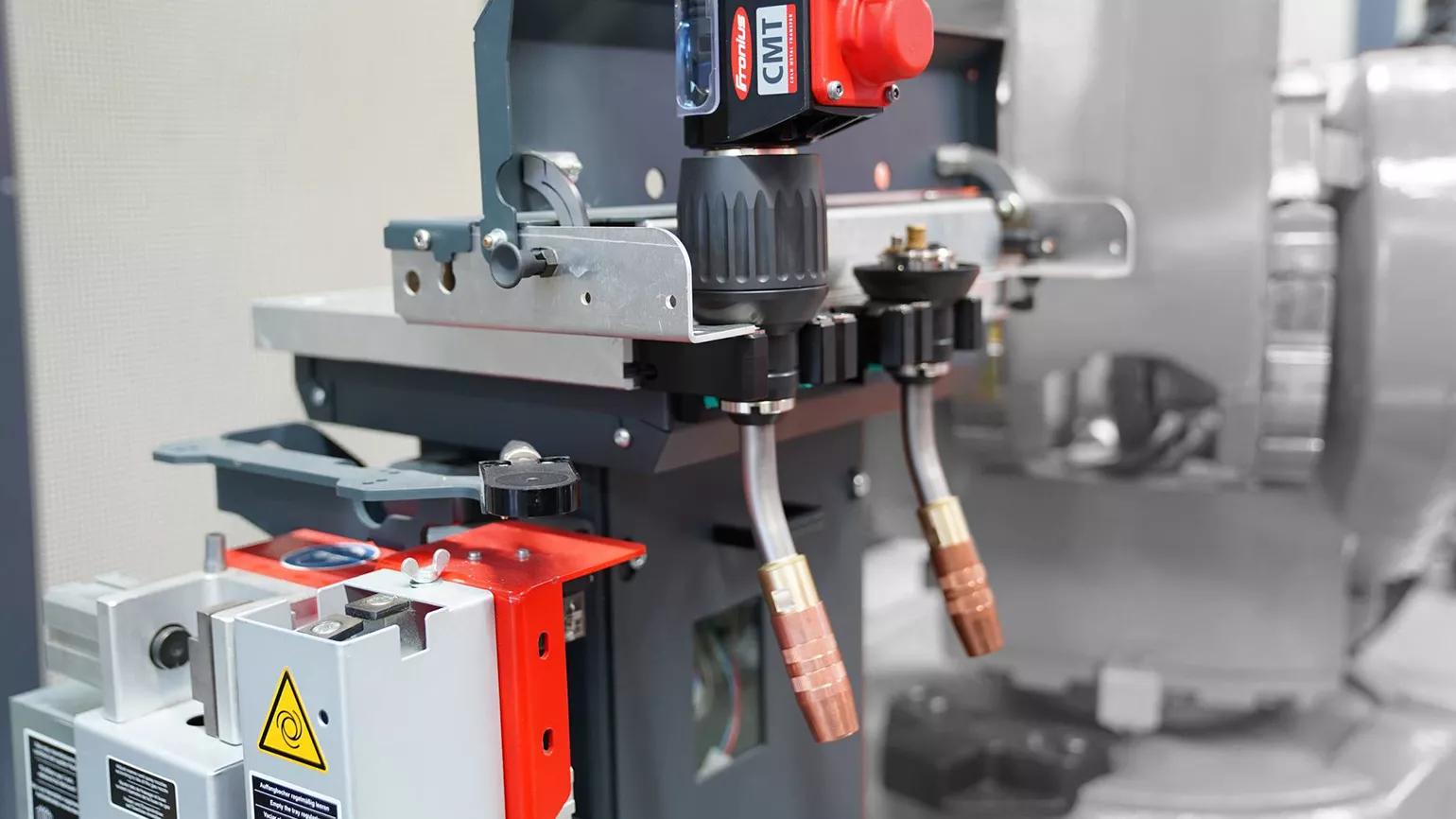

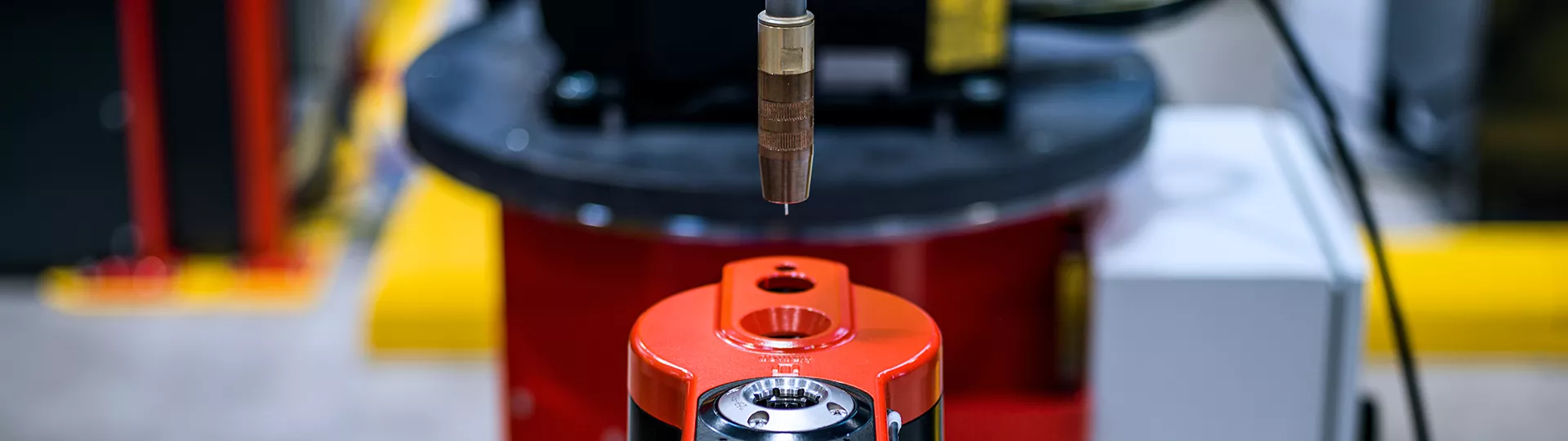

Robacta CTC – Contact tip changer

Changing station for contact tips

Automatic contact tip changeover in just 50 seconds.

Changing the contact tip manually is time-consuming and necessitates an interruption to production. The Robacta CTC automates this work step. Changing the tip takes no more than 50 seconds - without production being halted for someone to intervene.

Pre-defined torques also reduce the risk of operating errors by maintenance personnel, thus extending the service life of the equipment.

Advantages of Robacta CTC

Optimization of production costs

- Higher productivity due to reduced robot downtime

- Defined torques mean operating errors are less likely

- Defined contact tip service life: change cycle can be adapted to contact tip wear

Faster contact tip changeover

- Contact tip changeover up to 10x faster

- No interruption to production

- 10 contact tips can be changed without human intervention

Rapid payback

- Pays for itself within 6-24 months when used in three-shift operation

- Reduces demands on the time of maintenance personnel

Check your savings as well as the payback period with our payback calculator.

Robacta CTC versions

Depending on the diameter of the contact tip and gas nozzle, there are corresponding versions of Robacta CTC:

- Contact tip M6 ø8 / Gas nozzle ø25

- Contact tip M6 ø8 / Gas nozzle ø27

- Contact tip M8x1.5 ø10 / Gas nozzle ø25

- Contact tip M8x1,5 ø10 / Gas nozzle ø27

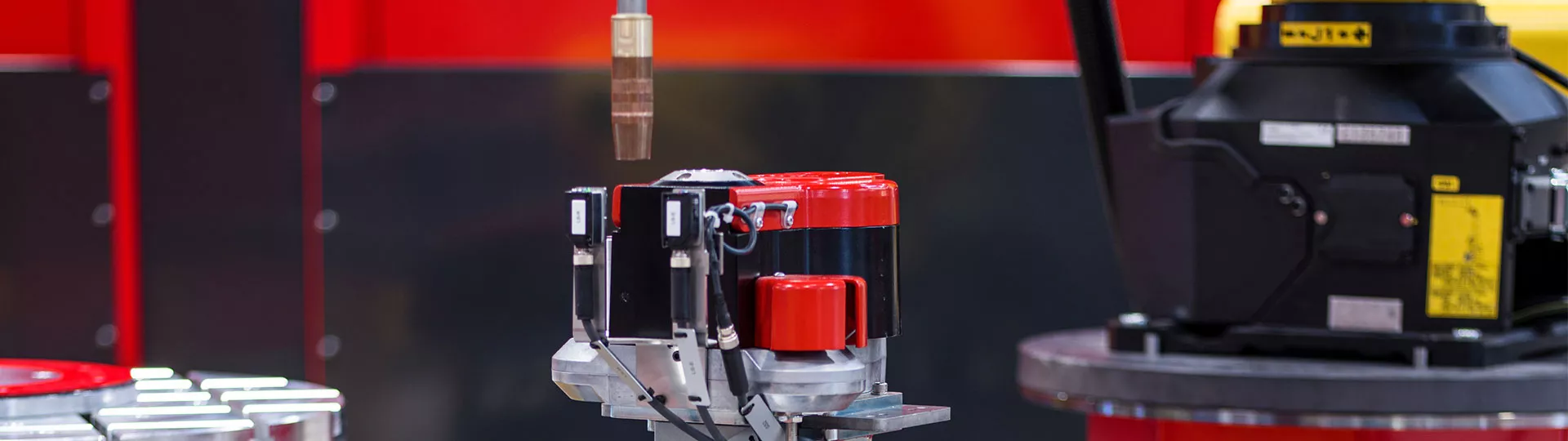

Robacta TX/i – Torch exchange

Changing station for torch body

Automatic torch body changeover in just 30 seconds.

The complete torch body is changed automatically without the need for human intervention while production continues. This ensures that all wearing parts that impact on the TCP and weld seam quality are replaced.

When the Robacta TX/i is used, different torch body geometries can be applied alternately - in one robot cell. Depending on the application, a whole welding cell can be saved.

Advantages of Robacta TX/i

Faster than manual changeover

- Torch body incl. all wearing parts changed in just 30 seconds, thus up to 13x faster than a manual change

- Greater output due to reduced robot downtime

- 10 torch bodies can be changed without manual intervention

High weld seam quality

- Avoid worn out contact tips that would impact on the TCP or cause welding faults

- No contamination on wearing parts to negatively affect the gas shield

Optimization of investment costs

- Make savings through multiple robot cell use

- Different parts can be welded in one robot cell

- Complete welding tasks on a part with just one robot