What Is

Resistance Spot Welding?

Resistance Spot Welding: Spot-By-Spot for the Perfect Welding Result

Resistance spot welding has been used in industrial production since around 1930 in order to join together sheets made of different combinations of metals. Applications are mainly in the automotive industry in bodywork and vehicle construction, but are also found in other areas of sheet metal processing. The electrical industry uses resistance spot welding to produce contact sets for relays, connections of coils or capacitors. With certain restrictions, it is also possible to join materials that are otherwise not well suited to welding.

Resistance Spot Welding: This Is How It Works

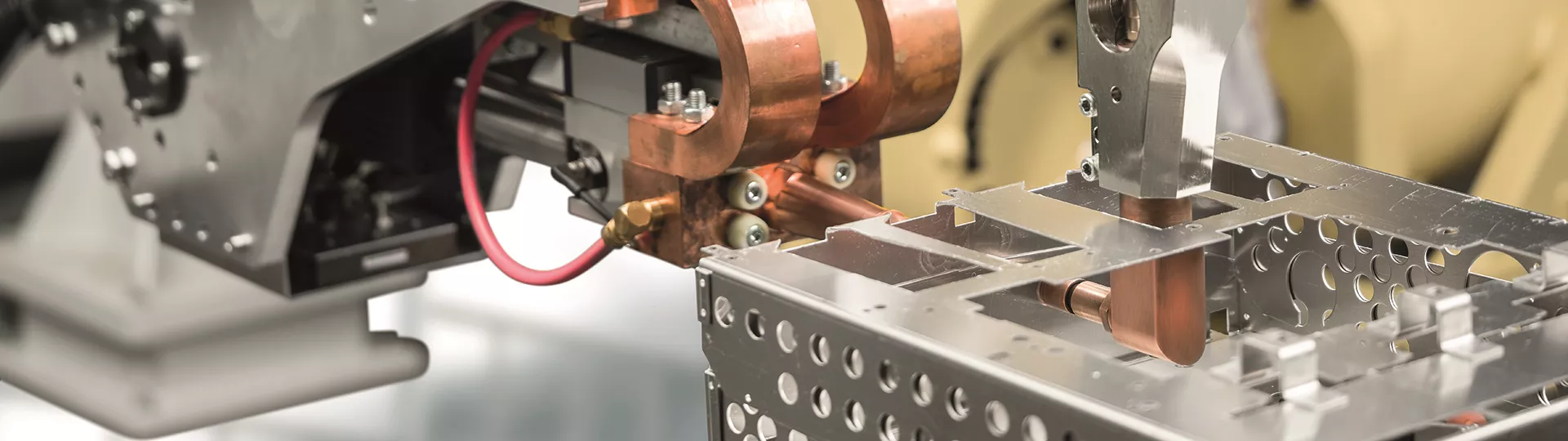

Resistance spot welding is an energy-efficient and productive welding process, in which no shielding gas needs to be supplied. The two parts that need to be connected are positioned precisely on top of each other. Two electrodes press the workpieces together mechanically and fix them in place. A high voltage then generates a current flow between the two electrodes. The workpieces provide resistance here. This means that the metal heats up a lot and liquefies in selected spots. Due to the mechanical pressure of the electrodes, the two workpieces fuse together and are inextricably joined together after cooling.

Efficient Spot Welding with DeltaSpot

Resistance Spot Welding Without Cap Milling

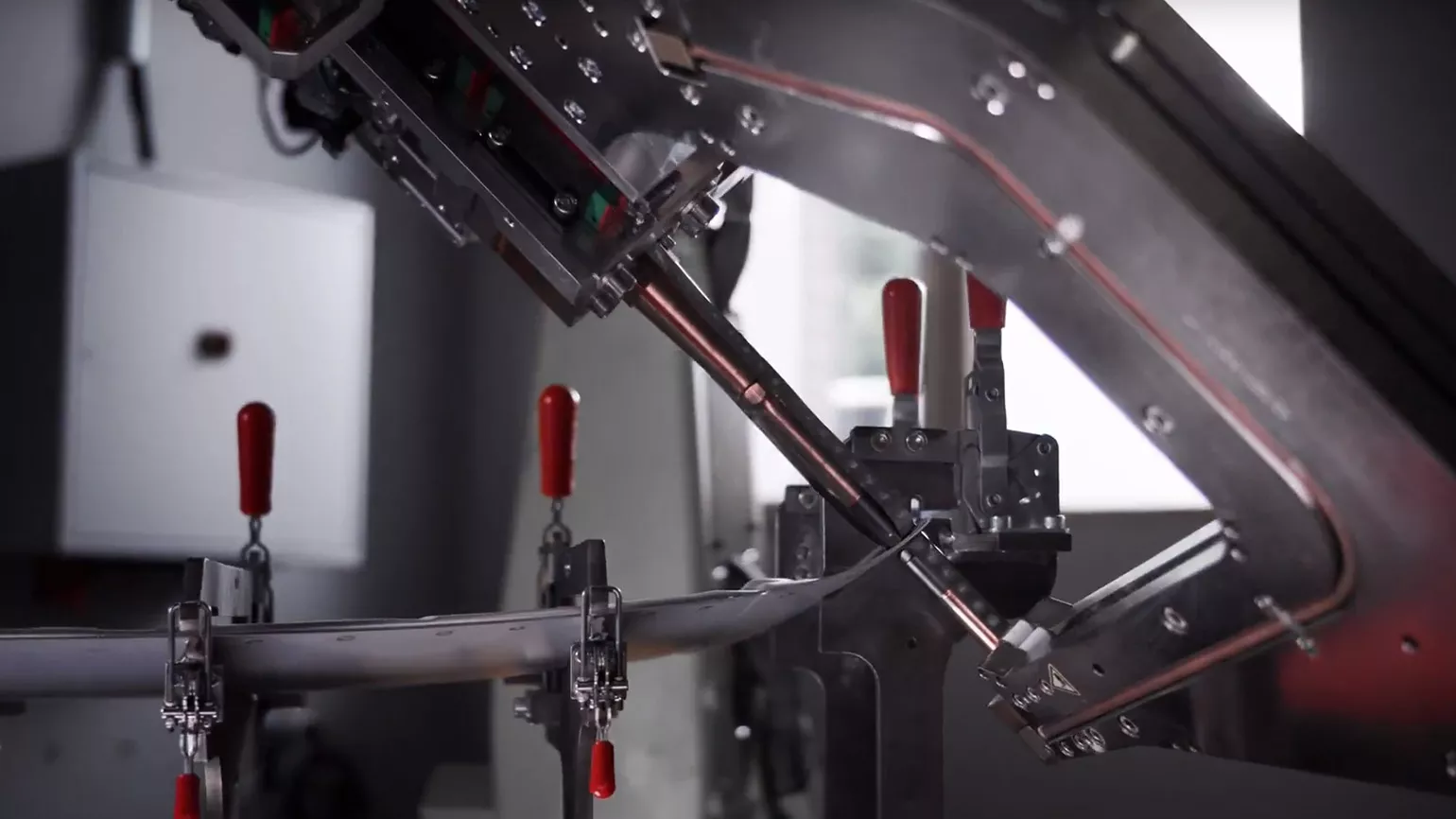

DeltaSpot is an innovative resistance spot welding process for aluminum, steel and other materials. Its most distinctive feature is the revolving process tape, which is located between the electrodes and the sheets to be joined. The constant movement of the tape results in a continuous welding process of consistently high quality.

With DeltaSpot, welding results are precise and 100% reproducible. The process tape transfers the welding current and protects the electrodes’ contact surfaces against contamination by aluminum, zinc or organic residues. This means that there is no need for laborious cap milling on the electrodes.

What Materials Are Suitable for Resistance Spot Welding?

Resistance spot welding is mainly used in the bodywork area of the automotive industry, but also in sheet processing production for joining sheet metals. Special applications can also be found in the electrical industry and electronics production, e.g. in the production of capacitors, contact sets for relays and circuit breakers. It is possible to weld a wide range of metals and metal combinations. With certain restrictions, it is also possible to join materials that otherwise cannot be welded.