Can cobots attract more young talent to welding?

Times have changed and welding is increasingly becoming a high-tech profession. As well as increasing productivity in commercial and industrial enterprises, welding automation will counteract the growing shortage of skilled workers and make the profession cleaner, safer, and more appealing. The career ladder for welders is now high and ranges from a welding specialist to an International Welding Engineer (IWE).

The major advantages of cobot welding systems

Even the best welding professionals can’t produce

welds around the clock with a consistent level of quality. Cobots, on the other

hand, master this task with ease, and guarantee 100% reproducible, identical

welds. Equipped with our advanced welding machines, such as the TPS 400i CMT or

the Multiprocess iWave 400i AC/DC CMT, a wide range of metals can be welded,

including steel, stainless steel, aluminum, copper, and titanium. Innovative

Welding Packages, such as “Low Spatter Control” (LSC), “Pulse Multi Control”

(PMC), or the world-famous “Cold Metal Transfer” (CMT) can also be used.

The LSC function produces a modified, low-spatter dip transfer arc with an increased deposition rate. PMC offers an optimized pulsed arc, with stabilizers for penetration and arc length ensuring the best welding quality and high welding speeds. CMT combines a new type of droplet detachment with a reversing wire motion, whereby the heat input is lower than with a conventional dip transfer arc. This makes the process particularly suitable for thin sheet welding.

“One of the major advantages of cobot welding systems, especially the Fronius systems, is how easy and intuitive it is to program the welding processes. This makes it much easier to get started with automated welding.”

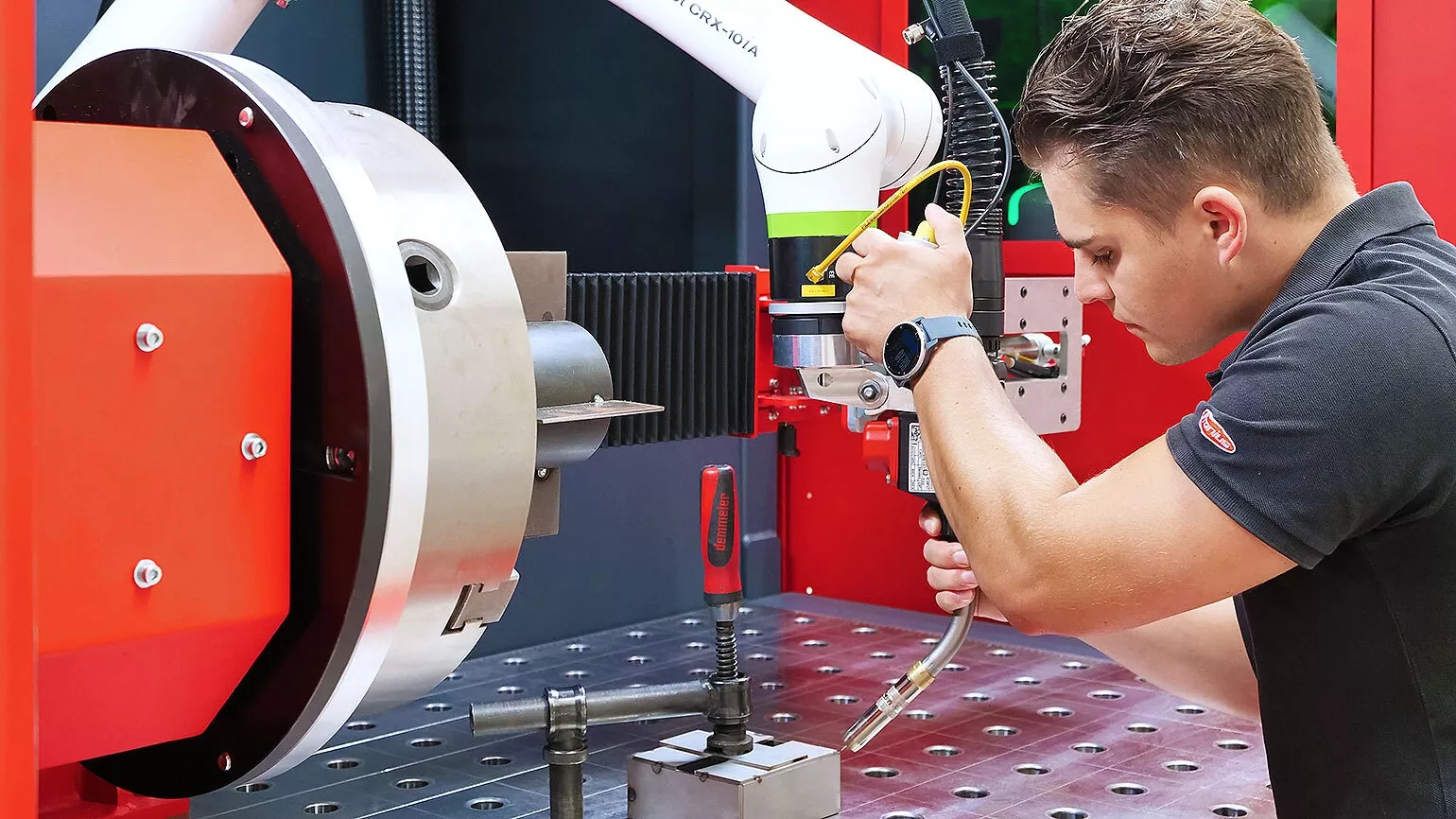

Three steps to the welding program

“Compared to programming industrial robots, cobot teaching requires hardly any training for the majority of applications. Welding specialists in particular, who are used to working with touchscreens and have some computer skills, are able to weld their first components after just a few hours,” explains Christian.

Valid welding parameters from your smartphone

Thanks to our practical WeldConnect app, welders have

a personal parameter manager to hand at all times. The innovative online

welding assistant offers professional support in selecting suitable welding

parameters. These can be saved as a job and transferred to the cobot system’s

welding machine via NFC signal so welders can get started with welding straight

away.

The WeldConnect app can store numerous jobs, which can be accessed at any time. Young welding specialists in particular, who are used to using smartphones, appreciate the app, as it provides reliable welding parameters for a wide range of tasks. Together with the WeldConnect app, cobots are helping to alleviate the shortage of skilled workers and make welding an appealing career choice again.

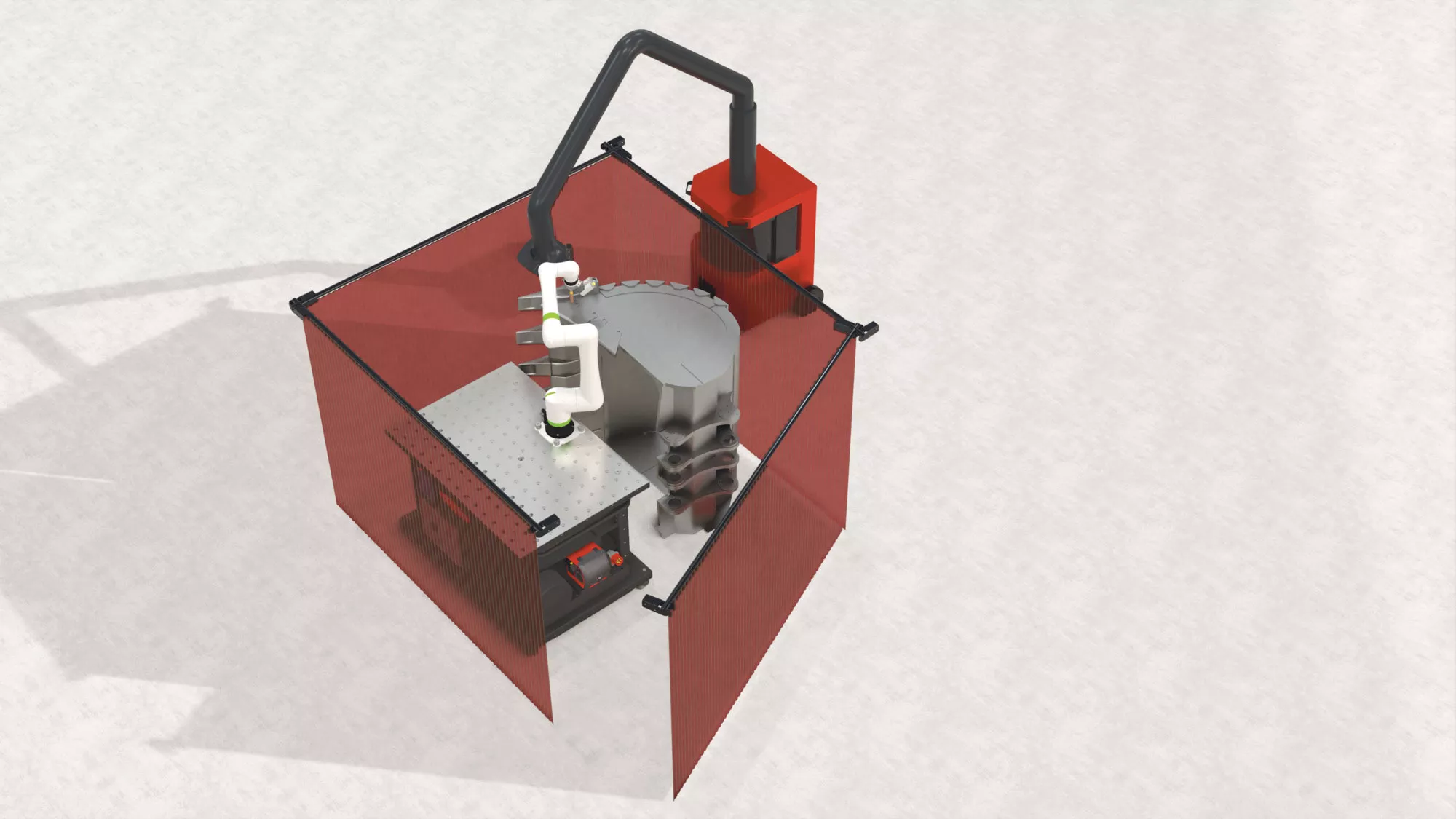

Mobile and flexible use: the CWC-mobile

“Those who need to weld larger items such as excavator buckets can push the CWC-mobile to the ready-to-weld component with ease,” says Christian, highlighting the versatility of the system.

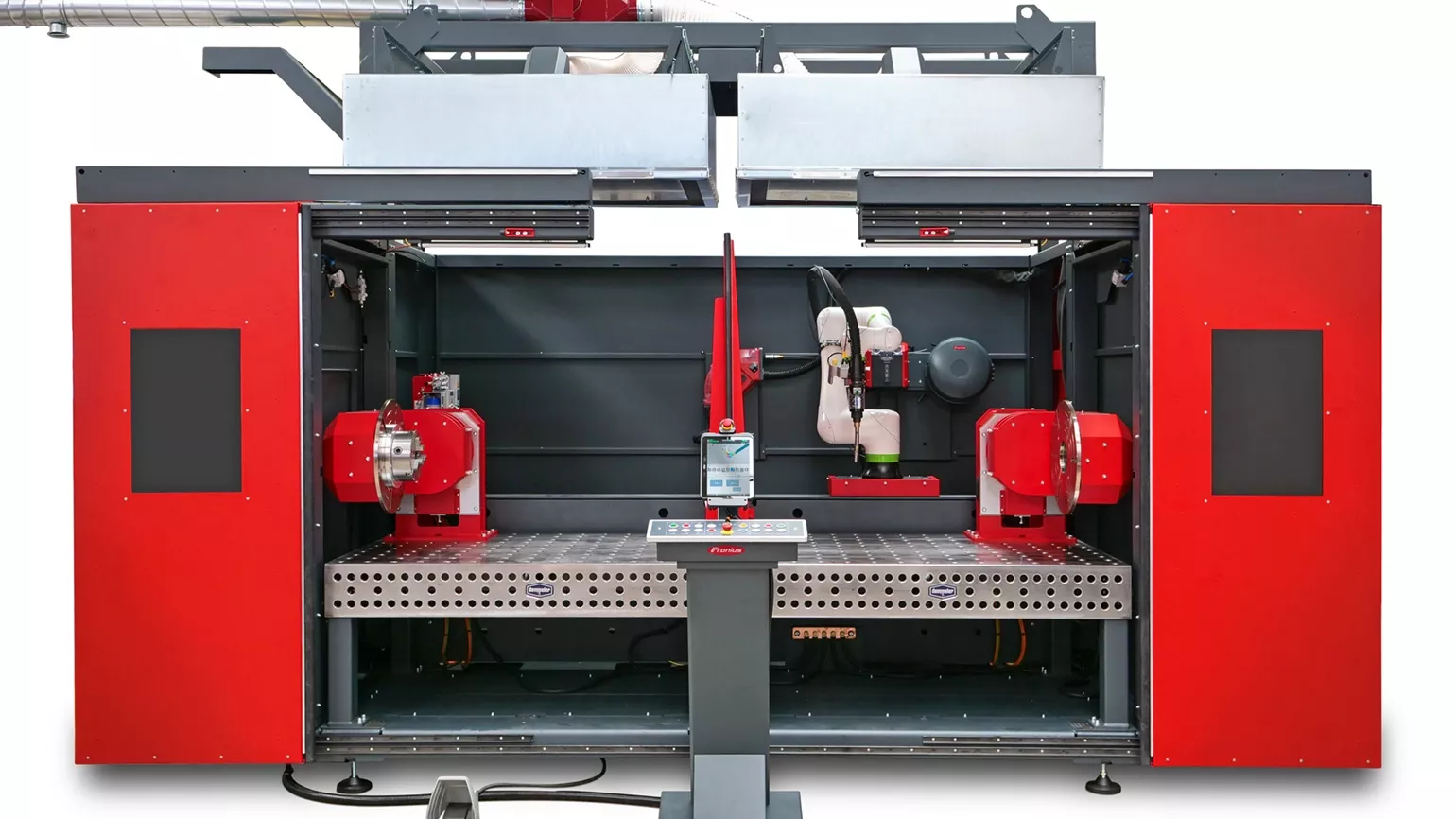

Single and dual systems to suit component dimensions and requirements

The CWC-D two-station solution is ideal for welding components with a length of up to 3 meters. If you remove the central partition wall that is screwed to the welding table, this creates an extended work surface of 3,000 x 1,000 x 600 mm for one-station operation.

“With two-station operation, the system enables welding to be carried out in parallel to setup and is ideal for small-series production of components with a maximum side length of 1.5 meters. While welding is being carried out on one side, the other side can be equipped to increase productivity. Both stations can weld components weighing up to 2 tons,” explains Christian.

Bringing together cobots and welding robots

Our cobots are an ideal way to get started in the world of automation. They enable the robot’s workings to be understood through manual teaching and the kinematics to be learned without a high risk of injury. Welding specialists benefit from better understanding of the kinematic processes, which is an advantage, especially when starting to work with robotic welding later on.

Increase productivity with offline programming

With the Fronius Pathfinder offline programming

software, welding processes can be programmed independently of the cobot

welding system, without any interruption to ongoing production. Unlike manual

teaching, the software enables welds to be copied and mirrored, scanning

processes to be created, and complex movement sequences to be simulated. This

minimizes downtime and increases productivity by up to 80%, especially for

complex component geometries. As soon as a program has been created, it is

transferred to the welding cell and manually adjusted if necessary. Another

advantage of Fronius is that the software and welding system come from a single

source and work perfectly together.

High level of safety with our cobots

We worked with an external safety inspector to carry out a series of intensive safety tests, which delivered impressive results. These tests included attempts to pierce a glove with wire—unsuccessfully! The impact force of the gas nozzle and the edges of the torch holder were also measured and lie safely within the defined limits. Of particular note is the fact that the water-cooled welding torches are lukewarm within seconds of completing the welding job, effectively minimizing the risk of burns. All these results confirm that our products meet the highest safety standards and ensure maximum safety.

The path to automation with our cobots

We are there for our customers right from the start

and offer customized automation solutions, ranging from simple systems to

complex applications.

“As a general

contractor, we help our customers select the ideal solutions for them, whether

that be cobots, welding robots, or mechanized systems such as welding

carriages, circumferential and longitudinal seam welding systems, seam welders,

or orbital systems. Our advice doesn’t stop once you’ve made a purchase. We

also support our customers during commissioning and have a global service

network to provide rapid, reliable help with any problems. This ensures our customers

benefit from a high level of efficiency and safety with their welding processes,”

concludes Christian.