Fair MagazineSCHWEISSEN & SCHNEIDEN 2025

Velo – Technological innovation for perfect MIG/MAG seams

2025-09-08Manual MIG/MAG welding requires concentration, precision, and endurance. Even for experienced professionals, keeping the speed constant and guiding the torch evenly over long seams in particular can be incredibly difficult, often resulting in fatigue, quality deviations, and physical strain. Velo, short for the brand new Velocity Assistant from Fronius, is an intelligent solution to this challenge. The system takes manual welding to a new level by actively supporting torch guidance and keeping the welding speed constant. It will be unveiled for the first time at SCHWEISSEN & SCHNEIDEN in Essen and at FABTECH in Chicago.

Welcome to the future of welding: the new Fortis product series

2025-09-08When the doors to SCHWEISSEN & SCHNEIDEN open in Essen on September 15, welding professionals arriving from around the world will find a very special highlight waiting for them: Fortis, a completely new generation of MIG/MAG welding machines from Fronius. Developed to meet modern manufacturing requirements, Fortis is ready to set completely new standards in terms of flexibility, connectivity, and ease of use.

Manual welding: In a tight spot, people remain essential

2025-08-25

A welder balances at great height on a lighthouse. The wind is whistling, the space is tight. But the weld has to be perfect: millimeter-precise and permanent. A few kilometers away, a farmer sits in the cab of his combine harvester. The harvest season is in full swing and every single hour counts. But a technical problem threatens to sabotage the schedule. Two locations, one thing in common: reliability under pressure. Which Fronius welding machines can step up to these situations––and why is manual welding under extreme conditions the measure of everything?

Outsourcing prototyping and commissioning contract manufacturing pays off

2025-08-18

Prototyping is an essential step in the conception and design of a new product. At this early stage of the product development process, designs and construction methods are tested and validated using models. Wherever welded joints are required, quality is key. After all, they are often safety-relevant and must comply with international standards. Not every company is equipped for costly prototype construction. Specialized Fachbetriebehigh-tech companies offer a 360° all-round service from the feasibility study to pre-series production and beyond.

Safe welding with protective equipment

2025-08-12

A day in a welding workshop is as exciting as it is challenging. Sparks dance through the air, molten metal runs red-hot as the welder’s hand moves with deft precision, the arc burns with an intense glow. In the midst of this dramatic scene, a fine thread of welding fume rises. But as thrilling as welding is, welding specialists would be exposed to significant dangers unless the right protective measures are in place. Only those who take effective safety precautions and consistently adhere to safety regulations can significantly minimize the risk of work-related illnesses and injuries. But when they do, a dangerous working environment becomes a safe place where precision, skill, and passion are the name of the game.

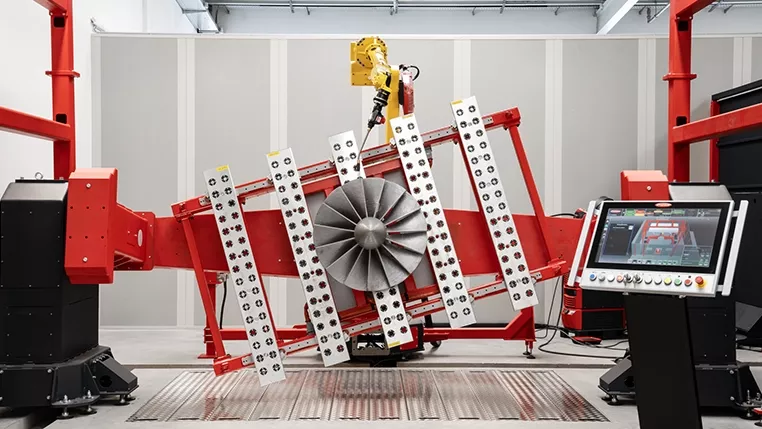

TRUMPF drives efficiency with new LaserHybrid welding system

2025-08-11TRUMPF Maschinen Austria GmbH + Co. KG, based in Pasching, has gained a global reputation thanks to its innovative technologies. The company’s extensive product range includes systems for die and panel bending as well as large-format bending machines and fully automated solutions. In addition to the Austrian State Prize for Innovation 2012, the awards the company has received since the turn of the millennium include the Fraunhofer Institute’s “Fabrik 2011” prize. Setting itself high standards for productivity and quality, Trumpf counts on state-of-the-art welding technology in its production.

The unseen hazard of welding

2025-08-07When we think about manual welding, we often picture gleaming arcs, flying sparks, and plumes of smoke. Vivid scenes like these shape our idea of welding, which is often perceived as harsh and dangerous. But this picture falls short of reality, because visible risks such as arc radiation, hot metal spatter, or welding fume can actually be managed very effectively thanks to modern protective equipment and clear safety standards. Ideally, professional welders are equipped with helmets, gloves, and protective clothing that reliably protect them from external influences. But one often underestimated aspect is a hazard that remains unseen: electrical current.

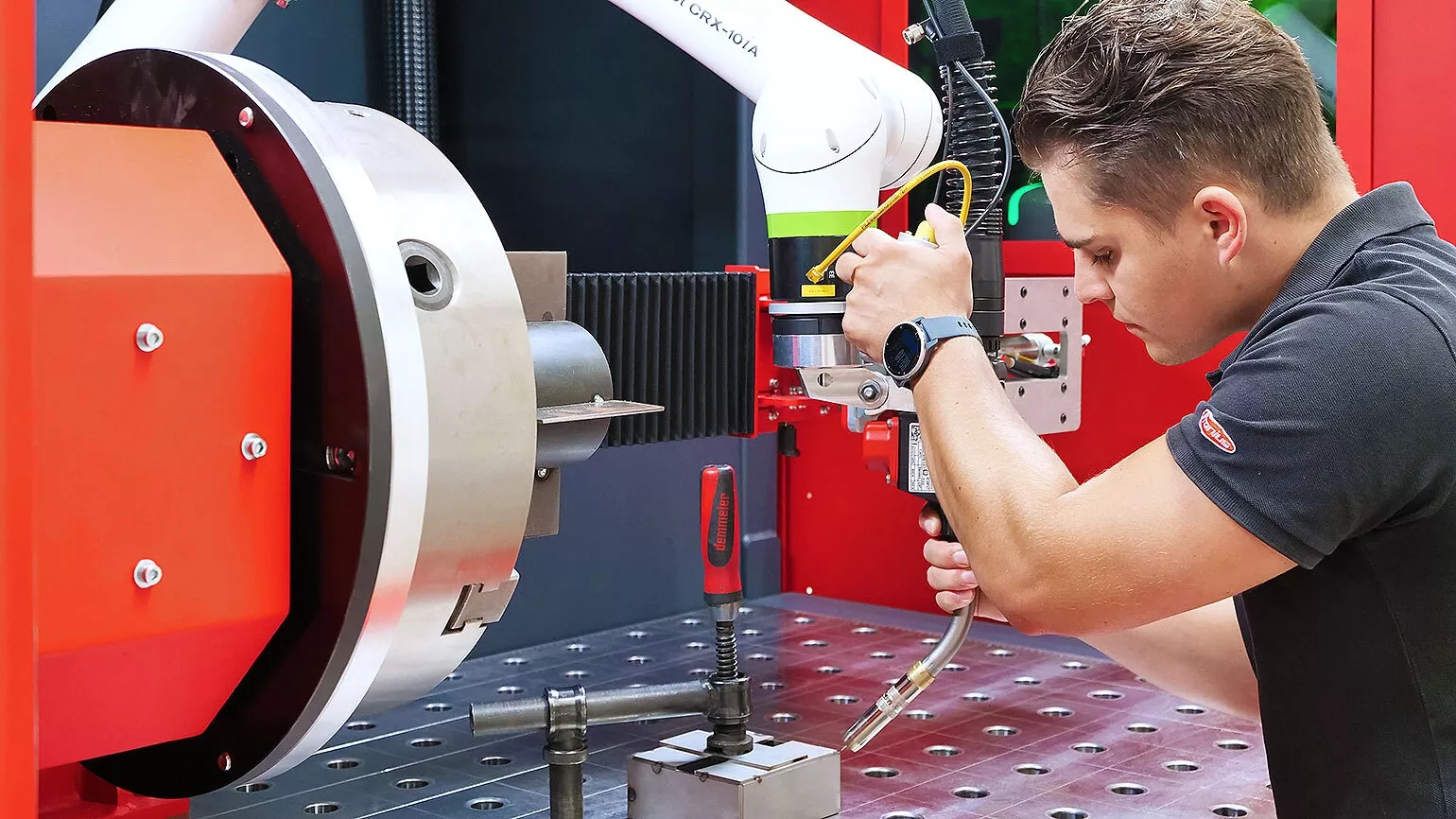

Can cobots attract more young talent to welding?

2025-08-05Welding remains a vital joining process in the metalworking industry and it requires in-depth specialist knowledge and skill. Despite the attractive salary, the number of young people taking up this profession continues to decline, as it is often regarded as unappealing, harmful to health, and dirty. This is where cobots come in. Not only do they make welding more interesting and safe, they also make it more profitable—even for small batch sizes.

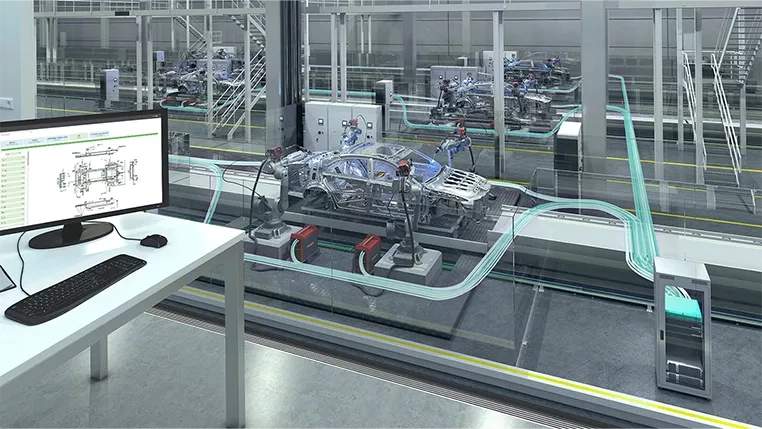

Unleashing excellence in welding

2025-08-04Industry 4.0 has fundamentally changed the field of industrial welding, making networked systems, data-based quality assurance, and automated process control essential components of modern manufacturing. At Fronius, we were early to recognize that digitalization is not an end in itself, but a tool with which we can upgrade our customers’ production workflows to leave them fully equipped for future challenges.

Fit for the future thanks to smart robot welding technology

2025-07-31

Pursuing progress and innovation in consultation with the customer, trendsetting Austrian company Anton Paar manufactures high-precision measuring devices for a wide range of industries. Its dedicated research, engineering, and production teams aspire to keep pushing the boundaries of what’s possible. Today, Anton Paar GmbH is the world leader in density and concentration measurement, rheometry, and the analysis of dissolved CO2. A growing shortage of skilled workers and ever-increasing quantities call for intelligent production solutions, so the company invested in a latest-generation robotic welding cell.

Metal 3D printing on the rise worldwide

2025-07-28

These days, we live in an extremely challenging, tense time. Global economic and geopolitical tensions, combined with supply chain bottlenecks, put us to the test on an almost daily basis. Risky dependencies exist in the procurement of components. Production is set to become increasingly environmentally friendly, economical, and individualized. Series products are increasingly being replaced by customized products manufactured in small batches. This is where metal 3D printing comes in. Fronius Welding is setting a milestone with the CMT Additive Pro process variant.

Ergonomic welding – a contradiction in terms?

2025-07-24

Whenever series production is not a consideration, welding is frequently carried out by hand. Welders often work in positions that strain the joints and muscles, for example when welding while forced to adopt awkward postures. This results in complaints such as sprains of the lower back or arms, which not only affect the health of welding professionals, but also come at the expense of the company’s productivity. Companies are therefore increasingly focusing on ergonomics during welding.

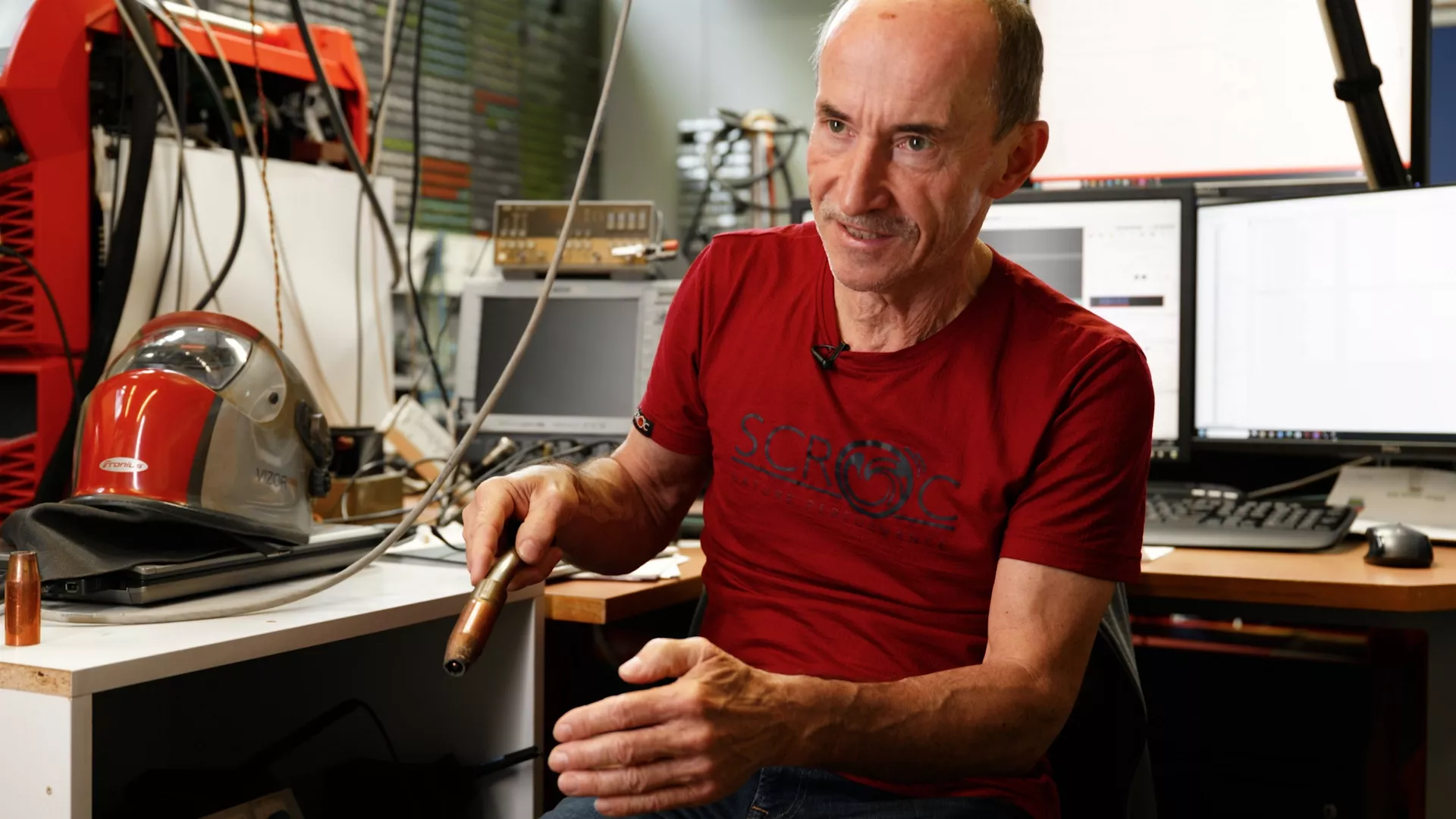

CMT turns 20: Unrivaled precision and stability

2025-07-14

Since its introduction in 2005, the Cold Metal Transfer (CMT) process developed by Fronius has fundamentally changed welding technology. CMT set new standards in precision, process stability and application diversity—and in a surprising way: A simple light bulb played a decisive role in its development. Joe Artelsmair explains exactly how this came about in an exclusive interview. As one of the key developers, he was involved right from the start and has witnessed first hand how the process evolved from a promising research project to a key technology in modern joining technology.

Sustainability by Design

2025-07-04

We have been working meticulously to carve out our position as an innovation leader in welding technology. It is therefore no surprise that our research and development work in the last 40 years has resulted in numerous milestones in welding technology, which at the same time have always focused on quality, resource conservation and sustainability. Our innovations always aim to provide customers with the highest quality, while also saving valuable resources, be it time and money, or energy and materials.

Fronius VSP: how we have global customer proximity down to a fine art

2025-07-01

Fronius is passionate about welding. To ensure the customer enjoys the finest benefits with the highest levels of satisfaction, we have always made it our mission—in the spirit of technology leadership—to meet the highest quality requirements. But in terms of customer service and support too, we have steadily evolved over decades into a first-class provider. Responsible for this is our VSP (German abbreviation for “sales and service process”), which has been a tradition at Fronius for more than 25 years and cannot be found anywhere else in the welding technology sector.

Virtual welding: new training prospects

2025-06-26

The welding industry is facing a problem: even companies whose primary task is welding are unable to escape the clear shortage of skilled workers in every area. Furthermore, the challenging combination of metallurgy, physics, and electrical engineering is accompanied by certain dangers that could act to deter potential young welders from joining the industry. Taking a look through the augmented reality glasses of our new Welducation Simulator may provide the answer to both issues, while also protecting the environment.

From easels to arcs: meet our (welding) masters

2025-06-23

How broad the range of objects that welded art can create is exemplified by Rich Baker, Jordí Diez Fernandez, Andrea Stahl and Cédric Surmin—four creatives who have dedicated themselves to the world of sculptural metalwork and forged careers for themselves from their passion.