Velo –

Technological innovation for perfect MIG/MAG seams

Velo, short for the brand new Velocity Assistant from Fronius, is an intelligent solution to this challenge. The system takes manual welding to a new level by actively supporting torch guidance and keeping the welding speed constant. It will be unveiled for the first time at SCHWEISSEN & SCHNEIDEN in Essen and at FABTECH in Chicago.

How does Velo work?

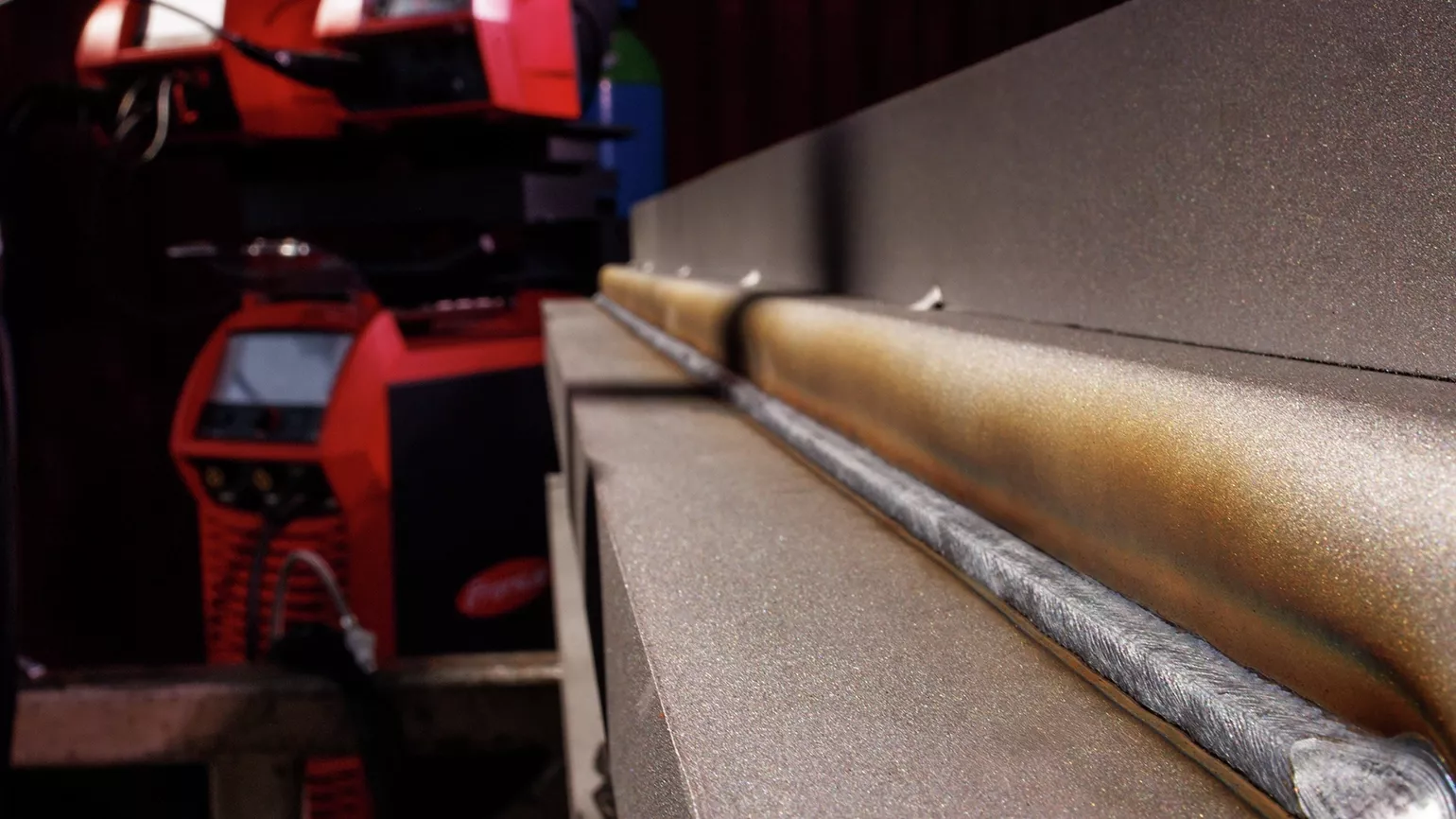

At the heart of the Velo concept is a second

wire (the so-called ‘Velo wire’) that works without an arc and without an

additional gas feed. It is a rigid wire that touches the workpiece and

generates a forward movement through friction, ‘pushing’ the torch along the

seam edge, notch, or chamfer while keeping the distance between the contact tip

and workpiece constant. The wire adds very little additional material to the

seam, with the wire consumption corresponding exactly to the seam length.

More versatility, less strain

Velo is suitable for a wide range of

applications—from thin sheets to thick, in steel, CrNi, or high-strength steel.

Operators in sectors such as commercial vehicle construction, heavy

engineering, steel construction, and apparatus engineering in particular will

be quick to appreciate its strengths. The supportive guidance function ensures

high-quality results and noticeably reduces the workload of welding

specialists.

Test users report significantly greater precision and noticeably less physical strain thanks to Velo, especially during complex or long welding tasks.

Franziska Eichhorn, Strategic Product Manager at Fronius International

Whether a beginner or a veteran, Velo helps all

While

beginners quickly achieve high-quality seams thanks to the guided movement,

experienced welders benefit from the ergonomic support and consistent quality.

Under certain conditions, Velo even achieves welding speeds comparable to those

of robotic welding for a real productivity boost!

Retrofit quickly, work flexibly

Retrofitting Velo to existing welding

systems is also incredibly simple. It is compatible with all current TPS/i

devices with an output of 320 A or more as well as with iWave Multiprocess PRO

systems. All that’s needed is the wirefeeder for the Velo wire, a suitable

torch adapter with wire feeding system, and the corresponding software

activation,

and you’re ready to go!

Practical and full 360 movement

The Velo holder can be rotated 360° without

tools and locks securely into place. If accessibility is restricted, it can be

simply unclipped from the holder and set to one side. A large operating range

is ensured through the five-meter-long wire feeding system. Velo is activated

directly on the torch itself, allowing welders to switch between manual and

assisted guidance at any time.

With

Velo, Fronius demonstrates how intelligent technologies can revolutionize

manual welding. The combination of technological innovation, ergonomics, and

simple integration makes Velo a real game-changer for anyone who wants to

achieve perfect MIG/MAG seams. Don’t miss out and try Velo out for yourself at

SCHWEISSEN & SCHNEIDEN!