Fit for the future

thanks to smart robot welding technology

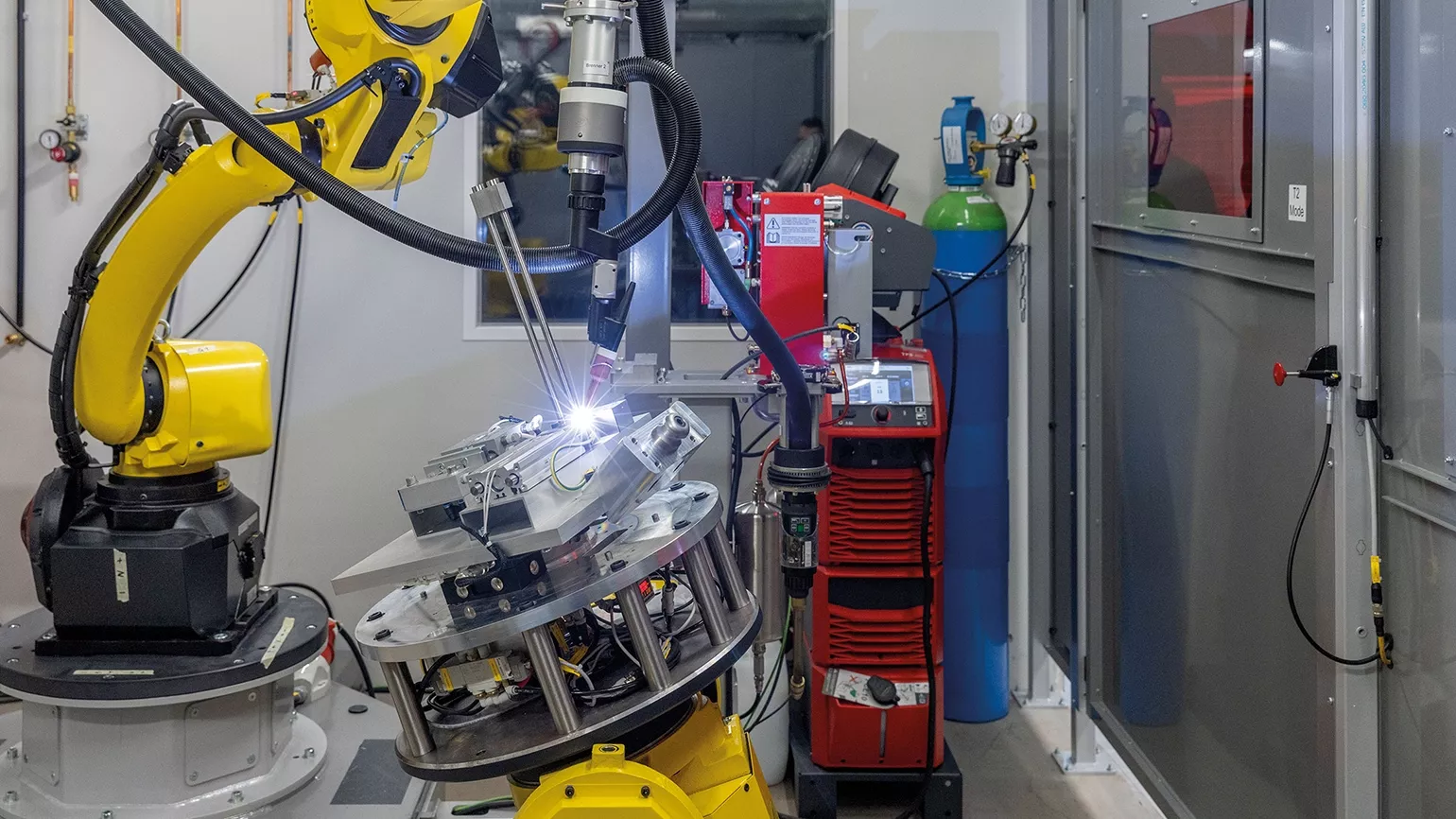

Autonomous welding and a broad range of components

A range of factors made designing the system especially challenging for engineering and programming teams, including components of various shapes, weights, and sizes, different gripping, positioning, and storage possibilities, the option to use two different welding processes (TIG and MIG/MAG) on a single component, as well as the use of forming gas to protect the components against tarnishing, which is necessary for cylindrical bodies.

“We were looking for a reliable partner who was very similar to us in terms of precision and quality. We wanted someone who would really listen to us, respond to our preferences, and propose sustainable solutions. A partner that would give us a competitive edge for years to come,” explains Daniel Moik, department manager for joining technologies. “Fronius International met these criteria for a sustainable partnership. In close cooperation with our technicians, the welding automation team developed a robotic welding cell that meets our requirements in every respect. On top of that, Fronius is ready to work with us to evolve the system and adapt it to new needs.”

Synonymous with efficiency: Fronius Pathfinder

Starting points, work angles of the welding torches, torch offsets in the corner areas, and all reorientations of the welding robot are all taken into account during these simulations. Pathfinder identifies instances where the robot range is exceeded, known as axis limits. By the software operators correcting the storage location of the workpiece and positioning it within arm's length of the welding robot, potential collisions between the torch and various component edges are avoided at an early stage.

Sources of errors are identified in good time

Once a welding program has been set up in Pathfinder, it is translated by a so-called post-processor into the specific code of the Fanuc welding robot. It can then be transferred to the welding system via data transfer using a LAN connection, for example. A key feature that provides effective support for production planning as a whole is the “Determination of cycle time” function, which includes welding speeds as well as gas pre-flow and end crater filling times. Compared to teaching with the robot controller, Pathfinder can achieve a time savings of up to 90%, depending on the component geometry and welding requirements.

Customized for Anton Paar

Workflow 1:

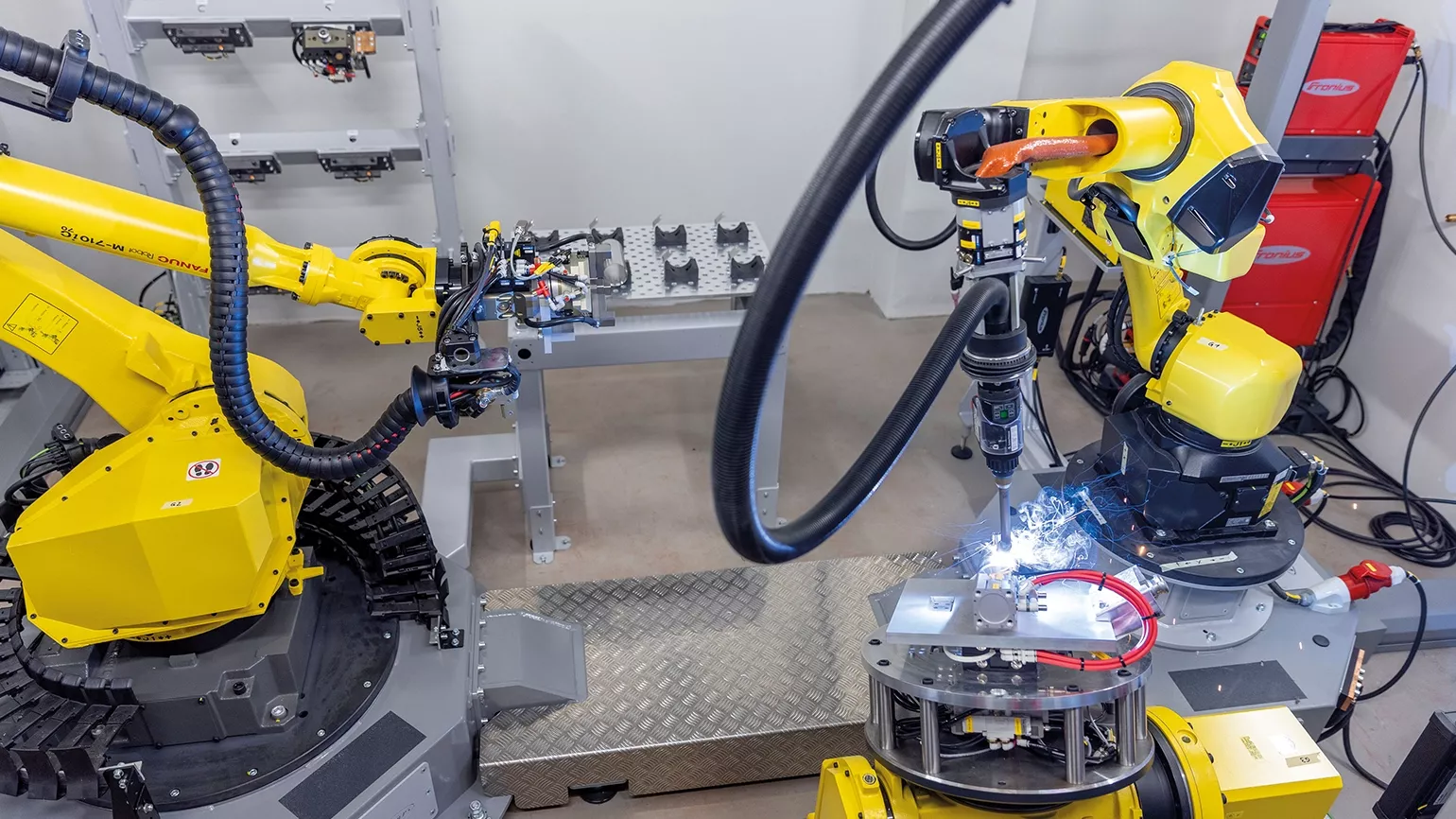

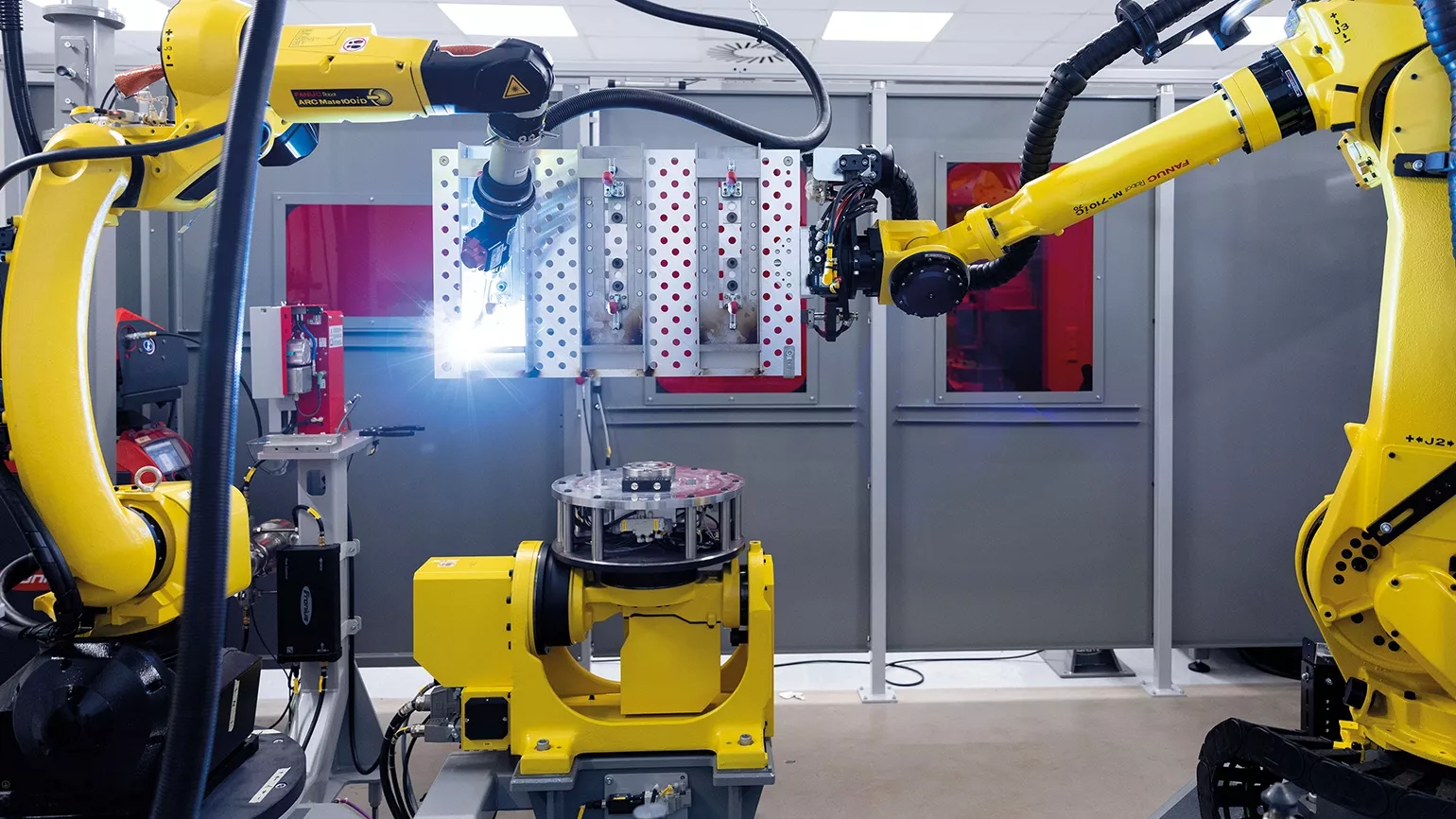

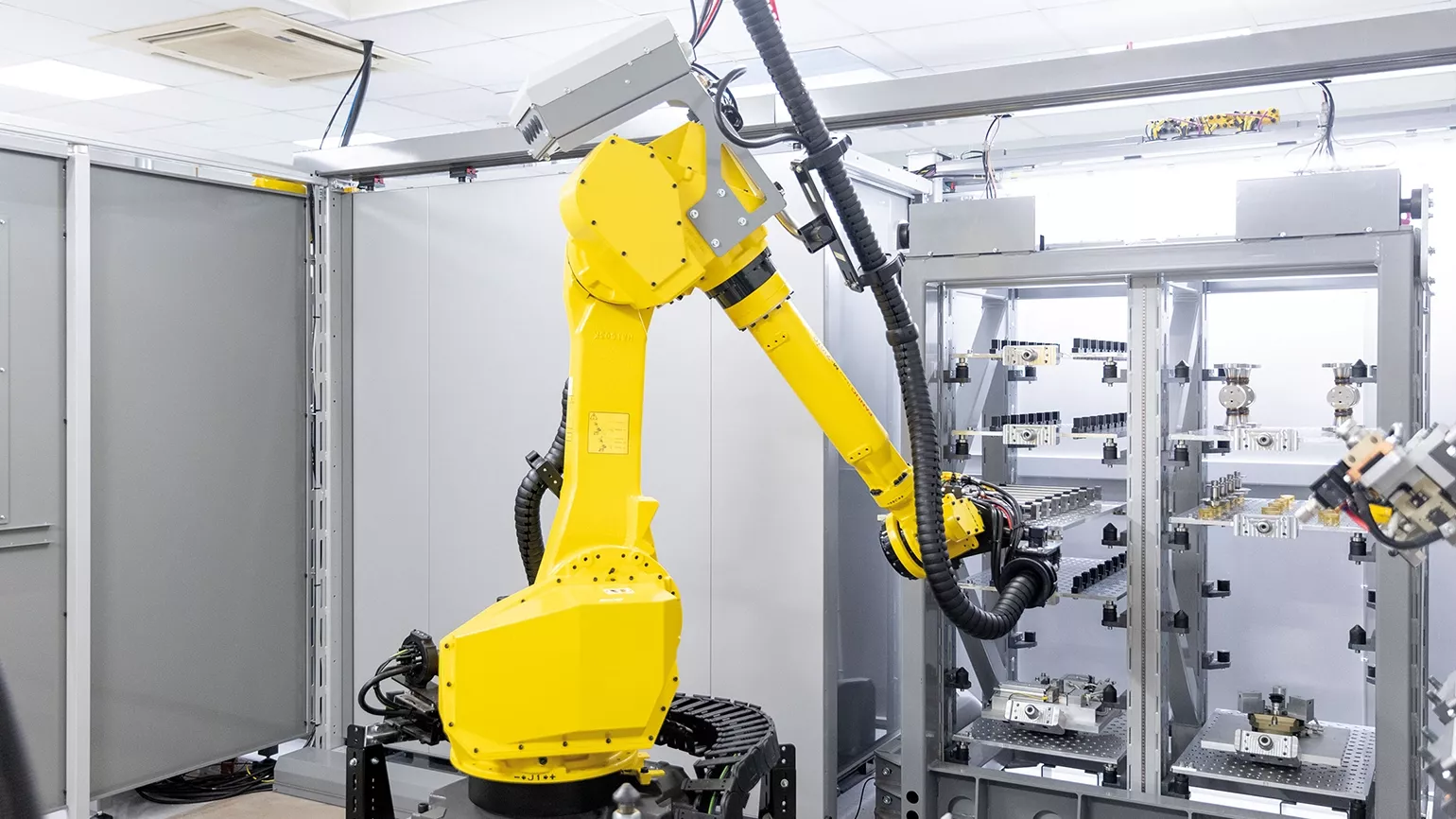

The components are welded on the turn-tilt positioner. A pallet loaded with components is removed from the pallet rack and temporarily stored on a pallet storage table. The handling robot then attaches a suitable gripper for picking up components, with six different ones being kept in what is known as a gripper station. Equipped with the gripper, the handling robot picks up the components and fixes them in a component-specific clamping device, which is already installed on the manipulator. The robot always removes one component at a time, which is then joined and returned to the pallet.

Workflow 2:

The components are welded directly on the pallets, with the handling robot transporting the pallets from the pallet rack and positioning them in front of the welding robot. The handling and welding robots can then perform coordinated movements together during the welding process, enabling them to weld not just simple seam geometries but complex ones as well.

Workflow 3:

The components are removed individually, positioned by the handling robot, and move in sync with the welding robot during welding. This is called “coordinated motion.”

Making sure the system knows what to do

First, pallets and components are created together in the HMI-T21 RS system controls, which are provided with four important pieces of information by the relevant welding specialist: (1) the pallet type and (2) the type, (3) the number, and (4) the position of the components on the pallet—for example, how many main carriers or oscillator housings are located in which position on which pallet.

If a specific gripper is required for pallet handling, as described in Workflow 1, the system operator must select it in the system. As previously mentioned, there are a total of six different grippers available, all of which are kept in a gripper station.

Teaching

gripping and depositing positions

The

conventional handling sequence itself—picking up the pallet, positioning it for

welding, transporting it back, and depositing it—is a standard program and

requires no intervention from the operator. This is referred to in the field as

an “encapsulated” function. Only the gripping positions have to be specified.

If a new component is “moved in” and not recognized by one of the depositing or receiving stations, the automatic run pauses. The welding specialist is prompted to start a teaching process with the robot controller—the Fanuc iPendant—and receives step-by-step instructions from the system software. Based on this, the system “learns” the required gripping/depositing position for the relevant station (e.g., for the clipboard). This position is stored in a register and is available for the handling process from that point on. The automatic run can then continue to the next station. If the component is also unknown there, this position must also be taught. Once all the stations have been worked through as described, the handling robot transports all other identical components through the system automatically, without interruption.

If a pallet should have seven components but there are only three components on it, this is no issue for the system. It detects an “empty grip” and automatically moves to the next component position.

Custom-made: the teach pallet

In

addition to the standard offset assignment, which favors simple component

shapes, Anton Paar wanted to be able to deposit up to 30 metal components at

any point on a pallet. Fronius responded by creating the “Teach pallet”

function. Selecting this function makes it possible to separately teach the

position of each component on the pallet.

“These two versions, offset and teach

pallet, offer us maximum flexibility in component placement,” explains Dr. Ingo

Riemenschneider, department manager for production automation. “It doesn’t

always make sense for us to define component positions using offset distances.

We have to fix some components in different orientations because of their

complex shapes.”

As

precise as on the first day—even after months

When

the welding specialists want to start a welding process, they use their

handheld scanner to scan the item number on the component data sheet.

“If the system detects the item number

and thus the component, it knows about the handling and welding process and

starts operation. Everything is controlled via the HMI-T21 RS. The system

stores which gripper and which device are needed for each of the components,”

explains Riemenschneider. “The same applies to the argon flushing time during

forming and the seam time. The system also knows whether and what data is

required for process data recording.”

Months

later, the robotic welding cell is still just as precise as on the first day,

and the weld seam is perfectly positioned in the same place. This can also be

attributed to the fact that Anton Paar manufactures the components with

micrometer precision and joins them with an exemplary level of quality.

Components

can be turned multiple times—even during forming

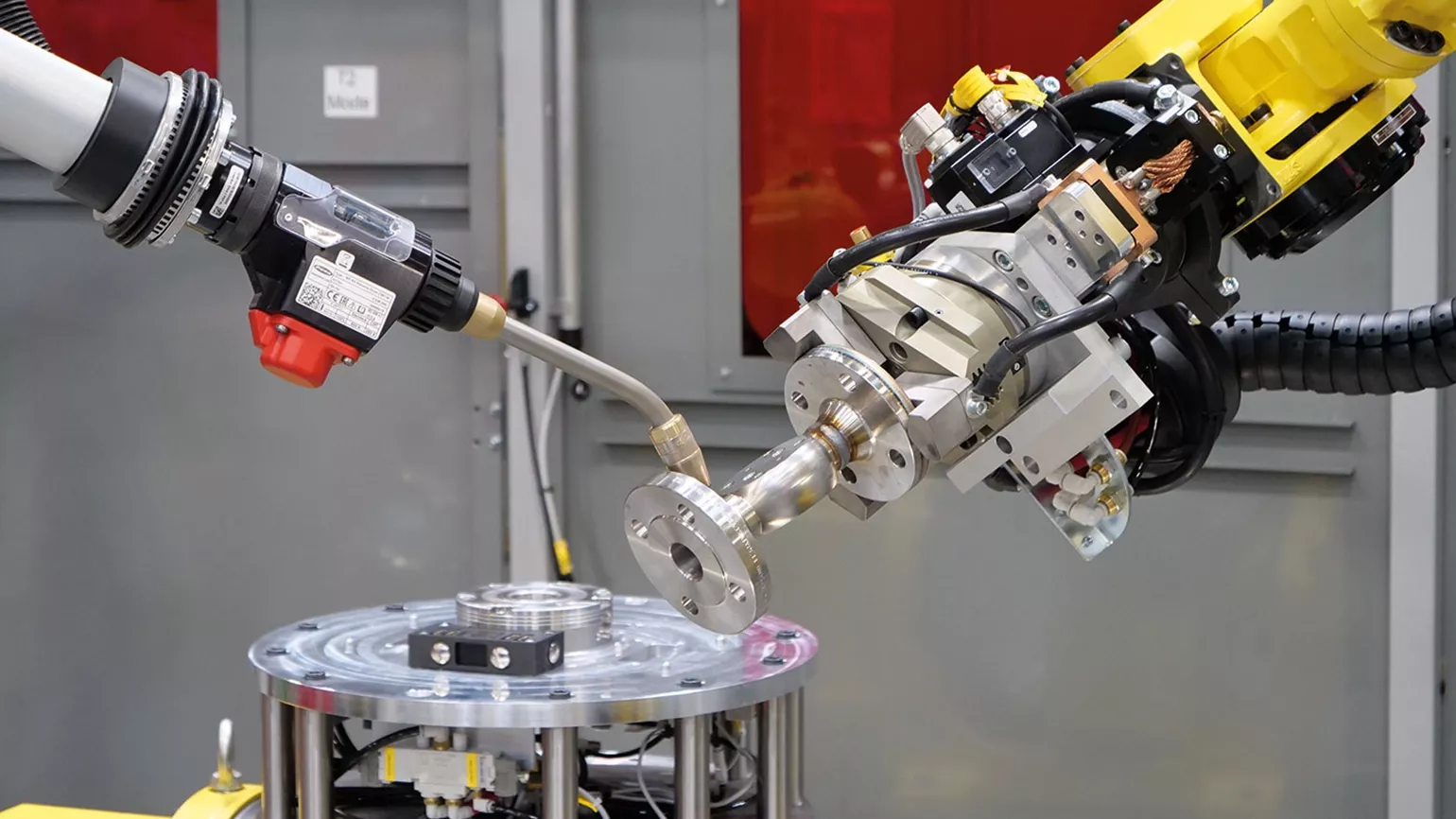

The

turn-tilt positioner has a media conduit for four flow-through lines, two for

air and two for argon, and can transmit up to 32 input-output signals (IOs). It

is made of plastic and was produced by Anton Paar using 3D printing. If

components need to be formed, the handling robot first retrieves the required

clamping device from the pallet rack and clamps it on the manipulator with the

help of a special clamping system. From that point on, both the air lines for

the pneumatic cylinders and the gas lines for flushing with argon are

connected. The electrical signals are now also transmitted by the clamping

device. The handling robot then positions the components and the system sends

the signal for clamping. Forming can now be carried out, followed by welding.

The system is designed in such a way that the components can be turned several

times on a single clamping device.

“It is important to us that all processes and properties that were implemented in the system are open in terms of their repeatability. The matter of whether a turning process is carried out once or a hundred times has to be irrelevant from the perspective of the system. Given that the complexity of our components is constantly changing, we and the experts at Fronius put a lot of energy into making the processes as unrestricted as possible,” notes Riemenschneider.

Residual oxygen measurement made by Anton Paar

At the apex of welding technology

It was particularly important for Anton Paar’s welding specialists to be able to combine two welding processes for a component—for example, TIG for welding the root pass and MAG for welding the final run. However, the final choice of welding method depends on the welding calculations and the required resistance of the individual components.“Our welding tests are the deciding factor in whether we use special processes such as CMT (cold metal transfer), PMC (pulse multi control), or LSC (low spatter control). The process we then decide on depends on the wall thickness of the component, on the type of weld, for example square butt or fillet weld, and on the required welding depths and micrographs,” Moik explains. “We need about six or seven tests before we go into series production. If the heat input would be too great due to the nature of the material, the CMT ‘cold’ welding process is of course suitable. If we want to boost productivity by increasing the welding speed, we look at PMC. If welding needs to be particularly low spatter, LSC might be a good choice, primarily because this prevents expensive rework.”

Our innovative processes, a system concept that is both intelligent and flexible, and the ongoing potential to continue developing the robotic welding system ensure that Anton Paar’s sensitive, high-precision measuring devices will have perfect weld seams for years to come. The company’s welders simultaneously benefit from increased safety and protection of their health as they are shielded from the arc and its emissions by the enclosure and extraction system.