Unleashing excellence in welding

We kick-started this digital revolution in

1998 by launching TransPuls Synergic (TPS), the first digitally

process-controlled welding system—and have been setting the benchmark in

welding technology ever since. Fast forward to today, and our WeldCube portfolio

not only enables the central recording, analysis, and management of welding

data, but takes transparency, traceability, and efficiency to a new level. This

means our customers can guarantee high-quality welds while saving time and

money.

WeldCube Air offers an easy introduction to cloud-based data management. Welding certificates and WPS documents are managed centrally—paperless, secure, and retrievable at any time. The platform is ready for use right away, requires no additional software, and helps welding supervisors ensure their production complies with the relevant standards.

WeldCube Air offers an easy introduction to cloud-based data management. Welding certificates and WPS documents are managed centrally—paperless, secure, and retrievable at any time. The platform is ready for use right away, requires no additional software, and helps welding supervisors ensure their production complies with the relevant standards.

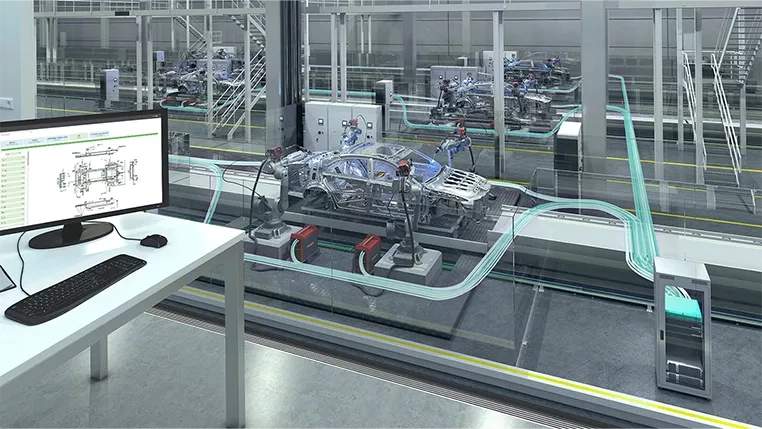

WeldCube Premium takes

it a step further. Featuring detailed dashboards, REST API interfaces, and

comprehensive process documentation, this is the ideal solution for companies

looking to place a consistent focus on an Industry 4.0 strategy. Integrated

into MES and ERP systems, the solution enables a seamless flow of data—from

planning to quality assurance. Traceability, process stability, and central job

management are just a few of the advantages.

A

further key to success is the open

system architecture of our solutions. Our welding systems can also be

seamlessly integrated into existing IT environments via standardized interfaces

such as OPC UA and MQTT. Customers can set up their own data management

solutions, put resources to best use, and implement individual evaluations all

to suit their own commercial needs. This flexibility is crucial when it comes

to meeting the requirements of a dynamic market.

“But we’re already thinking ahead. Industry 5.0 is shifting the focus back to people and enhancing interactions between humans and machines. And we’re right at the cutting edge here as well.”

Joachim Böck,, Team Lead Digital Welding Solutions at Fronius International

Our WeldCube Navigator supports

welders with visual step-by-step instructions, preset welding parameters, and

intuitive operation directly from the welding torch. This reduces errors,

shortens training times, and takes the pressure off skilled workers, for

example when working with a wide variety of components—a key advantage given

the increasing shortage of trained welders.

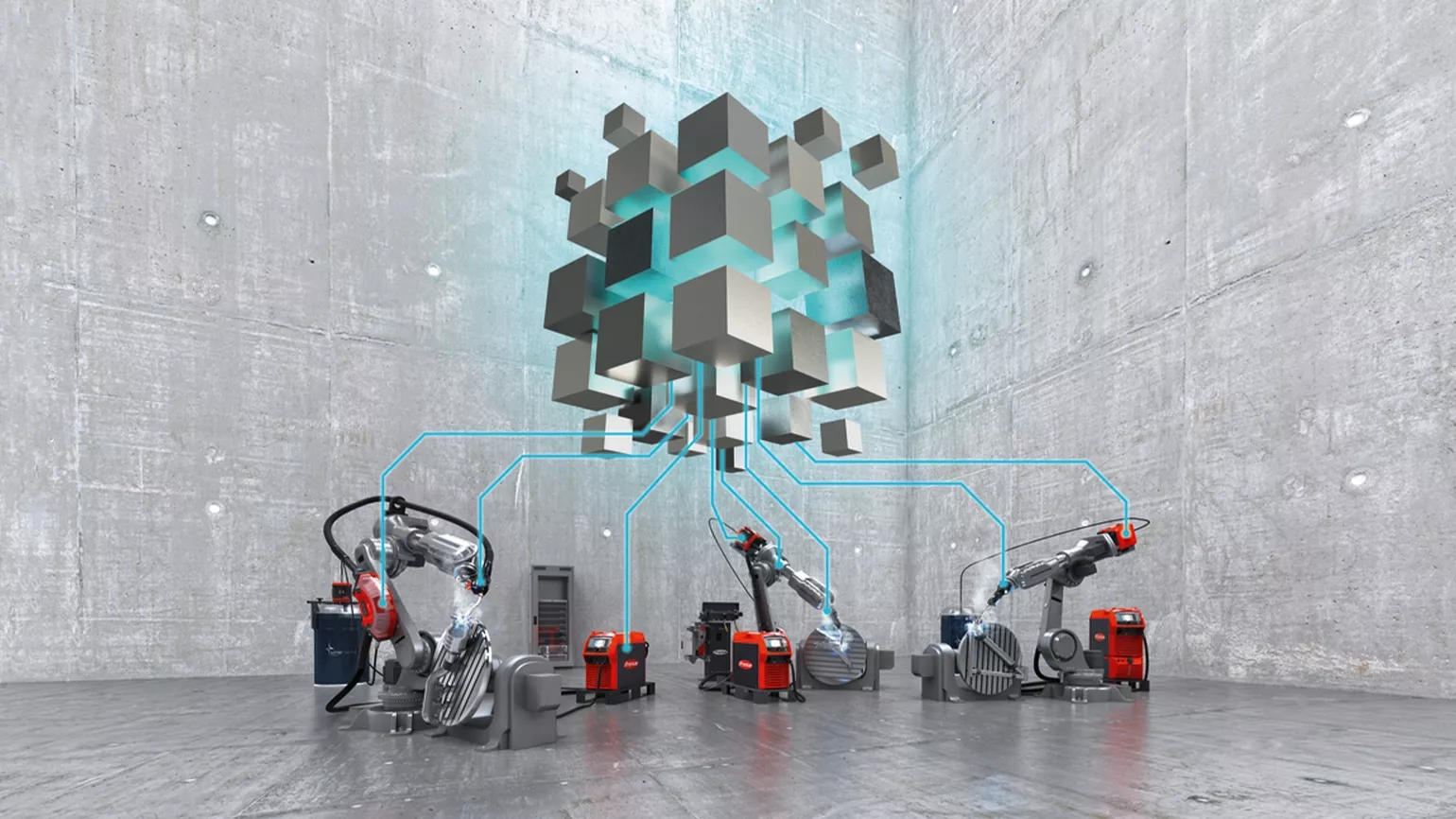

Our

solutions create space for human creativity and experience while automating

routine tasks. Easy-to-operate cobots

complement human input and enable collaborative processes at the highest level

of quality. They perform repetitive welding tasks with consistent precision,

reducing human fatigue, errors, and rework.

Companies find that using cobots pays off in several respects. For one, these scalable solutions make it possible to maintain production capacities along with a high standard of quality. And with skilled workers in short supply, they lighten the load by taking on monotonous or strenuous tasks.

Companies find that using cobots pays off in several respects. For one, these scalable solutions make it possible to maintain production capacities along with a high standard of quality. And with skilled workers in short supply, they lighten the load by taking on monotonous or strenuous tasks.

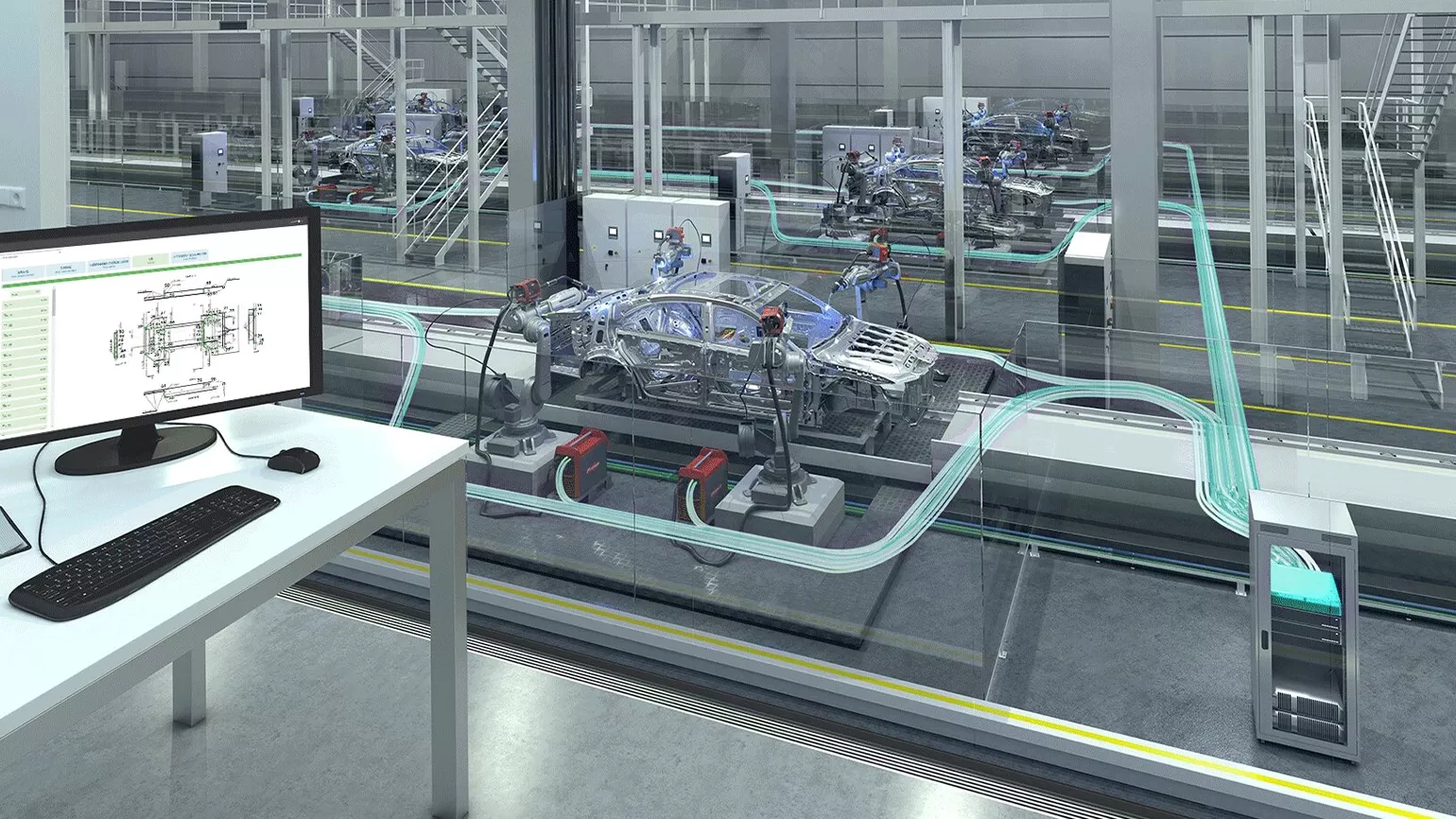

When

it comes to prototyping, modern simulation technology is a key aspect. One

great example is the Fronius Pathfinder

software, which simulates welding sequences on the digital twin of a

component without interrupting ongoing production. The software identifies axis

limits, calculates start and end points as well as paths, and independently

sets teach points. Errors and collisions can be identified in advance and

welding sequences optimized, saving time and money. There is also the option to

simulate material distortion as part of a feasibility study and create analyses

for the correct welding sequence.

“Fronius stands for excellence in welding—now and in the future. We listen carefully to what our customers need and develop solutions that are not only cutting edge, but also offer real added value in everyday life. From series production to plant construction, our WeldCube products and cobots combine the best of both worlds—machine-driven precision with human know-how. This is our shared vision for the future of welding—connected, intelligent, and human.”

Joachim Böck,, Team Lead Digital Welding Solutions at Fronius International

More about this topic

Vernetztes Schweißen/Cross-linked welding, September 16, 10–10:45 a.m.

How can we use digitalization and automation to increase quality and productivity in welding production?