Outsourcing prototyping and commissioning contract

manufacturing pays off

Expertise in welding technology and metallurgy

The development of innovative products usually

runs parallel to technical progress. New, difficult-to-join metals are often

used in complex designs, such as high-strength steel or aluminum, magnesium,

and titanium alloys. In order for these materials to be welded to a high

quality, extensive specialist knowledge is required—both in welding technology

and metallurgy. High temperatures and rapid cooling times change the

microstructure and significantly influence the mechanical properties of the

components. If the wrong welding parameters are selected, this can lead to

undesirable residual stresses, fusion defects, pores, cracks, or welding

notches. Filler metals and shielding gas mixtures can also influence the

properties of a weld. Contamination, for example with carbon, can have a

negative effect on ductility (the ability of a material to deform under load

without breaking).

Feasibility studies—the first steps in prototyping

Welding new types of components and materials is

associated with both legal and financial risks. Nobody wants to imagine what

could happen if structural components of buildings, bridges, ships, vehicles,

or airplanes were inadequately welded; it is therefore not only large

industrial enterprises but also smaller firms that rely on feasibility studies

and prototyping. If welding robots are to be used on the production line,

simulations can help. With suitable software and virtual prototypes—so-called

digital twins of physical components—strategies can be developed to avoid

welding errors. Interfering contours and singularities are detected at an early

stage, and measures to minimize distortions and stresses can be planned by

integrating clamping devices.

Welding tests reveal valuable data

As soon as the feasibility tests have been

successfully completed, the welding tests on the physical component begin and

the first prototypes are created. Depending on the base material and seam

geometry, different sensors are used for weld seam detection and quality

assurance. Welding data management software records every single parameter such

as wire feed speed, voltage, or amperage, and ensures the subsequent

reproducibility of welds.

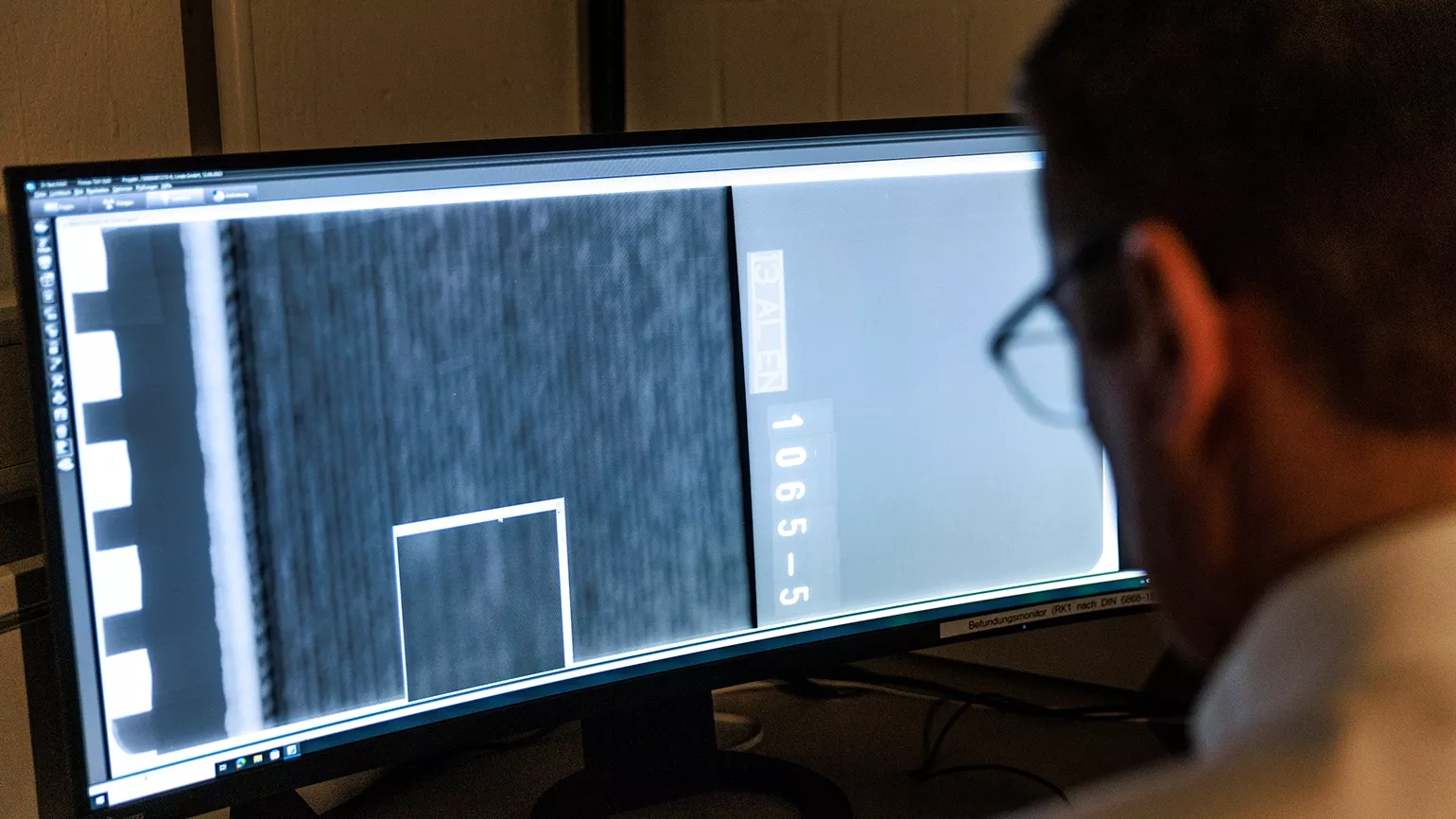

Following the joining work, the components are measured to detect any warpage. Where the necessary resources are available, the welded components are tested in the laboratory. In addition to non-destructive testing, destructive testing methods are also used here. Common methods are ultrasonic, dye penetrant, and X-ray tests as well as tensile, bending, and notch impact tests. Prototyping is an iterative process in which prototypes are repeatedly adapted and refined based on the knowledge gained.

Following the joining work, the components are measured to detect any warpage. Where the necessary resources are available, the welded components are tested in the laboratory. In addition to non-destructive testing, destructive testing methods are also used here. Common methods are ultrasonic, dye penetrant, and X-ray tests as well as tensile, bending, and notch impact tests. Prototyping is an iterative process in which prototypes are repeatedly adapted and refined based on the knowledge gained.

Purchasing welding expertise reduces costs and risks

In such a dynamic environment as we find today in both

the industrial and commercial sectors, not every company can meet every

challenge. Sometimes there is a lack of skilled personnel, fully automated

high-tech welding systems, and production lines. Robot welding cells cost

hundreds of thousands of dollars and qualified programmers are anything but

cheap.

It may therefore be more sensible to outsource feasibility studies and prototype production before immediately investing in new systems, employees, and products. This provides valid parameters for the start of production as well as for integrating new welding systems. By outsourcing the welding-relevant tests during the product development phase, companies can save themselves a considerable amount of the costs and risks that are always associated with developing new products. Equally as valuable is the ability to learn what will definitely not work—and thus to avoid future mistakes.

It may therefore be more sensible to outsource feasibility studies and prototype production before immediately investing in new systems, employees, and products. This provides valid parameters for the start of production as well as for integrating new welding systems. By outsourcing the welding-relevant tests during the product development phase, companies can save themselves a considerable amount of the costs and risks that are always associated with developing new products. Equally as valuable is the ability to learn what will definitely not work—and thus to avoid future mistakes.

Fronius supports the welding of critical components

We offer metalworking companies a customized

service in compliance with the relevant standards, consisting

of feasibility studies and prototyping as well as pre-series and series

production. Our experienced, certified welding professionals support commercial

and industrial customers with state-of-the-art technology and comprehensive

expert knowledge in joining difficult-to-weld components and materials.

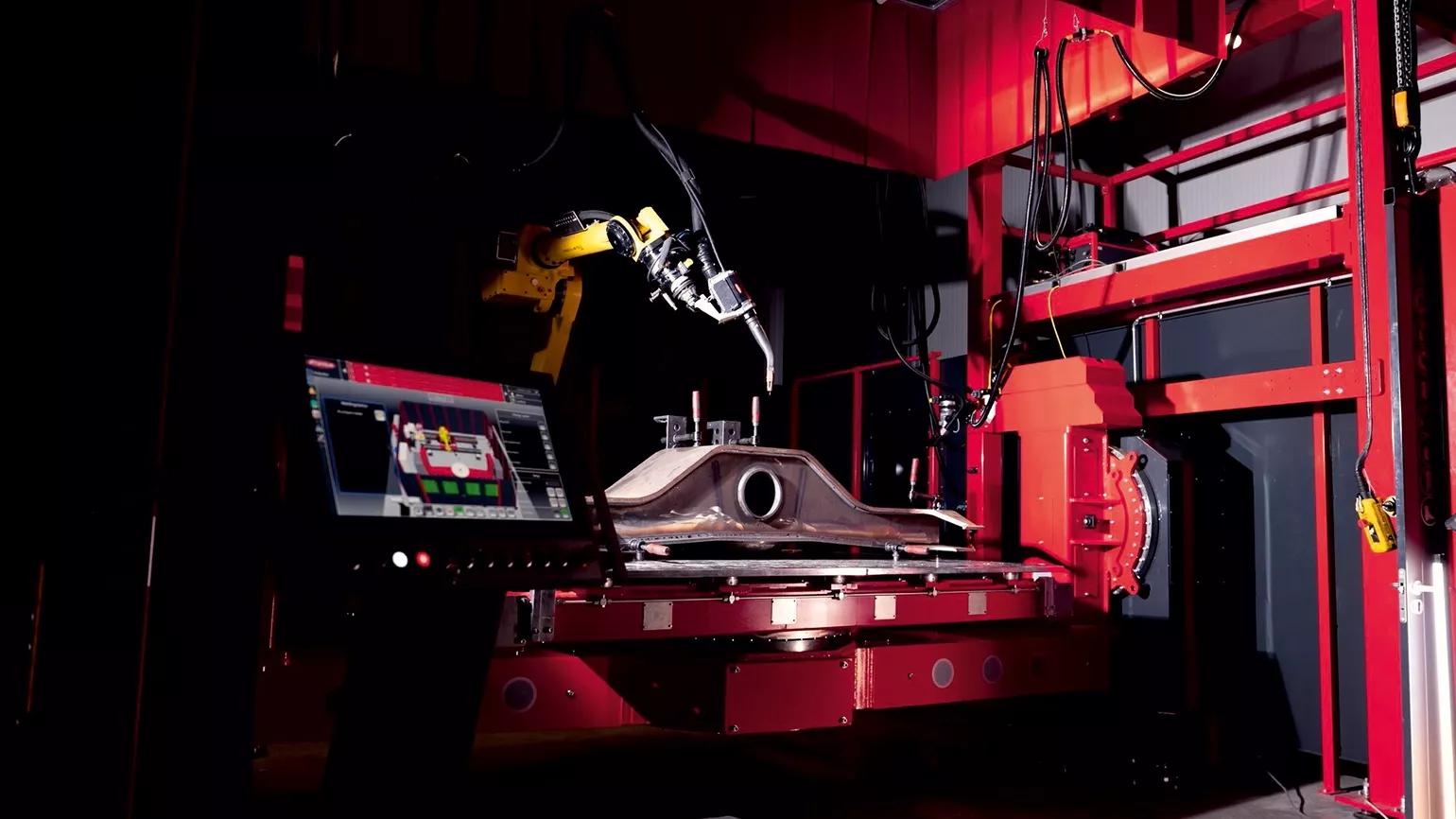

Feasibility studies are initially carried out at the Fronius site in Wels, followed by prototype production if requested. This requires that our client submit their welding specifications as well as the 3D data of components and clamping devices. We then perform a virtual analysis of this information, in order to draw conclusions about weldability, accessibility, and cycle time. Problems that arise are discussed together with the customer and optimization and solution options are developed.

Feasibility studies are initially carried out at the Fronius site in Wels, followed by prototype production if requested. This requires that our client submit their welding specifications as well as the 3D data of components and clamping devices. We then perform a virtual analysis of this information, in order to draw conclusions about weldability, accessibility, and cycle time. Problems that arise are discussed together with the customer and optimization and solution options are developed.

Complete service package—from the feasibility study to the finished product

As soon as valid welding data is available and the

first prototypes have been successfully welded, we develop a production concept

and, if requested, take over the series production; if this is to take place at

the customer’s premises, we can also design, build, and supply all the

customized robotic welding systems needed on request.

Furthermore, on-site commissioning services, employee training, and regular maintenance and calibration of the systems are all part of the comprehensive service package, which is supported around the world by a network of 38 subsidiaries and Fronius Sales and Service Partners in over 60 countries.

Furthermore, on-site commissioning services, employee training, and regular maintenance and calibration of the systems are all part of the comprehensive service package, which is supported around the world by a network of 38 subsidiaries and Fronius Sales and Service Partners in over 60 countries.

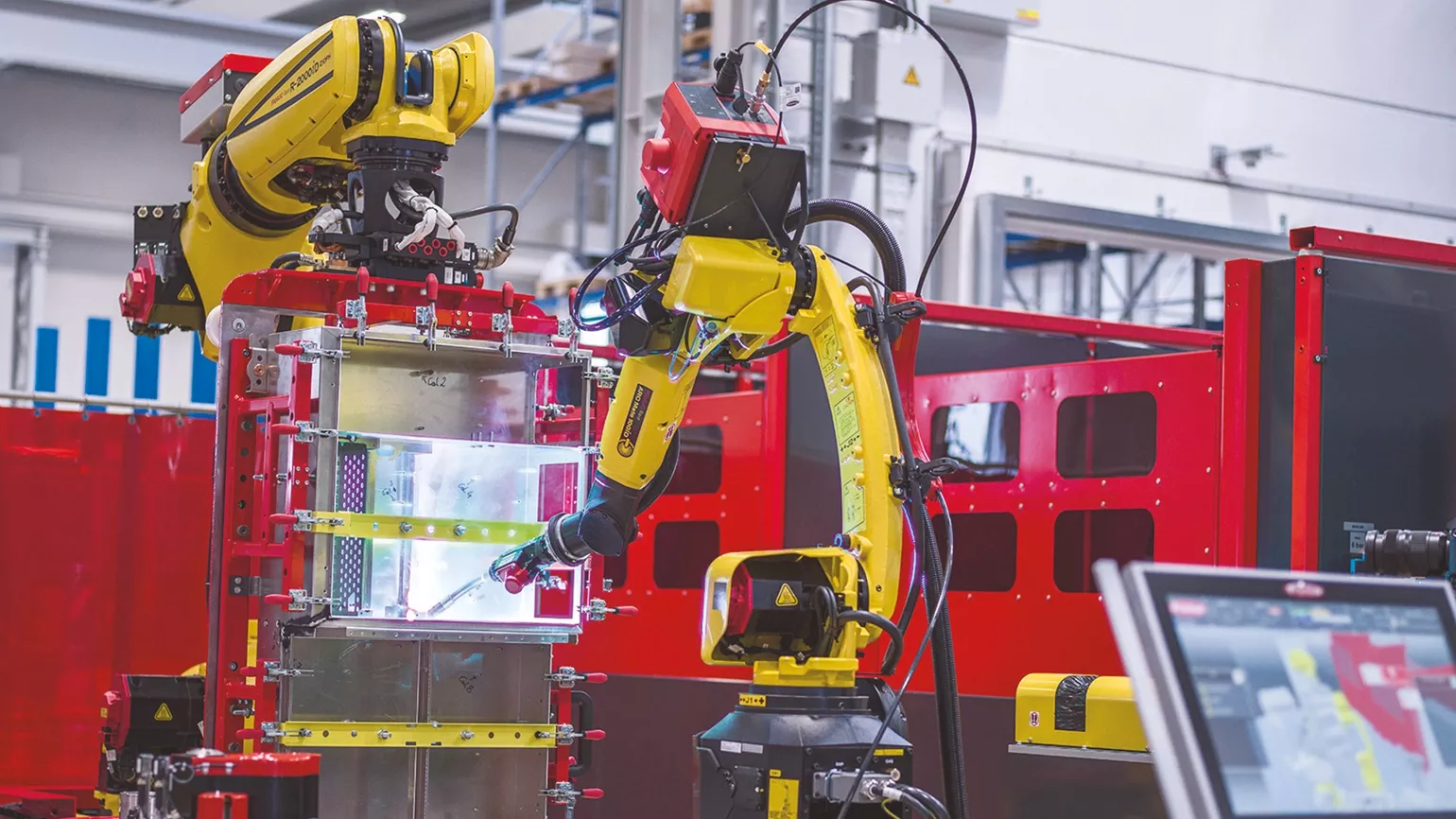

Additive manufacturing on the rise

Additive

manufacturing places specific requirements on the

welding process. This technology enables complex, custom-designed components to

be produced with high precision and low material consumption. One example of

this is pipeline construction, where completely new standards and requirements

are currently under development. As a member of the “Joint working group for

additively manufactured components under the Pressure Equipment Directive of

the German Institute for Standardization (DIN)”, at Fronius we are at the

forefront of this work. Working in collaboration with MIGAL.CO, Linde

Engineering, and TÜV SÜD, we took part in the model qualification

of an additively welded pipe branch in the form of a pressure vessel. The

working group assessed the applicability of the draft standard prEN 13445-14 to

the components of unfired pressure vessels. This collaboration resulted in our

new Fronius Additive Pro characteristic for the Wire Arc Additive Manufacturing

(WAAM) process, which enables fast, cost-efficient, and precise component

production.