Safe welding

with protective equipment

Hazards due to arc radiation

The result is an acute inflammation of the cornea and conjunctiva known in the medical field as keratoconjunctivitis photoelectrica—and referred to simply as “arc eye” in the trade. This painful reaction is the result of intense UV exposure and can be reliably avoided by using eye protection for every welding activity.

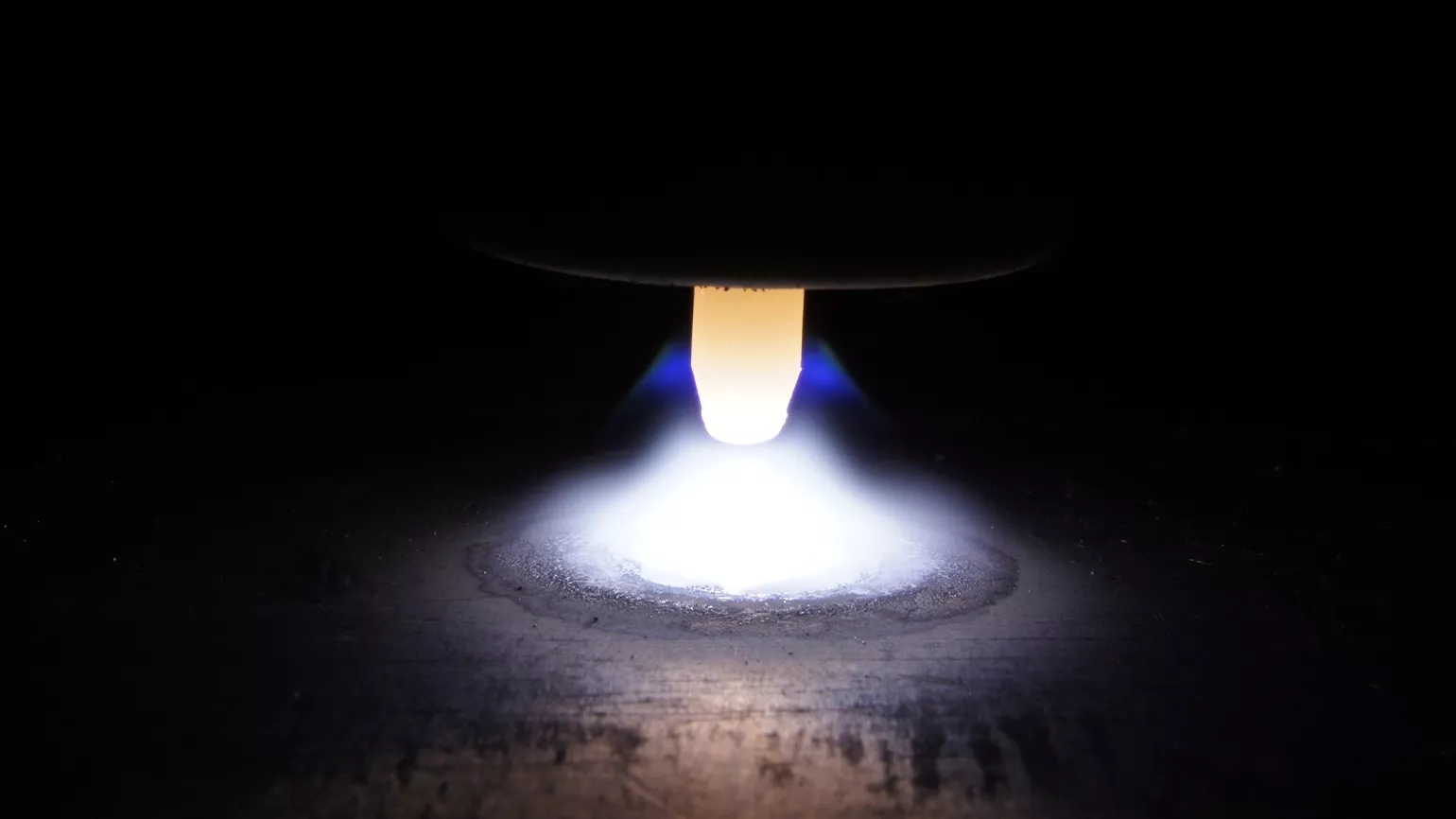

What exactly is an arc?

An arc consists of an electrically conductive plasma that forms between the electrode and the workpiece. This plasma contains:

- Electrons (negatively charged)

- Ions (positively charged)

- Photons—light particles that emit radiation in the visible, UV, and IR range

- Neutral particles—non-ionized gas atoms

- Metal vapor—vaporized particles from the electrode and workpiece

The so-called arc column reaches extreme temperatures of between 3,700 and 15,700 degrees Celsius (equivalent to around 4,000 to 16,000 Kelvin). Heat and radiation make the arc an equally impressive and dangerous tool—so handling it safely is a top priority.

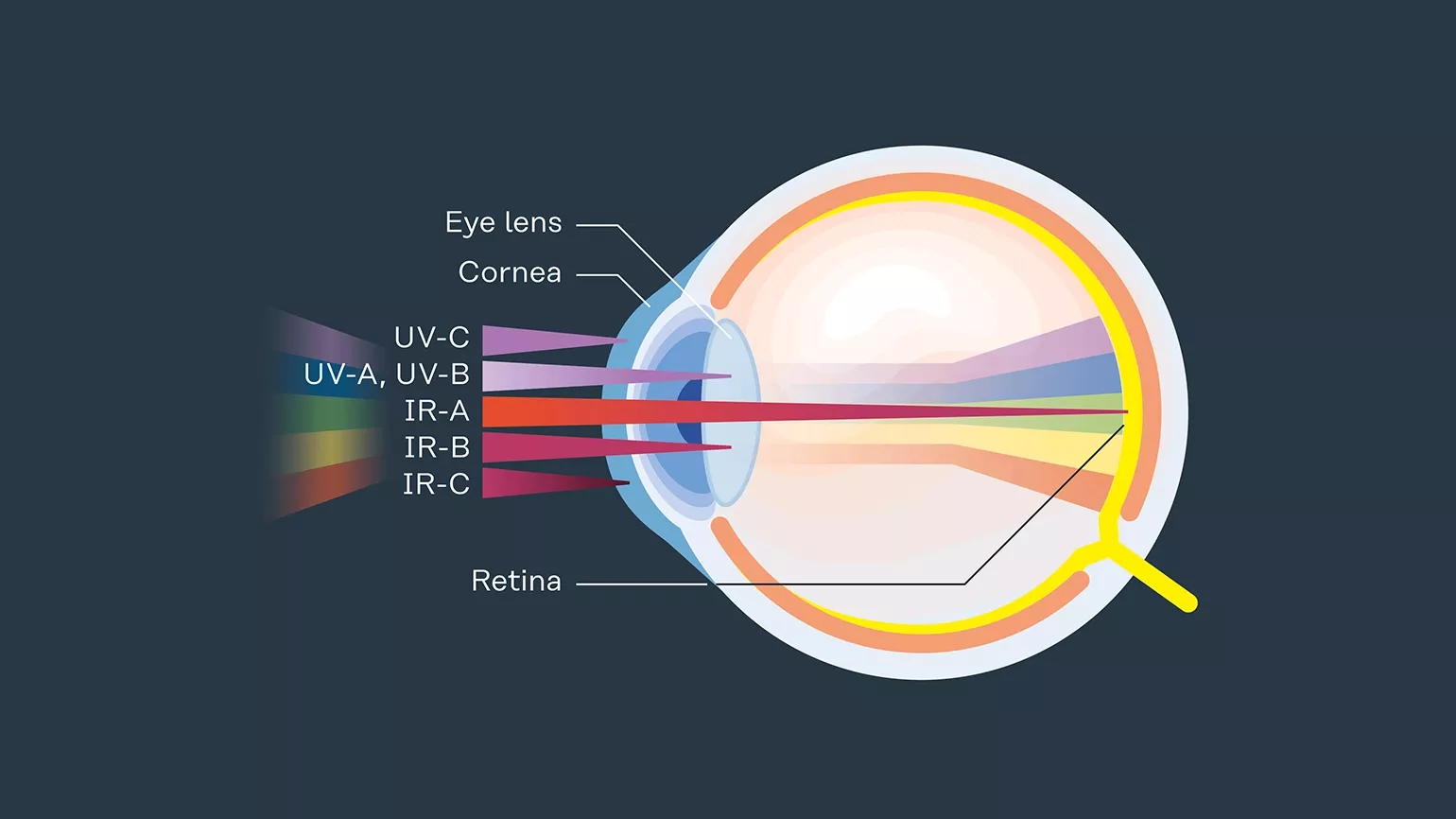

Types of light in the arc—radiation and effect

The arc emits different types of radiation, each of which carries its own health risks. Handling these types of radiation with care is crucial to safety in the workplace.

1. Visible light

This type of light has a strong dazzling effect and can significantly impair vision. This poses a safety risk for welders, especially during precision work.

2. Infrared radiation (IR)

This radiation penetrates deep into the tissue and is often only perceived as heat. However, prolonged or intense exposure can lead to serious thermal damage—including skin burns.

3. Ultraviolet radiation (UV)

This is considered the most dangerous type of radiation during welding. UV rays can cause acute inflammation of the cornea and conjunctiva—colloquially referred to as “arc eye” (see above). It also poses a risk to the skin, as UV radiation can cause sunburn and significantly increase the risk of skin cancer with repeated exposure.How should you respond to arc eye injuries?

Experiences like these are not uncommon among welders. Many resort to home remedies in a pinch by rinsing their eyes with saline solution or applying cloths soaked in cold milk. While they mean well, these remedies can do more harm than good.

This is because arc eye causes microscopic injuries to the cornea—leaving minute scars that can easily become inflamed. Home remedies such as milk or non-sterile compresses can actually aggravate the inflammation and delay the healing process.

For this reason, we can only recommend that if you have symptoms such as burning, watery eyes, sensitivity to light, or a feeling of sand in the eyes, it is vital to seek medical advice immediately.

“I know welders who can hardly see anything during TIG welding—because they didn’t adequately protect themselves for decades and have never taken the symptoms seriously,” Bichler cautions.

The medical perspective:

“The symptoms must be taken seriously and treated immediately to avoid permanent damage,” explains Dr. Diana Pöppl from the Austrian General Accident Insurance Institution (AUVA). With expert treatment, injuries usually heal completely within 24 to 48 hours.

Typical symptoms include redness, very watery eyes, sensitivity to light, and the feeling of having a foreign body in the eye. Dr. Pöppl advises: “Contact lenses should be removed immediately and the eyelids kept closed. Under no circumstances should you rub the eye with your fingers—this will only make the inflammation worse.”

Medical treatment usually initially includes antibiotic eye drops and anti-inflammatory medication.

Recurring arc eye—underestimated long-term

consequences

If the eyes are repeatedly exposed to intense UV

radiation during welding, there is a risk of serious health consequences. If it

happens repeatedly, arc eye can cause chronic inflammation and permanent damage

to the cornea. This results in increased susceptibility to further injury, a

greater risk of developing cataracts—and in the worst case even blindness.

Protection starts with the right equipment

Consistent eye protection is essential when it comes

to effectively avoiding these risks. Welders should always wear tested helmets

with reliable UV and IR filters. Equally important are certified welding protection screens, as they also protect people in the vicinity from hazardous radiation. “Regular breaks and targeted training also help to increase safety,” stresses Dr. Pöppl from AUVA.

An investment in quality—modern welding helmets on the

job

A welding helmet is more than just workwear—it’s a key element of the personal

protective equipment. When you invest in quality, you’re not only protecting

your health but also making work more efficient and comfortable.Here are two examples of our high-grade helmets:

Vizor 4000 Air/3X Professional:

Equipped with an integrated fresh air supply, this helmet provides ideal

protection and is very comfortable to wear—making it perfect for long

periods of welding work in demanding conditions.

Vizor Crystal:

The Vizor Crystal features innovative anti-glare technology, which lets you perceive color almost as clearly as you would through a clear glass window in light conditions. But it’s in darkness that the helmet displays its full potential, giving welders a detailed and high-contrast view of the weld pool with razor-sharp clarity—for the ultimate in precision work.

What other hazards pose a risk for welding teams?

Full-body protection is a

must

The most effective protection consists of

shielding the entire body from top to bottom. This can only be done by using

complete personal protective equipment (PPE) that is tailored to the specific

welding requirements. This PPE includes: - A high-quality welding helmet with reliable glare protection

- Suitable safety goggles for grinding and prep work

- Flame-retardant, heat-resistant protective clothing

- Robust protective gloves with high mechanical and thermal resistance

Consistently adhering to these protective measures is the only way to effectively minimize the various hazards inherent in welding—and create safe and healthy working conditions for the long term.

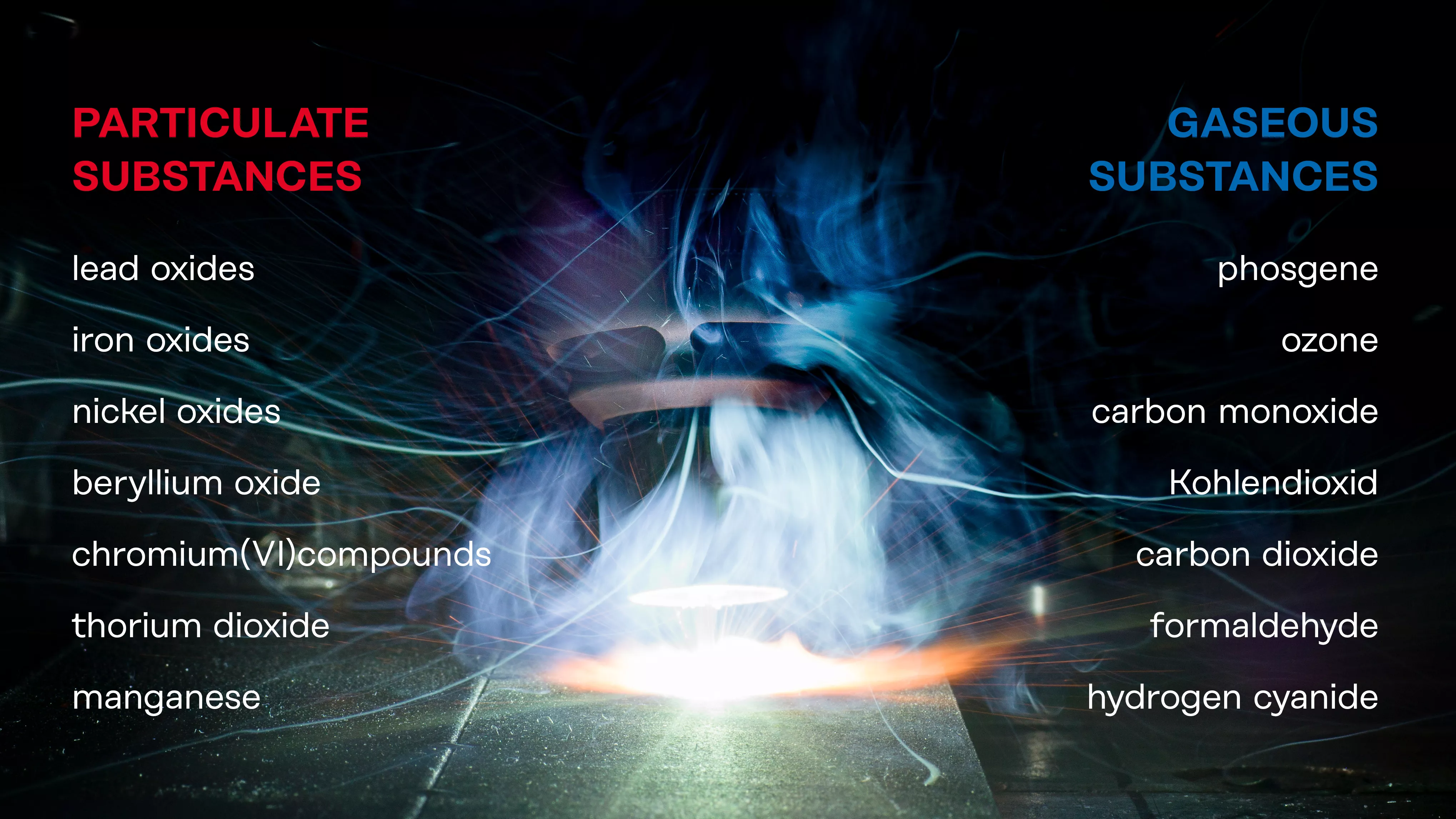

Dangers caused by welding fume

How is welding fume produced?

The harmful gaseous substances result from the shielding gases used (e.g., argon and carbon dioxide) as well as from reactions with surface impurities such as paint, oil, or solvents. Depending on the process and material, ozone and nitrous gases can also form.

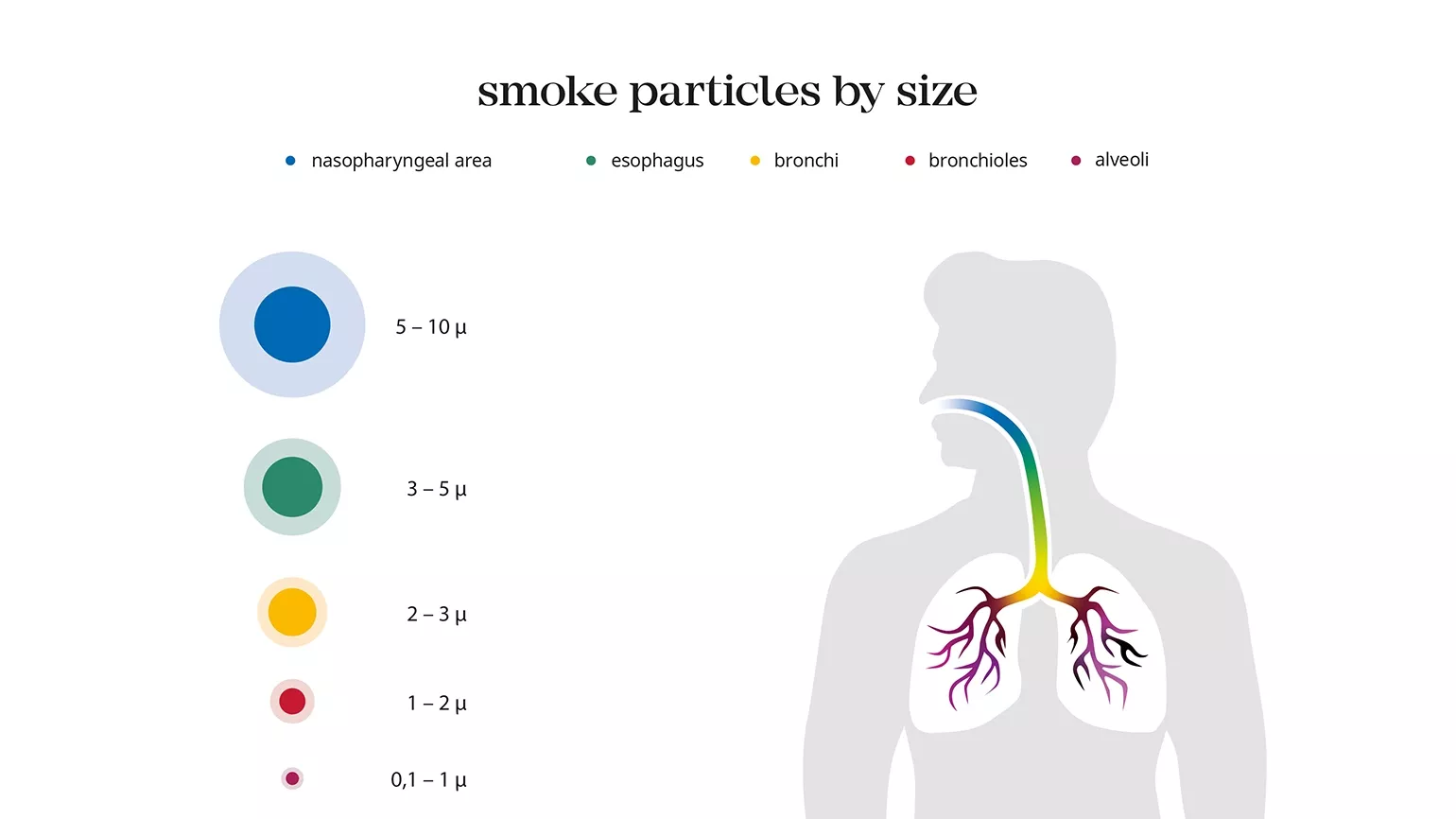

Particle sizes and their effects

The composition and quantity of harmful substances depend on several factors:

the welding process, the process parameters, the filler metal, and the

properties of the workpiece surface.Harmful particulate substances are broken down into two subgroups:

- Inhalable fraction (I dust): Particles with a diameter < 10 µm

- Alveolar dust fraction (A dust): Particles with a diameter < 2.5 µm

One particularly critical aspect is that the majority of particles produced during welding are alveolar—and many are even smaller than 1 µm. Ultra-fine particles (< 0.1 µm) pose a particular hazard. Because they are so minuscule they can penetrate deep into the alveoli, where they are harmful to health.

Welding fume—the underestimated health hazard

-

Substances harmful to the respiratory tract and lungs

This group includes metal oxides such as aluminum, iron, and magnesium oxides in particular. Prolonged exposure can irritate the respiratory tract and damage lung tissue. Potential consequences include chronic bronchitis, a narrowing of the airways, or abnormal accumulations of iron known as siderosis, in which iron oxides are deposited in the lungs. There is also a greater chance of developing pulmonary fibrosis—a lung disease in which lung tissue becomes damaged and scarred—when welding fume occurs in high concentrations.

-

Toxic substances

These substances become harmful once certain concentration limits are exceeded and include carbon monoxide, nitrogen oxides, ozone, and manganese, copper, and zinc oxides. In high doses, they can cause severe poisoning—sometimes with life-threatening consequences.

-

Carcinogenic substances

Some components of welding fume are considered carcinogenic, especially chromium (VI) compounds, nickel oxides, and cobalt oxide. These substances are primarily released when welding high-alloy steels. They have a long-term and particularly insidious effect, as they can cause malignant cell changes.

Protective measures—taking effective action according to the STOP principle

Protection against welding fume centers on the proven STOP principle: substitution, technical measures, organizational measures, and personal protective equipment. Working on this basis, individual safety policies can be determined as part of a risk assessment and implemented in a targeted way that suits the working environment.Substitution: Avoid harmful substances before they occur

Emissions can be significantly reduced right from the point when processes and materials are selected:

- Choose the right welding process: Processes such as TIG welding produce significantly less fumes and are preferable where technically feasible.

- Optimize filler metals: Around 95% of welding fume comes from the filler metal, so it pays to use low-emission welding wires.

- Adjust shielding gases: The composition of the gas can also influence the emission rate.

- Use machine settings: Modern welding machines with functions such as Pulse Multi Control (PMC) or Low Spatter Control (LSC) stabilize the arc, reduce spatter—and therefore also inhibit fumes.

Technical protective measures: Stop emissions where they occur

Technical solutions help to capture harmful substances directly at the point of origin:

- Encapsulated systems: Closed welding cells with integrated extraction—such as in robot welding systems—offer a high level of protection.

- Extraction technology: Fume extraction torches, adjustable hoods, or stationary extraction systems ensure effective capture of emissions.

- Room ventilation systems: Building extraction systems, ceiling-mounted air purifiers, or regular cross ventilation improve air quality in the entire working area.

- Structural measures: Keeping welding workstations separate reduces the spread of harmful substances.

Organizational protective measures: Designing work

processes for safety

Organizing the workplace effectively can also significantly reduce exposure:

- Workplace design: Clean workpieces, ergonomic working positions, and limited exposure times all increase safety.

- Maintenance and control: Extraction and ventilation systems and welding machines must be checked and serviced at regular intervals.

- Training: Only people who know the risks can apply protective measures consistently—which makes regular training essential.

Personal protective measures: Respiratory

protection—the final defense

Respiratory protection is mandatory when technical and

organizational measures are not sufficient or cannot be fully implemented. In

many cases, it is also used as additional protection to further minimize

exposure to harmful substances.

A call to action for companies

It’s vital that the health of welding specialists be given top priority. Companies are required to provide comprehensive protection for their employees—including high-quality protective equipment, regular training, and healthy working conditions.We support metalworking companies by offering a wide range of PPE that meets the highest safety standards—to ensure safety, efficiency, and accountability at work, every day.