Electrical current

The unseen hazard of welding

But one often underestimated aspect is a hazard that remains unseen: electrical current.

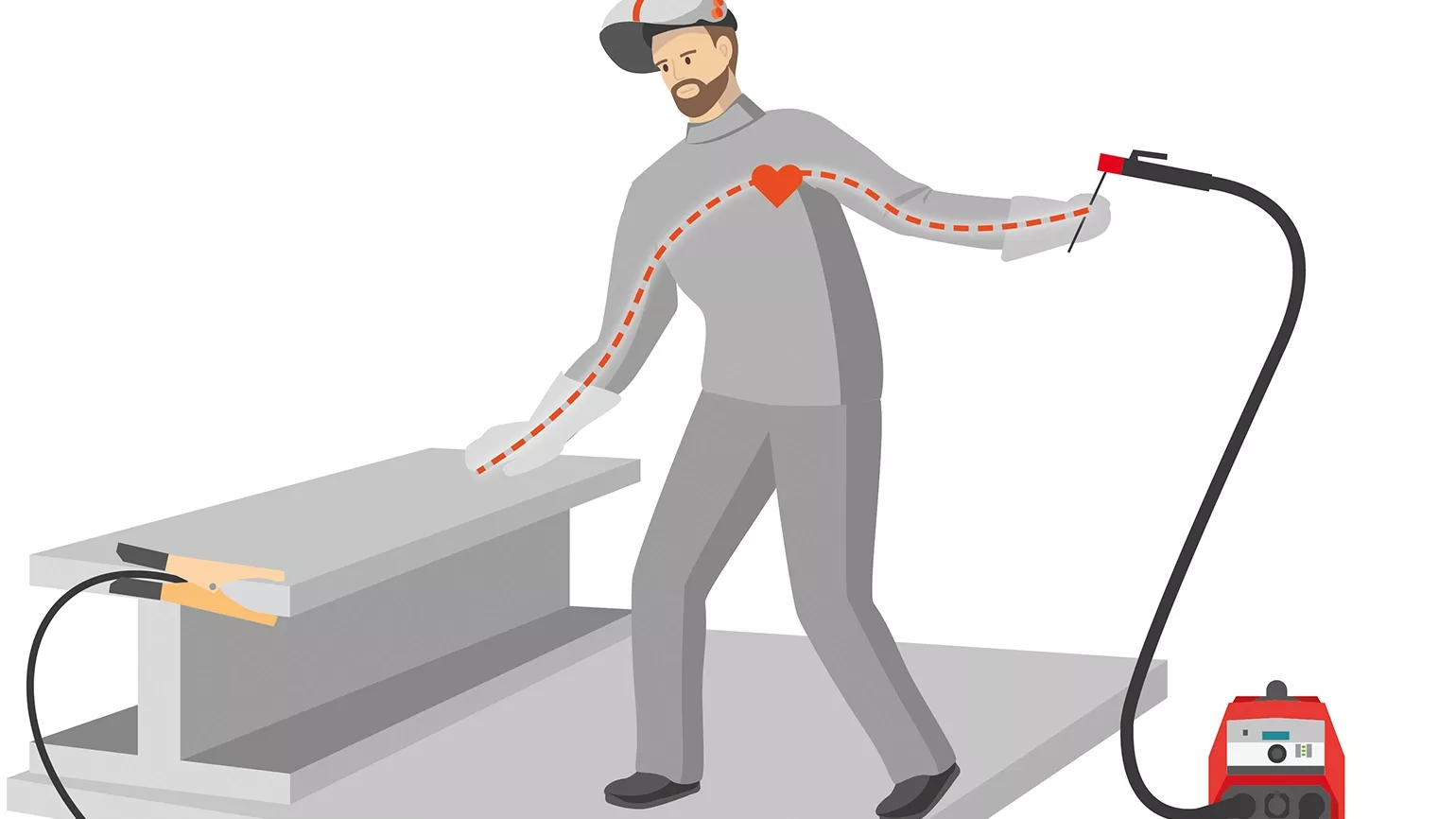

Electrical current always takes the shortest path through the body between the point of entry and the point of exit. If it runs through both hands, for example, the current not only flows through the arms and upper body, but also vital organs such as the heart—with potentially fatal consequences (drawing 1).

Caution around open circuit voltage

While live parts of commercially available electrical

appliances are protected against contact, arc welding poses an increased risk

because the open circuit voltage can become dangerous contact

voltage—especially if the workpiece (ground) and the electrode or non-insulated

parts of the electrode holder are touched at the same time. In this case, the

current travels through the human body.

Depending on the operating conditions, fixed maximum

limits apply to the open circuit voltage. There is an electrical hazard to

humans starting at voltages of more than 25 V AC (RMS) or

60 V DC and where there is the potential for a sufficiently high

current to flow at the same time.

Even low amperages can be lethal

When electrical current travels through the human

body, it has a stimulating effect on muscles, nerves, and the cardiovascular

system. Potential consequences range from muscle cramps and respiratory arrest

to “current marks”—small, point-like burns at the entry and exit points of the

current. Amperages of 30 milliamperes or more pose an acute risk to life.

The “let-go current” is between 10 and 15 mA for alternating current and

around 50 mA for direct current. If this threshold is exceeded, muscle

cramps can be so severe that those affected are no longer able to let go of

live parts without assistance—an especially high risk for welding specialists

in everyday working life.

Alternating current is considered to be significantly

more dangerous than direct current, as it can affect the heart’s natural rhythm

and trigger ventricular fibrillation. Another factor that often goes

underestimated is that even low amperages of between 1 and 10 mA are

sufficient to trigger involuntary reflex movements, which often result in

secondary accidents. These uncontrolled reactions could, for example, lead to a

fall from a ladder or other injuries.

In addition to the amperage, the duration of exposure

to the human body also plays a decisive role in the risk of injury. The longer

the flow of current lasts, the more serious the impacts on health. For this

reason, it is essential that welding specialists wear suitable protective

equipment at all times. In Europe, welding gloves must meet the requirements of

the EN 12477 standard, while work shoes should be protection class S3 in

accordance with EN ISO 20345.

How do you determine the danger?

The amperage (I) is dependent on the applied voltage (U) and the resistance (R) and follows Ohm’s law (U = R x I). If you want to determine the amperage, a human resistance (without protective equipment) of 1,000 ohms can be assumed from hand to hand or hand to foot. If the welding machine has an open circuit voltage of 50 V according to the rating plate, a potentially lethal current of 50 mA can pass through the body in accordance with Ohm’s law (I = U / R).

Caution when welding with several welding machines

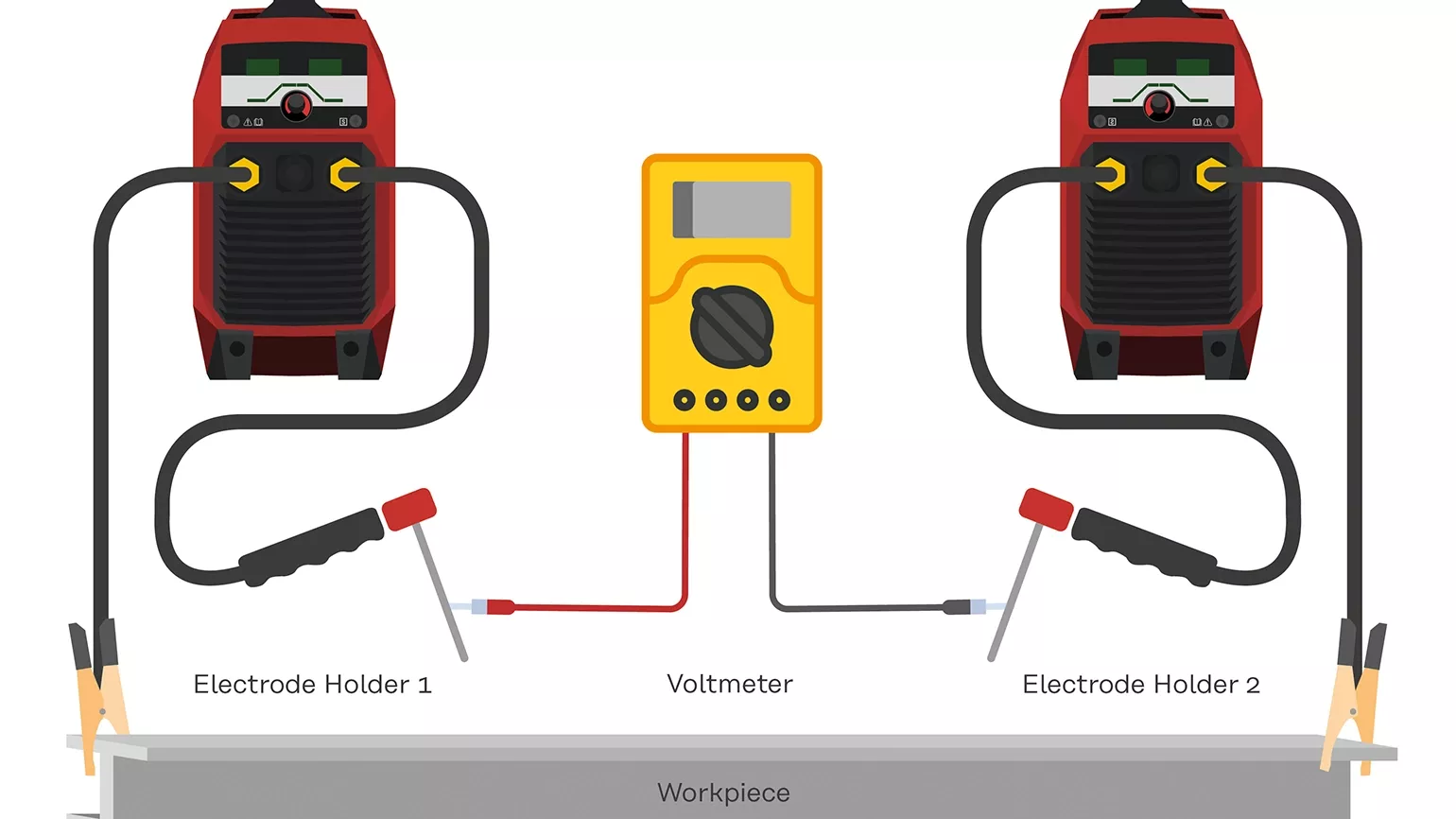

If welding specialists are working on a workpiece with

several welding machines at the same time or on components with a conductive

connection, the contact voltage that occurs—especially the open circuit

voltage—can reach levels higher than permitted. In many cases, this hazardous

situation is not immediately evident.

But the situation becomes especially critical when

welding with different polarities at the same time. In this case, the total

open circuit voltages of the welding machines can lead to dangerously high

voltage levels when welding with direct current (DC).

“This

happens fairly often, especially on construction sites,”

reports Franz Bichler, a welding trainer at Fronius International. “In the past, we often worked in pairs or

threes when welding components several meters long—and even with different

polarities, to get the best results on complex components. If the grounding is

faulty in a situation like this, the accumulated voltage can pass through the

welder’s body—with life-threatening consequences such as electric shocks,

cardiac arrhythmia, or severe burns.”

The employer’s duty to protect and inform

Effective protective measures can prevent workplace

accidents, and the employer is responsible for making sure these are

implemented. International standards and regulations—such as those published by

the ISO (International Organization for Standardization), ASME (American

Society of Mechanical Engineers), AWS (American Welding Society), and DIN

(German Institute for Standardization)—form the basis for safe working

conditions.

Welding specialists must be informed of the

potential hazards in all cases. The distance between the welders must be

selected so that simultaneous contact with two welding torches or electrode

holders is ruled out. If this is not possible, the work areas must be separated

by insulating partitions. In addition, appropriate measurements need to be

taken to ensure that the total voltage does not exceed the maximum permissible

open circuit voltage.

What needs to be taken into account during welding?

Before starting work, welding specialists must ensure

that the welding machines they are using are in perfect condition. Those that

are not in use or are left unattended must be switched off and disconnected

from the power supply. Devices must always be operated in accordance with the

protection class shown on the rating plate—in compliance with the relevant

operating instructions.

Devices in protection class IP21 may only be used in

dry indoor areas. A protection class of IP23 is required as a minimum for

outdoor use. Return lead cables should be connected as close as possible to the

welding area—either directly to the workpiece or to its support.

In the event of faults, the power supply must be

disconnected immediately, either by switching off the device or removing the

mains plug. Any damage to welding machines, mains leads, or hosepacks must be

reported to the welding supervisor immediately. Under no circumstances may

defective devices be used again or opened without authorization—especially not

by removing the protective cover.

Hazards due to stray welding current

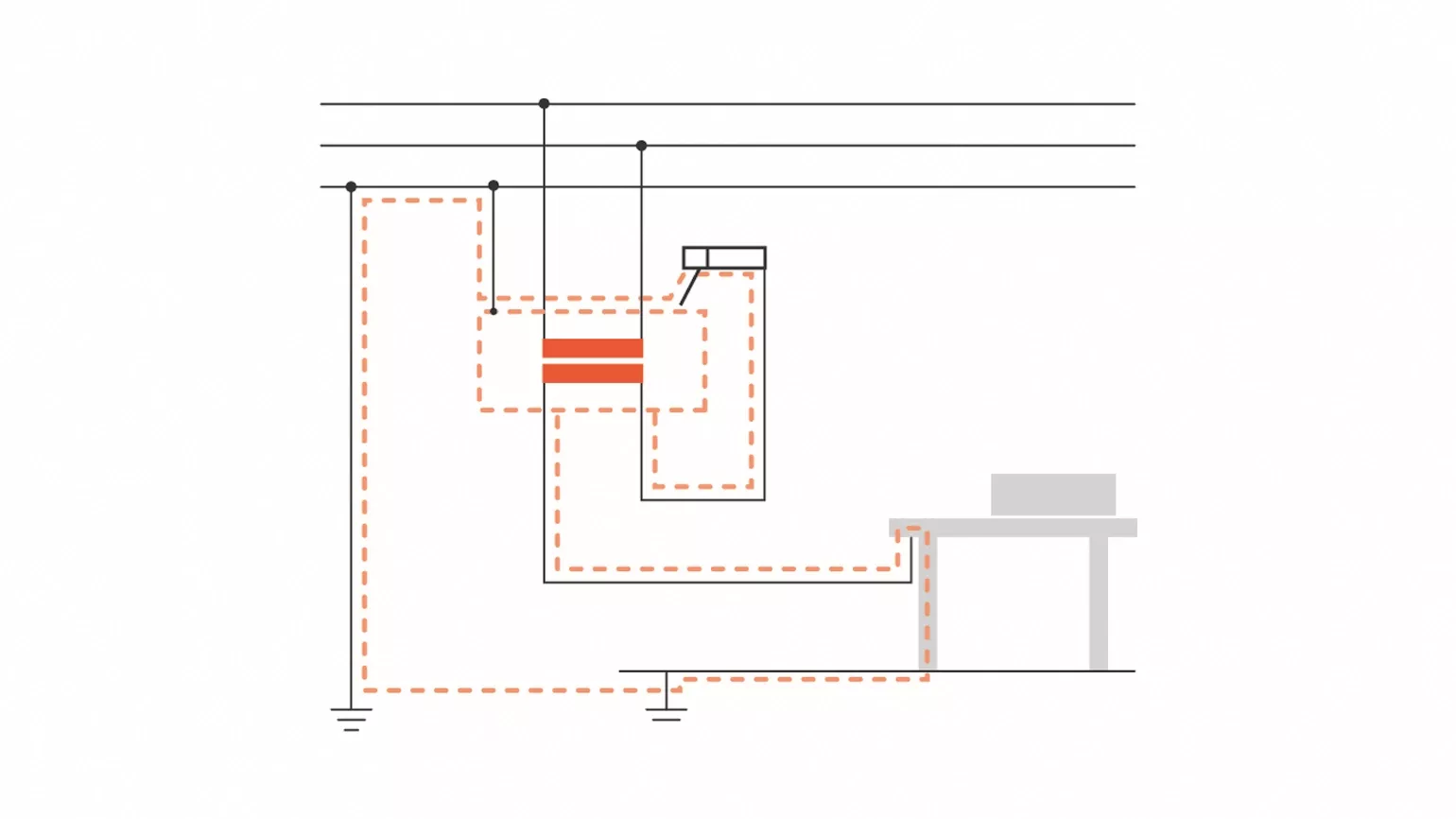

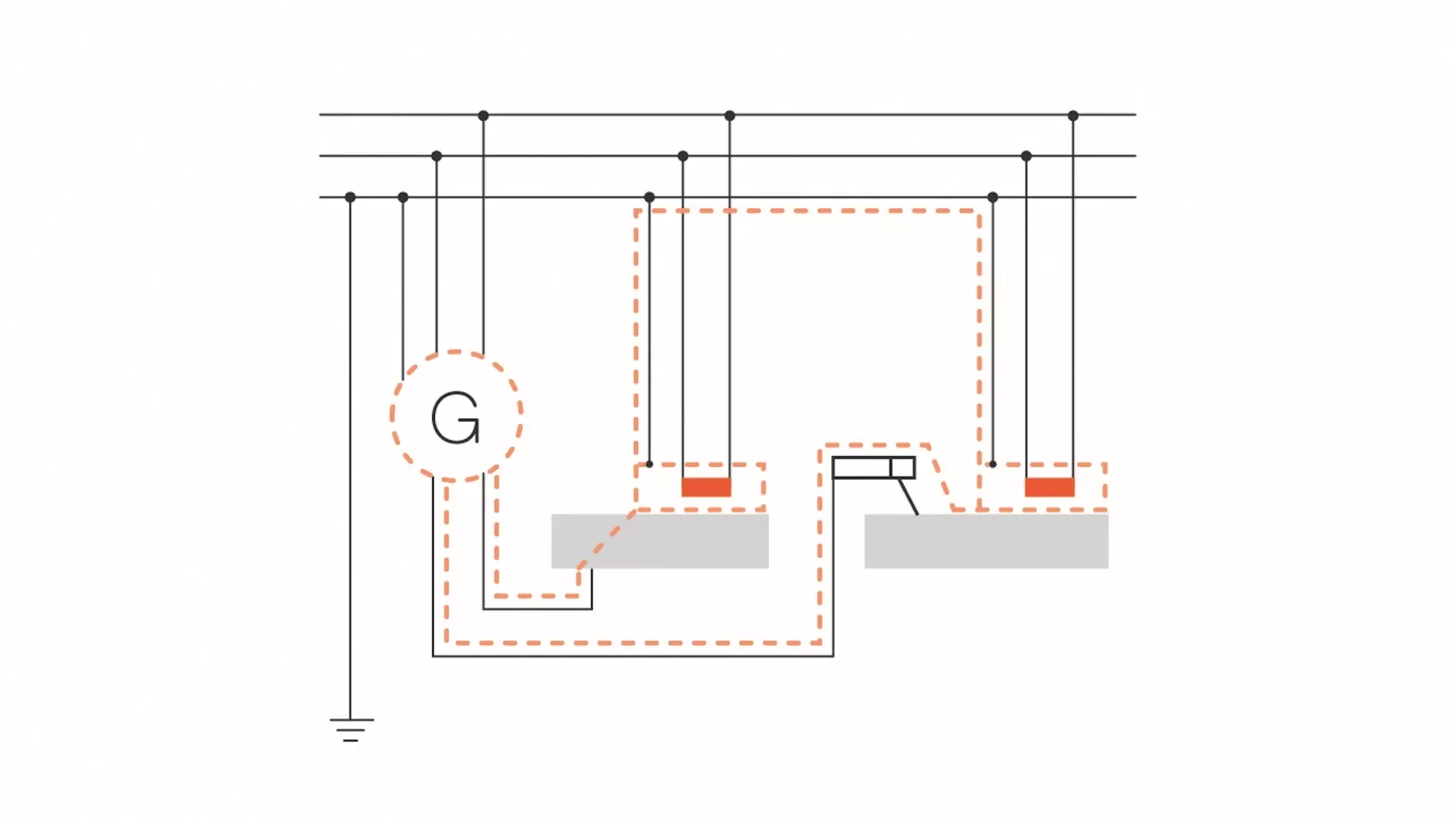

Carelessness and inattention are the most common causes of breaks in the ground conductor and resulting accidents. Typical examples might include uninsulated electrode holders that are set down on the welding machine or power hand tools left on the welding table during welding work (drawings 3 and 4).

If, in exceptional cases, workpieces have to be welded while suspended from a crane hook, they must be carefully shielded—for example, using dry textile ropes or an insulated swivel hook. In cases where suspended work baskets are used while welding, these must be fitted with suitable insulation. Only insulated equipment may be used when welding and working with power tools at the same time.

Working in conditions with high electrical voltage

You can use the following rule of thumb to assess whether there is an increased risk during arc welding: If the free space between electrically conductive parts positioned opposite one another is less than two meters—in length, width, height, or diameter—you should assume that there is an increased electrical risk.

Make sure to take particular care in wet, damp, or hot workplaces, as the resistance of human skin, protective clothing, and protective equipment may be significantly reduced by moisture or perspiration in these environments. Workplaces should be considered “wet” if workwear is soaked with moisture and can therefore conduct electricity—which significantly increases the risk of an electrical accident.

Protective measures in the event of increased

electrical risk

Only approved welding machines marked with the [S]

symbol may be used for work involving an increased electrical hazard. Special

protective measures are also required to ensure welding specialists are

protected from electrically conductive parts as well as damp floors and walls

by means of insulating underlays or intermediate layers of material.

If this shielding cannot be provided due to additional hazards—such as a risk of falling—or a lack of space, work may only be carried out while wearing dry, undamaged workwear. In situations where you cannot guarantee that clothing will remain dry, such as in hot environments, only direct current machines may be used for manual arc welding.

The open circuit voltage of the devices used should be kept as low as possible—depending on the welding tasks and device properties—and must not exceed 75 V. Welding machines must not be set up in the immediate danger zone. Protective extra-low voltage must be used for remote control of these devices.

Also ensure that welders do not work alone on these jobs—suitable supervision must be provided during welding. Only qualified specialists may carry out welding work involving an increased electrical hazard.

Summary and conclusion

Safety comes first when welding. Improper handling of

welding machines can have serious consequences—especially due to high open

circuit voltages, stray welding current, or when working in conditions

involving increased electrical hazards. However, these risks can be

significantly reduced by consistently observing suitable protective measures.

Special attention is required in wet, damp, or hot workplaces, where the protection provided by clothing and equipment may be impaired. If faults occur, appropriate steps must be taken immediately to prevent personal injury and damage to property.