Metal 3D printing

on the rise worldwide

This is where metal 3D printing comes in. Fronius Welding is setting a milestone with the CMT Additive Pro process variant.

Creating shapes layer by layer

Metal 3D printing, like all other 3D printing

processes, is a manufacturing process that has revolutionized the production of

many products both technically and economically. Building a product

layer-by-layer, which seemed like science fiction years ago, is a reality

today. Three-dimensional objects can now be produced through the layered,

additive build-up of weld metal. This welding wire-based method of additive

manufacturing is gaining momentum, as it increases the flexibility and thus the

competitiveness of many companies. Potential applications can be found in the

automotive, electronics and consumer goods, oil and gas, aerospace, power plant

construction, toolmaking, medical technology, and construction industries.

Possibilities and advantages

Classic production processes often require complex

molds and tools to be constructed, and are associated with long lead times and

high set-up costs. Additive manufacturing helps to significantly shorten

development cycles. Printing components on demand accelerates prototype

construction (rapid prototyping), enables just-in-time production—doing away

with stockholding—and simplifies repair work.

When spare parts are needed, the correct “recipes” are selected in the software and printed as required. There are hardly any limits for component geometries. Even complicated honeycomb and cavity constructions that could not be realized with conventional methods are possible.

Metal 3D printing really comes into its own in prototype construction: design weaknesses can be identified at an early stage and corrected without time-consuming, cost-intensive mold construction. This accelerates innovation processes and increases operational efficiency.

Additively manufactured, topology-optimized (structure and load flow-compatible) components are often significantly lighter than conventionally manufactured components—and thus contribute to reducing energy consumption in vehicles or aircraft, for example. Their high strength and low weight also offer a high degree of material and operational safety.

The processes involved in metal 3D printing are

divided into two fundamental types: powder-based and wire-based. In

powder-based processes, the layers are built up using molten metal powder. The

most common method currently, the powder bed process, boasts a high degree of

precision, but is relatively slow. The wire-based process builds up the

workpiece by melting the wire using either an electron beam, a laser, or an

arc. These processes have a high deposition rate and therefore help to cut

production times.

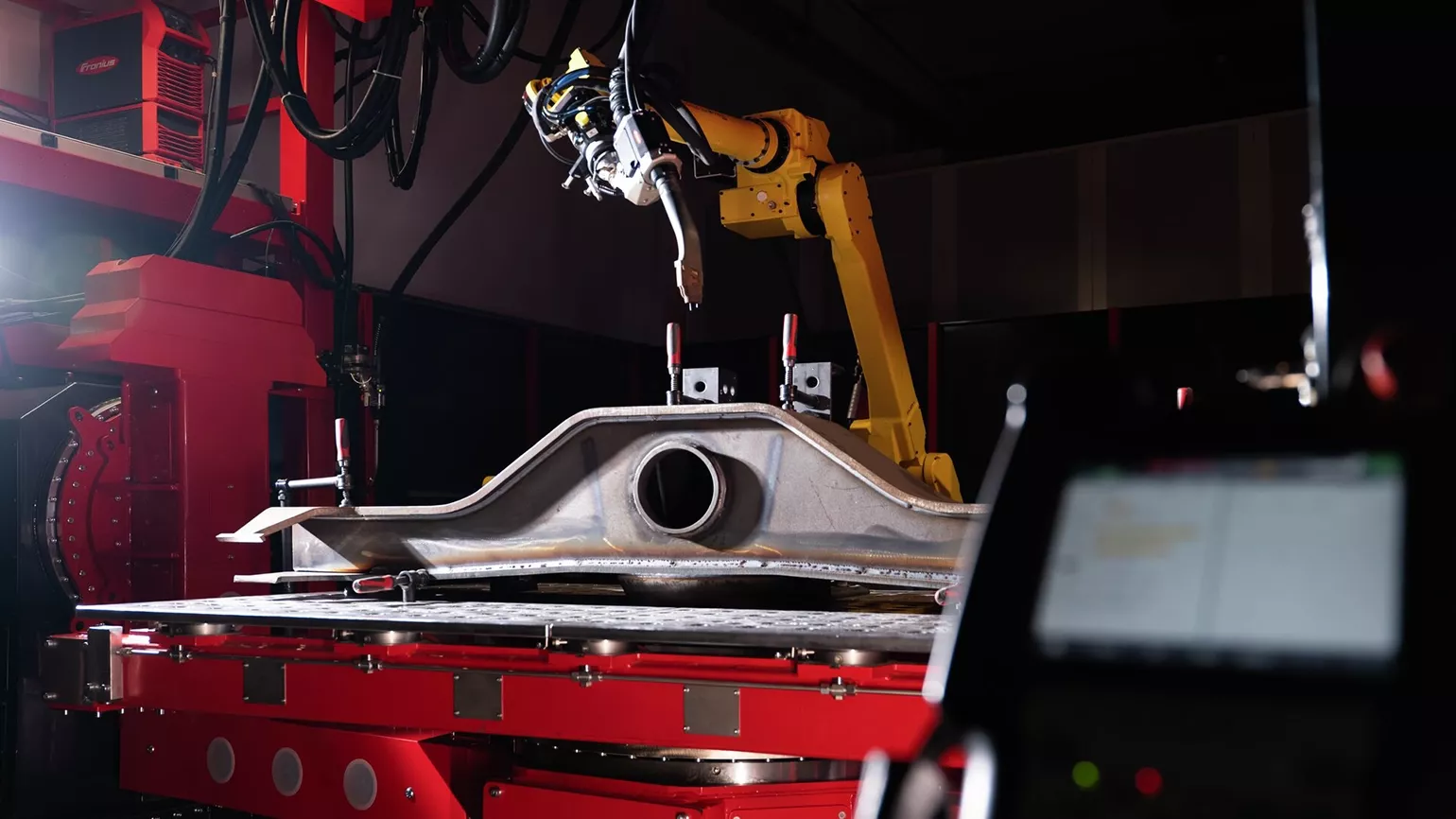

Wire arc direct energy deposition, or DED-Arc for short, is arc-based and uses the gas metal arc welding process (GMAW). This variant currently has a deposition rate of up to 4 kg/h, but this figure is expected to increase in the future as special processes and multi-wire solutions come on stream.

At the heart of DED-Arc is a stable welding process such as Fronius CMT Additive Pro. There is no need for costly vacuum chambers, such as those required in the electron beam process. “The right welding path in combination with the right welding processes and parameters are crucial for a good printing result,” explains Wolfgang Scherleitner, Head of Prototyping & Manufacturing Center. “With CMT Additive Pro, we have launched a revolutionary, 3D-optimized welding process with impressive features such as an especially even layer structure, as well as high quality and stability. Together with the iWave Multiprocess Pro welding machine, it provides perfectly coordinated equipment that is compatible with all common welding robots and opens up a wide range of possibilities.”

With CMT (Cold Metal Transfer), Fronius has been

offering a highly stable, easily controllable, and comparatively cool welding

process for decades. Used worldwide in additive manufacturing, the process has

now been optimized for metal 3D printing and offers a process-integrated deposition rate stabilizer in addition

to layer-optimizing power correction. This ensures a constant wire speed, which

leads to an even, predictable layer build-up.

In additive manufacturing, the welding wire melted per unit of time must correspond to the volume specified in the welding program. The CMT universal characteristic is regulated to an average constant welding current, with the result that different stickout values (CTWD—contact tip to work distance) lead to different wire speeds, which is why the layer build-up cannot be reproduced one-to-one. Fronius CMT Additive Pro, on the other hand, is regulated to the average constant wire speed and remains at this value regardless of the stickout.

The power correction regulates the heat input and keeps the width and height ratio of the bead constant, regardless of the temperature of the base material and the welded beads. If a new filler material is required during the layer build-up, the arc must be ignited again after the refilling process—a new welding start is required. This can lead to a lack of fusion or weld reinforcement in the start area. Fronius solves this with a pulsed HotStart function modified for CMT Additive Pro. As with CMT universal, the starting current is increased, but the system switches to a pulsed arc in the start phase, thus achieving significantly more power and the same deposition rate as in the main current phase.

In summary, CMT universal has been supplemented with valuable features for optimum 3D printing results and everything has been combined in one characteristic. The team of experts at the Prototyping and Manufacturing Center are on hand to come up with even more solutions for demanding welding challenges.

When spare parts are needed, the correct “recipes” are selected in the software and printed as required. There are hardly any limits for component geometries. Even complicated honeycomb and cavity constructions that could not be realized with conventional methods are possible.

Metal 3D printing really comes into its own in prototype construction: design weaknesses can be identified at an early stage and corrected without time-consuming, cost-intensive mold construction. This accelerates innovation processes and increases operational efficiency.

Additively manufactured, topology-optimized (structure and load flow-compatible) components are often significantly lighter than conventionally manufactured components—and thus contribute to reducing energy consumption in vehicles or aircraft, for example. Their high strength and low weight also offer a high degree of material and operational safety.

DED-Arc: Metal 3D printing with high-end welding

technology

The processes involved in metal 3D printing are

divided into two fundamental types: powder-based and wire-based. In

powder-based processes, the layers are built up using molten metal powder. The

most common method currently, the powder bed process, boasts a high degree of

precision, but is relatively slow. The wire-based process builds up the

workpiece by melting the wire using either an electron beam, a laser, or an

arc. These processes have a high deposition rate and therefore help to cut

production times.

Wire arc direct energy deposition, or DED-Arc for short, is arc-based and uses the gas metal arc welding process (GMAW). This variant currently has a deposition rate of up to 4 kg/h, but this figure is expected to increase in the future as special processes and multi-wire solutions come on stream.

At the heart of DED-Arc is a stable welding process such as Fronius CMT Additive Pro. There is no need for costly vacuum chambers, such as those required in the electron beam process. “The right welding path in combination with the right welding processes and parameters are crucial for a good printing result,” explains Wolfgang Scherleitner, Head of Prototyping & Manufacturing Center. “With CMT Additive Pro, we have launched a revolutionary, 3D-optimized welding process with impressive features such as an especially even layer structure, as well as high quality and stability. Together with the iWave Multiprocess Pro welding machine, it provides perfectly coordinated equipment that is compatible with all common welding robots and opens up a wide range of possibilities.”

Exclusive 3D features in a single welding

characteristic

With CMT (Cold Metal Transfer), Fronius has been

offering a highly stable, easily controllable, and comparatively cool welding

process for decades. Used worldwide in additive manufacturing, the process has

now been optimized for metal 3D printing and offers a process-integrated deposition rate stabilizer in addition

to layer-optimizing power correction. This ensures a constant wire speed, which

leads to an even, predictable layer build-up.

In additive manufacturing, the welding wire melted per unit of time must correspond to the volume specified in the welding program. The CMT universal characteristic is regulated to an average constant welding current, with the result that different stickout values (CTWD—contact tip to work distance) lead to different wire speeds, which is why the layer build-up cannot be reproduced one-to-one. Fronius CMT Additive Pro, on the other hand, is regulated to the average constant wire speed and remains at this value regardless of the stickout.

The power correction regulates the heat input and keeps the width and height ratio of the bead constant, regardless of the temperature of the base material and the welded beads. If a new filler material is required during the layer build-up, the arc must be ignited again after the refilling process—a new welding start is required. This can lead to a lack of fusion or weld reinforcement in the start area. Fronius solves this with a pulsed HotStart function modified for CMT Additive Pro. As with CMT universal, the starting current is increased, but the system switches to a pulsed arc in the start phase, thus achieving significantly more power and the same deposition rate as in the main current phase.

In summary, CMT universal has been supplemented with valuable features for optimum 3D printing results and everything has been combined in one characteristic. The team of experts at the Prototyping and Manufacturing Center are on hand to come up with even more solutions for demanding welding challenges.

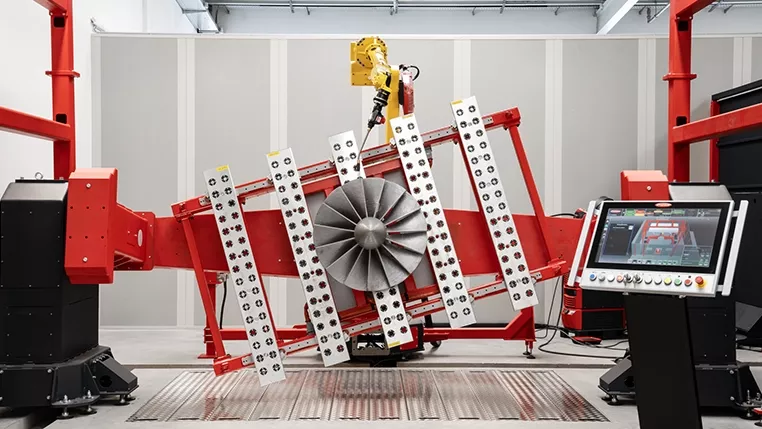

360° service from the feasibility study to the pilot series

In its prototyping

center, Fronius provides a comprehensive service package.

Here, tailor-made solutions are developed for individual requirements, which

optimize customers’ additive manufacturing processes and realize highly complex

components. From the initial consultation and feasibility check to the

manufacturing of parts, everything is carried out in close coordination with

the client, and with the highest degree of discretion. The aim is to minimize

the time-to-market and fully utilize the potential of innovation and technology

in the projects.

The experts support the production of the

initial prototypes and pre-series and ensure customers get off to a smooth

start with the additive manufacturing process. In addition, customers will

receive valid recommendations on the welding process, profitability, quality,

and implementation options, or the costs for the prototype and the start of

production. The 1,000 m² prototyping center in Wels, Austria, has several

isolated robot cells and systems, and offers full service packages, including

offline programming and simulations, metallurgical investigations, 3D component

measurement, complete data documentation, and much more.

Fronius assists with the development of standards

As a member of the “Joint working group for additively

manufactured components under the Pressure Equipment Directive of the German

Institute for Standardization (DIN),” Fronius participated in the model

qualification of an additively manufactured component in collaboration with

MIGAL.CO, Linde Engineering, and TÜV SÜD. The working group assessed the

applicability of the draft standard prEN 13445-14 to the components of unfired

pressure vessels.

The entire process chain was checked using a pressure vessel in the form of a pipe branch. As per the design template, the branch (additively applied area up to the stub) was formed on a conventionally manufactured aluminum base pipe with a cut-out provided for this purpose.

The entire process chain was checked using a pressure vessel in the form of a pipe branch. As per the design template, the branch (additively applied area up to the stub) was formed on a conventionally manufactured aluminum base pipe with a cut-out provided for this purpose.

Aluminum, the naturally hardened wrought alloy, is

mainly used in plant construction because of its excellent low-temperature

toughness down to minus 273 °C. However, it places high demands on the welding

process. It is not only the process selection and the process parameters that

are decisive for the result, but also the choice of filler material, which

plays a fundamental role in metal 3D printing. Tight tolerances apply both to

the wire diameter and to the chemical composition, with the aim being to include

as little hydrogen as possible. Furthermore, the wire must be free of

inclusions and neatly wound onto a spool to ensure that the manufacturing

process runs smoothly. Based on the requirements, CMT Mix was chosen for the

additive build-up of the first weld layers and CMT Additive Pro for the

subsequent wall build-up, where the power correction function significantly

influenced the heat input.

The individual test pieces were subjected to non-destructive and destructive testing as per the requirements of prEN 13445-14. Visual and dimensional tests (VT), volume tests (RT-D), and surface tests (PT) were used as non-destructive testing processes to provide evidence that the pieces were free from faults both externally and internally.

The following video provides detailed information on the model qualification of the pressure vessel: LindeEngineering, TÜV Süd, MIGAL.CO, Fronius

The individual test pieces were subjected to non-destructive and destructive testing as per the requirements of prEN 13445-14. Visual and dimensional tests (VT), volume tests (RT-D), and surface tests (PT) were used as non-destructive testing processes to provide evidence that the pieces were free from faults both externally and internally.

The following video provides detailed information on the model qualification of the pressure vessel: LindeEngineering, TÜV Süd, MIGAL.CO, Fronius