Planet

Ecological responsibility

Decarbonization and climate protection

As an industrial company, we are aware of the effects of our business activities on climate and environment. We take care not to waste energy and resources in any areas and thus are eager to reduce our greenhouse gas emissions.

Our actions along the way:

1. Conversion to renewable energy sources

In 2023, 95% of the energy required at Fronius International GmbH already comes from renewable sources, of which 22% comes from the use of ambient heat from heat pump systems, 4% from biomass, 3% from self-generated electricity from photovoltaic systems, 66% from purchased green electricity and 1% from purchased district heating from a biomass heating plant.

To gradually phase out the use of fossil fuels, we are working to completely replace fuel oil and natural gas as energy sources with renewable energy sources as part of our decarbonization roadmap. While fuel oil as an energy source has already been outsourced, the already low requirement for natural gas will be fully substituted by the end of 2025.

2. Expansion of our PV Facilities

Fronius strives to generate as much of its own electrical energy as possible using photovoltaic systems. In 2023, our PV systems at the Austrian locations had an output of 4.15 megawatt peak (MWp).

The expansion enabled us to increase our own electricity generation to 2.12 GWh in 2023.

3. Increase energy efficiency

The conscious decision to use new and resource-saving technologies is anchored in all areas of the company. We continuously implement measures to optimize energy consumption.

The internal energy monitoring tool is used to continuously monitor and analyze daily energy flows and consumption at site, building, area and meter level. Automated data collection allows energy use and consumption to be controlled and optimized in a targeted manner.

Greenhouse gas emissions

At Fronius, we record our direct and indirect greenhouse gas emissions. Scope 1 includes emissions from energy consumption directly at our sites, including cooling, heating and process energy, and fuel consumption by our vehicle fleet. Scope 2 contains the indirect emissions from the use of purchased electricity and purchased heat. Other indirect greenhouse gas emissions occurring outside our company fall under Scope 3.

Resource and waste management

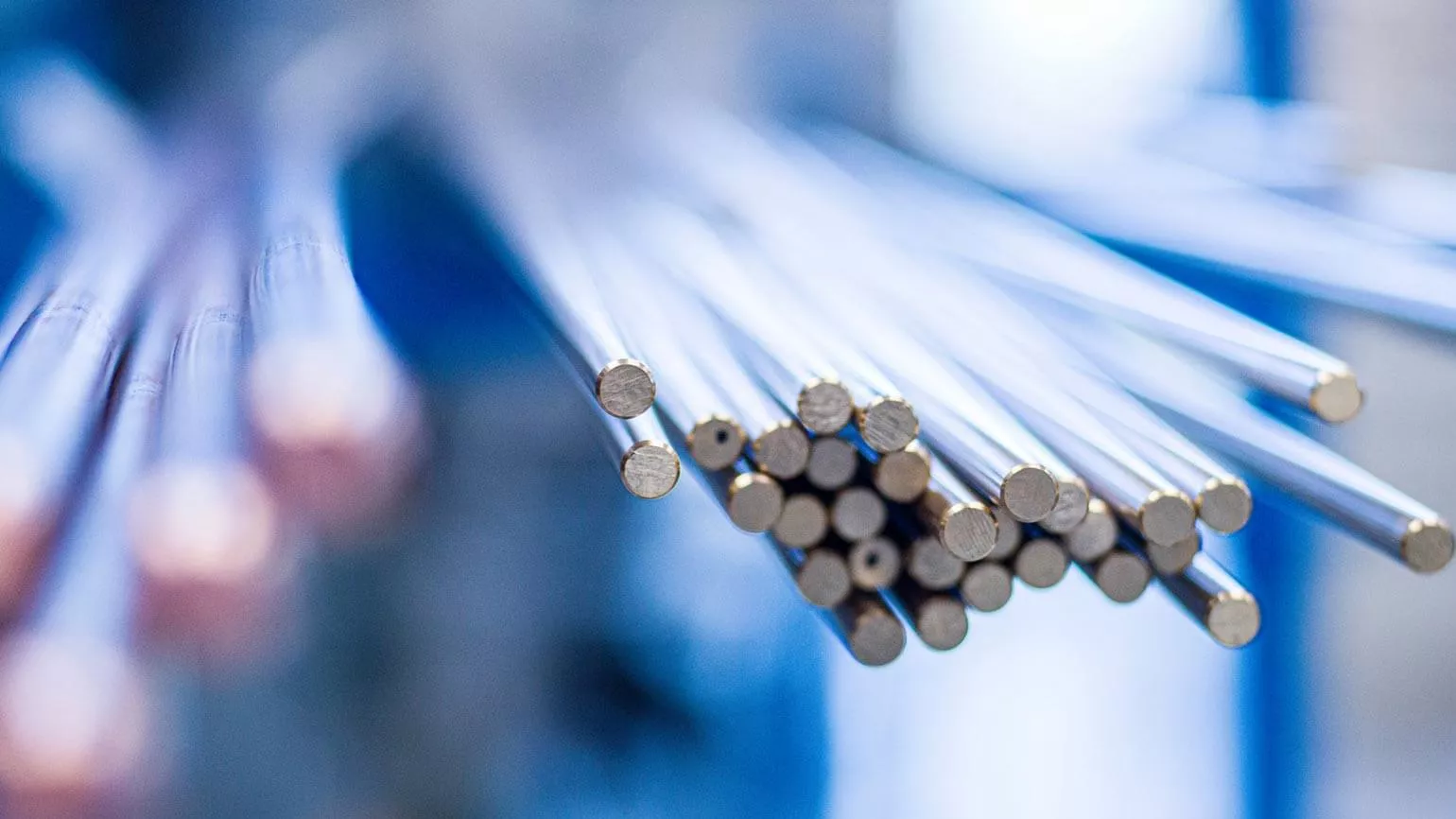

Materials and raw material usage

Thanks to good cooperation between product development and manufacturing, we design efficient and sustainable production processes, saving valuable materials and energy.

The total consumption of materials and raw materials at Fronius International GmbH in the reporting year was 26,151 tons, of which 68 % was accounted for by semi-finished products, 16% by raw materials, 11% by packaging and 4% by auxiliary and operating materials.

Water consumption

At the Fronius International GmbH sites, all sanitary rooms and irrigation systems have been optimized. At the Sattledt site, there is an 800 m³ rainwater collection basin, which is available not only for firefighting purposes but also for garden irrigation.

Water consumption at Fronius International GmbH amounted to 49,230 m³ in the year under review. Around 97% of the water consumed came from the municipal water supply, the rest from surface water, rainwater and groundwater.

Waste and recycling management

Fronius has set itself the goal of avoiding waste as far as possible and returning the unavoidable waste to the cycle as valuable resources as far as possible. This saves the use of raw materials, some of which are only available in very limited quantities on our planet or whose extraction can be very energy-intensive or harmful to the environment.

In 2023, the total waste volume amounted to 4,302 tons. Although the volume of waste generated has increased compared with the previous year, the recycling rate of the waste generated is improving increasingly. Currently, 72% of our waste is recycled - these recyclables are processed for reuse by our waste management companies. A further 27% of waste is thermally recycled. Smaller quantities are composted (0.5%) or landfilled (0.2%).

A total of about 50 different types of waste are collected and subsequently sent for recycling or disposal. As a manufacturer and distributor of products, Fronius is subject to numerous legal requirements and obligations.