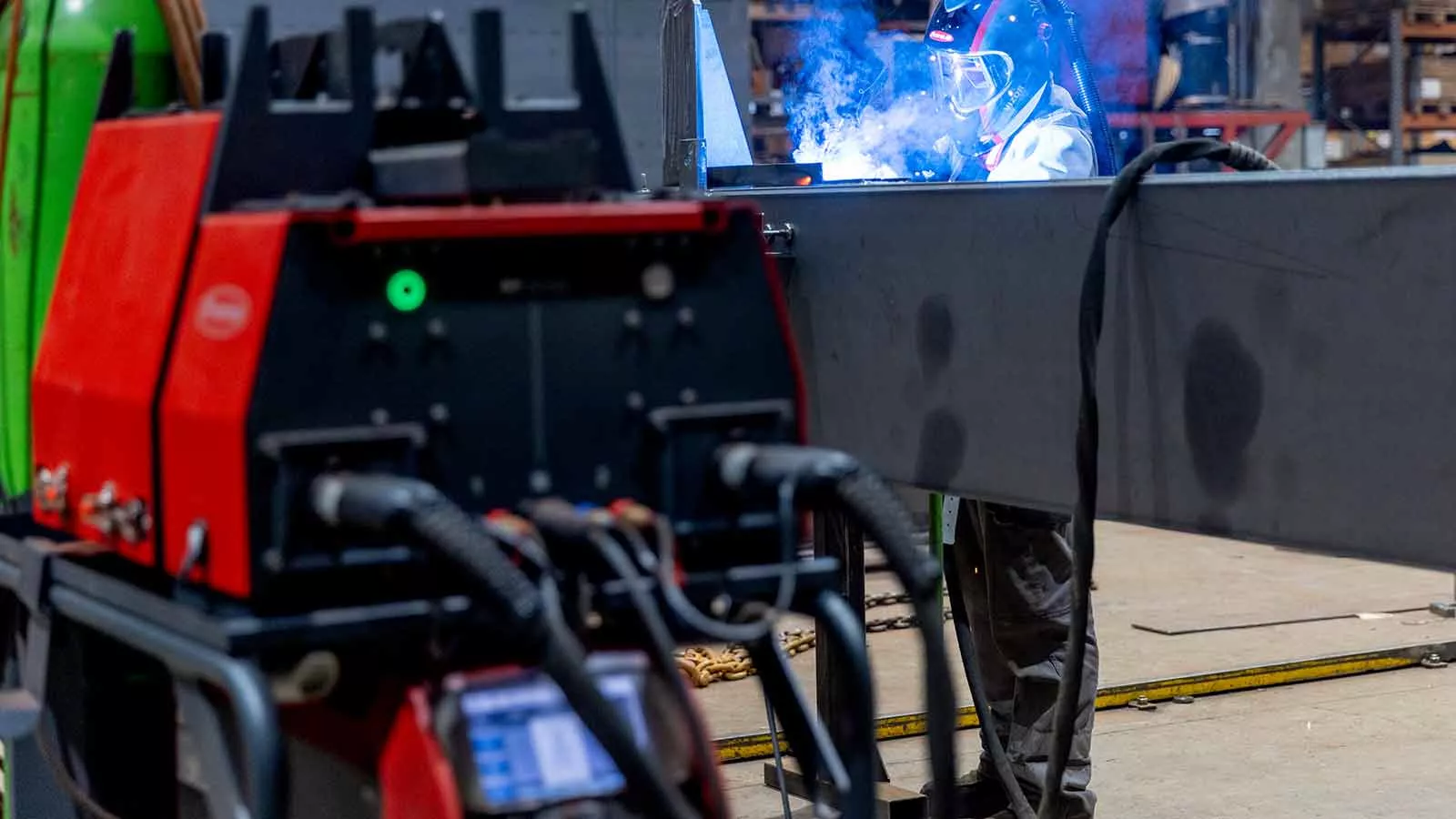

Dual Wire Feeder

WF 25i Dual

Two welding torches, two wirespools...

...but just one welding system

Greater productivity and potential savings: with the WF 25i Dual, you always have the right wire at hand, regardless of whether there are two different filler metals or wire diameters. So there’s no need to exchange wirespools, wear parts, or the welding torch.

The Dual Wire Feeder ensures stable wirefeeding and is the perfect choice, especially for the manufacture of construction machinery or shipbuilding, the automotive sector, or pipeline construction without additional system or application complexity. Combined with the TPS/i, it is the ideal solution for your needs, helping you to unleash your full welding potential.

Your benefits

At the touch of a button

The process line is changed at the touch of a button and this can be done via the torch trigger, directly on the wirefeeder, or on the welding system. Switching to the active process line takes just a few milliseconds.

Increase the deposition rate

For welding without compromise: thanks to stable wirefeeding of up to 25 m/min, you can achieve a higher deposition rate without affecting the weld quality.

Easy wire change

Two wirespool holders with a support diameter of 300 and 450 mm can be used. The Dual Wire Feeder makes changing filler metals quick and easy. What’s more, the option to use different wire diameters from 0.8 – 1.6 mm means you have the right wire to hand for every welding challenge.

Quickly and easily set parameters

Simpler, more flexible welding: you can set parameters and optimize the device on either the JobMaster welding torch, the welding system’s display, or the RC panel.Modular, robust, flexible

It’s all within your grasp: the modular design of the WF 25i Dual means you can build a system that really works for you. Depending on the welding application, it can be mounted compactly on the trolley or with the crane in difficult to access welding environments. For an operating radius of up to 25 m, the Trabant is the right choice for unleashing your welding potential. This makes welding with the Dual Wire Feeder simple and user-friendly.

Compact and versatile

Welding made easier: the option of trolley mounting means the entire system can also be used on cranes and can be quickly moved depending on where it needs to be used.

Flexibility on the Trabant and crane

The wirefeeder and wirespools can be used on the Trabant, providing complete flexibility. If you work with large or difficult to access components, then the WF 25i Dual with crane attachment is your ideal companion.

Versatile solutions

Your complete solution: the WF 25i Dual is fully compatible with the TPS/i and iWave. A range of mounting options on the welding system, a crane, or Trabant ensure maximum flexibility. Changing the active process line takes just a touch of a button on the welding torch!The WF 25i Dual is fully compatible with...

Technical data

| WF 25i Dual incl. D300 spool holder |

WF 25i Dual incl. D450 spool holder |

|

| Wire drive | 2x 4-roller drive | |

| Wire diameter | 0.8 – 1.6 mm (0.02 – 0.06 in.) | |

| Wirefeed speed | 1 – 25 m/min (39.37 – 984.25 ipm) | |

| Wirespool diameter | max. 2x 300 mm | max. 2x 450 mm |

| Wirespool weight | max. 2x 19 kg (42 lbs) | max. 2x 27.2 kg (60 lbs) |

| Protection class | IP23 | IP20 |

| Length | 62.0 cm (24.4 in.) | 61.6 cm (24.3 in.) |

| Width | 56.7 cm (22.3 in.) | 50.6 cm (19.9 in.) |

| Height | 44.5 cm (17.5 in.) | 42.4 cm (16.7 in.) |

| Weight | 46.55 kg (102.6 lbs) | 38.55 kg (85 lbs) |