Underwater welding training for Greek navy divers

Metal structures underwater also need to be inspected, repaired, and welded. This is where, for example, naval divers from the Greek armed forces come into play. However, underwater welding requires not only experienced divers, but also first-class welding expertise. The latter was imparted by the Greek Fronius representative 4 PRO Ltd.: the company was responsible for delivering underwater welding training to five service personnel. The participants were trained in accordance with ISO 15618-1:2016 – a standard of the European Welding Federation.

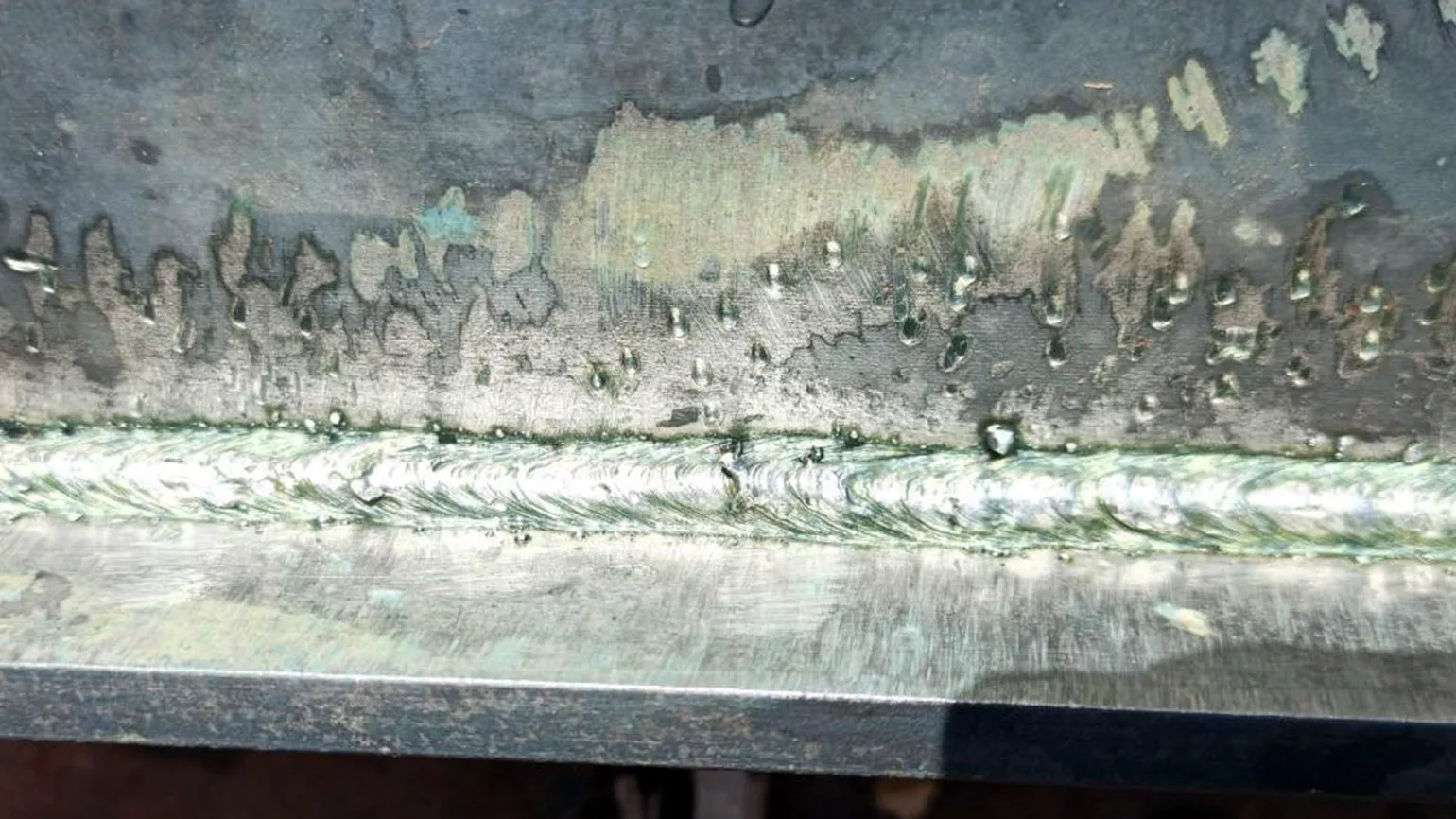

In addition to the theory element, 4 PRO initially trained the navy divers on the welding equipment at the in-house training center. After dry training had been completed, it then got serious: the participants practiced what they had learned under real conditions – in the sea off the Greek coast.

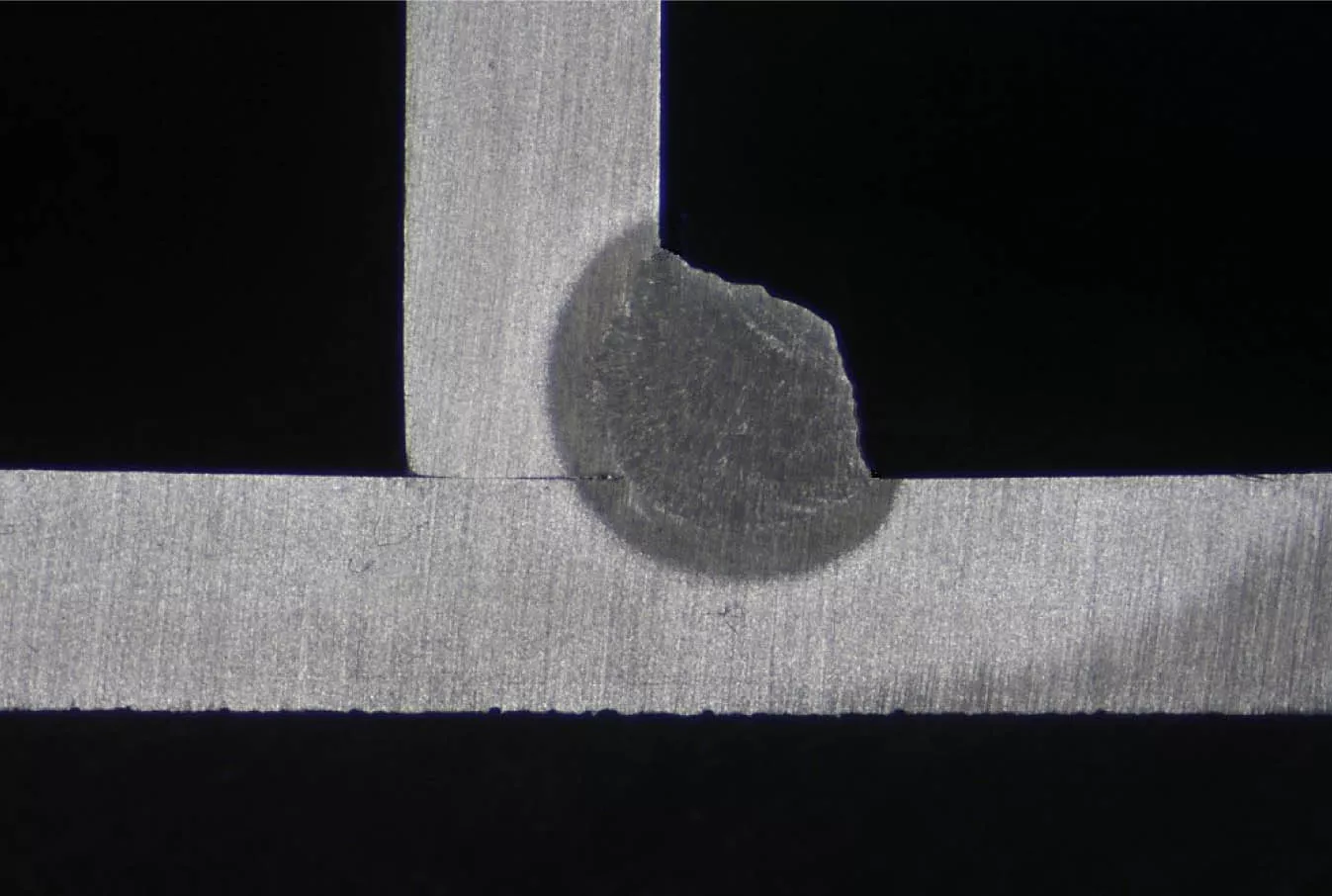

The Fronius TransSteel 4000 Pulse was used during both the training and the subsequent test – in combination with special welding torches and electrodes for underwater use from the manufacturer BROCO. “The TransSteel Pulse is ideal because its extremely stable arc enables high-quality weld seams and safe underwater use,” emphasizes Yiannis Emmanouilidis, CEO of 4 PRO and underwater welding trainer of the Welding Greek Institute.

The welding samples of all participants were subsequently evaluated by the Welding Greek Institute and the five navy divers passed their certification as international underwater welders with flying colors.