Intelligently optimize shielding gas consumption

Our intelligent gas controller helps to cut gas usage by up to 40 percent

At Fronius, we take a holistic approach to welding—quality, efficiency, and sustainability are inseparable for us. With our intelligent gas controller, we optimize shielding gas usage. The result: up to 40% less gas consumption while maintaining consistently high welding quality—in practice, often even significantly more.

Shielding gas is not only costly but also energy-intensive to produce. Every liter saved conserves resources, reduces emissions, and lowers the CO₂ footprint—a clear competitive advantage for our customers.

Three ways to save shielding gas

With the intelligent gas controller, we’ve developed a technology that saves gas in multiple ways:

- No blow out: The gas controller smooths the gas flow at startup and prevents unnecessary losses.

- Performance-based regulation: The gas flow dynamically adapts to the welding power, or

- Jobspecific dosing: The optimal gas amount can be individually defined for each weld seam.

Don’t let shielding gas escape unused

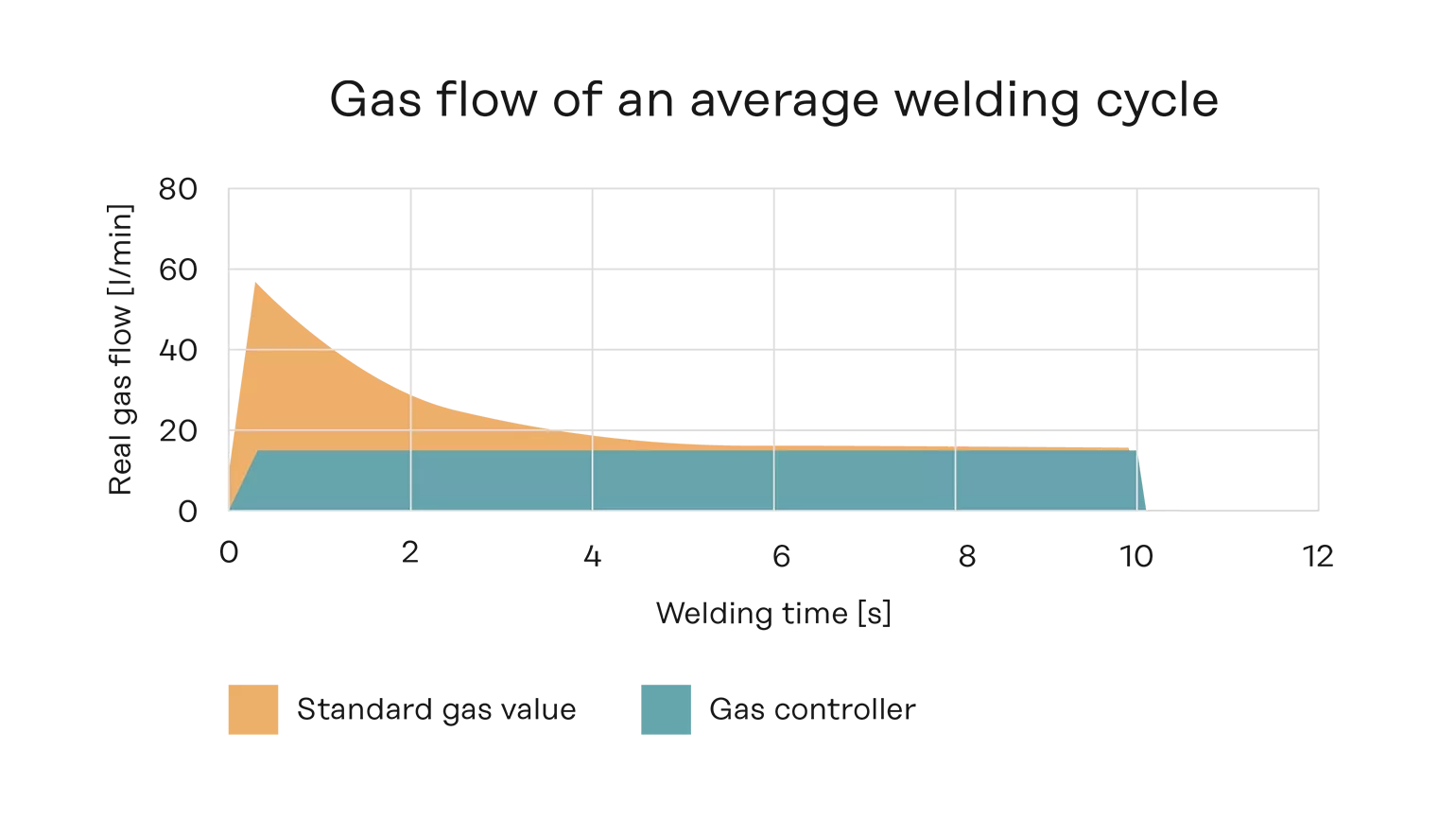

Our intelligent gas controller prevents the typical “blow out” at the start of welding, where conventional systems briefly consume up to 55 l/min—even though only 18 l/min may be needed. These peaks add up to significant but avoidable costs—especially during tack welding and with many short seams.

The desired gas flow is established immediately and maintained consistently—without losses. Additionally, the intelligent gas controller enables performance-based or individually defined gas dosing for each welding job. This means the highest demand is not set across the board, but exactly what is needed for perfect quality—seam by seam!

All welding solutions from our TPS/i and iWave product lines can be retrofitted with an intelligent Fronius gas controller at any time. Just a few hardware components are installed in the wire feeder or split box, and the intelligent gas controller is ready to go. This makes any production process instantly more efficient, sustainable, and economical.

Our experts will be happy to show you how much shielding gas your company can save. For more information and to schedule an appointment, click here:

Make your appointment now!

Get expert advice from the Fronius team and discover your individual savings potential.