ArcTig

Contact

Would you like to find out more about the product?

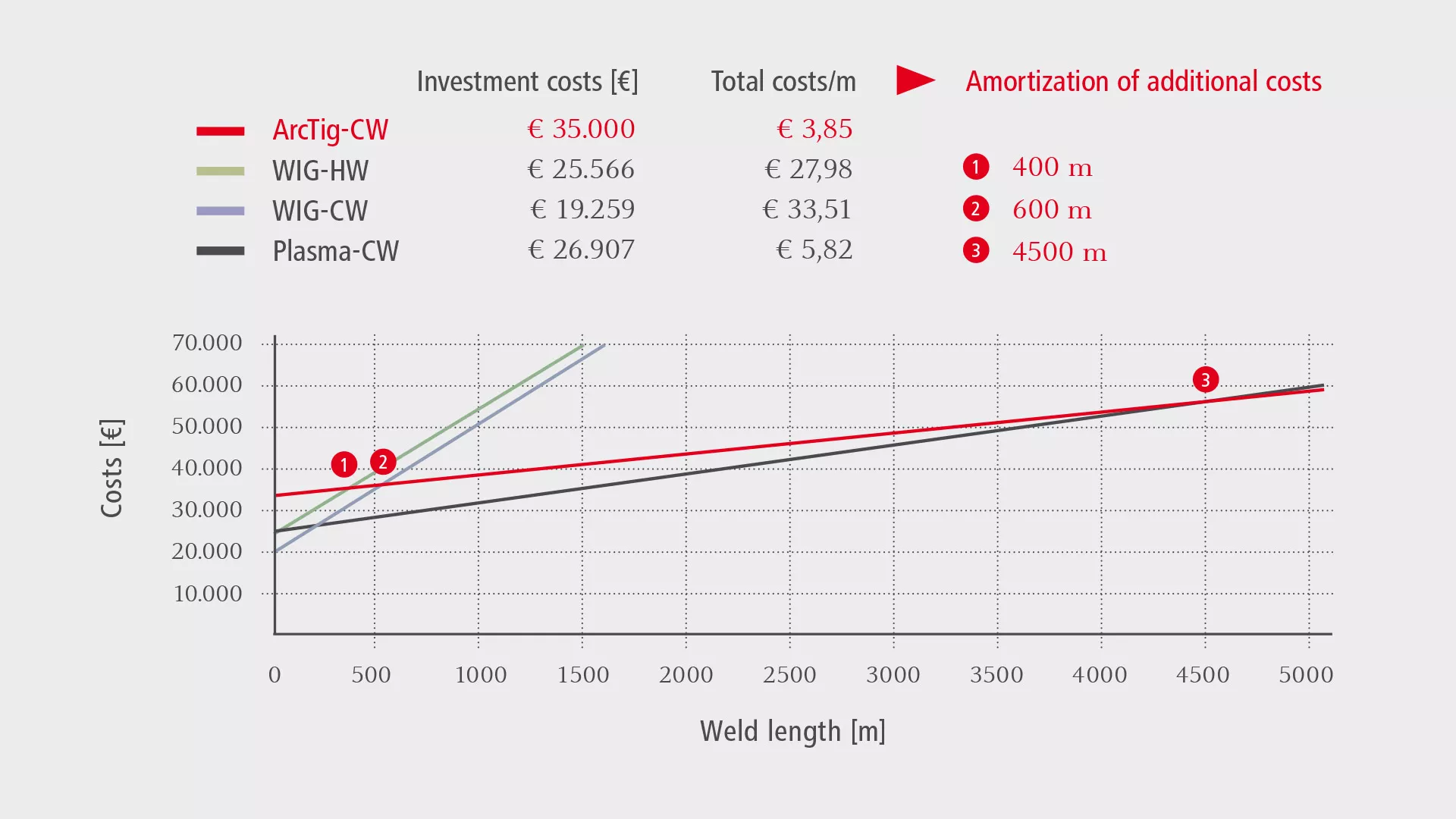

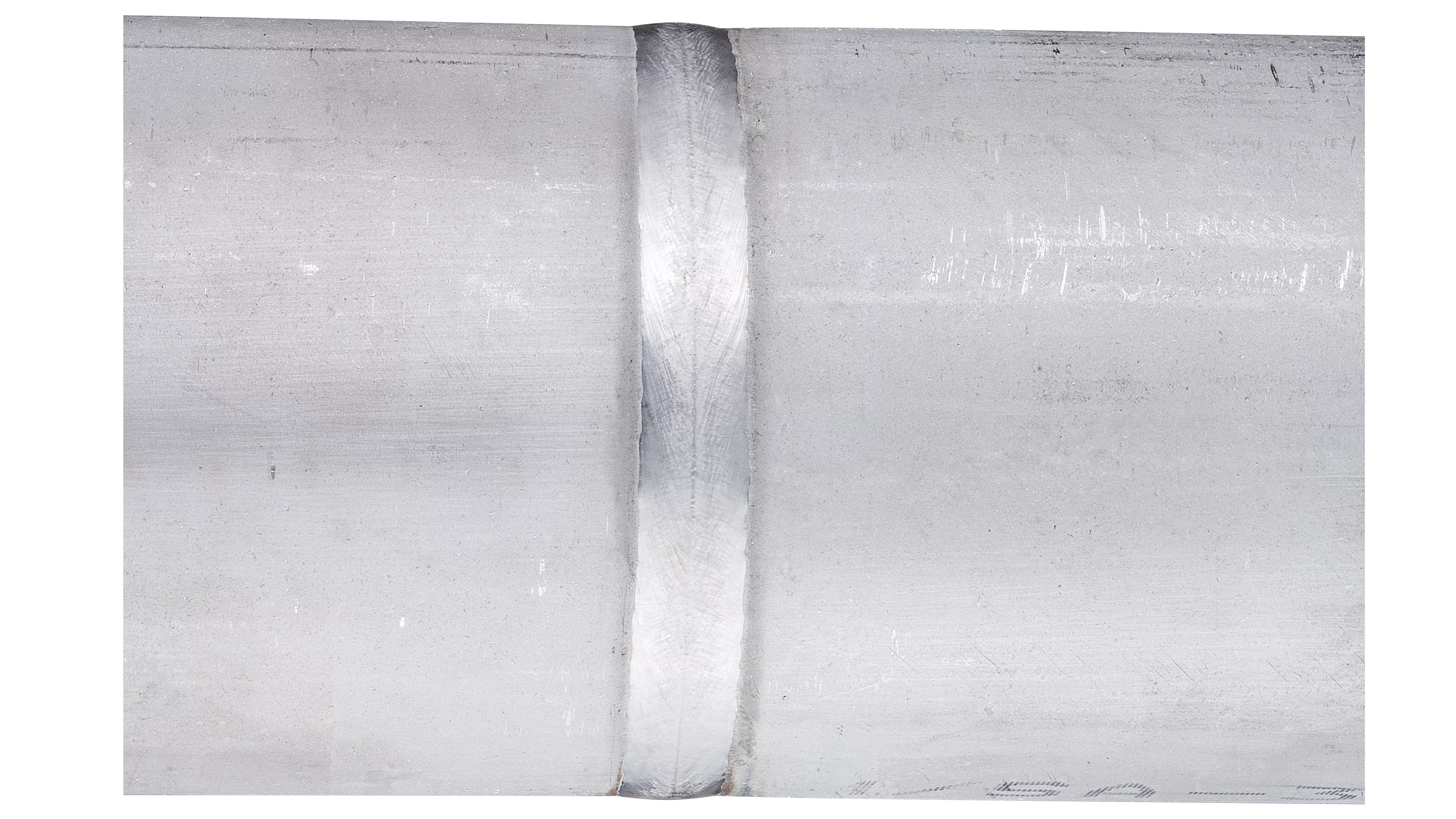

With the new ArcTig welding process, Fronius will also be presenting an ideal solution for all those who have the very highest quality requirements for their weld seams and yet are simultaneously looking for a simple – and above all, cost-effective – solution for their welding applications. Preparatory work and reworking can be significantly reduced.

Applications

- Construction of tanks and vessels

- Pipeline construction

- Continuous production of pipes

- Special machine construction

- Turbine production

Your benefits

Reduction of preparatory work and reworking

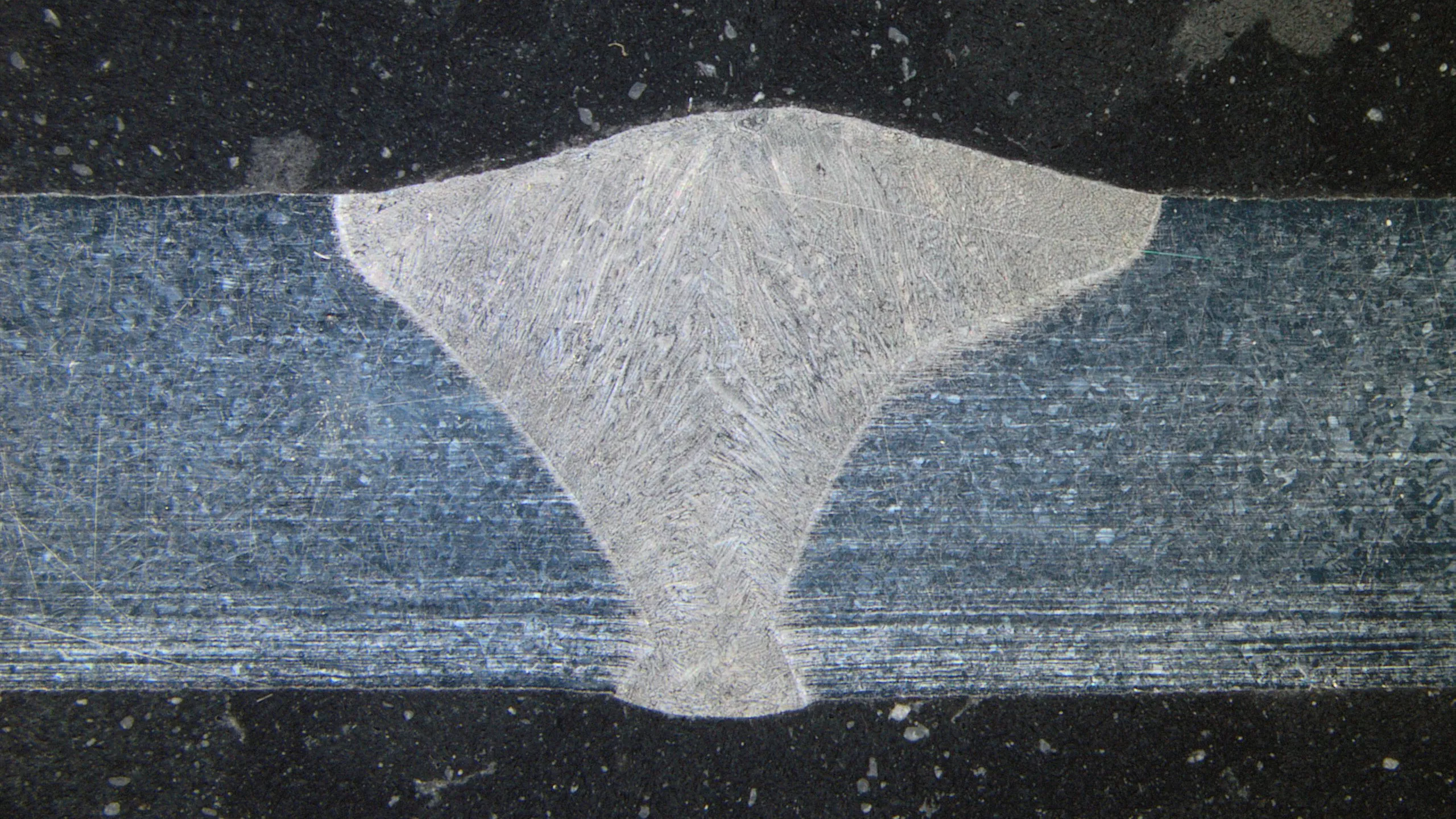

- Minimal to no joint preparation up to a material thickness of 10 mm

- No weld-pool support needed

- Low level of weld seam crowning and low distortion

- No spatter

Easy to use

- Welding parameters are easy to set and select

- Easy changing and regrinding of electrodes

- Electrode clamping system for setting the free end of the electrode

- Flexibility in terms of welding position

Reduction of the weld seam volume

- Welding operations in materials up to 8 mm thick without joint preparation

- Savings on gas, filler metal and electricity

Increased welding speed

- Up to a 100% increase in the welding speed compared to the traditional TIG process

Downloads

| Application example | Pipeline construction |

| Material thickness | 6 mm |

| Welding position | PA |

| Welding speed | 30 cm/min |

| Welding current | 320 A |

| Voltage | 18.8 V |

| Weld layers | 1 weld layer |

| Joint preparation | none |