FMW Multi Welding System

Mechanised Multi Welding

Please choose your desired product.

Contact

Would you like to find out more about the product?

Product details

Quick change of welding process thanks to FMW.

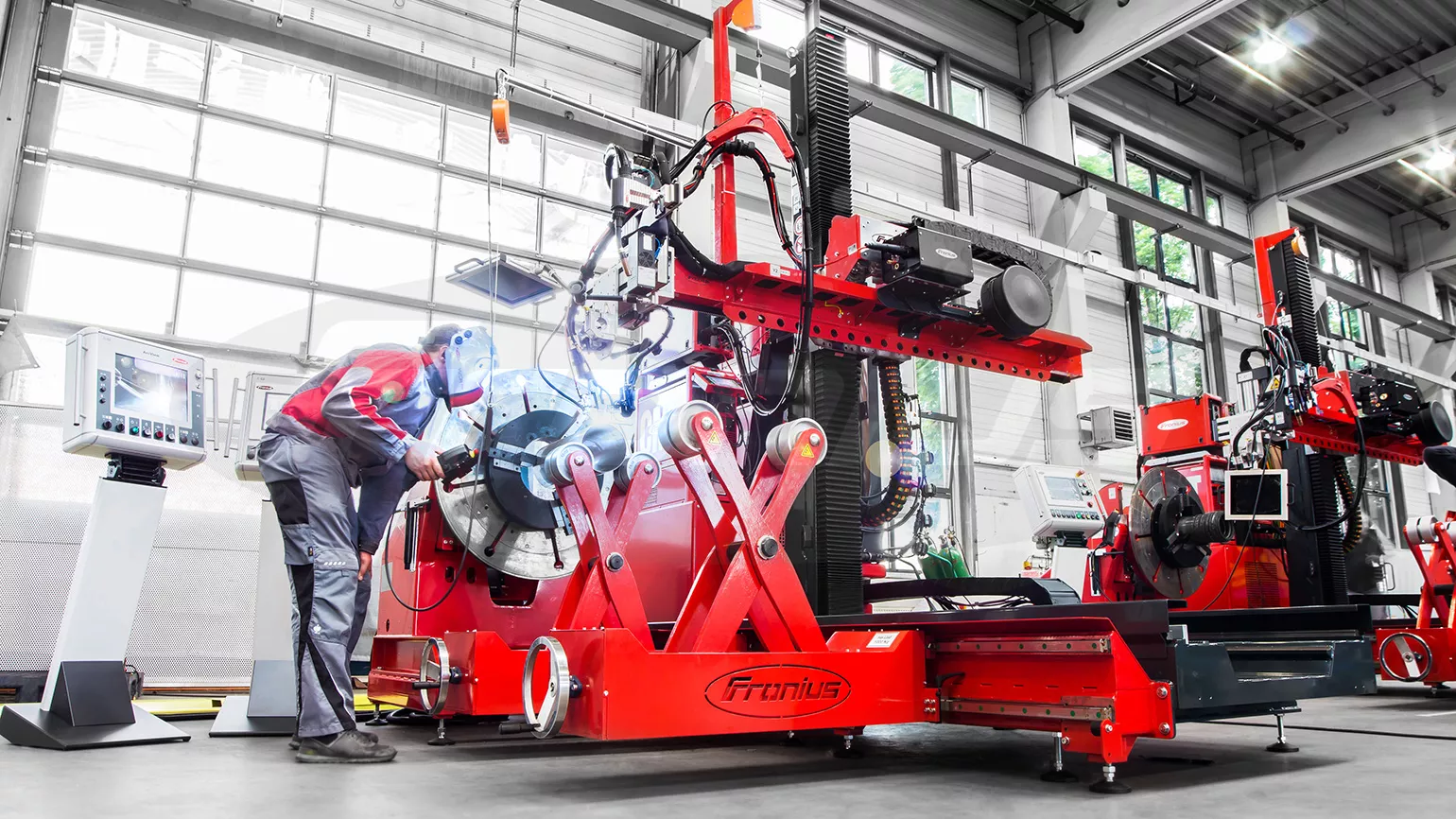

The Fronius Multi Welding System enables the welding process to be changed in no time. Equipped with quick-release catches, the welding torches can be changed in seconds. The intuitive HMI opens up entirely new possibilities and saves time. It has never been so easy to develop customer-specific process control and program the welding process.

Features.

- Human Machine Interface - system controller

- Multi welding processes - max. eight different welding processes

- Variety of automatic welding torches - up to three different welding torches with the same hosepack

- Circumferential weld, longitudinal seam and both combined in multi welding axes

- Ten different axes that can be controlled via HMI and remote control

- Modular, expandable welding system concept

- Q-Master quality management software

- ArcView camera system

HMI T10.

This high-end system controller enables up to ten motorised travel axes to be controlled, supported by a graphical interface. The remote control can be used to access all relevant functions.

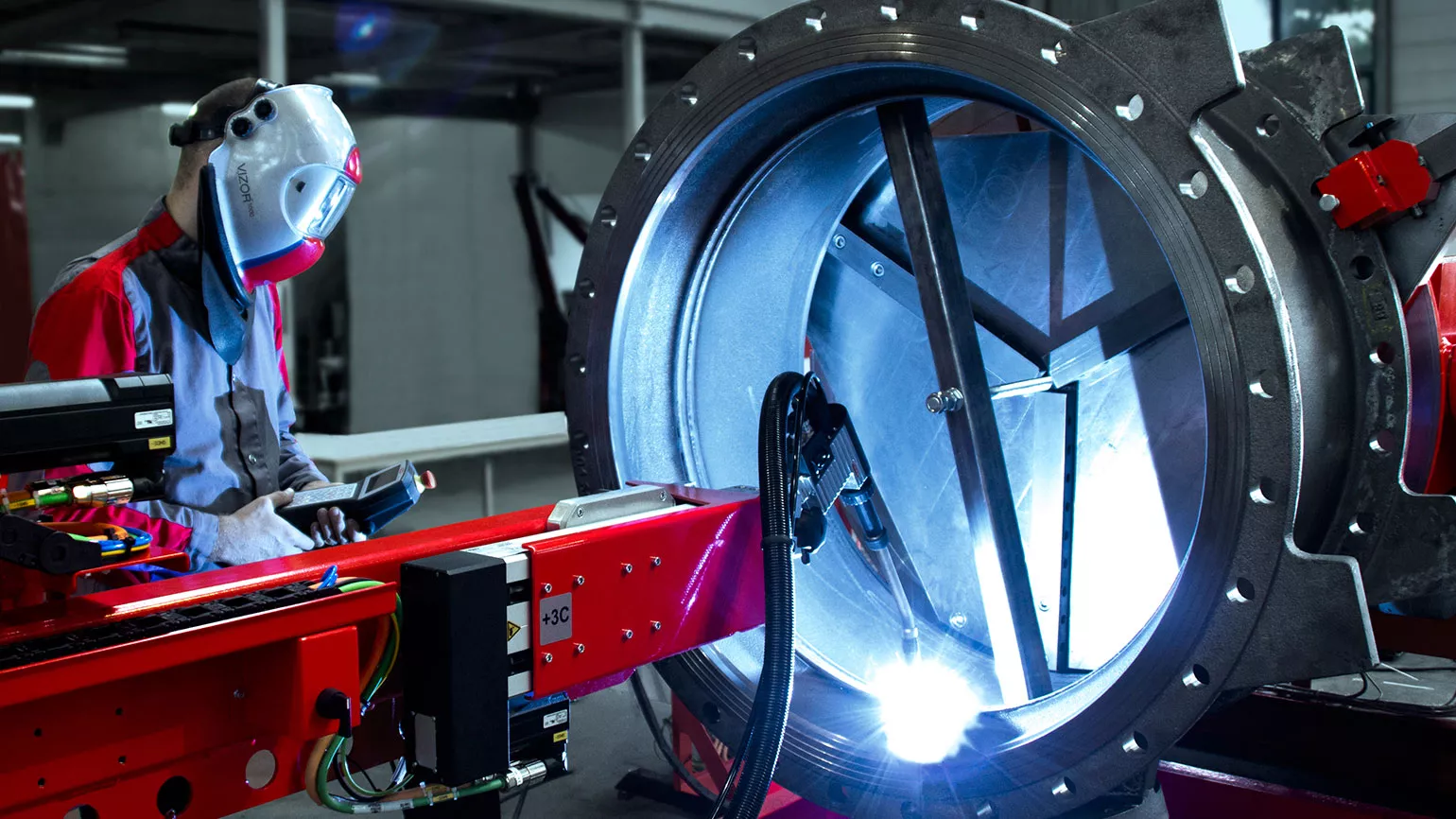

ArcView.

The camera module is fitted to the welding torch and sends live images to the upright console and the internet via Ethernet.

Power source set.

Different configurations available.

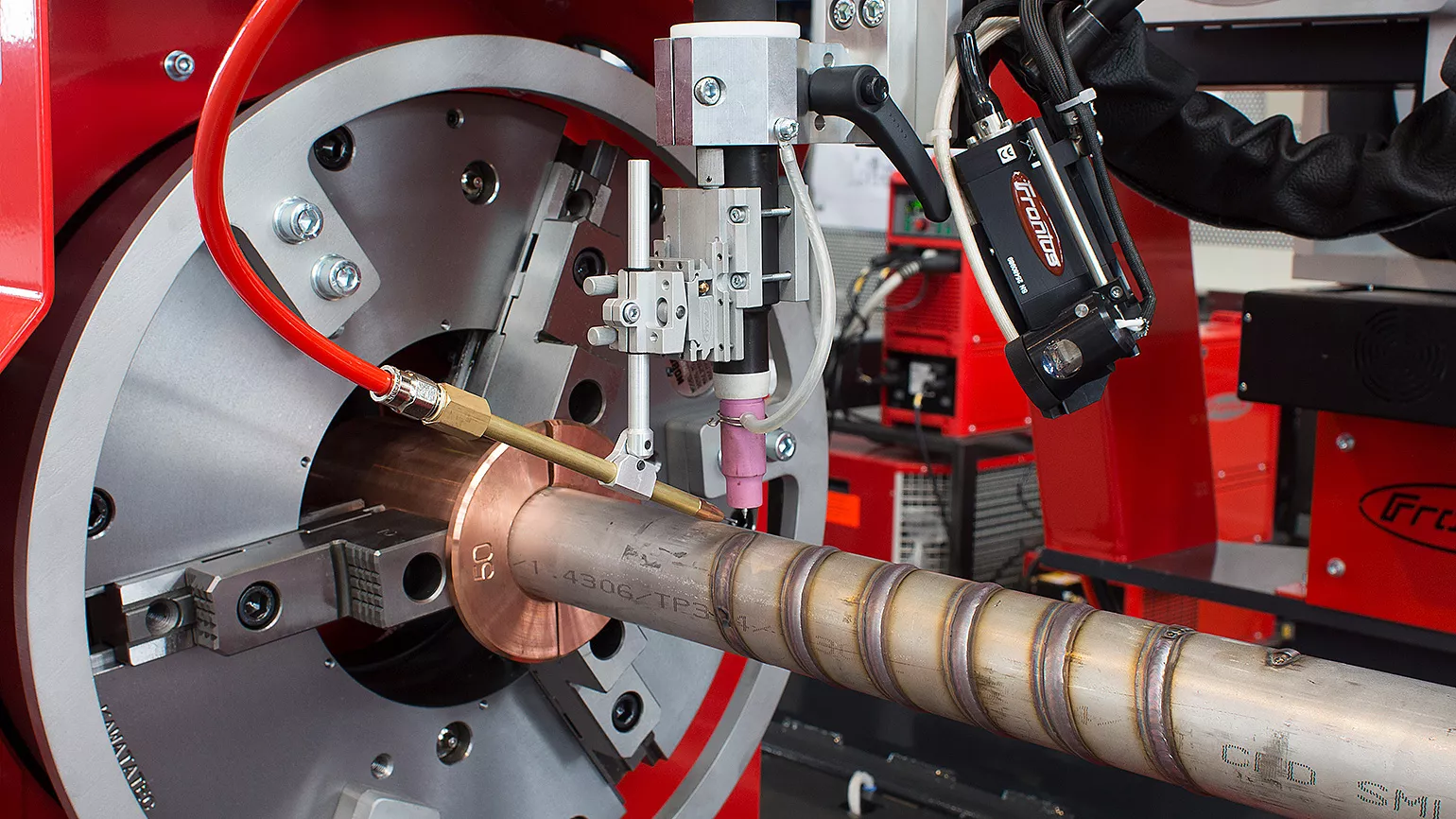

AVC / OSC.

Arc Voltage Control (AVC) and oscillation (OSC) via motor slide.

Column & boom.

Equipped with servo motors for horizontal and vertical travel. The upright console is an additional horizontal travel axis.

Support units.

Adjustable support units for perfect component guiding. Linear guides facilitate precise and easy movement.

Positioner.

For vertical and horizontal component positioning. Axes can be used as travel or welding axes.

Different models available depending on the requirement.

Longitudinal seam welding.

In horizontal and vertical workpiece position.

Circumferential welding.

In horizontal and vertical workpiece position.

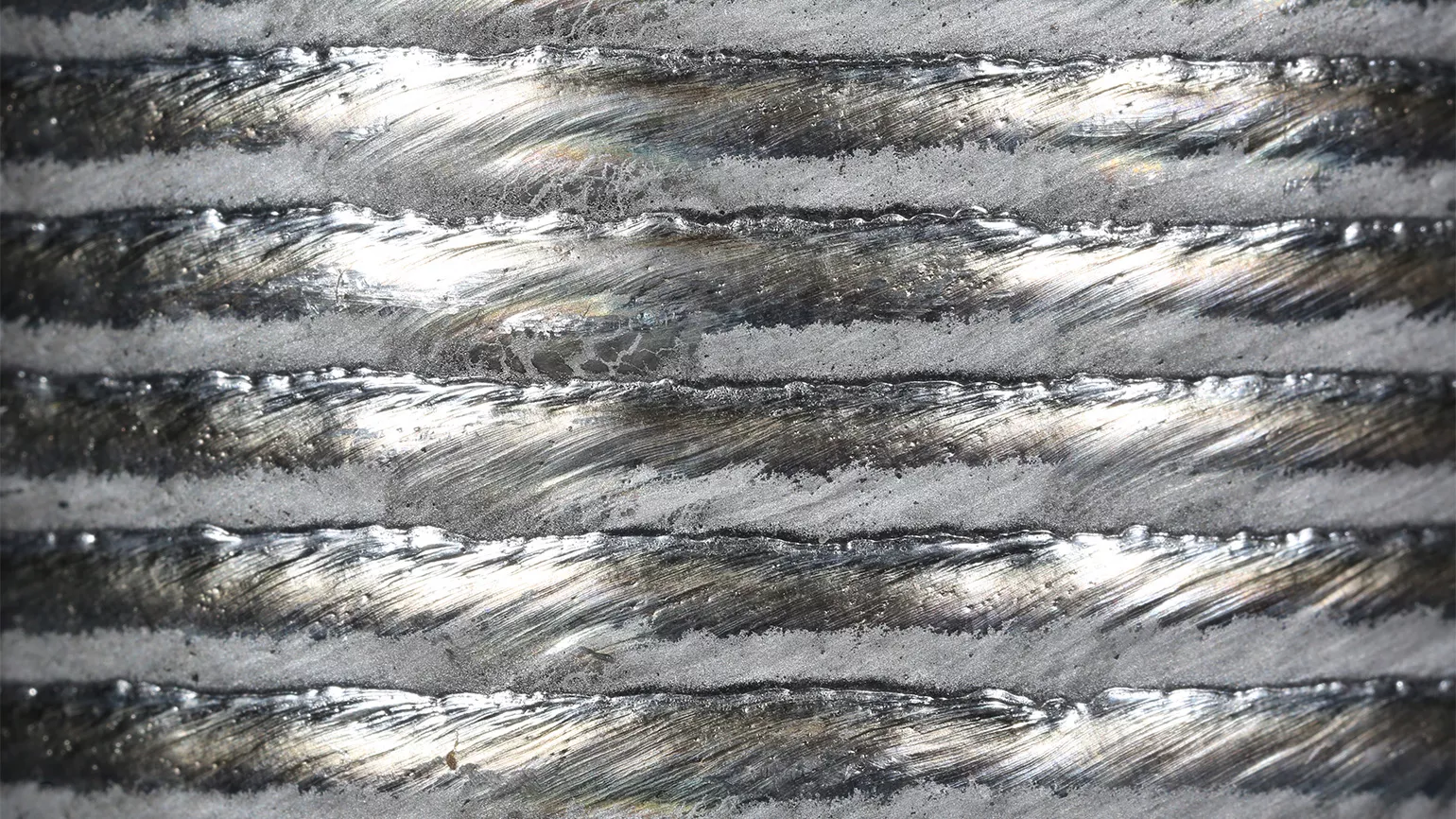

Cladding.

Multiple welding axes are used.