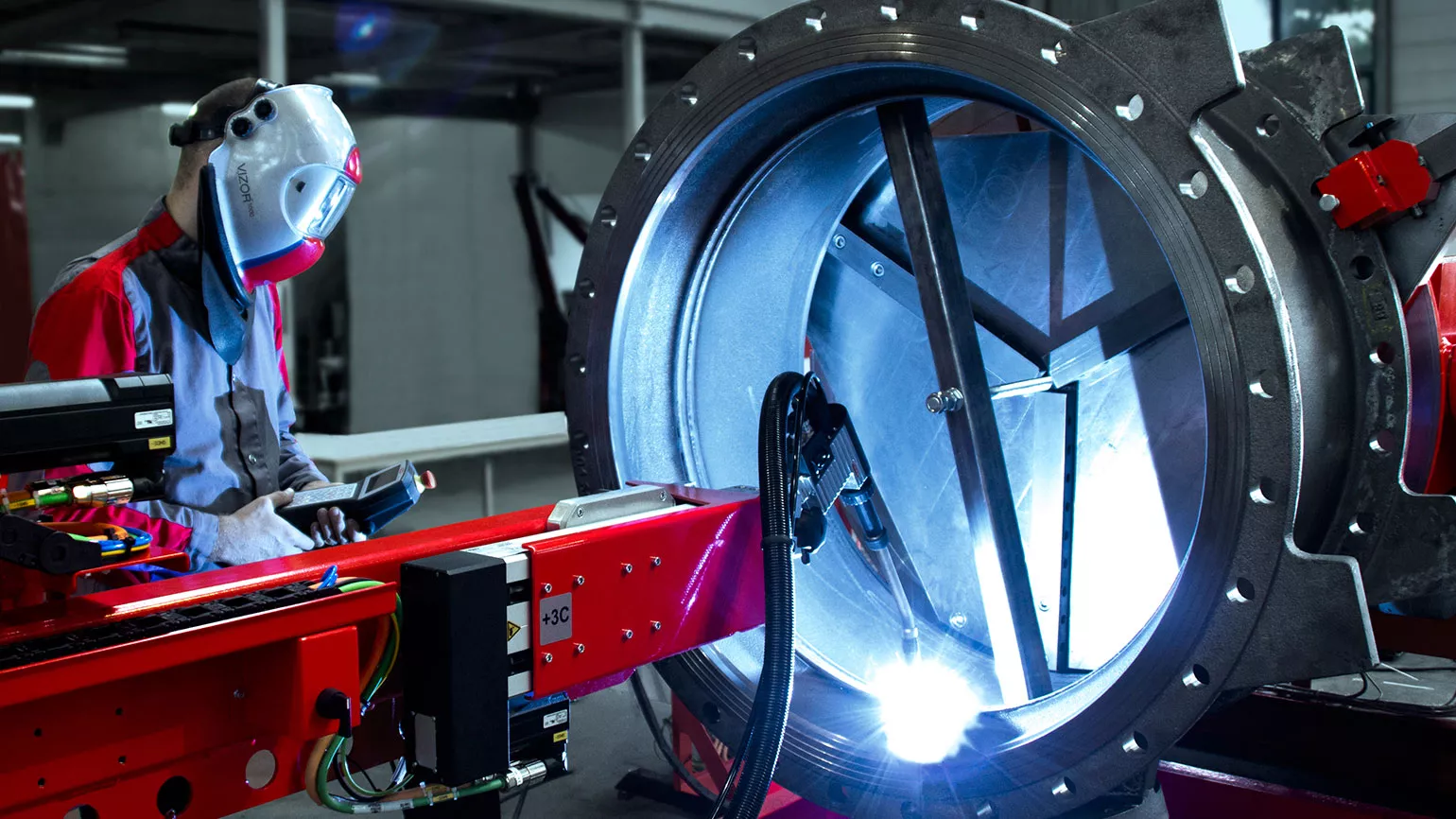

FTW 24-120 PRO tubesheet welder

Mechanised orbital welding

Please choose your desired product.

Contact

Would you like to find out more about the product?

Product details

Features.

Compact, ergonomic design

Increases productivity while maintaining optimum quality and reproducibility

Time-saving, simple positioning

User-friendly operation

Pneumatic clamping system

Variety of mandrels and clamping jaws for different pipe inside diameters

Precise adjustment units for user-dependent torch adjustment

Special welding torch with Multilock quick-connect system and water cooling

Hanging devices (optional) for different applications

Practical handle to quickly start welding programs

Three-point support (optional)

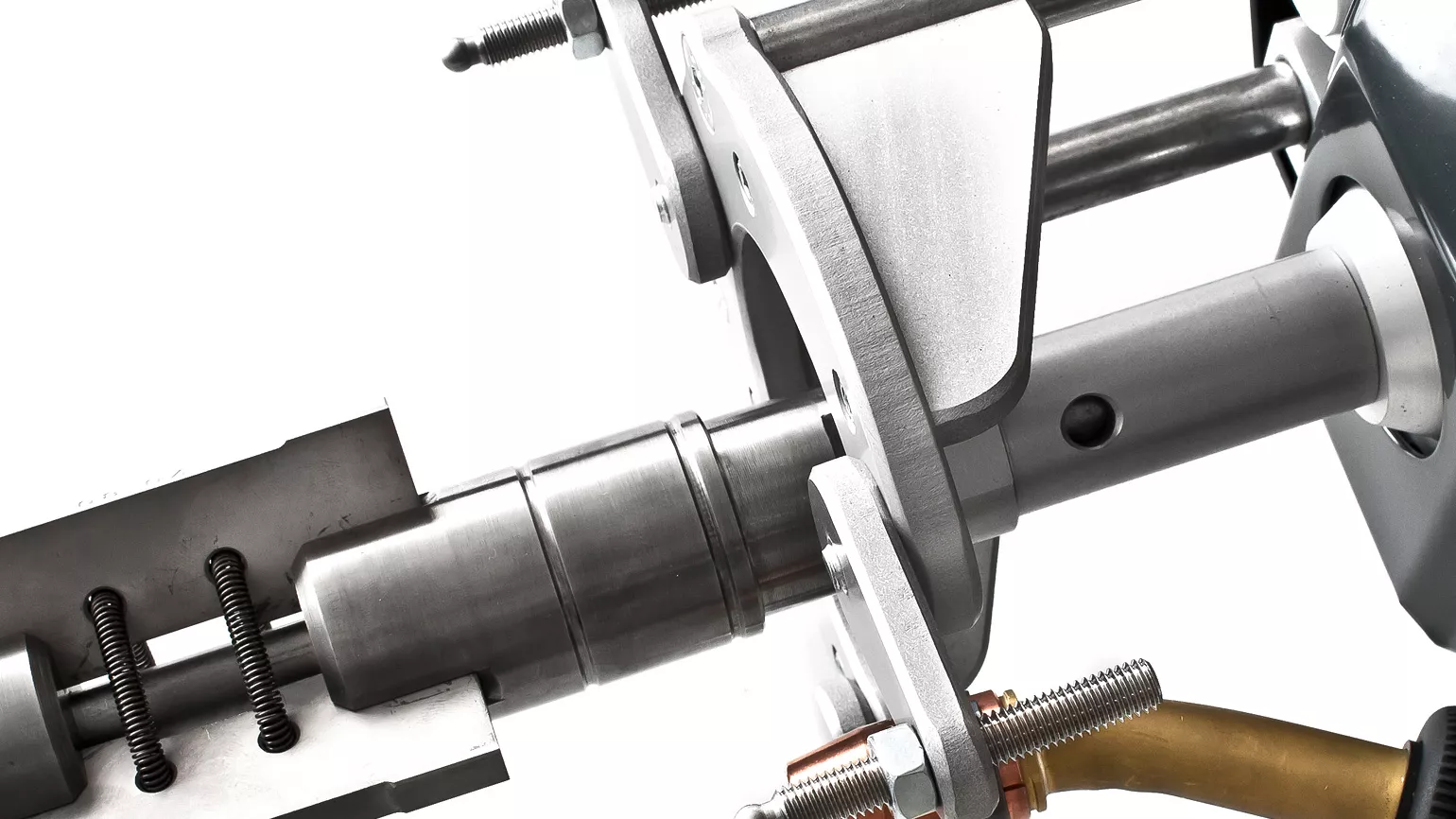

Multilock welding torch.

Special water-cooled welding torch with Multilock quick-connect system for speedy changing or calibration of the torch body (elbow available in 20°/30°).

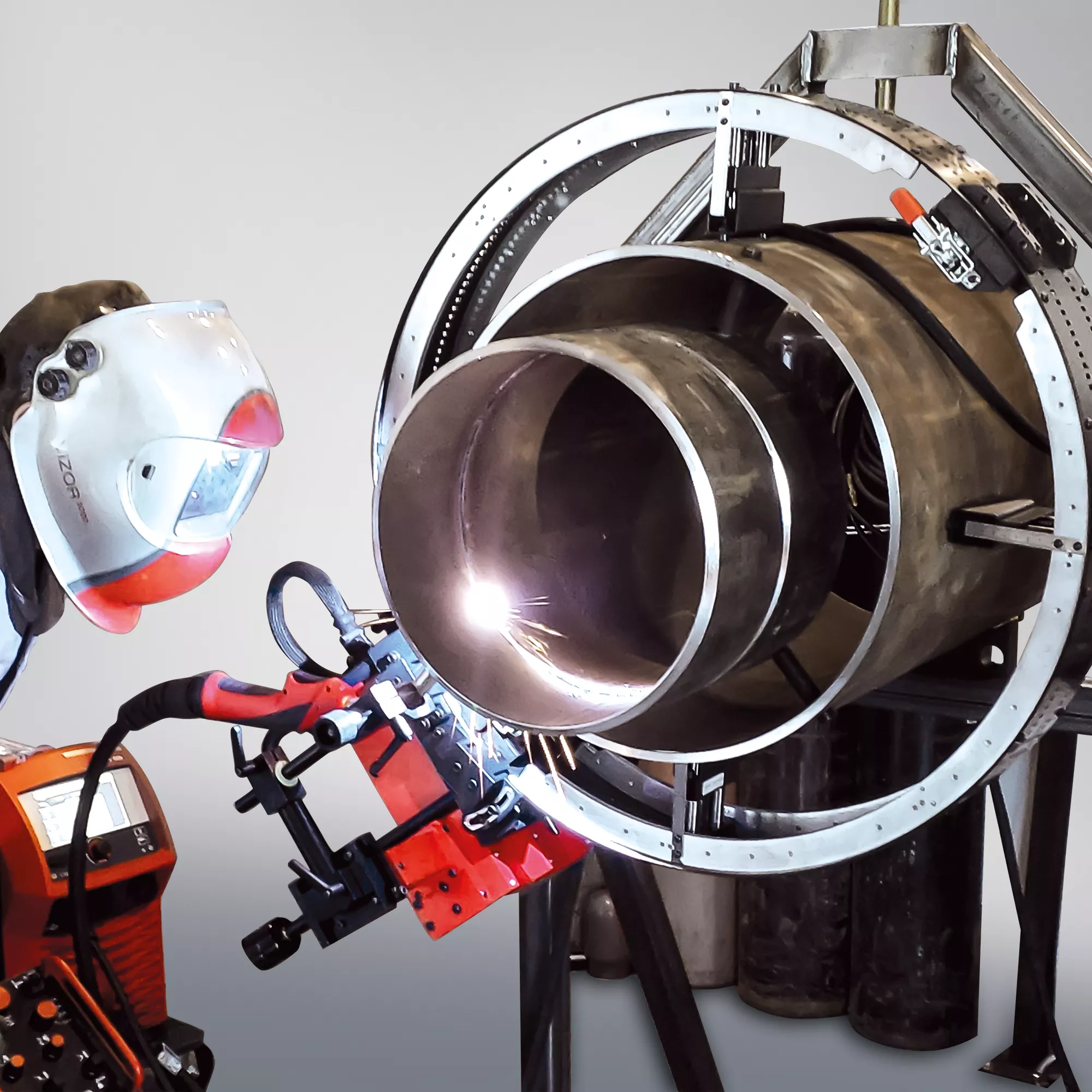

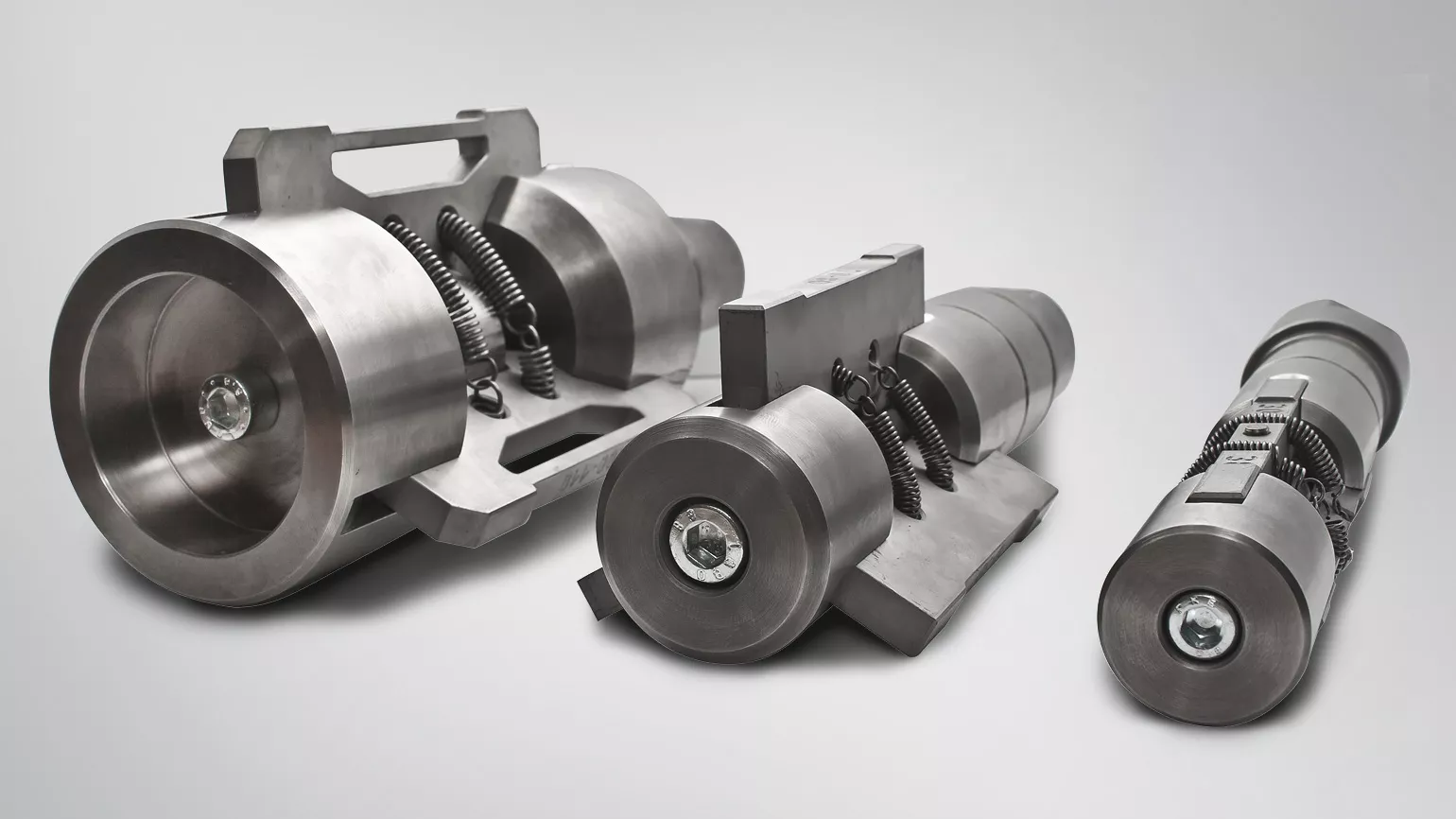

Clamping system.

Various mandrels/clamping jaws/bearing rings in a practical storage case. Pneumatics are used for clamping.

Three-point support (optional).

Precisely distance the welding torch using the pneumatic three-point support – even with varying tube protrusions.

Adjustment units with fixing.

Two rotary buttons and two locking levers enable the welding torch to be precisely adjusted and fixed in place.

Hanging device.

Can be used for vertical or horizontal welding positions. When used in conjunction with a spring balancer, allows “weightless” positioning.

Handle.

Ergonomic handle for starting welding programs. This can also be used when removed from the hanging device.

Features.

- Sturdy housing

- Graphical user interface

- Touch display

- Multifunctional dial

- Replaceable protective film for display

- Parameters can be programmed and stored

- Variety of languages

- Job switch (optional)

Touch display.

User-friendly touchscreen operation.

Multifunctional dial.

For selecting and correcting parameters, even during automatic program sequences.

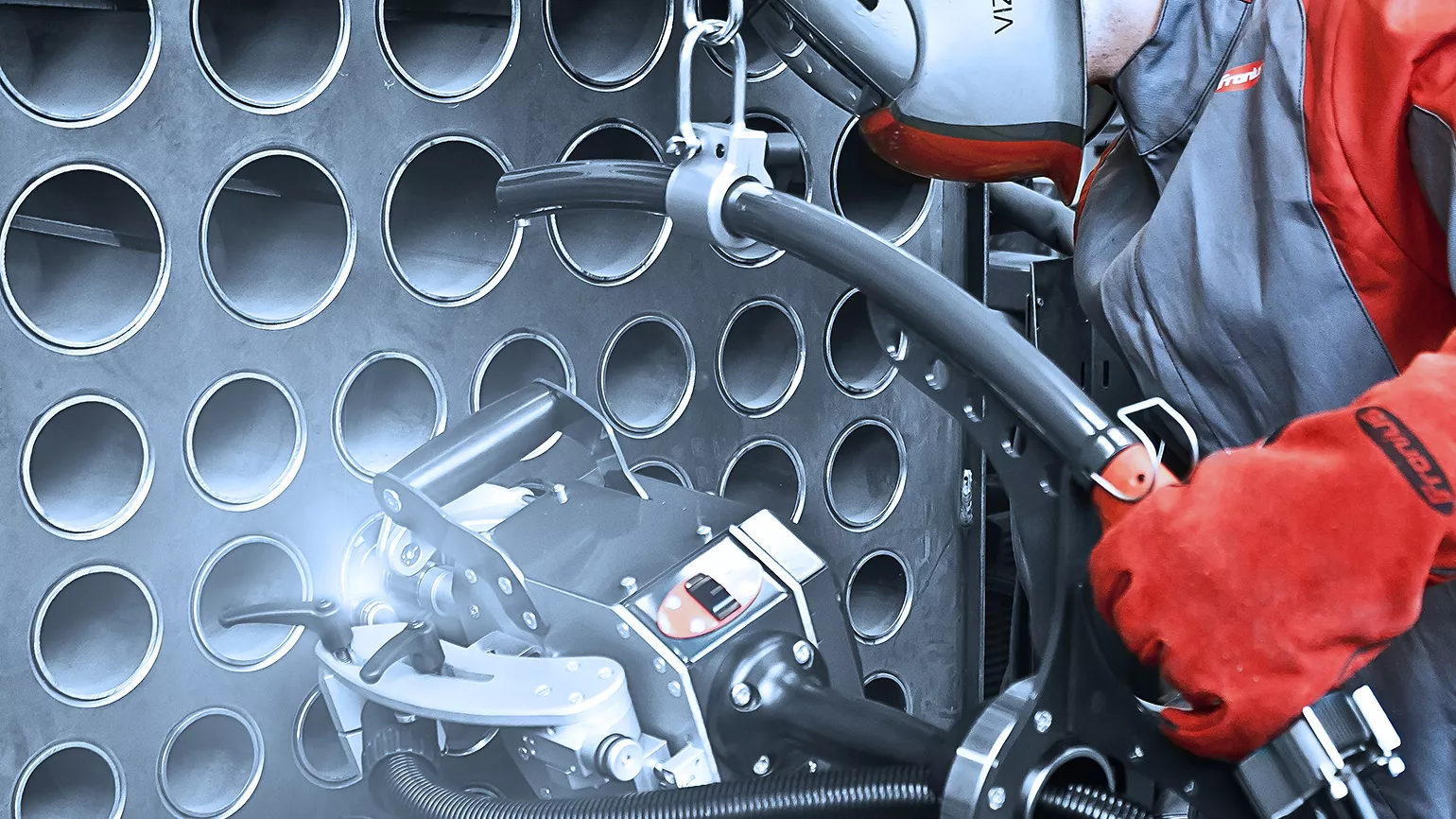

Mandrels.

Three mandrels cover a tube inside diameter range of 30 to 120 mm (other diameters available on request).

Clamping jaws.

Three mandrels cover a tube inside diameter range of 30 to 120 mm (other diameters available on request).

Bearing rings.

Bearing rings for different pipe diameters.