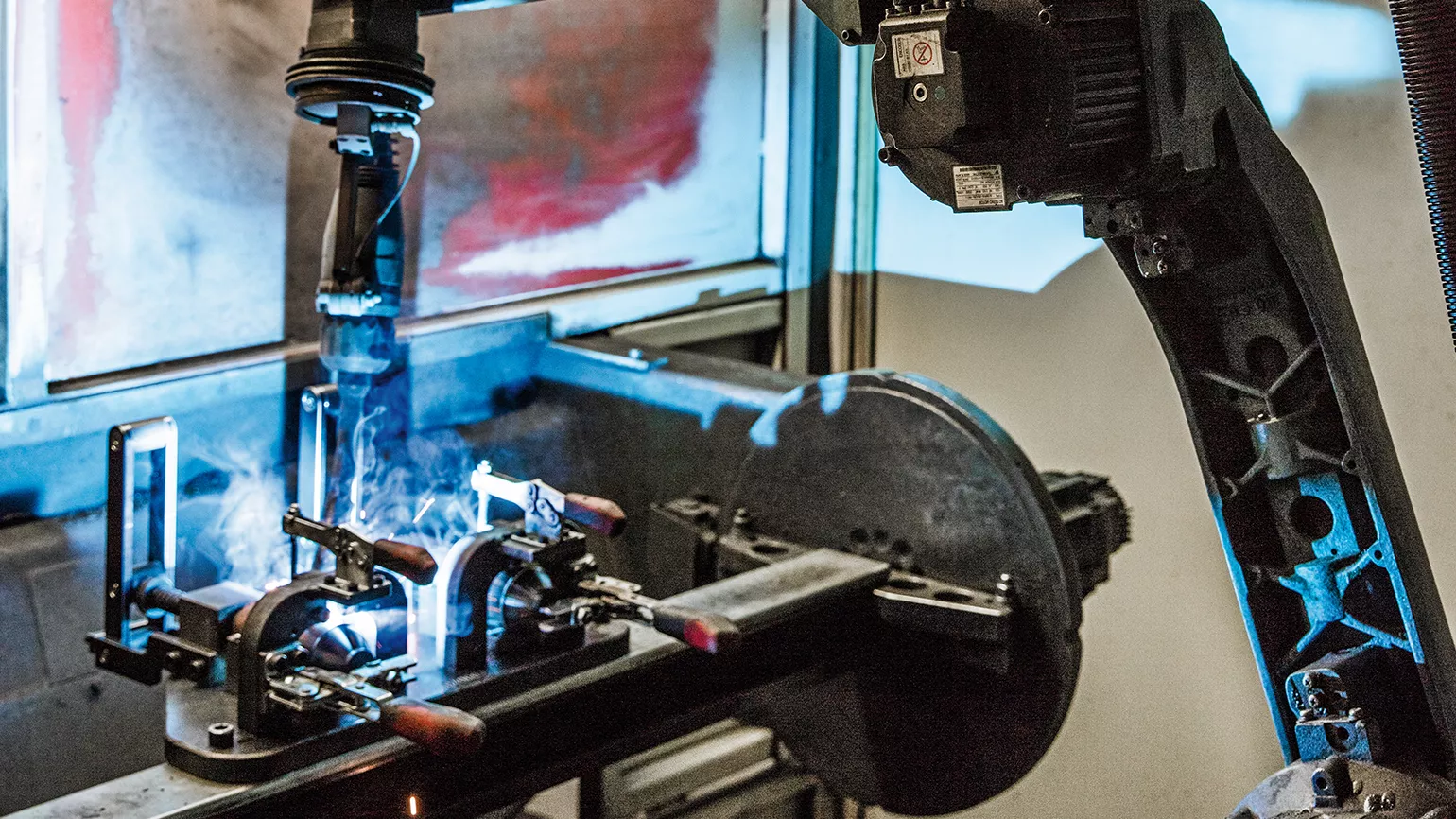

Steel Welding

Always a secure connection

Challenge of steel welding

Steel remains the most widespread parent material in metal construction ahead of aluminum and stainless steel.

Its high strength and the low costs make it a popular construction material. Out of all materials, steel is the easiest to weld. The biggest challenge is keeping the material distortion as low as possible. Selecting the correct welding process plays an important part in this.

Interesting facts about steel

Steel is primarily composed of iron and a maximum of 2.06% carbon. Alloys with a higher proportion of carbon are known as cast iron. If the proportion of sulfur and phosphorus accompanying iron is less than 0.025%, it is called stainless steel.

Not every steel can also be welded: only pure steels, i.e. alloys with a carbon content of less than 0.22%, are suitable for this process. As a rule, the more impure the alloy, the harder it is to weld the steel.

Of particular importance are high-strength and super-high-strength steels. In addition to lightweight construction in the automotive industry, for example, they are also used for mobile cranes, concrete pumps, agricultural and forestry machinery. However, they are more difficult to weld than conventional steel alloys. The manufacturer's processing instructions should always be followed without fail.

Steel exists in a wide range of forms:

- Flat steel

- Round steel

- Profile pipes

- Square pipes

This is how to prepare steel for welding

- Clean

Before welding, remove coarse contamination from the steel in order to achieve good results. - Remove rust

Remove rusty areas in the parent material before welding so that no bonding flaws occur in the weld metal. - Remove oil or grease

Oily parent material makes the welding process more difficult and may, among other things, cause poor results. You should therefore remove the oil from the steel before welding. - Preheat

In case of higher material thicknesses, you should preheat the part before welding to slow down the cooling time. This prevents a high degree of hardness in the microstructure, in turn preventing cracking.

Welding process for steel

In principle, all welding processes are suitable for joining steel. However, the MIG/MAG process is primarily used because this allows for the highest welding speeds.